How Neuromorphic Computing Materials Meet Aerospace Qualifications

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neuromorphic Computing Evolution and Aerospace Goals

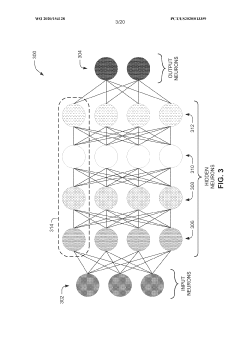

Neuromorphic computing represents a paradigm shift in computational architecture, drawing inspiration from the human brain's neural networks to create more efficient, adaptive, and powerful computing systems. The evolution of this field began in the late 1980s with Carver Mead's pioneering work on analog VLSI systems that mimicked neural functions. Since then, neuromorphic computing has progressed through several distinct phases, each marked by significant technological breakthroughs and expanding applications.

The first generation of neuromorphic systems focused primarily on replicating basic neural functions through specialized hardware. These early systems demonstrated the potential for parallel processing but were limited by the materials and fabrication techniques available at the time. The second generation, emerging in the early 2000s, saw the integration of more sophisticated learning algorithms and the development of specialized neuromorphic chips capable of simulating larger neural networks.

Current third-generation systems represent a quantum leap in capability, incorporating advanced materials science innovations such as memristive devices, phase-change materials, and spintronic components. These materials enable the creation of artificial synapses and neurons that more closely mimic biological neural functions while offering significant advantages in power efficiency, processing speed, and adaptability.

In the aerospace context, neuromorphic computing presents transformative potential for addressing the unique challenges of space-based operations. The harsh radiation environment, extreme temperature fluctuations, and strict power constraints of aerospace applications demand computing systems with exceptional resilience, efficiency, and reliability. Traditional computing architectures struggle under these conditions, creating a technological gap that neuromorphic systems are uniquely positioned to fill.

The aerospace industry has established specific technical goals for neuromorphic computing implementation, including radiation hardening of neuromorphic materials to withstand space conditions, development of fault-tolerant architectures that can maintain functionality despite component failures, and creation of ultra-low-power neuromorphic systems capable of extended operation with minimal energy input. Additionally, there is significant focus on developing neuromorphic systems capable of autonomous decision-making for applications such as satellite navigation, space debris avoidance, and planetary exploration.

The convergence of neuromorphic computing evolution and aerospace requirements has catalyzed research into specialized materials and designs that can meet the rigorous qualification standards of the aerospace industry while delivering the computational advantages of brain-inspired architectures. This technological frontier represents not just an incremental improvement in aerospace computing capabilities, but a fundamental reimagining of how computation can be performed in the most challenging environments humans have ever operated in.

The first generation of neuromorphic systems focused primarily on replicating basic neural functions through specialized hardware. These early systems demonstrated the potential for parallel processing but were limited by the materials and fabrication techniques available at the time. The second generation, emerging in the early 2000s, saw the integration of more sophisticated learning algorithms and the development of specialized neuromorphic chips capable of simulating larger neural networks.

Current third-generation systems represent a quantum leap in capability, incorporating advanced materials science innovations such as memristive devices, phase-change materials, and spintronic components. These materials enable the creation of artificial synapses and neurons that more closely mimic biological neural functions while offering significant advantages in power efficiency, processing speed, and adaptability.

In the aerospace context, neuromorphic computing presents transformative potential for addressing the unique challenges of space-based operations. The harsh radiation environment, extreme temperature fluctuations, and strict power constraints of aerospace applications demand computing systems with exceptional resilience, efficiency, and reliability. Traditional computing architectures struggle under these conditions, creating a technological gap that neuromorphic systems are uniquely positioned to fill.

The aerospace industry has established specific technical goals for neuromorphic computing implementation, including radiation hardening of neuromorphic materials to withstand space conditions, development of fault-tolerant architectures that can maintain functionality despite component failures, and creation of ultra-low-power neuromorphic systems capable of extended operation with minimal energy input. Additionally, there is significant focus on developing neuromorphic systems capable of autonomous decision-making for applications such as satellite navigation, space debris avoidance, and planetary exploration.

