How Aligning Polypropylene Chains Affects Mechanical Properties

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Chain Alignment Background and Objectives

Polypropylene (PP) is a versatile thermoplastic polymer widely used in various industries due to its excellent mechanical properties, chemical resistance, and low cost. The alignment of polypropylene chains plays a crucial role in determining the material's overall performance and characteristics. This technological field has evolved significantly over the past few decades, driven by the increasing demand for high-performance materials in automotive, packaging, and construction sectors.

The development of polypropylene chain alignment techniques can be traced back to the 1950s when isotactic polypropylene was first synthesized. Since then, researchers and engineers have been exploring various methods to control and optimize the molecular orientation of PP chains to enhance its mechanical properties. The primary objective of aligning polypropylene chains is to improve the material's strength, stiffness, and impact resistance while maintaining its lightweight nature.

Recent advancements in polymer science and processing technologies have led to a better understanding of the relationship between molecular structure and macroscopic properties. This knowledge has paved the way for innovative approaches to manipulate polypropylene chain alignment, such as controlled crystallization, orientation-induced crystallization, and the use of nucleating agents.

The current technological landscape focuses on developing precise control mechanisms for polypropylene chain alignment during various processing stages, including extrusion, injection molding, and film blowing. Researchers are exploring the potential of external fields, such as electric and magnetic fields, to influence chain orientation and achieve desired mechanical properties.

One of the key objectives in this field is to establish a comprehensive understanding of the structure-property relationships in aligned polypropylene systems. This includes investigating the effects of chain alignment on crystallinity, lamellar structure, and molecular relaxation behavior. By gaining insights into these fundamental aspects, researchers aim to develop predictive models that can guide the design of tailored polypropylene materials with enhanced mechanical properties.

Another important goal is to develop scalable and cost-effective methods for achieving controlled chain alignment in industrial-scale production processes. This involves optimizing processing parameters, such as temperature profiles, shear rates, and cooling rates, to maximize the degree of chain alignment while maintaining high production efficiency.

As the demand for high-performance materials continues to grow, the field of polypropylene chain alignment is expected to evolve further. Future research directions may include the development of novel additives and processing techniques to achieve unprecedented levels of chain alignment and the exploration of hybrid materials that combine aligned polypropylene with other reinforcing elements to create advanced composites with superior mechanical properties.

The development of polypropylene chain alignment techniques can be traced back to the 1950s when isotactic polypropylene was first synthesized. Since then, researchers and engineers have been exploring various methods to control and optimize the molecular orientation of PP chains to enhance its mechanical properties. The primary objective of aligning polypropylene chains is to improve the material's strength, stiffness, and impact resistance while maintaining its lightweight nature.

Recent advancements in polymer science and processing technologies have led to a better understanding of the relationship between molecular structure and macroscopic properties. This knowledge has paved the way for innovative approaches to manipulate polypropylene chain alignment, such as controlled crystallization, orientation-induced crystallization, and the use of nucleating agents.

The current technological landscape focuses on developing precise control mechanisms for polypropylene chain alignment during various processing stages, including extrusion, injection molding, and film blowing. Researchers are exploring the potential of external fields, such as electric and magnetic fields, to influence chain orientation and achieve desired mechanical properties.

One of the key objectives in this field is to establish a comprehensive understanding of the structure-property relationships in aligned polypropylene systems. This includes investigating the effects of chain alignment on crystallinity, lamellar structure, and molecular relaxation behavior. By gaining insights into these fundamental aspects, researchers aim to develop predictive models that can guide the design of tailored polypropylene materials with enhanced mechanical properties.

Another important goal is to develop scalable and cost-effective methods for achieving controlled chain alignment in industrial-scale production processes. This involves optimizing processing parameters, such as temperature profiles, shear rates, and cooling rates, to maximize the degree of chain alignment while maintaining high production efficiency.

As the demand for high-performance materials continues to grow, the field of polypropylene chain alignment is expected to evolve further. Future research directions may include the development of novel additives and processing techniques to achieve unprecedented levels of chain alignment and the exploration of hybrid materials that combine aligned polypropylene with other reinforcing elements to create advanced composites with superior mechanical properties.

