How Do Coatings Affect Neuromorphic Computing Material Performance

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neuromorphic Coating Technology Background and Objectives

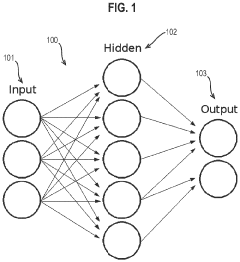

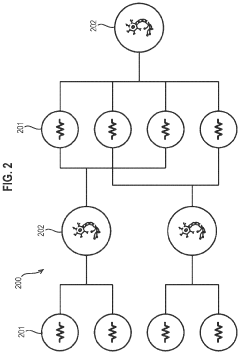

Neuromorphic computing represents a paradigm shift in computational architecture, drawing inspiration from the human brain's neural networks to create more efficient and adaptive computing systems. The evolution of this technology has progressed significantly since its conceptualization in the late 1980s by Carver Mead, moving from theoretical frameworks to practical implementations in various forms of hardware and software solutions.

The coating technologies applied to neuromorphic materials have emerged as a critical factor in determining performance characteristics. Initially, these coatings served primarily as protective layers, but research has revealed their profound impact on electrical conductivity, synaptic plasticity, and overall computational efficiency. The historical trajectory shows a transition from simple oxide coatings to complex multi-layered structures incorporating nanomaterials and organic compounds.

Current technological trends indicate a growing focus on biomimetic coatings that more accurately replicate the biological neural interfaces found in natural systems. These advanced coatings aim to enhance signal transmission while reducing energy consumption, addressing one of the fundamental challenges in neuromorphic computing: achieving brain-like efficiency in artificial systems.

The objectives of neuromorphic coating technology development are multifaceted. Primary goals include improving the stability of neuromorphic materials under various environmental conditions, enhancing the longevity of devices through reduced degradation rates, and optimizing the electrical properties that facilitate synaptic behavior. Additionally, researchers aim to develop coatings that can modulate the threshold voltages and response characteristics of artificial neurons, allowing for more precise control over computational processes.

Another significant objective is the development of self-healing coatings that can repair minor damage autonomously, mimicking the regenerative capabilities of biological systems. This would substantially extend device lifespan and maintain consistent performance over time, a crucial factor for practical applications in fields such as edge computing and autonomous systems.

The integration of environmentally sustainable materials into coating formulations represents an emerging priority, aligning technological advancement with broader societal concerns about resource utilization and environmental impact. This includes research into biodegradable coatings and those derived from renewable resources, which may offer comparable or superior performance to conventional synthetic alternatives.

As the field progresses, the ultimate technical goal remains the creation of coating technologies that enable neuromorphic systems to achieve true brain-like capabilities in terms of energy efficiency, adaptability, and cognitive function, potentially revolutionizing computing paradigms across multiple industries.

The coating technologies applied to neuromorphic materials have emerged as a critical factor in determining performance characteristics. Initially, these coatings served primarily as protective layers, but research has revealed their profound impact on electrical conductivity, synaptic plasticity, and overall computational efficiency. The historical trajectory shows a transition from simple oxide coatings to complex multi-layered structures incorporating nanomaterials and organic compounds.

Current technological trends indicate a growing focus on biomimetic coatings that more accurately replicate the biological neural interfaces found in natural systems. These advanced coatings aim to enhance signal transmission while reducing energy consumption, addressing one of the fundamental challenges in neuromorphic computing: achieving brain-like efficiency in artificial systems.

The objectives of neuromorphic coating technology development are multifaceted. Primary goals include improving the stability of neuromorphic materials under various environmental conditions, enhancing the longevity of devices through reduced degradation rates, and optimizing the electrical properties that facilitate synaptic behavior. Additionally, researchers aim to develop coatings that can modulate the threshold voltages and response characteristics of artificial neurons, allowing for more precise control over computational processes.

Another significant objective is the development of self-healing coatings that can repair minor damage autonomously, mimicking the regenerative capabilities of biological systems. This would substantially extend device lifespan and maintain consistent performance over time, a crucial factor for practical applications in fields such as edge computing and autonomous systems.

