How Circular Economy Principles Influence Polypropylene Tech Developments

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Circular Economy and Polypropylene Evolution

The circular economy concept has significantly influenced the evolution of polypropylene technology, driving innovation towards more sustainable and resource-efficient practices. This paradigm shift has led to a reimagining of the entire lifecycle of polypropylene products, from production to disposal and recycling.

Initially, polypropylene production focused primarily on creating durable, cost-effective materials for various applications. However, as circular economy principles gained traction, the industry began to prioritize recyclability and biodegradability. This shift prompted researchers and manufacturers to develop new grades of polypropylene that maintain desirable properties while being easier to recycle or decompose.

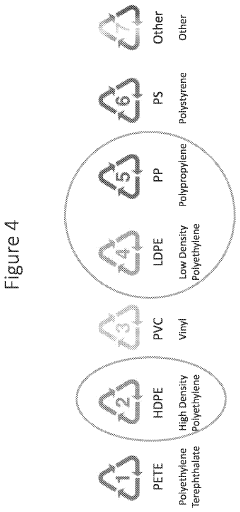

One of the key developments in this evolution has been the improvement of mechanical recycling processes for polypropylene. Advanced sorting technologies, such as near-infrared spectroscopy and artificial intelligence-driven systems, have enhanced the ability to separate different types of plastics, including various grades of polypropylene. This has led to higher quality recycled polypropylene, which can be used in a wider range of applications.

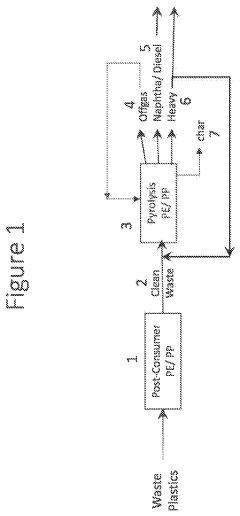

Chemical recycling techniques have also emerged as a promising avenue for polypropylene circularity. Processes like pyrolysis and gasification break down polypropylene into its chemical building blocks, allowing for the creation of virgin-quality material. This approach addresses the limitations of mechanical recycling, particularly for contaminated or mixed plastic waste.

Biodegradable polypropylene variants have been developed in response to circular economy demands. These materials incorporate additives or are synthesized with modified molecular structures that allow for faster decomposition in specific environments. While not suitable for all applications, biodegradable polypropylene offers a solution for single-use items and packaging.

The circular economy has also driven innovations in product design. Manufacturers are now creating polypropylene products with disassembly and recycling in mind. This includes the use of mono-material designs, easily separable components, and standardized coloring to facilitate sorting and recycling processes.

Furthermore, the concept of upcycling has gained prominence, where recycled polypropylene is transformed into higher-value products. This approach not only extends the material's lifecycle but also creates new market opportunities and enhances the perceived value of recycled plastics.

As the circular economy continues to shape polypropylene technology, we are witnessing a convergence of material science, recycling technology, and sustainable design principles. This holistic approach is paving the way for a more sustainable future for polypropylene, aligning its development with the broader goals of resource conservation and environmental stewardship.

Initially, polypropylene production focused primarily on creating durable, cost-effective materials for various applications. However, as circular economy principles gained traction, the industry began to prioritize recyclability and biodegradability. This shift prompted researchers and manufacturers to develop new grades of polypropylene that maintain desirable properties while being easier to recycle or decompose.

One of the key developments in this evolution has been the improvement of mechanical recycling processes for polypropylene. Advanced sorting technologies, such as near-infrared spectroscopy and artificial intelligence-driven systems, have enhanced the ability to separate different types of plastics, including various grades of polypropylene. This has led to higher quality recycled polypropylene, which can be used in a wider range of applications.

Chemical recycling techniques have also emerged as a promising avenue for polypropylene circularity. Processes like pyrolysis and gasification break down polypropylene into its chemical building blocks, allowing for the creation of virgin-quality material. This approach addresses the limitations of mechanical recycling, particularly for contaminated or mixed plastic waste.