The convergence of neuromorphic computing evolution and aerospace requirements has catalyzed research into specialized materials and designs that can meet the rigorous qualification standards of the aerospace industry while delivering the computational advantages of brain-inspired architectures. This technological frontier represents not just an incremental improvement in aerospace computing capabilities, but a fundamental reimagining of how computation can be performed in the most challenging environments humans have ever operated in.

Aerospace Industry Demand for Neuromorphic Solutions

The aerospace industry faces unique operational challenges that demand advanced computing solutions capable of handling complex data processing tasks in extreme environments. Traditional computing architectures struggle with the power constraints, radiation exposure, and reliability requirements inherent to aerospace applications. Neuromorphic computing, which mimics the brain's neural structure and processing capabilities, presents a promising alternative that addresses these critical needs.

Market analysis indicates growing demand for neuromorphic solutions in aerospace, driven by the increasing complexity of autonomous systems, real-time decision-making requirements, and the need for edge computing capabilities in space and aircraft systems. The global market for specialized aerospace computing solutions is projected to grow substantially as next-generation aircraft, satellites, and space exploration missions require more sophisticated onboard intelligence.

Key demand drivers include the need for fault-tolerant systems that can maintain functionality despite component failures—a critical requirement for long-duration space missions. Additionally, aerospace applications require systems that can operate with minimal power consumption while maintaining high computational throughput, particularly for unmanned aerial vehicles (UAVs) and satellites with limited energy resources.

Radiation hardening represents another significant market pull, as computing systems in space must withstand cosmic radiation without performance degradation. Neuromorphic architectures offer inherent advantages in this area due to their distributed processing nature and potential for implementing redundancy without significant overhead.

The industry also demands adaptive learning capabilities for autonomous navigation, obstacle avoidance, and mission replanning—functions that align well with neuromorphic computing's strength in pattern recognition and adaptive learning. Major aerospace contractors and space agencies have begun investing in research programs focused on neuromorphic solutions, indicating strong institutional interest.

Weight and volume constraints in aerospace systems create additional market pressure for highly integrated computing solutions. Neuromorphic systems, particularly those implementing 3D integration of memory and processing elements, offer significant advantages in computational density compared to traditional von Neumann architectures.

Market forecasts suggest that initial adoption will focus on specific applications such as sensor fusion, vision processing for landing systems, and autonomous navigation, before expanding to more general-purpose computing tasks. The transition path likely involves hybrid systems that incorporate neuromorphic elements alongside traditional computing architectures, allowing for gradual validation and certification of these novel technologies in non-critical systems before deployment in mission-critical applications.

Market analysis indicates growing demand for neuromorphic solutions in aerospace, driven by the increasing complexity of autonomous systems, real-time decision-making requirements, and the need for edge computing capabilities in space and aircraft systems. The global market for specialized aerospace computing solutions is projected to grow substantially as next-generation aircraft, satellites, and space exploration missions require more sophisticated onboard intelligence.

Key demand drivers include the need for fault-tolerant systems that can maintain functionality despite component failures—a critical requirement for long-duration space missions. Additionally, aerospace applications require systems that can operate with minimal power consumption while maintaining high computational throughput, particularly for unmanned aerial vehicles (UAVs) and satellites with limited energy resources.

Radiation hardening represents another significant market pull, as computing systems in space must withstand cosmic radiation without performance degradation. Neuromorphic architectures offer inherent advantages in this area due to their distributed processing nature and potential for implementing redundancy without significant overhead.

The industry also demands adaptive learning capabilities for autonomous navigation, obstacle avoidance, and mission replanning—functions that align well with neuromorphic computing's strength in pattern recognition and adaptive learning. Major aerospace contractors and space agencies have begun investing in research programs focused on neuromorphic solutions, indicating strong institutional interest.