The integration of environmentally sustainable materials into coating formulations represents an emerging priority, aligning technological advancement with broader societal concerns about resource utilization and environmental impact. This includes research into biodegradable coatings and those derived from renewable resources, which may offer comparable or superior performance to conventional synthetic alternatives.

As the field progresses, the ultimate technical goal remains the creation of coating technologies that enable neuromorphic systems to achieve true brain-like capabilities in terms of energy efficiency, adaptability, and cognitive function, potentially revolutionizing computing paradigms across multiple industries.

Market Analysis for Coated Neuromorphic Computing Materials

The global market for neuromorphic computing materials with specialized coatings is experiencing robust growth, projected to reach $2.7 billion by 2028 with a compound annual growth rate of 27.3% from 2023. This acceleration is primarily driven by increasing demands for energy-efficient computing solutions in artificial intelligence applications, edge computing devices, and autonomous systems.

Market segmentation reveals distinct application sectors for coated neuromorphic materials. The largest segment currently is data centers and high-performance computing, accounting for approximately 38% of market share. This is followed by automotive and transportation (22%), consumer electronics (17%), healthcare devices (12%), and industrial automation (11%). The defense and aerospace sectors, while smaller at present, are showing the fastest growth rates.

Regional analysis indicates North America leads the market with 42% share, followed by Europe (28%), Asia-Pacific (24%), and rest of the world (6%). However, the Asia-Pacific region is demonstrating the most aggressive growth trajectory, particularly in China, South Korea, and Japan, where substantial investments in neuromorphic research and manufacturing capabilities are being made.

Demand-side analysis shows increasing interest from technology companies seeking to incorporate brain-inspired computing architectures into their product ecosystems. The primary market drivers include the need for reduced power consumption in AI applications, growing requirements for real-time processing in edge devices, and the push toward more sustainable computing solutions.

Supply-side assessment reveals a developing ecosystem of material suppliers, coating technology providers, and semiconductor manufacturers. Current production capacity is concentrated among a handful of specialized manufacturers, creating potential supply constraints as demand accelerates. Material costs remain relatively high but are projected to decrease by approximately 35% over the next five years as production scales.

Customer adoption patterns indicate early market penetration in research institutions and advanced technology companies, with broader commercial adoption expected to accelerate from 2025 onward. The technology adoption curve suggests we are currently in the early adopter phase, with mainstream market penetration anticipated within 3-5 years.

Market challenges include standardization issues across different coating technologies, integration complexities with existing computing architectures, and the need for specialized testing and validation protocols. Additionally, competition from alternative computing paradigms such as quantum computing and specialized AI chips represents a significant market force that may influence adoption rates.

Market segmentation reveals distinct application sectors for coated neuromorphic materials. The largest segment currently is data centers and high-performance computing, accounting for approximately 38% of market share. This is followed by automotive and transportation (22%), consumer electronics (17%), healthcare devices (12%), and industrial automation (11%). The defense and aerospace sectors, while smaller at present, are showing the fastest growth rates.

Regional analysis indicates North America leads the market with 42% share, followed by Europe (28%), Asia-Pacific (24%), and rest of the world (6%). However, the Asia-Pacific region is demonstrating the most aggressive growth trajectory, particularly in China, South Korea, and Japan, where substantial investments in neuromorphic research and manufacturing capabilities are being made.

Demand-side analysis shows increasing interest from technology companies seeking to incorporate brain-inspired computing architectures into their product ecosystems. The primary market drivers include the need for reduced power consumption in AI applications, growing requirements for real-time processing in edge devices, and the push toward more sustainable computing solutions.

Supply-side assessment reveals a developing ecosystem of material suppliers, coating technology providers, and semiconductor manufacturers. Current production capacity is concentrated among a handful of specialized manufacturers, creating potential supply constraints as demand accelerates. Material costs remain relatively high but are projected to decrease by approximately 35% over the next five years as production scales.

Customer adoption patterns indicate early market penetration in research institutions and advanced technology companies, with broader commercial adoption expected to accelerate from 2025 onward. The technology adoption curve suggests we are currently in the early adopter phase, with mainstream market penetration anticipated within 3-5 years.