Biodegradable polypropylene variants have been developed in response to circular economy demands. These materials incorporate additives or are synthesized with modified molecular structures that allow for faster decomposition in specific environments. While not suitable for all applications, biodegradable polypropylene offers a solution for single-use items and packaging.

The circular economy has also driven innovations in product design. Manufacturers are now creating polypropylene products with disassembly and recycling in mind. This includes the use of mono-material designs, easily separable components, and standardized coloring to facilitate sorting and recycling processes.

Furthermore, the concept of upcycling has gained prominence, where recycled polypropylene is transformed into higher-value products. This approach not only extends the material's lifecycle but also creates new market opportunities and enhances the perceived value of recycled plastics.

As the circular economy continues to shape polypropylene technology, we are witnessing a convergence of material science, recycling technology, and sustainable design principles. This holistic approach is paving the way for a more sustainable future for polypropylene, aligning its development with the broader goals of resource conservation and environmental stewardship.

Market Demand for Sustainable Plastics

The demand for sustainable plastics, particularly in the context of polypropylene (PP) technology developments, has been steadily increasing in recent years. This surge is driven by growing environmental concerns, stricter regulations, and changing consumer preferences. The circular economy principles have significantly influenced this market trend, pushing for more recyclable and reusable plastic solutions.

Polypropylene, being one of the most widely used plastics globally, has become a focal point for sustainability efforts. The market for sustainable PP is expanding rapidly, with projections indicating substantial growth over the next decade. This demand is not limited to a single sector but spans across various industries, including packaging, automotive, consumer goods, and construction.

In the packaging industry, which accounts for a significant portion of PP consumption, there's a notable shift towards eco-friendly alternatives. Companies are increasingly seeking PP materials that can be easily recycled or biodegraded, responding to consumer demands for more environmentally responsible packaging solutions. This trend is particularly evident in the food and beverage sector, where sustainable PP packaging is becoming a key differentiator for brands.

The automotive industry is another major driver of sustainable PP demand. As automakers strive to reduce vehicle weight and improve fuel efficiency, they are turning to lightweight, recyclable PP components. The push for circular economy principles in this sector has led to increased interest in PP materials that can be easily disassembled and recycled at the end of a vehicle's life cycle.

Consumer goods manufacturers are also contributing to the growing demand for sustainable PP. From household items to electronics, there's a rising preference for products made from recycled or recyclable PP. This shift is largely driven by environmentally conscious consumers who are willing to pay a premium for sustainable products.

The construction industry, traditionally a significant consumer of PP, is increasingly adopting circular economy principles. This has led to a growing demand for PP materials that can be recycled or repurposed at the end of a building's lifespan. Sustainable PP is being used in various applications, from insulation materials to piping systems, reflecting the industry's move towards more environmentally friendly practices.

Government regulations and policies promoting circular economy principles have also played a crucial role in shaping the market demand for sustainable PP. Many countries have implemented or are considering regulations that mandate the use of recycled content in plastic products or impose taxes on non-recyclable plastics. These regulatory pressures are compelling businesses across industries to seek out more sustainable PP solutions, further driving market demand.

Polypropylene, being one of the most widely used plastics globally, has become a focal point for sustainability efforts. The market for sustainable PP is expanding rapidly, with projections indicating substantial growth over the next decade. This demand is not limited to a single sector but spans across various industries, including packaging, automotive, consumer goods, and construction.

In the packaging industry, which accounts for a significant portion of PP consumption, there's a notable shift towards eco-friendly alternatives. Companies are increasingly seeking PP materials that can be easily recycled or biodegraded, responding to consumer demands for more environmentally responsible packaging solutions. This trend is particularly evident in the food and beverage sector, where sustainable PP packaging is becoming a key differentiator for brands.