Weight and volume constraints in aerospace systems create additional market pressure for highly integrated computing solutions. Neuromorphic systems, particularly those implementing 3D integration of memory and processing elements, offer significant advantages in computational density compared to traditional von Neumann architectures.

Market forecasts suggest that initial adoption will focus on specific applications such as sensor fusion, vision processing for landing systems, and autonomous navigation, before expanding to more general-purpose computing tasks. The transition path likely involves hybrid systems that incorporate neuromorphic elements alongside traditional computing architectures, allowing for gradual validation and certification of these novel technologies in non-critical systems before deployment in mission-critical applications.

Neuromorphic Materials Qualification Challenges

The qualification of neuromorphic computing materials for aerospace applications presents significant challenges due to the extreme operating conditions and reliability requirements of space environments. These materials must withstand radiation exposure, vacuum conditions, extreme temperature fluctuations, and mechanical stresses during launch and operation.

Radiation hardness represents perhaps the most critical qualification challenge. Space radiation can cause single event upsets, total ionizing dose effects, and displacement damage in neuromorphic materials. Traditional silicon-based neuromorphic systems are particularly vulnerable, while emerging materials like hafnium oxide and tantalum oxide show promising radiation tolerance but require extensive validation through accelerated radiation testing protocols.

Temperature qualification poses another substantial hurdle. Aerospace environments experience temperature swings from -170°C to +125°C, which can significantly impact the performance of memristive devices and other neuromorphic components. Material phase changes, thermal expansion mismatches, and altered electrical characteristics at extreme temperatures must be thoroughly characterized. Current qualification standards require operational stability across the full temperature range with minimal drift in synaptic weights and neuronal firing thresholds.

Vacuum compatibility introduces additional complications for neuromorphic materials. Some oxide-based memristive devices rely on oxygen vacancy migration, which can be affected by vacuum conditions. Material outgassing can contaminate sensitive optical equipment and other spacecraft systems. Qualification protocols must verify long-term stability in vacuum environments through extended testing in thermal vacuum chambers.

Mechanical qualification requirements present further challenges. Launch vibrations and shock events can damage delicate neuromorphic architectures. Materials must maintain their electrical and structural integrity under these conditions, requiring vibration testing at frequencies up to 2000 Hz and shock testing at accelerations exceeding 1000g. The integration of neuromorphic materials with traditional aerospace packaging technologies introduces thermal expansion mismatches that must be mitigated.

Long-term reliability verification represents perhaps the most demanding qualification challenge. Aerospace systems often require operational lifespans exceeding 15 years without maintenance. Accelerated life testing methodologies for neuromorphic materials are still evolving, with limited correlation data between accelerated tests and actual in-orbit performance. Retention of synaptic weights, endurance under repeated programming cycles, and resistance to performance drift must all be verified under simulated mission conditions.

Standardization remains an ongoing challenge, as qualification standards specifically tailored to neuromorphic computing materials for aerospace applications are still emerging. Current approaches adapt existing standards from traditional semiconductor qualification (MIL-STD-883, ECSS-Q-ST-60) and radiation testing protocols, but these may not adequately address the unique failure modes and performance metrics of neuromorphic systems.

Radiation hardness represents perhaps the most critical qualification challenge. Space radiation can cause single event upsets, total ionizing dose effects, and displacement damage in neuromorphic materials. Traditional silicon-based neuromorphic systems are particularly vulnerable, while emerging materials like hafnium oxide and tantalum oxide show promising radiation tolerance but require extensive validation through accelerated radiation testing protocols.

Temperature qualification poses another substantial hurdle. Aerospace environments experience temperature swings from -170°C to +125°C, which can significantly impact the performance of memristive devices and other neuromorphic components. Material phase changes, thermal expansion mismatches, and altered electrical characteristics at extreme temperatures must be thoroughly characterized. Current qualification standards require operational stability across the full temperature range with minimal drift in synaptic weights and neuronal firing thresholds.