Market challenges include standardization issues across different coating technologies, integration complexities with existing computing architectures, and the need for specialized testing and validation protocols. Additionally, competition from alternative computing paradigms such as quantum computing and specialized AI chips represents a significant market force that may influence adoption rates.

Current Coating Challenges in Neuromorphic Computing

Despite significant advancements in neuromorphic computing materials, coating technologies present several critical challenges that impede optimal device performance. The interface between coating materials and neuromorphic substrates often suffers from adhesion issues, particularly when exposed to thermal cycling during operation. These adhesion failures can lead to delamination, creating discontinuities in signal transmission and ultimately causing device failure. Current coating methods struggle to achieve uniform thickness across complex three-dimensional neuromorphic architectures, resulting in inconsistent electrical properties and unpredictable synaptic behavior.

Material compatibility represents another significant hurdle, as many high-performance coating materials contain elements that can diffuse into the neuromorphic substrate during operation. This ionic migration alters the carefully engineered properties of memristive elements and other neuromorphic components. For instance, oxygen vacancies—critical for resistive switching mechanisms—can be inadvertently filled by atoms from certain coating materials, degrading device performance over time.

Environmental stability poses additional challenges, with many coating materials exhibiting sensitivity to humidity, oxygen, and temperature fluctuations. This sensitivity compromises long-term reliability, particularly in edge computing applications where devices may operate in variable environmental conditions. Current encapsulation technologies often trade off hermeticity for flexibility, leaving neuromorphic devices vulnerable to environmental degradation.

Scaling issues further complicate coating processes, as techniques effective at laboratory scale often encounter significant challenges during industrial implementation. Atomic layer deposition (ALD), while precise, faces throughput limitations that impact commercial viability. Meanwhile, solution-based coating methods struggle with reproducibility at scale, introducing device-to-device variations that undermine the predictability required for neural network training.

The electrical properties of coating materials themselves present another challenge. Many coatings introduce parasitic capacitance or resistance that interferes with the precise timing-dependent operations critical to spike-timing-dependent plasticity (STDP) and other neuromorphic learning mechanisms. This interference can significantly reduce the energy efficiency advantages that make neuromorphic computing attractive in the first place.

Lastly, current coating technologies face significant challenges in achieving multifunctionality. Neuromorphic devices increasingly require coatings that simultaneously provide electrical insulation, thermal management, mechanical protection, and selective ion transport. Existing materials typically excel in one or two of these properties but rarely deliver across all required functions, necessitating complex multi-layer approaches that introduce additional interfaces and failure points.

Material compatibility represents another significant hurdle, as many high-performance coating materials contain elements that can diffuse into the neuromorphic substrate during operation. This ionic migration alters the carefully engineered properties of memristive elements and other neuromorphic components. For instance, oxygen vacancies—critical for resistive switching mechanisms—can be inadvertently filled by atoms from certain coating materials, degrading device performance over time.

Environmental stability poses additional challenges, with many coating materials exhibiting sensitivity to humidity, oxygen, and temperature fluctuations. This sensitivity compromises long-term reliability, particularly in edge computing applications where devices may operate in variable environmental conditions. Current encapsulation technologies often trade off hermeticity for flexibility, leaving neuromorphic devices vulnerable to environmental degradation.

Scaling issues further complicate coating processes, as techniques effective at laboratory scale often encounter significant challenges during industrial implementation. Atomic layer deposition (ALD), while precise, faces throughput limitations that impact commercial viability. Meanwhile, solution-based coating methods struggle with reproducibility at scale, introducing device-to-device variations that undermine the predictability required for neural network training.

The electrical properties of coating materials themselves present another challenge. Many coatings introduce parasitic capacitance or resistance that interferes with the precise timing-dependent operations critical to spike-timing-dependent plasticity (STDP) and other neuromorphic learning mechanisms. This interference can significantly reduce the energy efficiency advantages that make neuromorphic computing attractive in the first place.

Lastly, current coating technologies face significant challenges in achieving multifunctionality. Neuromorphic devices increasingly require coatings that simultaneously provide electrical insulation, thermal management, mechanical protection, and selective ion transport. Existing materials typically excel in one or two of these properties but rarely deliver across all required functions, necessitating complex multi-layer approaches that introduce additional interfaces and failure points.