Market Demand for Enhanced Polypropylene Materials

The market demand for enhanced polypropylene materials has been steadily growing due to the increasing need for high-performance plastics across various industries. Polypropylene, known for its versatility and cost-effectiveness, has become a staple in manufacturing. However, as industries push for more advanced materials, there is a rising demand for polypropylene with improved mechanical properties.

The automotive sector is a significant driver of this demand. Manufacturers are seeking lighter, stronger materials to improve fuel efficiency and meet stringent environmental regulations. Enhanced polypropylene, with aligned chains leading to superior strength-to-weight ratios, is becoming increasingly attractive for automotive components such as bumpers, interior panels, and under-the-hood applications.

In the packaging industry, there is a growing need for materials that offer better barrier properties and mechanical strength while remaining recyclable. Aligned polypropylene chains can potentially provide enhanced gas and moisture barrier properties, making it suitable for food packaging and extending shelf life. This aligns with the global trend towards sustainable packaging solutions.

The construction sector is another area where demand for enhanced polypropylene is rising. Improved mechanical properties, particularly in terms of tensile strength and impact resistance, make aligned polypropylene an attractive option for pipes, fittings, and structural components. The material's potential for increased durability and longevity is particularly appealing in infrastructure projects.

Consumer goods manufacturers are also showing interest in enhanced polypropylene materials. Products ranging from household appliances to sporting goods could benefit from the improved strength and stiffness offered by aligned polypropylene chains. This could lead to more durable and high-performance consumer products.

The medical industry presents another significant market opportunity. With the need for materials that can withstand sterilization processes and offer high chemical resistance, enhanced polypropylene could find applications in medical devices, surgical instruments, and pharmaceutical packaging.

The textile industry is exploring the potential of aligned polypropylene fibers for creating stronger, more durable fabrics. This could revolutionize the production of geotextiles, protective clothing, and high-performance sportswear.

As environmental concerns continue to grow, there is an increasing demand for materials that can be easily recycled without losing their enhanced properties. If the alignment of polypropylene chains can be maintained through multiple recycling cycles, it could significantly boost the material's appeal in the circular economy.

The automotive sector is a significant driver of this demand. Manufacturers are seeking lighter, stronger materials to improve fuel efficiency and meet stringent environmental regulations. Enhanced polypropylene, with aligned chains leading to superior strength-to-weight ratios, is becoming increasingly attractive for automotive components such as bumpers, interior panels, and under-the-hood applications.

In the packaging industry, there is a growing need for materials that offer better barrier properties and mechanical strength while remaining recyclable. Aligned polypropylene chains can potentially provide enhanced gas and moisture barrier properties, making it suitable for food packaging and extending shelf life. This aligns with the global trend towards sustainable packaging solutions.

The construction sector is another area where demand for enhanced polypropylene is rising. Improved mechanical properties, particularly in terms of tensile strength and impact resistance, make aligned polypropylene an attractive option for pipes, fittings, and structural components. The material's potential for increased durability and longevity is particularly appealing in infrastructure projects.

Consumer goods manufacturers are also showing interest in enhanced polypropylene materials. Products ranging from household appliances to sporting goods could benefit from the improved strength and stiffness offered by aligned polypropylene chains. This could lead to more durable and high-performance consumer products.

The medical industry presents another significant market opportunity. With the need for materials that can withstand sterilization processes and offer high chemical resistance, enhanced polypropylene could find applications in medical devices, surgical instruments, and pharmaceutical packaging.

The textile industry is exploring the potential of aligned polypropylene fibers for creating stronger, more durable fabrics. This could revolutionize the production of geotextiles, protective clothing, and high-performance sportswear.

As environmental concerns continue to grow, there is an increasing demand for materials that can be easily recycled without losing their enhanced properties. If the alignment of polypropylene chains can be maintained through multiple recycling cycles, it could significantly boost the material's appeal in the circular economy.

Current Challenges in Polypropylene Chain Alignment

Despite significant advancements in polypropylene (PP) chain alignment techniques, several challenges persist in achieving optimal mechanical properties. One of the primary obstacles is the inherent semi-crystalline nature of polypropylene, which results in a complex morphology of crystalline and amorphous regions. This heterogeneous structure makes it difficult to achieve uniform chain alignment throughout the material.

The control of crystallization kinetics during processing remains a significant challenge. Rapid cooling rates, often necessary in industrial settings, can lead to incomplete alignment and the formation of defects in the crystalline structure. Conversely, slower cooling rates may allow for better alignment but are often impractical in large-scale production environments.