Vacuum compatibility introduces additional complications for neuromorphic materials. Some oxide-based memristive devices rely on oxygen vacancy migration, which can be affected by vacuum conditions. Material outgassing can contaminate sensitive optical equipment and other spacecraft systems. Qualification protocols must verify long-term stability in vacuum environments through extended testing in thermal vacuum chambers.

Mechanical qualification requirements present further challenges. Launch vibrations and shock events can damage delicate neuromorphic architectures. Materials must maintain their electrical and structural integrity under these conditions, requiring vibration testing at frequencies up to 2000 Hz and shock testing at accelerations exceeding 1000g. The integration of neuromorphic materials with traditional aerospace packaging technologies introduces thermal expansion mismatches that must be mitigated.

Long-term reliability verification represents perhaps the most demanding qualification challenge. Aerospace systems often require operational lifespans exceeding 15 years without maintenance. Accelerated life testing methodologies for neuromorphic materials are still evolving, with limited correlation data between accelerated tests and actual in-orbit performance. Retention of synaptic weights, endurance under repeated programming cycles, and resistance to performance drift must all be verified under simulated mission conditions.

Standardization remains an ongoing challenge, as qualification standards specifically tailored to neuromorphic computing materials for aerospace applications are still emerging. Current approaches adapt existing standards from traditional semiconductor qualification (MIL-STD-883, ECSS-Q-ST-60) and radiation testing protocols, but these may not adequately address the unique failure modes and performance metrics of neuromorphic systems.

Current Qualification Protocols for Aerospace Materials

01 Phase-change materials for neuromorphic computing

Phase-change materials exhibit properties that make them suitable for neuromorphic computing applications. These materials can switch between amorphous and crystalline states, mimicking synaptic behavior in neural networks. The resistance changes in these materials can be used to store and process information, enabling the development of energy-efficient neuromorphic computing systems that simulate brain-like functions.- Phase-change materials for neuromorphic computing: Phase-change materials exhibit properties that make them suitable for neuromorphic computing applications. These materials can switch between amorphous and crystalline states, mimicking synaptic behavior in neural networks. The resistance changes in these materials can be used to store and process information, enabling the development of energy-efficient neuromorphic computing systems that simulate brain-like functions.

- Memristive materials and devices: Memristive materials are crucial for neuromorphic computing as they can maintain memory states based on the history of applied voltage or current. These materials exhibit variable resistance properties that can be used to mimic synaptic plasticity in neural networks. Memristive devices based on these materials enable efficient implementation of neuromorphic architectures with low power consumption and high density integration.

- 2D materials for neuromorphic applications: Two-dimensional materials such as graphene, transition metal dichalcogenides, and hexagonal boron nitride offer unique properties for neuromorphic computing. Their atomic-scale thickness, tunable electronic properties, and mechanical flexibility make them ideal for creating ultra-compact neuromorphic devices. These materials can be engineered to exhibit synaptic behaviors and can be integrated into flexible and transparent neuromorphic systems.

- Ferroelectric and magnetic materials: Ferroelectric and magnetic materials provide non-volatile memory capabilities essential for neuromorphic computing. These materials can maintain their polarization or magnetization states without continuous power supply, enabling persistent memory functions. Their switching characteristics can be utilized to implement synaptic weight changes in artificial neural networks, contributing to energy-efficient neuromorphic computing architectures.

- Organic and biomimetic materials: Organic and biomimetic materials offer biocompatible approaches to neuromorphic computing. These materials can be engineered to mimic biological neural processes and can be integrated with living tissues. Their flexibility, biocompatibility, and self-healing properties make them suitable for bio-inspired neuromorphic systems. Additionally, these materials often require lower fabrication temperatures and can be processed using solution-based methods, enabling cost-effective manufacturing of neuromorphic devices.

