Neuromorphic Computing Materials: Compliance with Automotive Standards

OCT 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neuromorphic Computing Evolution and Objectives

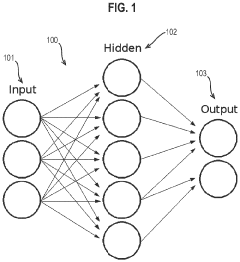

Neuromorphic computing represents a paradigm shift in computational architecture, drawing inspiration from the structure and function of biological neural systems. The evolution of this field began in the late 1980s with Carver Mead's pioneering work at Caltech, where he first proposed using analog VLSI systems to mimic neurobiological architectures. This marked the conceptual foundation of hardware systems that could emulate the brain's parallel processing capabilities and energy efficiency.

The 1990s witnessed limited progress due to technological constraints, but the early 2000s brought renewed interest as traditional von Neumann architectures approached physical limitations in performance scaling. By 2010-2015, significant advancements in materials science, particularly memristive devices and phase-change materials, accelerated development in neuromorphic hardware implementations.

Current neuromorphic computing objectives focus on creating systems that can process sensory data with the efficiency and adaptability of biological neural networks. For automotive applications specifically, these systems aim to enable real-time processing of multiple sensory inputs from vehicle environments, supporting advanced driver assistance systems (ADAS) and autonomous driving capabilities while maintaining strict power constraints.

A critical objective is developing neuromorphic materials and architectures that meet the stringent reliability requirements of automotive standards, including temperature tolerance (-40°C to 125°C), vibration resistance, and extended operational lifespans (10-15 years). These systems must demonstrate deterministic behavior while preserving the adaptive learning capabilities inherent to neuromorphic design.

Energy efficiency represents another primary goal, with targets to achieve computational efficiencies exceeding 10 TOPS/W (trillion operations per second per watt), significantly surpassing conventional GPU/CPU architectures for specific perceptual tasks relevant to automotive applications. This efficiency is crucial for implementing advanced AI capabilities within the power constraints of vehicle electrical systems.

The integration pathway aims to evolve from current supplementary processing units toward core decision-making systems in vehicles. Near-term objectives include developing neuromorphic sensors for specific automotive applications (visual perception, LIDAR data processing), while mid-term goals focus on creating unified neuromorphic systems capable of multi-sensory integration and decision support. Long-term objectives envision fully compliant neuromorphic computing platforms that can handle end-to-end autonomous driving functions while meeting all automotive certification requirements.

The 1990s witnessed limited progress due to technological constraints, but the early 2000s brought renewed interest as traditional von Neumann architectures approached physical limitations in performance scaling. By 2010-2015, significant advancements in materials science, particularly memristive devices and phase-change materials, accelerated development in neuromorphic hardware implementations.

Current neuromorphic computing objectives focus on creating systems that can process sensory data with the efficiency and adaptability of biological neural networks. For automotive applications specifically, these systems aim to enable real-time processing of multiple sensory inputs from vehicle environments, supporting advanced driver assistance systems (ADAS) and autonomous driving capabilities while maintaining strict power constraints.

A critical objective is developing neuromorphic materials and architectures that meet the stringent reliability requirements of automotive standards, including temperature tolerance (-40°C to 125°C), vibration resistance, and extended operational lifespans (10-15 years). These systems must demonstrate deterministic behavior while preserving the adaptive learning capabilities inherent to neuromorphic design.

Energy efficiency represents another primary goal, with targets to achieve computational efficiencies exceeding 10 TOPS/W (trillion operations per second per watt), significantly surpassing conventional GPU/CPU architectures for specific perceptual tasks relevant to automotive applications. This efficiency is crucial for implementing advanced AI capabilities within the power constraints of vehicle electrical systems.

The integration pathway aims to evolve from current supplementary processing units toward core decision-making systems in vehicles. Near-term objectives include developing neuromorphic sensors for specific automotive applications (visual perception, LIDAR data processing), while mid-term goals focus on creating unified neuromorphic systems capable of multi-sensory integration and decision support. Long-term objectives envision fully compliant neuromorphic computing platforms that can handle end-to-end autonomous driving functions while meeting all automotive certification requirements.

Automotive Market Demand for Neuromorphic Solutions

The automotive industry is experiencing a significant transformation driven by the integration of advanced computing technologies. Neuromorphic computing, which mimics the neural structure and function of the human brain, is emerging as a promising solution for next-generation automotive applications. Market analysis indicates a growing demand for neuromorphic solutions in the automotive sector, primarily driven by the increasing complexity of autonomous driving systems and the need for more efficient, real-time processing capabilities.

Current automotive computing systems face limitations in processing the massive amounts of sensor data required for advanced driver assistance systems (ADAS) and autonomous driving. Traditional computing architectures consume substantial power and exhibit latency issues that can compromise safety-critical functions. Neuromorphic computing offers a potential solution by providing energy-efficient, parallel processing capabilities that can handle complex pattern recognition tasks with minimal power consumption.

Market research forecasts suggest that the global market for automotive AI hardware, including neuromorphic chips, is expected to grow substantially over the next decade. This growth is fueled by the automotive industry's push toward Level 3-5 autonomous vehicles, which require sophisticated computing solutions capable of processing and responding to environmental data in real-time.