The automotive industry is another major driver of sustainable PP demand. As automakers strive to reduce vehicle weight and improve fuel efficiency, they are turning to lightweight, recyclable PP components. The push for circular economy principles in this sector has led to increased interest in PP materials that can be easily disassembled and recycled at the end of a vehicle's life cycle.

Consumer goods manufacturers are also contributing to the growing demand for sustainable PP. From household items to electronics, there's a rising preference for products made from recycled or recyclable PP. This shift is largely driven by environmentally conscious consumers who are willing to pay a premium for sustainable products.

The construction industry, traditionally a significant consumer of PP, is increasingly adopting circular economy principles. This has led to a growing demand for PP materials that can be recycled or repurposed at the end of a building's lifespan. Sustainable PP is being used in various applications, from insulation materials to piping systems, reflecting the industry's move towards more environmentally friendly practices.

Government regulations and policies promoting circular economy principles have also played a crucial role in shaping the market demand for sustainable PP. Many countries have implemented or are considering regulations that mandate the use of recycled content in plastic products or impose taxes on non-recyclable plastics. These regulatory pressures are compelling businesses across industries to seek out more sustainable PP solutions, further driving market demand.

Challenges in Polypropylene Recycling

Polypropylene recycling faces numerous challenges that hinder the widespread adoption of circular economy principles in the plastics industry. One of the primary obstacles is the contamination of polypropylene waste streams. Unlike other plastics, polypropylene is often used in food packaging and consumer goods, which leads to a high level of organic and inorganic contaminants. These impurities can significantly degrade the quality of recycled polypropylene, making it unsuitable for many high-value applications.

Another major challenge is the degradation of polypropylene during the recycling process. The polymer chains in polypropylene can break down due to heat and mechanical stress during reprocessing, resulting in a loss of mechanical properties and overall quality. This degradation limits the number of times polypropylene can be effectively recycled, posing a significant barrier to achieving a truly circular economy for this material.

The variety of additives used in polypropylene products also complicates recycling efforts. Flame retardants, stabilizers, and colorants are often incorporated into polypropylene to enhance its properties for specific applications. However, these additives can interfere with recycling processes and may not be compatible with new product requirements, making it difficult to maintain consistent quality in recycled polypropylene.

Sorting and separation of polypropylene from mixed plastic waste streams present another significant challenge. While technologies like near-infrared spectroscopy have improved plastic sorting capabilities, the efficiency and accuracy of these systems for polypropylene are still not optimal. This is particularly problematic for small or multi-layered polypropylene items, which are often misclassified or end up in landfills due to the difficulties in sorting.

The economic viability of polypropylene recycling is also a major hurdle. The cost of collecting, sorting, and processing polypropylene waste often exceeds the value of the recycled material, especially when compared to virgin polypropylene. This economic imbalance is exacerbated by fluctuations in oil prices, which directly affect the cost competitiveness of recycled versus virgin polypropylene.

Lastly, the lack of standardization in polypropylene products and recycling processes poses a challenge to creating a consistent and high-quality recycled product. The wide range of polypropylene grades and formulations used in different applications makes it difficult to establish uniform recycling protocols and quality standards for recycled polypropylene. This variability can lead to inconsistent performance in recycled materials, deterring potential users from incorporating them into their products.

Another major challenge is the degradation of polypropylene during the recycling process. The polymer chains in polypropylene can break down due to heat and mechanical stress during reprocessing, resulting in a loss of mechanical properties and overall quality. This degradation limits the number of times polypropylene can be effectively recycled, posing a significant barrier to achieving a truly circular economy for this material.

The variety of additives used in polypropylene products also complicates recycling efforts. Flame retardants, stabilizers, and colorants are often incorporated into polypropylene to enhance its properties for specific applications. However, these additives can interfere with recycling processes and may not be compatible with new product requirements, making it difficult to maintain consistent quality in recycled polypropylene.

Sorting and separation of polypropylene from mixed plastic waste streams present another significant challenge. While technologies like near-infrared spectroscopy have improved plastic sorting capabilities, the efficiency and accuracy of these systems for polypropylene are still not optimal. This is particularly problematic for small or multi-layered polypropylene items, which are often misclassified or end up in landfills due to the difficulties in sorting.