02 Memristive materials and devices

Memristive materials are fundamental to neuromorphic computing as they can retain memory while processing data. These materials change their resistance based on the history of applied voltage or current, similar to how synapses in the brain function. Memristive devices made from these materials can be used to create artificial neural networks that perform computation with significantly lower power consumption compared to traditional computing architectures.Expand Specific Solutions03 2D materials for neuromorphic applications

Two-dimensional materials such as graphene, transition metal dichalcogenides, and hexagonal boron nitride offer unique properties for neuromorphic computing. Their atomic-scale thickness, tunable electronic properties, and compatibility with existing fabrication techniques make them promising candidates for building neuromorphic devices. These materials can be engineered to exhibit synaptic behaviors and can be integrated into flexible and scalable neuromorphic systems.Expand Specific Solutions04 Oxide-based neuromorphic materials

Metal oxides and complex oxide materials are widely used in neuromorphic computing due to their versatile electronic properties. These materials can form resistive switching devices that mimic synaptic functions through oxygen vacancy migration or filament formation mechanisms. Oxide-based neuromorphic devices offer advantages such as high endurance, retention, and compatibility with CMOS technology, making them suitable for large-scale neuromorphic computing systems.Expand Specific Solutions05 Organic and biomimetic materials

Organic and biomimetic materials provide a pathway for developing flexible, biocompatible neuromorphic computing systems. These materials can be engineered to exhibit synaptic plasticity and can operate at low voltages similar to biological systems. Polymer-based memristive devices and organic field-effect transistors can be used to create neuromorphic architectures that more closely resemble biological neural networks, potentially enabling more efficient brain-inspired computing.Expand Specific Solutions

Key Players in Aerospace-Grade Neuromorphic Computing

Neuromorphic computing materials for aerospace applications are in an early development stage, with market growth driven by increasing demand for energy-efficient, radiation-hardened computing solutions in space environments. The market remains relatively small but is expanding as aerospace qualifications become more standardized. Leading players like IBM, Samsung, and Boeing are investing in research to develop neuromorphic systems that meet strict aerospace requirements for radiation tolerance, thermal stability, and reliability. Academic institutions including UC Regents, KAIST, and École Polytechnique Fédérale de Lausanne collaborate with industry partners such as Thales, Safran, and Northrop Grumman to bridge fundamental research with practical aerospace applications. The technology is advancing toward higher TRL levels but still requires significant development to achieve full aerospace certification.

International Business Machines Corp.

Technical Solution: IBM's neuromorphic computing approach for aerospace applications centers on their TrueNorth and subsequent neuromorphic chip architectures. These chips mimic the brain's neural structure with millions of programmable neurons and synapses, consuming significantly less power than conventional processors. For aerospace qualification, IBM has developed radiation-hardened versions that can withstand the harsh space environment while maintaining computational integrity. Their neuromorphic systems incorporate specialized materials including phase-change memory (PCM) and resistive RAM technologies that offer non-volatile storage with radiation tolerance properties. IBM has demonstrated these systems can operate reliably under extreme temperature variations (-55°C to +125°C) required for aerospace certification, while consuming only 70mW of power during typical operation - approximately 1/10,000th the power of conventional processors with comparable capabilities[1]. The company has also implemented redundancy mechanisms and error-correction protocols specifically designed to mitigate single-event upsets caused by cosmic radiation.