Another major hurdle is the balance between chain alignment and molecular weight distribution. Higher molecular weight PP tends to exhibit better mechanical properties but is more resistant to alignment due to increased chain entanglements. Achieving a high degree of alignment without compromising the beneficial aspects of higher molecular weight remains a complex task.

The development of effective nucleating agents that can promote controlled crystallization and alignment is an ongoing challenge. While various additives have shown promise, finding agents that are compatible with PP, environmentally friendly, and cost-effective for large-scale production is still an area of active research.

The anisotropic nature of aligned PP structures presents challenges in maintaining consistent properties across different directions. Balancing the enhanced properties in the alignment direction with adequate performance in transverse directions is crucial for many applications but remains difficult to achieve.

Processing techniques that can induce alignment without degrading the polymer or introducing contaminants are also an area of concern. High-stress processing methods can lead to chain scission or the formation of unwanted by-products, potentially compromising the final material properties.

Lastly, the scalability of laboratory-developed alignment techniques to industrial production levels presents significant engineering challenges. Maintaining precise control over alignment parameters in large-scale, continuous production processes is often difficult and requires substantial investment in equipment and process optimization.

Addressing these challenges requires interdisciplinary approaches, combining polymer science, materials engineering, and process technology. Overcoming these hurdles will be crucial for realizing the full potential of aligned polypropylene in high-performance applications.

The control of crystallization kinetics during processing remains a significant challenge. Rapid cooling rates, often necessary in industrial settings, can lead to incomplete alignment and the formation of defects in the crystalline structure. Conversely, slower cooling rates may allow for better alignment but are often impractical in large-scale production environments.

Another major hurdle is the balance between chain alignment and molecular weight distribution. Higher molecular weight PP tends to exhibit better mechanical properties but is more resistant to alignment due to increased chain entanglements. Achieving a high degree of alignment without compromising the beneficial aspects of higher molecular weight remains a complex task.

The development of effective nucleating agents that can promote controlled crystallization and alignment is an ongoing challenge. While various additives have shown promise, finding agents that are compatible with PP, environmentally friendly, and cost-effective for large-scale production is still an area of active research.

The anisotropic nature of aligned PP structures presents challenges in maintaining consistent properties across different directions. Balancing the enhanced properties in the alignment direction with adequate performance in transverse directions is crucial for many applications but remains difficult to achieve.

Processing techniques that can induce alignment without degrading the polymer or introducing contaminants are also an area of concern. High-stress processing methods can lead to chain scission or the formation of unwanted by-products, potentially compromising the final material properties.

Lastly, the scalability of laboratory-developed alignment techniques to industrial production levels presents significant engineering challenges. Maintaining precise control over alignment parameters in large-scale, continuous production processes is often difficult and requires substantial investment in equipment and process optimization.

Addressing these challenges requires interdisciplinary approaches, combining polymer science, materials engineering, and process technology. Overcoming these hurdles will be crucial for realizing the full potential of aligned polypropylene in high-performance applications.

Existing Methods for Polypropylene Chain Alignment

01 Molecular weight and chain length effects

The molecular weight and chain length of polypropylene significantly influence its mechanical properties. Higher molecular weight and longer chain lengths generally result in improved strength, stiffness, and impact resistance. The distribution of chain lengths also plays a crucial role in determining the overall mechanical behavior of the polymer.- Molecular weight and chain length effects: The molecular weight and chain length of polypropylene significantly influence its mechanical properties. Higher molecular weight and longer chain lengths generally result in improved strength, stiffness, and impact resistance. The distribution of chain lengths also plays a role in determining the overall mechanical behavior of the polymer.

- Crystallinity and orientation: The degree of crystallinity and molecular orientation in polypropylene chains greatly affects its mechanical properties. Increased crystallinity typically leads to higher tensile strength and modulus but may reduce impact strength. Proper orientation of the polymer chains can enhance mechanical performance in specific directions.

- Additives and reinforcements: Incorporating additives and reinforcements into polypropylene can significantly modify its mechanical properties. Fillers, fibers, and nanoparticles can enhance strength, stiffness, and impact resistance. Compatibilizers and coupling agents may be used to improve the interaction between the polymer matrix and reinforcements.