The economic viability of polypropylene recycling is also a major hurdle. The cost of collecting, sorting, and processing polypropylene waste often exceeds the value of the recycled material, especially when compared to virgin polypropylene. This economic imbalance is exacerbated by fluctuations in oil prices, which directly affect the cost competitiveness of recycled versus virgin polypropylene.

Lastly, the lack of standardization in polypropylene products and recycling processes poses a challenge to creating a consistent and high-quality recycled product. The wide range of polypropylene grades and formulations used in different applications makes it difficult to establish uniform recycling protocols and quality standards for recycled polypropylene. This variability can lead to inconsistent performance in recycled materials, deterring potential users from incorporating them into their products.

Current Circular Polypropylene Solutions

01 Polypropylene synthesis and production methods

Various methods for synthesizing and producing polypropylene, including catalytic processes, polymerization techniques, and reactor designs. These methods aim to improve the efficiency and quality of polypropylene production, resulting in materials with enhanced properties for diverse applications.- Polypropylene composition and manufacturing: Various methods and compositions for manufacturing polypropylene with improved properties are described. These include techniques for producing high-performance polypropylene resins with enhanced mechanical strength, thermal stability, and processability. The compositions may involve specific catalysts, additives, or processing conditions to achieve desired characteristics.

- Polypropylene blends and copolymers: Development of polypropylene blends and copolymers to enhance specific properties such as impact resistance, flexibility, or heat resistance. These materials may combine polypropylene with other polymers or incorporate comonomers to create tailored materials for various applications.

- Polypropylene fiber and film production: Innovations in the production of polypropylene fibers and films, including methods to improve tensile strength, elongation properties, and barrier characteristics. These advancements may involve specialized extrusion techniques, orientation processes, or surface treatments.

- Polypropylene additives and modifiers: Use of various additives and modifiers to enhance the properties of polypropylene, such as nucleating agents, stabilizers, flame retardants, or reinforcing fillers. These additives can improve crystallization behavior, long-term stability, fire resistance, or mechanical properties of polypropylene products.

- Recycling and sustainability of polypropylene: Methods for recycling polypropylene and improving its sustainability, including techniques for separating and purifying recycled polypropylene, incorporating recycled content into new products, and developing biodegradable or bio-based polypropylene alternatives.

02 Polypropylene blends and composites

Development of polypropylene blends and composites by combining polypropylene with other materials or additives. These formulations aim to enhance specific properties such as strength, durability, or thermal resistance, making the resulting materials suitable for a wide range of industrial and consumer applications.Expand Specific Solutions03 Polypropylene modification techniques

Methods for modifying polypropylene to improve its properties or functionalities. These techniques may include chemical treatments, surface modifications, or the incorporation of specific additives to enhance characteristics such as adhesion, printability, or compatibility with other materials.Expand Specific Solutions04 Polypropylene applications in packaging and films

Innovations in using polypropylene for packaging materials and film production. This includes developments in film extrusion, multi-layer structures, and specialized coatings to improve barrier properties, printability, and overall performance of polypropylene-based packaging solutions.Expand Specific Solutions05 Recycling and sustainability of polypropylene

Advancements in polypropylene recycling technologies and sustainable production methods. This includes processes for recovering and reprocessing polypropylene waste, as well as the development of bio-based or biodegradable polypropylene alternatives to address environmental concerns.Expand Specific Solutions

Key Players in Circular Polypropylene

The circular economy principles are significantly influencing polypropylene technology developments, as the industry transitions towards more sustainable practices. This market is in a growth phase, driven by increasing demand for recyclable and eco-friendly materials. The global polypropylene market size is projected to expand, with key players like Chevron U.S.A., Inc., Kingfa Sci. & Tech. Co., Ltd., and China Petroleum & Chemical Corp. leading innovations. These companies are investing in advanced recycling technologies and bio-based polypropylene production, demonstrating the industry's commitment to circular economy principles. The technology maturity varies, with traditional polypropylene production being well-established, while circular economy-focused innovations are still evolving, presenting opportunities for further advancements and market differentiation.