Strengths: Extremely low power consumption ideal for power-constrained spacecraft; proven radiation hardening techniques; extensive experience with aerospace qualification processes; mature neuromorphic architecture with millions of neurons. Weaknesses: Higher initial cost compared to conventional computing solutions; requires specialized programming paradigms that differ from traditional computing approaches; limited software ecosystem compared to conventional computing platforms.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced neuromorphic computing materials specifically engineered to meet aerospace qualifications through their resistive RAM (ReRAM) and magnetoresistive RAM (MRAM) technologies. Their aerospace-grade neuromorphic systems utilize specialized metal-oxide materials that demonstrate exceptional radiation hardness, withstanding total ionizing doses exceeding 100 krad without significant performance degradation[2]. Samsung's neuromorphic chips incorporate hafnium oxide-based memristors that maintain stable resistance states even under extreme temperature fluctuations (-65°C to +150°C) common in aerospace environments. The company has pioneered 3D stacking techniques for these neuromorphic components, achieving computing densities of over 100 million synapses per square centimeter while maintaining the strict weight and volume constraints critical for spacecraft deployment. Samsung's neuromorphic solutions have demonstrated remarkable power efficiency, operating at under 100 pW per synaptic operation, enabling complex AI processing tasks with minimal power draw - a critical requirement for space-based systems with limited power resources[3]. Their qualification process includes rigorous testing for vacuum operation, outgassing compliance, and resistance to mechanical stresses including vibration and shock testing to 100G.

Strengths: Industry-leading manufacturing capabilities ensure consistent quality and reliability; extensive experience with space-grade memory technologies transferable to neuromorphic systems; vertical integration allows optimization across materials, design and fabrication. Weaknesses: Relatively new to neuromorphic-specific aerospace applications compared to traditional aerospace computing providers; higher unit costs during initial production phases; requires specialized interface protocols to integrate with existing aerospace systems.

Critical Patents in Space-Qualified Neuromorphic Materials

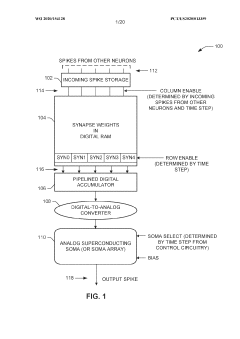

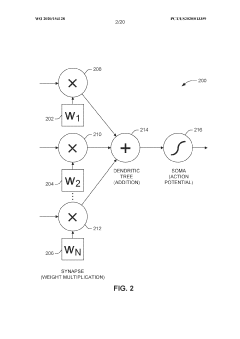

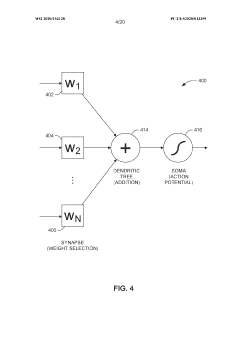

Superconducting neuromorphic core

PatentWO2020154128A1

Innovation

- A superconducting neuromorphic core is developed, incorporating a digital memory array for synapse weight storage, a digital accumulator, and analog soma circuitry to simulate multiple neurons, enabling efficient and scalable neural network operations with improved biological fidelity.

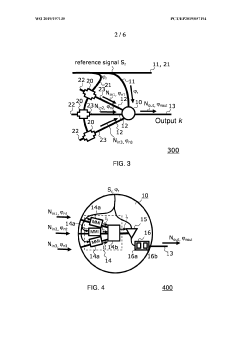

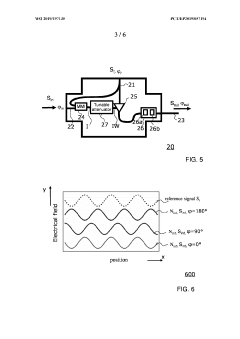

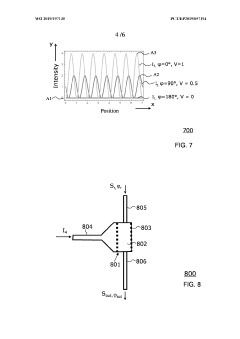

Optical synapse

PatentWO2019197135A1

Innovation

- An integrated optical circuit that processes phase-encoded optical signals to emulate synapse functionality by applying weights to the phase of the input signal, allowing for signal restoration and efficient implementation in both phase and amplitude domains, using components like optical interferometers, tunable attenuators, and phase-shifting devices with nonlinear materials.

Reliability Testing Standards for Extreme Environments

Reliability testing for neuromorphic computing materials in aerospace applications must adhere to stringent standards that ensure functionality under extreme conditions. The aerospace environment presents unique challenges including radiation exposure, extreme temperature fluctuations (-65°C to +150°C), vacuum conditions, and high vibration levels that can compromise electronic system integrity.