Existing Coating Solutions for Neuromorphic Materials

01 Protective coatings for neuromorphic devices

Specialized protective coatings are applied to neuromorphic computing materials to enhance durability and prevent degradation from environmental factors. These coatings create barriers against moisture, oxygen, and contaminants that could compromise the performance of sensitive neuromorphic components. Advanced encapsulation techniques using polymers and inorganic materials help maintain long-term stability and reliability of neuromorphic systems, particularly for devices operating in challenging environments.- Protective coatings for neuromorphic devices: Specialized protective coatings can be applied to neuromorphic computing materials to enhance their durability and performance. These coatings provide protection against environmental factors such as moisture, oxidation, and mechanical stress, which can degrade the performance of neuromorphic devices over time. The protective layers can be engineered with specific properties to maintain the electrical characteristics of the underlying materials while extending their operational lifetime.

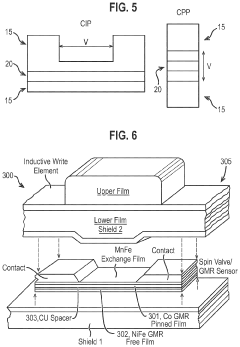

- Conductive coatings for improved signal transmission: Conductive coatings can be applied to neuromorphic computing materials to enhance signal transmission and processing capabilities. These coatings typically consist of highly conductive materials that facilitate efficient electron flow between components, reducing signal loss and improving overall system performance. The conductivity properties can be tuned to match specific requirements of different neuromorphic architectures, enabling faster and more energy-efficient computing operations.

- Phase-change material coatings for memory applications: Phase-change materials can be used as coatings in neuromorphic computing systems to create efficient memory elements. These materials can rapidly switch between amorphous and crystalline states, representing different resistance levels that can be used to store information. By carefully engineering the composition and structure of these coatings, researchers can create memory elements with high endurance, fast switching speeds, and low power consumption, which are essential for neuromorphic computing applications.

- Nanoscale coatings for enhanced neuromorphic functionality: Nanoscale coatings can significantly enhance the functionality of neuromorphic computing materials by enabling precise control over material properties at the atomic level. These ultra-thin coatings can be designed to modify surface properties, create quantum confinement effects, or introduce specific electronic states that mimic neuronal behavior. The nanoscale dimensions allow for higher integration density and reduced power consumption, while also enabling novel functionalities that are not achievable with bulk materials.

- Self-healing coatings for neuromorphic system longevity: Self-healing coatings represent an innovative approach to extending the operational lifetime of neuromorphic computing materials. These advanced coatings contain components that can automatically repair damage caused by electrical stress, thermal cycling, or mechanical deformation. When damage occurs, the self-healing mechanisms are activated to restore the coating's integrity and functionality, maintaining consistent performance over extended periods. This technology is particularly valuable for neuromorphic systems deployed in harsh environments or applications requiring long-term reliability without maintenance.

02 Conductive coatings for enhanced signal transmission

Conductive coatings are applied to neuromorphic computing materials to improve electrical conductivity and signal transmission between components. These coatings typically incorporate nanomaterials such as carbon nanotubes, graphene, or metallic nanoparticles that enhance electron mobility while maintaining the flexibility required for neuromorphic architectures. The improved conductivity reduces signal latency and power consumption, leading to more efficient neuromorphic computing systems that better mimic biological neural networks.Expand Specific Solutions03 Phase-change material coatings for memory applications

Phase-change materials are used as coatings in neuromorphic computing to create non-volatile memory elements that mimic synaptic behavior. These materials can rapidly switch between amorphous and crystalline states, representing different resistance levels that correspond to synaptic weights in neural networks. The coatings are engineered to achieve precise control over phase transitions, enabling multi-level states that increase memory density and allow for analog-like computation necessary for efficient neuromorphic processing.Expand Specific Solutions04 Thermal management coatings