Braskem SA

Technical Solution: Braskem has developed a circular economy approach for polypropylene (PP) through its I'm green™ portfolio. This includes recycled PP and bio-based PP made from sugarcane. Their recycled PP uses advanced sorting and recycling technologies to produce high-quality recycled resin. The bio-based PP reduces carbon footprint by up to 80% compared to fossil-based PP[1]. Braskem has also implemented a design for circularity strategy, creating PP grades that are easier to recycle and reuse in new products. They've partnered with recycling companies to establish closed-loop systems for PP packaging[2].

Strengths: Diverse circular solutions (recycled and bio-based), significant carbon footprint reduction, established partnerships for closed-loop systems. Weaknesses: Limited availability of bio-based feedstock, potential higher costs compared to traditional PP.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed advanced recycling technology for plastic waste, including PP. Their Exxtend™ technology can process a wide range of plastic waste that is difficult to recycle mechanically. The process breaks down plastics into molecular building blocks that can be used to create virgin-quality plastics[5]. For PP specifically, ExxonMobil has introduced Vistamaxx™ performance polymers, which can be used to enhance the properties of recycled PP, improving its performance and expanding its applications. They've also developed Exceed™ XP performance polymers that can be used in multi-layer films to improve recyclability while maintaining performance[6].

Strengths: Advanced recycling technology capable of handling difficult-to-recycle plastics, performance-enhancing additives for recycled PP. Weaknesses: High energy requirements for advanced recycling, potential challenges in sourcing sufficient plastic waste feedstock.

Innovations in Polypropylene Circularity

Process to produce polypropylene-based composition from post-consumer resins and articles made of said compositions

PatentWO2019224129A1

Innovation

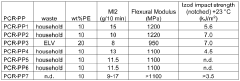

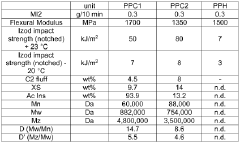

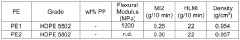

- A process involving a combination of polypropylene post-consumer resin (PCR) and virgin impact propylene copolymer, along with polyethylene resin, is used to enhance the stiffness and impact properties of the polypropylene-based composition, achieving a balance suitable for applications requiring low MI2 values and good impact resistance at low temperatures.

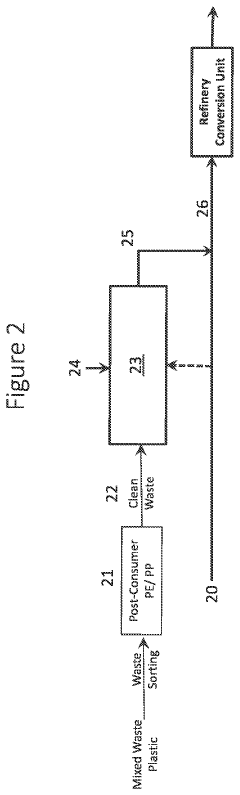

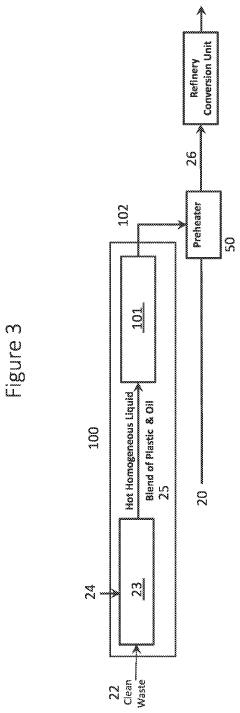

Circular economy for plastic waste to polypropylene and base oil via refinery hydrocracking unit

PatentActiveUS20230313052A1

Innovation

- A continuous process that blends waste plastics with petroleum feedstock, then passes the mixture to a hydrocracking unit in an oil refinery, allowing for the production of high-quality polypropylene and other fuels, while minimizing energy consumption and maintaining refinery operations.