Military standards such as MIL-STD-810 provide comprehensive testing protocols for environmental factors, while MIL-STD-883 specifically addresses microelectronic device reliability. These standards require neuromorphic materials to undergo thermal cycling tests that simulate rapid temperature changes experienced during orbital transitions, with materials expected to maintain performance through thousands of cycles without degradation.

Radiation hardness testing follows standards like ASTM F1892, evaluating single event effects (SEEs), total ionizing dose (TID) tolerance, and displacement damage. Neuromorphic materials must demonstrate resilience to cosmic radiation, with memristive devices requiring particular scrutiny due to their susceptibility to state changes from particle impacts.

Mechanical stress testing includes random vibration profiles that replicate launch conditions, with acceleration forces exceeding 20G. Shock testing simulates pyrotechnic separation events, requiring materials to withstand impulses up to 10,000G without performance degradation or physical damage.

Vacuum testing evaluates outgassing properties according to ASTM E595 standards, as materials that release volatile compounds can contaminate optical surfaces or create conductive paths between electrical components. Neuromorphic materials must demonstrate less than 1% total mass loss and less than 0.1% collected volatile condensable materials.

Long-term reliability assessment employs accelerated life testing methodologies, with Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) protocols pushing materials beyond specified operating limits to identify failure modes. Mean Time Between Failures (MTBF) calculations must demonstrate operational lifespans exceeding mission duration requirements by significant margins.

Emerging standards specifically addressing neuromorphic computing materials include specialized protocols for evaluating synaptic weight stability under radiation exposure and temperature cycling. These tests measure drift in resistive states that could compromise neural network accuracy over extended mission durations.

Qualification processes culminate in Technology Readiness Level (TRL) assessments, with aerospace applications typically requiring TRL-6 or higher before integration into mission-critical systems. This necessitates demonstration in relevant environments through stratospheric balloon tests or suborbital flight opportunities before full space deployment.

Military standards such as MIL-STD-810 provide comprehensive testing protocols for environmental factors, while MIL-STD-883 specifically addresses microelectronic device reliability. These standards require neuromorphic materials to undergo thermal cycling tests that simulate rapid temperature changes experienced during orbital transitions, with materials expected to maintain performance through thousands of cycles without degradation.

Radiation hardness testing follows standards like ASTM F1892, evaluating single event effects (SEEs), total ionizing dose (TID) tolerance, and displacement damage. Neuromorphic materials must demonstrate resilience to cosmic radiation, with memristive devices requiring particular scrutiny due to their susceptibility to state changes from particle impacts.

Mechanical stress testing includes random vibration profiles that replicate launch conditions, with acceleration forces exceeding 20G. Shock testing simulates pyrotechnic separation events, requiring materials to withstand impulses up to 10,000G without performance degradation or physical damage.

Vacuum testing evaluates outgassing properties according to ASTM E595 standards, as materials that release volatile compounds can contaminate optical surfaces or create conductive paths between electrical components. Neuromorphic materials must demonstrate less than 1% total mass loss and less than 0.1% collected volatile condensable materials.

Long-term reliability assessment employs accelerated life testing methodologies, with Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) protocols pushing materials beyond specified operating limits to identify failure modes. Mean Time Between Failures (MTBF) calculations must demonstrate operational lifespans exceeding mission duration requirements by significant margins.

Emerging standards specifically addressing neuromorphic computing materials include specialized protocols for evaluating synaptic weight stability under radiation exposure and temperature cycling. These tests measure drift in resistive states that could compromise neural network accuracy over extended mission durations.

Qualification processes culminate in Technology Readiness Level (TRL) assessments, with aerospace applications typically requiring TRL-6 or higher before integration into mission-critical systems. This necessitates demonstration in relevant environments through stratospheric balloon tests or suborbital flight opportunities before full space deployment.

