High Density Polyethylene and Its Role in Microplastics Reduction

HDPE Evolution and Goals

High Density Polyethylene (HDPE) has undergone significant evolution since its discovery in the 1950s. Initially developed as a durable, lightweight plastic for industrial applications, HDPE has become ubiquitous in modern society, finding use in packaging, construction, and consumer goods. The material's journey from a novel polymer to a global commodity has been marked by continuous improvements in production techniques and material properties.

The primary goal in HDPE development has been to enhance its strength-to-weight ratio, chemical resistance, and processability. Over the decades, researchers and manufacturers have focused on refining the polymerization process, leading to better control over molecular weight distribution and crystallinity. These advancements have resulted in HDPE grades with superior mechanical properties and increased versatility across various applications.

In recent years, the focus of HDPE evolution has shifted towards sustainability and environmental concerns. The growing awareness of microplastics pollution has placed HDPE under scrutiny, as it is a significant contributor to plastic waste in marine environments. This has led to a new set of goals in HDPE development, primarily centered on reducing its environmental impact while maintaining its beneficial properties.

Current objectives in HDPE research and development include improving biodegradability without compromising durability, enhancing recyclability, and developing bio-based alternatives. Researchers are exploring ways to modify HDPE's molecular structure to facilitate faster decomposition in natural environments while ensuring the material retains its strength and chemical resistance during its intended use.

Another critical goal is to reduce the generation of microplastics from HDPE products. This involves developing more stable formulations that resist fragmentation and weathering, as well as incorporating additives that promote faster degradation once the product enters the waste stream. The challenge lies in balancing these seemingly contradictory requirements – maintaining durability during use while ensuring rapid breakdown post-disposal.

The industry is also focusing on improving recycling technologies specific to HDPE. Goals include developing more efficient sorting and cleaning processes, as well as enhancing the quality of recycled HDPE to expand its use in high-value applications. This circular economy approach aims to reduce the demand for virgin HDPE production and minimize plastic waste.

As we look to the future, the evolution of HDPE is likely to be driven by these environmental considerations alongside traditional performance metrics. The ultimate goal is to create a version of HDPE that maintains its valuable properties while significantly reducing its contribution to microplastics pollution, thus ensuring its continued relevance in a more environmentally conscious world.

Market Demand Analysis

The market demand for High Density Polyethylene (HDPE) in relation to microplastics reduction has been steadily growing in recent years. This trend is driven by increasing environmental concerns and regulatory pressures to address plastic pollution. HDPE, known for its durability and recyclability, has emerged as a key material in the effort to reduce microplastic pollution.

Consumer awareness about the environmental impact of plastics has led to a shift in purchasing behavior. Many consumers now prefer products made from recyclable materials or those that contribute less to microplastic pollution. This has created a significant market opportunity for HDPE products, especially in packaging, consumer goods, and industrial applications.

The packaging industry, in particular, has seen a surge in demand for HDPE as an alternative to less recyclable plastics. Food and beverage companies are increasingly adopting HDPE packaging to meet sustainability goals and consumer expectations. The personal care and household products sectors have also shown growing interest in HDPE packaging solutions that can help reduce microplastic generation.

In the construction and automotive industries, there is a rising demand for HDPE products due to their durability and potential for recycling. These sectors are exploring innovative uses of HDPE to replace materials that contribute more significantly to microplastic pollution.

The recycling industry has experienced increased demand for HDPE recycling capabilities. As more companies commit to using recycled plastics in their products, the market for recycled HDPE has expanded. This has created new opportunities for recycling technologies and processes specifically tailored to HDPE.

Governments and environmental organizations worldwide are implementing stricter regulations on plastic use and disposal. This regulatory landscape has further boosted the demand for HDPE as a more environmentally friendly alternative to other plastics. Companies are seeking HDPE solutions to comply with these regulations and avoid potential fines or negative publicity.

The marine and coastal management sectors have shown particular interest in HDPE products designed to reduce microplastic pollution in aquatic environments. This includes specialized HDPE materials for marine equipment, coastal infrastructure, and water treatment systems.

Research and development in HDPE technology focused on microplastics reduction has also seen increased investment. Companies and academic institutions are exploring new formulations and manufacturing processes to enhance HDPE's properties and further minimize its contribution to microplastic pollution.

While the demand for HDPE in microplastics reduction is growing, it's important to note that challenges remain. These include the need for improved recycling infrastructure, consumer education on proper disposal, and continued innovation in HDPE formulations to enhance its environmental performance.

HDPE Challenges

High Density Polyethylene (HDPE) faces several significant challenges in its role in microplastics reduction. One of the primary issues is the material's durability and resistance to degradation, which, while beneficial for many applications, contributes to its persistence in the environment. HDPE can take hundreds of years to decompose naturally, leading to long-term accumulation in ecosystems.

The production process of HDPE also presents challenges. Traditional manufacturing methods often result in the release of microplastics during the pelletization and transportation stages. These tiny plastic particles can easily enter waterways and soil, exacerbating the microplastic pollution problem. Additionally, the energy-intensive nature of HDPE production contributes to its carbon footprint, raising concerns about its overall environmental impact.