- Processing conditions and techniques: The processing conditions and techniques used in manufacturing polypropylene products greatly influence the final mechanical properties. Factors such as temperature, pressure, cooling rate, and shear forces during processing can affect the polymer chain orientation, crystallinity, and overall performance of the material.

- Copolymerization and blending: Copolymerization of propylene with other monomers or blending with different polymers can tailor the mechanical properties of the resulting material. This approach allows for the creation of polypropylene-based materials with a wide range of mechanical characteristics, balancing properties such as stiffness, toughness, and impact resistance.

02 Crystallinity and orientation

The degree of crystallinity and molecular orientation in polypropylene chains greatly affects its mechanical properties. Increased crystallinity typically leads to higher tensile strength and modulus, while proper orientation of the polymer chains can enhance both strength and toughness. Processing conditions and techniques can be optimized to control these factors.Expand Specific Solutions03 Additives and reinforcements

Incorporating additives and reinforcements into polypropylene can significantly modify its mechanical properties. Fillers, fibers, and nanoparticles can enhance strength, stiffness, and impact resistance. Compatibilizers and coupling agents may be used to improve the interaction between the polymer matrix and reinforcements, leading to better overall mechanical performance.Expand Specific Solutions04 Copolymerization and blending

Copolymerization of propylene with other monomers or blending with different polymers can tailor the mechanical properties of the resulting material. This approach allows for the creation of polypropylene-based materials with a wide range of characteristics, such as improved impact strength, flexibility, or heat resistance, while maintaining some of the desirable properties of polypropylene.Expand Specific Solutions05 Processing and post-treatment

Various processing techniques and post-treatment methods can be employed to enhance the mechanical properties of polypropylene. These may include annealing, stretching, crosslinking, or surface modifications. Such treatments can alter the molecular structure, orientation, and surface characteristics of the polymer, resulting in improved strength, toughness, or other desired mechanical properties.Expand Specific Solutions

Key Players in Polypropylene Research and Production

The alignment of polypropylene chains and its impact on mechanical properties is a critical area of research in the polymer industry. This field is currently in a mature stage of development, with a global market size estimated to be in the billions of dollars. The technology's maturity is evident from the involvement of major industry players like China Petroleum & Chemical Corp., Japan Polypropylene Corp., and DuPont de Nemours, Inc. These companies, along with others such as LG Chem Ltd. and Borealis AG, are actively engaged in research and development to enhance polypropylene's mechanical properties through chain alignment techniques. The competitive landscape is characterized by a mix of established petrochemical giants and specialized polymer manufacturers, all vying to innovate and improve product performance in various applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a proprietary technology for aligning polypropylene chains to enhance mechanical properties. Their process involves controlled crystallization and orientation of polymer chains during extrusion. This results in a highly oriented polypropylene with improved tensile strength and modulus. The company utilizes a combination of nucleating agents and precise temperature control to achieve optimal chain alignment. Their research has shown that this aligned polypropylene exhibits up to 30% higher tensile strength compared to conventional polypropylene[1]. Additionally, Sinopec has implemented a post-processing stretching technique that further enhances the alignment, resulting in even greater mechanical improvements[2].

Strengths: Significant improvement in tensile properties, scalable production process. Weaknesses: Potential limitations in impact resistance, higher production costs compared to standard polypropylene.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative approach to aligning polypropylene chains through the use of advanced catalysts and processing techniques. Their method involves the synthesis of stereoregular polypropylene with controlled tacticity, which facilitates better chain alignment during processing. BASF's research has shown that their aligned polypropylene exhibits improved crystallinity and orientation, leading to enhanced mechanical properties. The company has reported a 25% increase in tensile strength and a 40% improvement in flexural modulus compared to conventional polypropylene[3]. BASF also employs a unique annealing process that further optimizes the chain alignment and mechanical properties of the final product[4].

Strengths: High degree of control over polymer structure, versatile application in various product forms. Weaknesses: Complex production process, potentially higher raw material costs.