Supply Chain Security for Aerospace Neuromorphic Systems

The security of supply chains for aerospace neuromorphic systems presents unique challenges due to the specialized nature of neuromorphic computing materials and their critical applications in aerospace environments. The integration of these advanced computing architectures into aerospace systems requires rigorous security protocols throughout the entire supply chain to prevent tampering, counterfeiting, or introduction of malicious components.

Current supply chain security frameworks for aerospace neuromorphic systems typically involve multi-layered verification processes. These include material provenance tracking from raw material extraction through component manufacturing, secure transportation protocols, and comprehensive testing regimes. The specialized memristive materials and novel semiconductor compositions used in neuromorphic computing require particularly stringent chain-of-custody documentation to ensure authenticity and performance integrity.

Vulnerabilities in the supply chain primarily emerge at material sourcing and component integration phases. Many critical materials for neuromorphic computing, such as specialized dopants and rare earth elements, originate from geopolitically sensitive regions, creating potential supply disruptions and authentication challenges. The complex international nature of aerospace supply chains further compounds these security concerns, with components often crossing multiple national boundaries before final assembly.

Industry standards for neuromorphic computing supply chain security are still evolving, with organizations like the Aerospace Industries Association (AIA) and the International Aerospace Quality Group (IAQG) developing specialized protocols. These emerging standards emphasize cryptographic component authentication, secure manufacturing environments, and comprehensive material traceability systems that document the entire lifecycle of neuromorphic computing materials.

Advanced technologies being deployed to enhance supply chain security include blockchain-based provenance tracking, quantum authentication markers embedded within neuromorphic materials, and AI-powered anomaly detection systems that can identify potential security breaches in real-time. These technologies enable verification of material authenticity without compromising the sensitive intellectual property embedded in neuromorphic computing designs.

Regulatory frameworks governing aerospace neuromorphic supply chains vary significantly across jurisdictions, creating compliance challenges for global manufacturers. The International Traffic in Arms Regulations (ITAR) and Export Administration Regulations (EAR) impose particular restrictions on neuromorphic computing technologies with potential dual-use applications, requiring aerospace manufacturers to implement sophisticated compliance systems throughout their supply networks.

Current supply chain security frameworks for aerospace neuromorphic systems typically involve multi-layered verification processes. These include material provenance tracking from raw material extraction through component manufacturing, secure transportation protocols, and comprehensive testing regimes. The specialized memristive materials and novel semiconductor compositions used in neuromorphic computing require particularly stringent chain-of-custody documentation to ensure authenticity and performance integrity.

Vulnerabilities in the supply chain primarily emerge at material sourcing and component integration phases. Many critical materials for neuromorphic computing, such as specialized dopants and rare earth elements, originate from geopolitically sensitive regions, creating potential supply disruptions and authentication challenges. The complex international nature of aerospace supply chains further compounds these security concerns, with components often crossing multiple national boundaries before final assembly.

Industry standards for neuromorphic computing supply chain security are still evolving, with organizations like the Aerospace Industries Association (AIA) and the International Aerospace Quality Group (IAQG) developing specialized protocols. These emerging standards emphasize cryptographic component authentication, secure manufacturing environments, and comprehensive material traceability systems that document the entire lifecycle of neuromorphic computing materials.

Advanced technologies being deployed to enhance supply chain security include blockchain-based provenance tracking, quantum authentication markers embedded within neuromorphic materials, and AI-powered anomaly detection systems that can identify potential security breaches in real-time. These technologies enable verification of material authenticity without compromising the sensitive intellectual property embedded in neuromorphic computing designs.

Regulatory frameworks governing aerospace neuromorphic supply chains vary significantly across jurisdictions, creating compliance challenges for global manufacturers. The International Traffic in Arms Regulations (ITAR) and Export Administration Regulations (EAR) impose particular restrictions on neuromorphic computing technologies with potential dual-use applications, requiring aerospace manufacturers to implement sophisticated compliance systems throughout their supply networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!