Recycling HDPE poses another set of challenges. While the material is technically recyclable, the efficiency and effectiveness of recycling processes are often limited. Contamination from other materials, such as food residues or labels, can compromise the quality of recycled HDPE. Moreover, the variety of additives used in HDPE products can make it difficult to create a consistent recycled product, potentially limiting its applications.

The widespread use of single-use HDPE products, particularly in packaging, contributes significantly to plastic waste. Despite efforts to promote reusable alternatives, the convenience and cost-effectiveness of HDPE packaging continue to drive its consumption. This creates a tension between consumer habits and environmental sustainability goals.

Another challenge lies in the fragmentation of HDPE in the environment. As HDPE products break down into smaller pieces, they become increasingly difficult to remove from ecosystems. These microplastics can absorb and concentrate environmental pollutants, potentially introducing toxins into the food chain when ingested by marine life and other organisms.

The regulatory landscape surrounding HDPE and microplastics presents additional complexities. Varying regulations across different regions can make it challenging for manufacturers to implement consistent, global strategies for reducing microplastic pollution. Furthermore, the lack of standardized methods for measuring and monitoring microplastics in the environment hinders efforts to assess the full scope of the problem and evaluate the effectiveness of mitigation strategies.

Addressing these challenges requires a multifaceted approach, involving innovations in material science, improvements in recycling technologies, changes in consumer behavior, and the development of more comprehensive regulatory frameworks. The path forward for HDPE in microplastics reduction will likely involve a combination of technological advancements, policy interventions, and shifts in production and consumption patterns.

Current HDPE Solutions

01 Biodegradable HDPE composites

Development of biodegradable HDPE composites by incorporating natural fibers or biodegradable additives. These composites maintain the desirable properties of HDPE while reducing microplastic pollution through enhanced biodegradability.- Biodegradable HDPE composites: Developing biodegradable HDPE composites by incorporating natural fibers or biodegradable additives. This approach aims to reduce microplastic pollution by enhancing the degradability of HDPE materials while maintaining their desirable properties.

- Improved recycling techniques: Implementing advanced recycling technologies to efficiently process HDPE waste, reducing the amount of microplastics entering the environment. These techniques may include chemical recycling, mechanical recycling, or other innovative methods to break down HDPE into reusable components.

- HDPE surface modification: Modifying the surface properties of HDPE to reduce fragmentation and microplastic formation. This can involve treatments that enhance the material's resistance to environmental degradation or promote its controlled breakdown into non-harmful components.

- Microplastic filtration systems: Developing filtration systems specifically designed to capture HDPE microplastics in various environments, such as water treatment plants, industrial processes, or consumer products. These systems aim to prevent microplastics from entering ecosystems.

- Alternative materials to HDPE: Researching and developing alternative materials that can replace HDPE in various applications while offering similar properties and reduced environmental impact. This includes exploring bio-based polymers or other sustainable materials that do not contribute to microplastic pollution.

02 Improved recycling technologies

Advanced recycling technologies for HDPE, including chemical recycling and mechanical recycling processes. These methods aim to reduce microplastic generation by efficiently breaking down HDPE into reusable materials or monomers.Expand Specific Solutions03 Microplastic filtration systems

Development of filtration systems specifically designed to capture HDPE microplastics from water sources. These systems can be implemented in wastewater treatment plants or as standalone units to prevent microplastics from entering the environment.Expand Specific Solutions04 Alternative materials to replace HDPE

Research and development of alternative materials with similar properties to HDPE but with reduced environmental impact. These materials may include bioplastics or other synthetic polymers designed to degrade more rapidly in the environment.Expand Specific Solutions05 HDPE surface modifications

Techniques for modifying the surface of HDPE to reduce microplastic shedding. This may include coating technologies or chemical treatments that enhance the material's durability and resistance to fragmentation.Expand Specific Solutions

Key Industry Players

The high-density polyethylene (HDPE) industry, in the context of microplastics reduction, is in a mature yet evolving stage. The market size is substantial, driven by increasing environmental concerns and regulatory pressures. Technologically, the field is advancing rapidly, with major players like Dow Global Technologies, ExxonMobil Chemical Patents, and DuPont de Nemours leading innovation. These companies, along with others such as LG Chem and SINOPEC, are developing more sustainable HDPE formulations and recycling technologies. The competitive landscape is characterized by a mix of established petrochemical giants and specialized materials companies, all striving to balance performance with environmental responsibility in HDPE production and application.

Dow Global Technologies LLC

China Petroleum & Chemical Corp.