Environmental Impact Assessment

The environmental impact assessment of polypropylene (PP) technology developments influenced by circular economy principles reveals significant potential for reducing the material's ecological footprint. Circular economy approaches are driving innovations in PP production, use, and recycling, leading to more sustainable practices throughout the material's lifecycle.

In the production phase, circular economy principles are encouraging the development of bio-based PP alternatives. These materials, derived from renewable resources such as sugarcane or corn, have the potential to reduce greenhouse gas emissions and dependence on fossil fuels. Additionally, advancements in catalysis and process optimization are improving energy efficiency in PP manufacturing, further minimizing environmental impacts.

The use phase of PP products is being transformed by circular design principles. Innovations in product design are focusing on durability, repairability, and modularity, extending the lifespan of PP-based items. This shift reduces the demand for new PP production and mitigates waste generation. Furthermore, the development of PP grades with enhanced recyclability is facilitating easier material recovery at the end of a product's life.

Recycling technologies for PP are experiencing significant advancements due to circular economy influences. Mechanical recycling processes are being refined to produce higher quality recycled PP, expanding its potential applications. Emerging chemical recycling technologies, such as pyrolysis and depolymerization, are enabling the conversion of PP waste back into virgin-quality monomers, closing the material loop more effectively.

The implementation of these circular economy-driven technologies is projected to have substantial environmental benefits. Life cycle assessments indicate potential reductions in carbon emissions, energy consumption, and water usage associated with PP throughout its lifecycle. Moreover, the increased use of recycled PP is expected to alleviate pressure on landfills and reduce plastic pollution in marine environments.

However, challenges remain in fully realizing these environmental benefits. The scale-up of new recycling technologies and the establishment of efficient collection and sorting systems are crucial for maximizing the circular potential of PP. Additionally, ensuring the quality and safety of recycled PP for various applications, particularly in food contact and medical uses, requires ongoing research and regulatory considerations.

In conclusion, the influence of circular economy principles on PP technology developments is driving significant improvements in environmental performance. As these innovations continue to mature and scale, they have the potential to transform PP into a more sustainable material, aligning its use with broader environmental goals and resource conservation efforts.

In the production phase, circular economy principles are encouraging the development of bio-based PP alternatives. These materials, derived from renewable resources such as sugarcane or corn, have the potential to reduce greenhouse gas emissions and dependence on fossil fuels. Additionally, advancements in catalysis and process optimization are improving energy efficiency in PP manufacturing, further minimizing environmental impacts.

The use phase of PP products is being transformed by circular design principles. Innovations in product design are focusing on durability, repairability, and modularity, extending the lifespan of PP-based items. This shift reduces the demand for new PP production and mitigates waste generation. Furthermore, the development of PP grades with enhanced recyclability is facilitating easier material recovery at the end of a product's life.

Recycling technologies for PP are experiencing significant advancements due to circular economy influences. Mechanical recycling processes are being refined to produce higher quality recycled PP, expanding its potential applications. Emerging chemical recycling technologies, such as pyrolysis and depolymerization, are enabling the conversion of PP waste back into virgin-quality monomers, closing the material loop more effectively.

The implementation of these circular economy-driven technologies is projected to have substantial environmental benefits. Life cycle assessments indicate potential reductions in carbon emissions, energy consumption, and water usage associated with PP throughout its lifecycle. Moreover, the increased use of recycled PP is expected to alleviate pressure on landfills and reduce plastic pollution in marine environments.

However, challenges remain in fully realizing these environmental benefits. The scale-up of new recycling technologies and the establishment of efficient collection and sorting systems are crucial for maximizing the circular potential of PP. Additionally, ensuring the quality and safety of recycled PP for various applications, particularly in food contact and medical uses, requires ongoing research and regulatory considerations.