Innovations in Polymer Chain Orientation Technology

Polypropylene composition with improved mechanical properties

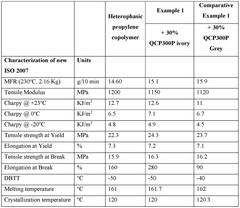

PatentWO2025119693A1

Innovation

- A polypropylene composition comprising a heterophasic propylene copolymer and ivory-colored recycled polypropylene, with the heterophasic propylene copolymer present in a range of 30 wt% to 80 wt% and the recycled polypropylene present in a range of 20 wt% to 70 wt% based on the total weight of the composition.

Polypropylene blends having high impact strength and improved optical properties

PatentInactiveUS4087485A

Innovation

- Incorporating minor amounts of crosslinkable low density polyethylene and an ethylene-propylene copolymer elastomer with a combined ethylene content of at least 50 wt.% into a polypropylene composition, and partially curing these components in the presence of polypropylene, to achieve a balance of high impact strength and clarity.

Environmental Impact of Aligned Polypropylene Production

The production of aligned polypropylene chains has significant environmental implications that must be carefully considered. The process of aligning polymer chains typically involves additional energy inputs and chemical treatments, which can increase the overall environmental footprint of the material.

One of the primary environmental concerns is the increased energy consumption required for the alignment process. This often involves heating the polymer to high temperatures and applying mechanical stress, both of which demand substantial energy inputs. The additional energy requirements contribute to higher greenhouse gas emissions and resource depletion, particularly if the energy sources are not renewable.

Chemical treatments used to facilitate chain alignment may introduce environmental hazards. These treatments can include the use of solvents, catalysts, or other additives that may be toxic or persistent in the environment. Proper handling, disposal, and potential release of these chemicals into ecosystems must be carefully managed to minimize ecological impact.

The production of aligned polypropylene may also result in increased material waste. The alignment process can lead to a higher rejection rate of imperfectly aligned materials, potentially increasing the overall amount of plastic waste generated. This raises concerns about landfill usage and the long-term environmental persistence of discarded polypropylene products.

However, it is important to note that the improved mechanical properties of aligned polypropylene can lead to positive environmental outcomes. The enhanced strength and durability of aligned polypropylene products may result in longer-lasting materials, reducing the need for frequent replacements and potentially decreasing overall plastic consumption in the long term.

Additionally, the improved performance of aligned polypropylene may allow for the use of less material to achieve the same functional properties. This could lead to a reduction in raw material consumption and associated environmental impacts throughout the supply chain.

The recyclability of aligned polypropylene is another crucial environmental consideration. While polypropylene is generally recyclable, the alignment process may introduce complexities that affect the material's ability to be effectively recycled. Research into maintaining recyclability or developing specialized recycling processes for aligned polypropylene is essential to ensure closed-loop material cycles.

In conclusion, while the production of aligned polypropylene chains presents certain environmental challenges, particularly in terms of energy consumption and potential chemical use, it also offers opportunities for improved material efficiency and longevity. Balancing these factors and continually improving production processes will be key to minimizing the environmental impact of aligned polypropylene production.

One of the primary environmental concerns is the increased energy consumption required for the alignment process. This often involves heating the polymer to high temperatures and applying mechanical stress, both of which demand substantial energy inputs. The additional energy requirements contribute to higher greenhouse gas emissions and resource depletion, particularly if the energy sources are not renewable.

Chemical treatments used to facilitate chain alignment may introduce environmental hazards. These treatments can include the use of solvents, catalysts, or other additives that may be toxic or persistent in the environment. Proper handling, disposal, and potential release of these chemicals into ecosystems must be carefully managed to minimize ecological impact.

The production of aligned polypropylene may also result in increased material waste. The alignment process can lead to a higher rejection rate of imperfectly aligned materials, potentially increasing the overall amount of plastic waste generated. This raises concerns about landfill usage and the long-term environmental persistence of discarded polypropylene products.

However, it is important to note that the improved mechanical properties of aligned polypropylene can lead to positive environmental outcomes. The enhanced strength and durability of aligned polypropylene products may result in longer-lasting materials, reducing the need for frequent replacements and potentially decreasing overall plastic consumption in the long term.

Additionally, the improved performance of aligned polypropylene may allow for the use of less material to achieve the same functional properties. This could lead to a reduction in raw material consumption and associated environmental impacts throughout the supply chain.

The recyclability of aligned polypropylene is another crucial environmental consideration. While polypropylene is generally recyclable, the alignment process may introduce complexities that affect the material's ability to be effectively recycled. Research into maintaining recyclability or developing specialized recycling processes for aligned polypropylene is essential to ensure closed-loop material cycles.