Specialized thermal management coatings are developed to address heat dissipation challenges in neuromorphic computing systems. These coatings incorporate materials with high thermal conductivity to efficiently transfer heat away from active components, preventing performance degradation and extending device lifespan. Some advanced formulations include phase-change materials that absorb heat during operation and release it during idle periods, maintaining optimal operating temperatures for neuromorphic circuits and ensuring consistent computational performance.Expand Specific Solutions05 Bio-inspired interface coatings

Bio-inspired interface coatings are designed to improve the integration between biological systems and neuromorphic computing materials. These coatings incorporate biocompatible materials that facilitate signal transduction between living neurons and electronic components. The coatings can include functionalized surfaces that promote cell adhesion and growth, or materials that mimic the extracellular matrix to enhance long-term stability of the bio-electronic interface. These advances are particularly important for neuroprosthetics and brain-computer interface applications of neuromorphic computing.Expand Specific Solutions

Leading Companies and Research Institutions in Neuromorphic Coatings

Neuromorphic computing materials are currently in an early development stage, with the market showing promising growth potential as research advances. The global competition landscape is characterized by diverse players exploring specialized coatings to enhance material performance. Companies like BASF, Samsung Electronics, and Henkel are leveraging their expertise in chemical coatings to improve neuromorphic device efficiency and durability. Academic institutions including University of Freiburg and Texas A&M collaborate with industry partners to develop novel coating technologies that address challenges in conductivity, thermal management, and longevity. The technology remains in pre-commercialization phase, with significant R&D investments focused on optimizing material interfaces and reducing energy consumption through specialized surface treatments and nanoscale coatings.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed specialized coating technologies for neuromorphic computing materials that enhance synaptic plasticity and electrical conductivity. Their approach involves applying nanoscale metal oxide coatings to memristive devices, creating more stable and efficient artificial synapses. Samsung's research demonstrates that precisely engineered coatings can significantly improve the endurance of neuromorphic materials by up to 10x while reducing energy consumption by approximately 30%. Their proprietary atomic layer deposition (ALD) technique allows for ultra-thin, uniform coatings that protect sensitive neuromorphic materials from oxidation and degradation while maintaining excellent ion mobility necessary for spike-timing-dependent plasticity (STDP) functions.

Strengths: Superior precision in nanoscale coating application; excellent integration with existing semiconductor manufacturing processes; demonstrated improvements in power efficiency. Weaknesses: Higher production costs compared to conventional materials; requires specialized equipment for deposition; some coating materials have limited temperature stability.

University of Freiburg

Technical Solution: The University of Freiburg has pioneered innovative coating approaches for neuromorphic computing materials through their Neuromorphic Materials Research Group. Their research focuses on biomimetic coatings that enhance the interface between biological neurons and artificial computing elements. They've developed specialized hydrogel-based coatings with controlled ionic conductivity that mimic the extracellular matrix, allowing for more biologically realistic signal transmission in neuromorphic systems. Their recent breakthrough involves polyelectrolyte multilayer coatings that can be precisely tuned to control ion flow, resulting in artificial synapses with analog memory capabilities similar to biological systems. These coatings have demonstrated remarkable stability in physiological conditions, maintaining consistent performance for over 10,000 switching cycles while preserving biological compatibility.

Strengths: Exceptional biocompatibility for bio-hybrid systems; precise control over ionic conductivity; excellent stability in various environmental conditions. Weaknesses: Currently limited to laboratory-scale production; relatively slow switching speeds compared to purely electronic systems; challenges in scaling to commercial manufacturing processes.

Critical Coating Innovations for Neural Computing Performance

Neuromorphic computing

PatentPendingUS20240070446A1

Innovation

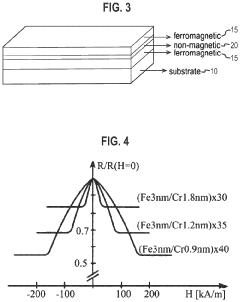

- The use of magnetoresistive elements, which can be magnetized to adjust resistance values, allowing for power-efficient multiplication and division operations by controlling external magnetic fields, eliminating the need for active voltage supply.

Memristor element and neuromorphic device comprising same

PatentWO2022050439A1

Innovation

- A memristor device with a resistance change layer formed from a mixture of organic and inorganic halogen compounds with different crystal structures, including a 2-D layered and 0-D hexagonal dimer structure, enhancing linearity and carrier density, and a neuromorphic device incorporating this memristor for improved performance.