In conclusion, the influence of circular economy principles on PP technology developments is driving significant improvements in environmental performance. As these innovations continue to mature and scale, they have the potential to transform PP into a more sustainable material, aligning its use with broader environmental goals and resource conservation efforts.

Policy Landscape for Circular Plastics

The policy landscape for circular plastics is rapidly evolving as governments and international organizations recognize the urgent need to address plastic waste and promote sustainable resource use. At the forefront of this shift are circular economy principles, which are increasingly being integrated into regulatory frameworks and industry standards for polypropylene and other plastics.

In the European Union, the Circular Economy Action Plan has set ambitious targets for plastic recycling and reuse. This includes a goal of ensuring all plastic packaging is recyclable or reusable by 2030. The EU's Single-Use Plastics Directive, implemented in 2021, further restricts certain single-use plastic items and mandates increased recycled content in plastic bottles.

Many countries are implementing extended producer responsibility (EPR) schemes for plastic packaging. These policies require manufacturers to take responsibility for the entire lifecycle of their products, including collection and recycling. Japan's EPR system for packaging has been in place since 1995, while more recent adopters include France, which introduced its Circular Economy Law in 2020.

China's ban on importing plastic waste has had global repercussions, forcing many countries to reassess their plastic waste management strategies. In response, several nations have implemented or proposed plastic taxes. The UK, for instance, introduced a tax on plastic packaging with less than 30% recycled content in April 2022.

International agreements are also shaping the policy landscape. The Basel Convention's Plastic Waste Amendments, effective from 2021, aim to make global trade in plastic waste more transparent and better regulated. Meanwhile, negotiations are underway for a global treaty on plastic pollution, which could significantly impact future polypropylene technologies and circular economy practices.

Many governments are also introducing policies to support research and development in circular plastics technologies. For example, the US Department of Energy's Plastics Innovation Challenge aims to develop technologies for plastic recycling and upcycling. Similarly, the EU's Horizon Europe program includes funding for research into circular economy solutions for plastics.

These policy developments are driving innovation in polypropylene technologies, encouraging the development of more easily recyclable grades, improved sorting and recycling processes, and technologies for chemical recycling. As policies continue to evolve, they are likely to further accelerate the transition towards a circular economy for polypropylene and other plastics.

In the European Union, the Circular Economy Action Plan has set ambitious targets for plastic recycling and reuse. This includes a goal of ensuring all plastic packaging is recyclable or reusable by 2030. The EU's Single-Use Plastics Directive, implemented in 2021, further restricts certain single-use plastic items and mandates increased recycled content in plastic bottles.

Many countries are implementing extended producer responsibility (EPR) schemes for plastic packaging. These policies require manufacturers to take responsibility for the entire lifecycle of their products, including collection and recycling. Japan's EPR system for packaging has been in place since 1995, while more recent adopters include France, which introduced its Circular Economy Law in 2020.

China's ban on importing plastic waste has had global repercussions, forcing many countries to reassess their plastic waste management strategies. In response, several nations have implemented or proposed plastic taxes. The UK, for instance, introduced a tax on plastic packaging with less than 30% recycled content in April 2022.

International agreements are also shaping the policy landscape. The Basel Convention's Plastic Waste Amendments, effective from 2021, aim to make global trade in plastic waste more transparent and better regulated. Meanwhile, negotiations are underway for a global treaty on plastic pollution, which could significantly impact future polypropylene technologies and circular economy practices.

Many governments are also introducing policies to support research and development in circular plastics technologies. For example, the US Department of Energy's Plastics Innovation Challenge aims to develop technologies for plastic recycling and upcycling. Similarly, the EU's Horizon Europe program includes funding for research into circular economy solutions for plastics.

These policy developments are driving innovation in polypropylene technologies, encouraging the development of more easily recyclable grades, improved sorting and recycling processes, and technologies for chemical recycling. As policies continue to evolve, they are likely to further accelerate the transition towards a circular economy for polypropylene and other plastics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!