In conclusion, while the production of aligned polypropylene chains presents certain environmental challenges, particularly in terms of energy consumption and potential chemical use, it also offers opportunities for improved material efficiency and longevity. Balancing these factors and continually improving production processes will be key to minimizing the environmental impact of aligned polypropylene production.

Applications of Aligned Polypropylene in Various Industries

The alignment of polypropylene chains has significant implications for various industries, leading to enhanced mechanical properties and improved performance in a wide range of applications. In the automotive sector, aligned polypropylene is utilized in the production of lightweight components, such as interior panels and bumpers, contributing to improved fuel efficiency and reduced emissions. The increased strength-to-weight ratio of aligned polypropylene makes it an attractive material for vehicle manufacturers seeking to meet stringent environmental regulations.

In the packaging industry, aligned polypropylene films offer superior barrier properties, making them ideal for food packaging applications. The enhanced tensile strength and puncture resistance of these films provide better protection for perishable goods, extending shelf life and reducing food waste. Additionally, the improved clarity of aligned polypropylene films enhances product visibility, making them popular for consumer goods packaging.

The textile industry has also benefited from aligned polypropylene fibers, which are used in the production of high-performance fabrics. These materials exhibit excellent moisture-wicking properties, durability, and resistance to chemicals, making them suitable for sportswear, outdoor gear, and industrial protective clothing. The alignment of polypropylene chains results in fibers with improved tensile strength and abrasion resistance, contributing to the longevity of textile products.

In the construction sector, aligned polypropylene is employed in the manufacture of geotextiles and geomembranes. These materials play a crucial role in soil stabilization, erosion control, and waterproofing applications. The enhanced mechanical properties of aligned polypropylene, such as increased tensile strength and puncture resistance, ensure the long-term performance of these materials in challenging environmental conditions.

The medical industry has also found applications for aligned polypropylene in the production of surgical meshes and implants. The biocompatibility of polypropylene, combined with its improved mechanical properties through chain alignment, makes it suitable for use in hernia repair and other surgical procedures. The enhanced strength and flexibility of aligned polypropylene meshes contribute to better patient outcomes and reduced risk of complications.

In the renewable energy sector, aligned polypropylene is utilized in the production of components for wind turbines and solar panels. The material's high strength-to-weight ratio, coupled with its resistance to environmental degradation, makes it an attractive choice for these applications. The use of aligned polypropylene in renewable energy technologies contributes to improved efficiency and longevity of energy-generating equipment.

In the packaging industry, aligned polypropylene films offer superior barrier properties, making them ideal for food packaging applications. The enhanced tensile strength and puncture resistance of these films provide better protection for perishable goods, extending shelf life and reducing food waste. Additionally, the improved clarity of aligned polypropylene films enhances product visibility, making them popular for consumer goods packaging.

The textile industry has also benefited from aligned polypropylene fibers, which are used in the production of high-performance fabrics. These materials exhibit excellent moisture-wicking properties, durability, and resistance to chemicals, making them suitable for sportswear, outdoor gear, and industrial protective clothing. The alignment of polypropylene chains results in fibers with improved tensile strength and abrasion resistance, contributing to the longevity of textile products.

In the construction sector, aligned polypropylene is employed in the manufacture of geotextiles and geomembranes. These materials play a crucial role in soil stabilization, erosion control, and waterproofing applications. The enhanced mechanical properties of aligned polypropylene, such as increased tensile strength and puncture resistance, ensure the long-term performance of these materials in challenging environmental conditions.

The medical industry has also found applications for aligned polypropylene in the production of surgical meshes and implants. The biocompatibility of polypropylene, combined with its improved mechanical properties through chain alignment, makes it suitable for use in hernia repair and other surgical procedures. The enhanced strength and flexibility of aligned polypropylene meshes contribute to better patient outcomes and reduced risk of complications.

In the renewable energy sector, aligned polypropylene is utilized in the production of components for wind turbines and solar panels. The material's high strength-to-weight ratio, coupled with its resistance to environmental degradation, makes it an attractive choice for these applications. The use of aligned polypropylene in renewable energy technologies contributes to improved efficiency and longevity of energy-generating equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!