HDPE Innovations

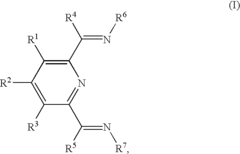

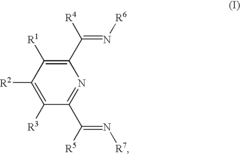

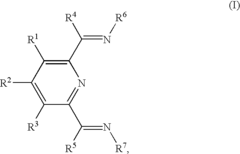

- Grafting Maleic Anhydride onto polyolefins serves as a compatibilizer, improving interfacial adhesion between polysulfones and polyolefins, allowing for the creation of blends with higher impact resistance without mineral oil.

- HDPE is produced using polymerization catalysts comprising iron or cobalt complexes of specific compounds, such as those with aryl and substituted aryl groups, which significantly reduce water vapor and oxygen transmission rates, making them suitable for improved packaging.

Environmental Impact

High Density Polyethylene (HDPE) has been widely used in various industries due to its durability and versatility. However, its environmental impact, particularly in relation to microplastics pollution, has become a growing concern. The persistence of HDPE in the environment contributes significantly to the accumulation of microplastics in ecosystems worldwide.

When HDPE products are improperly disposed of or break down over time, they fragment into smaller particles, eventually becoming microplastics. These tiny plastic particles, measuring less than 5mm in size, pose severe threats to marine life, terrestrial ecosystems, and potentially human health. Aquatic organisms often mistake microplastics for food, leading to malnutrition, internal injuries, and the bioaccumulation of toxins throughout the food chain.

The widespread use of HDPE in single-use items, such as plastic bags and packaging, exacerbates the microplastics problem. These products have short lifespans but persist in the environment for hundreds of years. As they degrade, they release harmful chemicals and additives, further contaminating soil and water resources.

Efforts to reduce the environmental impact of HDPE-derived microplastics have focused on several key areas. Improved waste management systems and recycling initiatives aim to prevent HDPE products from entering the environment in the first place. Additionally, research into biodegradable alternatives and the development of more environmentally friendly additives seeks to minimize the long-term impact of HDPE products that do end up in ecosystems.

The role of HDPE in microplastics reduction involves a multifaceted approach. Manufacturers are exploring ways to create more durable HDPE products that resist fragmentation, thereby reducing the generation of microplastics. Simultaneously, there is a push towards designing HDPE items that are easier to recycle, promoting a circular economy model that keeps plastic materials in use and out of the environment.

Innovative technologies are being developed to capture and remove microplastics from water bodies, addressing the existing pollution caused by HDPE and other plastics. These range from advanced filtration systems in wastewater treatment plants to novel materials that can attract and bind microplastics in aquatic environments.

Public awareness campaigns and policy initiatives play crucial roles in mitigating the environmental impact of HDPE-derived microplastics. By educating consumers about proper disposal methods and encouraging the use of reusable alternatives, these efforts aim to reduce the overall consumption and improper disposal of HDPE products.

Regulatory Framework

The regulatory framework surrounding High Density Polyethylene (HDPE) and its role in microplastics reduction is evolving rapidly as governments and international organizations recognize the urgent need to address plastic pollution. At the global level, the United Nations Environment Assembly (UNEA) has been instrumental in driving policy changes. In March 2022, UNEA adopted a resolution to develop a legally binding global treaty on plastic pollution by 2024, which is expected to have significant implications for HDPE production and use.

In the European Union, the Single-Use Plastics Directive, implemented in 2021, aims to reduce the impact of certain plastic products on the environment. While not specifically targeting HDPE, this directive has indirect effects on its use in packaging and consumer goods. The EU's Circular Economy Action Plan also emphasizes the need for sustainable plastic production and consumption, potentially influencing HDPE manufacturing processes and recycling initiatives.

In the United States, regulatory efforts are primarily led at the state level. California, for instance, has enacted legislation requiring all plastic packaging to be recyclable or compostable by 2032. This law will likely drive innovation in HDPE formulations and recycling technologies. Other states, such as New York and Maine, have implemented extended producer responsibility (EPR) programs for packaging materials, including those made from HDPE.

Asian countries are also taking steps to address plastic pollution. China's ban on importing plastic waste has led to increased domestic recycling efforts, potentially boosting the demand for recyclable HDPE products. Japan has set ambitious targets for plastic recycling and is promoting the use of bio-based plastics, which could impact the market for traditional HDPE.

International standards organizations play a crucial role in shaping the regulatory landscape. The International Organization for Standardization (ISO) has developed standards for plastics recycling and biodegradability, which influence HDPE production and end-of-life management. These standards are often adopted or referenced in national regulations, creating a more harmonized global approach to plastic sustainability.

Industry self-regulation is also emerging as a significant factor. Many multinational corporations have made voluntary commitments to reduce plastic waste and increase the use of recycled content in their packaging. These initiatives often exceed current regulatory requirements and can drive market-wide changes in HDPE usage and recycling practices.

As the regulatory framework continues to evolve, it is likely that we will see more stringent requirements for HDPE production, use, and disposal. Future regulations may focus on mandatory recycled content percentages, extended producer responsibility schemes, and stricter controls on microplastic emissions during the HDPE lifecycle. This evolving landscape presents both challenges and opportunities for the HDPE industry to innovate and adapt to a more sustainable future.