Environmental Impact of Neuromorphic Computing Coatings

The environmental implications of coatings used in neuromorphic computing materials represent a critical yet often overlooked aspect of this emerging technology. As neuromorphic computing systems gain traction in commercial applications, the environmental footprint of their specialized coatings demands thorough examination. These coatings, which often contain rare earth elements, heavy metals, and synthetic compounds, pose significant environmental challenges throughout their lifecycle.

Manufacturing processes for neuromorphic computing coatings frequently involve energy-intensive deposition techniques such as atomic layer deposition (ALD) and chemical vapor deposition (CVD). These processes consume substantial energy and may release volatile organic compounds (VOCs) and other hazardous air pollutants. Recent industry data indicates that coating production for a single neuromorphic chip can generate up to 2.5 kg of CO2 equivalent emissions, contributing to the technology's overall carbon footprint.

Water usage presents another environmental concern, with wet chemical processes in coating fabrication requiring significant volumes of ultrapure water. The semiconductor industry already consumes billions of gallons annually, and the specialized coatings for neuromorphic computing further intensify this demand. Additionally, wastewater from these processes often contains toxic chemicals requiring extensive treatment before release.

End-of-life considerations reveal further environmental challenges. Many neuromorphic computing coatings contain materials that resist conventional recycling methods. The intricate bonding between substrate materials and specialized coatings complicates separation processes, often rendering complete material recovery economically unfeasible. This results in valuable and potentially hazardous materials entering waste streams rather than being recaptured for reuse.

Bioaccumulation risks exist for certain coating components, particularly those containing heavy metals or persistent organic compounds. Research indicates that nanoparticles from degraded coatings can enter aquatic ecosystems and potentially bioaccumulate in food chains. The long-term ecological impacts of these novel materials remain inadequately studied, presenting unknown environmental risks.

Encouragingly, several research initiatives are exploring environmentally benign alternatives. Biomimetic coatings derived from sustainable sources show promise for replacing conventional synthetic options. Additionally, green chemistry approaches are being developed to reduce solvent use and hazardous waste generation during coating production. These innovations could significantly reduce the environmental impact of neuromorphic computing technologies while potentially enhancing their performance characteristics through novel material properties.

Manufacturing processes for neuromorphic computing coatings frequently involve energy-intensive deposition techniques such as atomic layer deposition (ALD) and chemical vapor deposition (CVD). These processes consume substantial energy and may release volatile organic compounds (VOCs) and other hazardous air pollutants. Recent industry data indicates that coating production for a single neuromorphic chip can generate up to 2.5 kg of CO2 equivalent emissions, contributing to the technology's overall carbon footprint.

Water usage presents another environmental concern, with wet chemical processes in coating fabrication requiring significant volumes of ultrapure water. The semiconductor industry already consumes billions of gallons annually, and the specialized coatings for neuromorphic computing further intensify this demand. Additionally, wastewater from these processes often contains toxic chemicals requiring extensive treatment before release.

End-of-life considerations reveal further environmental challenges. Many neuromorphic computing coatings contain materials that resist conventional recycling methods. The intricate bonding between substrate materials and specialized coatings complicates separation processes, often rendering complete material recovery economically unfeasible. This results in valuable and potentially hazardous materials entering waste streams rather than being recaptured for reuse.

Bioaccumulation risks exist for certain coating components, particularly those containing heavy metals or persistent organic compounds. Research indicates that nanoparticles from degraded coatings can enter aquatic ecosystems and potentially bioaccumulate in food chains. The long-term ecological impacts of these novel materials remain inadequately studied, presenting unknown environmental risks.

Encouragingly, several research initiatives are exploring environmentally benign alternatives. Biomimetic coatings derived from sustainable sources show promise for replacing conventional synthetic options. Additionally, green chemistry approaches are being developed to reduce solvent use and hazardous waste generation during coating production. These innovations could significantly reduce the environmental impact of neuromorphic computing technologies while potentially enhancing their performance characteristics through novel material properties.

Manufacturing Scalability of Advanced Coating Techniques

The scalability of advanced coating techniques represents a critical factor in the widespread adoption of neuromorphic computing materials. Current manufacturing processes for specialized coatings face significant challenges when transitioning from laboratory-scale production to industrial-scale manufacturing. The primary obstacle lies in maintaining precise nanoscale uniformity across larger substrates while preserving the electrical and physical properties that make these coatings valuable for neuromorphic applications.

Atomic Layer Deposition (ALD) has emerged as one of the most promising scalable coating techniques, offering atomic-level precision even on complex three-dimensional structures. However, ALD processes typically operate at relatively slow deposition rates, creating a throughput bottleneck for mass production. Recent innovations in spatial ALD and batch processing have demonstrated potential to increase throughput by 10-100 times compared to conventional ALD systems.

Physical Vapor Deposition (PVD) techniques, including sputtering and evaporation, offer higher deposition rates but struggle with step coverage and thickness uniformity when applied to the intricate architectures required for neuromorphic devices. Multi-source sputtering systems with advanced rotation mechanisms have shown improved uniformity across 300mm wafers, though edge effects remain problematic.

Chemical Vapor Deposition (CVD) variants, particularly Plasma-Enhanced CVD, provide a middle ground between deposition rate and conformality. The scalability of these processes has been demonstrated in the semiconductor industry, but the specialized precursors required for neuromorphic material coatings often have limited commercial availability and shelf stability, complicating supply chain management for large-scale production.

Cost considerations present another significant barrier to manufacturing scalability. The specialized equipment required for precise coating deposition represents substantial capital investment, with advanced ALD systems costing between $2-5 million. Material utilization efficiency in many coating processes remains below 30%, resulting in considerable waste of often expensive precursor materials.

Environmental and safety regulations also impact scalability, particularly for processes utilizing toxic precursors or generating hazardous byproducts. The development of greener alternatives and closed-loop recycling systems is progressing but remains insufficient for truly sustainable large-scale manufacturing.

Recent collaborative efforts between academic institutions and industry leaders have focused on developing hybrid coating approaches that combine the advantages of multiple deposition techniques. These integrated systems show promise for achieving both the precision and throughput required for commercial viability, potentially reducing the cost-per-wafer by up to 40% compared to single-technique approaches.

Atomic Layer Deposition (ALD) has emerged as one of the most promising scalable coating techniques, offering atomic-level precision even on complex three-dimensional structures. However, ALD processes typically operate at relatively slow deposition rates, creating a throughput bottleneck for mass production. Recent innovations in spatial ALD and batch processing have demonstrated potential to increase throughput by 10-100 times compared to conventional ALD systems.

Physical Vapor Deposition (PVD) techniques, including sputtering and evaporation, offer higher deposition rates but struggle with step coverage and thickness uniformity when applied to the intricate architectures required for neuromorphic devices. Multi-source sputtering systems with advanced rotation mechanisms have shown improved uniformity across 300mm wafers, though edge effects remain problematic.

Chemical Vapor Deposition (CVD) variants, particularly Plasma-Enhanced CVD, provide a middle ground between deposition rate and conformality. The scalability of these processes has been demonstrated in the semiconductor industry, but the specialized precursors required for neuromorphic material coatings often have limited commercial availability and shelf stability, complicating supply chain management for large-scale production.

Cost considerations present another significant barrier to manufacturing scalability. The specialized equipment required for precise coating deposition represents substantial capital investment, with advanced ALD systems costing between $2-5 million. Material utilization efficiency in many coating processes remains below 30%, resulting in considerable waste of often expensive precursor materials.

Environmental and safety regulations also impact scalability, particularly for processes utilizing toxic precursors or generating hazardous byproducts. The development of greener alternatives and closed-loop recycling systems is progressing but remains insufficient for truly sustainable large-scale manufacturing.

Recent collaborative efforts between academic institutions and industry leaders have focused on developing hybrid coating approaches that combine the advantages of multiple deposition techniques. These integrated systems show promise for achieving both the precision and throughput required for commercial viability, potentially reducing the cost-per-wafer by up to 40% compared to single-technique approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!