Vehicle manufacturers are particularly interested in neuromorphic solutions for their potential to reduce power consumption while maintaining or improving computational performance. This is especially critical for electric vehicles where energy efficiency directly impacts range. Additionally, the event-driven processing nature of neuromorphic systems aligns well with the unpredictable and dynamic driving environment, potentially offering more responsive and adaptable computing solutions.

Key application areas driving demand include advanced object recognition systems, predictive maintenance, in-cabin monitoring, and enhanced navigation systems. Tier 1 suppliers and OEMs are increasingly investing in neuromorphic research and development partnerships to secure competitive advantages in these domains.

Consumer expectations for more intuitive and responsive vehicle interfaces are also contributing to market demand. Neuromorphic systems excel at natural language processing and gesture recognition, enabling more human-like interactions with vehicle systems.

Regulatory trends toward stricter safety standards and reduced emissions are indirectly boosting interest in neuromorphic solutions. The technology's potential to enable more efficient driving algorithms and reduce overall vehicle energy consumption aligns with global automotive regulatory directions.

Despite this promising outlook, market adoption faces challenges related to technology maturity, integration complexity, and compliance with automotive-grade reliability standards. Automotive stakeholders are cautiously optimistic but require proven solutions that can withstand the rigorous demands of vehicle environments while meeting strict safety and reliability requirements.

Current automotive computing systems face limitations in processing the massive amounts of sensor data required for advanced driver assistance systems (ADAS) and autonomous driving. Traditional computing architectures consume substantial power and exhibit latency issues that can compromise safety-critical functions. Neuromorphic computing offers a potential solution by providing energy-efficient, parallel processing capabilities that can handle complex pattern recognition tasks with minimal power consumption.

Market research forecasts suggest that the global market for automotive AI hardware, including neuromorphic chips, is expected to grow substantially over the next decade. This growth is fueled by the automotive industry's push toward Level 3-5 autonomous vehicles, which require sophisticated computing solutions capable of processing and responding to environmental data in real-time.

Vehicle manufacturers are particularly interested in neuromorphic solutions for their potential to reduce power consumption while maintaining or improving computational performance. This is especially critical for electric vehicles where energy efficiency directly impacts range. Additionally, the event-driven processing nature of neuromorphic systems aligns well with the unpredictable and dynamic driving environment, potentially offering more responsive and adaptable computing solutions.

Key application areas driving demand include advanced object recognition systems, predictive maintenance, in-cabin monitoring, and enhanced navigation systems. Tier 1 suppliers and OEMs are increasingly investing in neuromorphic research and development partnerships to secure competitive advantages in these domains.

Consumer expectations for more intuitive and responsive vehicle interfaces are also contributing to market demand. Neuromorphic systems excel at natural language processing and gesture recognition, enabling more human-like interactions with vehicle systems.

Regulatory trends toward stricter safety standards and reduced emissions are indirectly boosting interest in neuromorphic solutions. The technology's potential to enable more efficient driving algorithms and reduce overall vehicle energy consumption aligns with global automotive regulatory directions.

Despite this promising outlook, market adoption faces challenges related to technology maturity, integration complexity, and compliance with automotive-grade reliability standards. Automotive stakeholders are cautiously optimistic but require proven solutions that can withstand the rigorous demands of vehicle environments while meeting strict safety and reliability requirements.

Current Neuromorphic Materials and Automotive Compliance Challenges

The current landscape of neuromorphic computing materials presents a complex interplay between technological innovation and automotive industry requirements. Traditional neuromorphic materials include memristors, phase-change materials, and spintronic devices, each offering unique advantages for brain-inspired computing architectures. However, their integration into automotive applications faces significant compliance challenges that must be addressed before widespread adoption.

Memristive devices, particularly those based on metal oxides like HfO2 and TiO2, demonstrate promising synaptic behavior but struggle with temperature stability across the automotive range (-40°C to 125°C). Recent testing by automotive semiconductor manufacturers reveals performance degradation outside the 0-70°C range typically specified for consumer electronics, creating reliability concerns for critical automotive systems.

Phase-change materials (PCMs) such as Ge2Sb2Te5 offer excellent data retention characteristics but face challenges with power consumption and thermal management—critical factors in automotive environments where heat dissipation is already a significant design constraint. Current PCM implementations typically consume 30-50% more power than traditional computing architectures, creating efficiency barriers for battery-powered and energy-conscious vehicle systems.

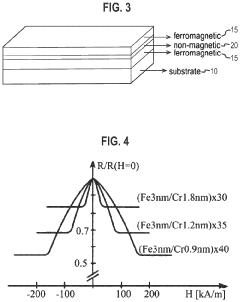

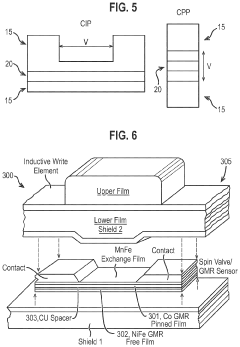

Spintronic neuromorphic materials show promising energy efficiency but currently lack the maturity in manufacturing processes required by automotive qualification standards. The ISO 26262 functional safety requirements demand statistical evidence of reliability that emerging spintronic technologies have yet to accumulate, creating a certification bottleneck.

Material durability represents another critical compliance challenge. Automotive components must withstand 10-15 years of operation under harsh conditions including vibration, humidity, and chemical exposure. Current neuromorphic materials demonstrate accelerated degradation under these conditions, with write endurance typically falling below automotive requirements of 10^9 cycles over vehicle lifetime.

Supply chain considerations further complicate compliance efforts. Many advanced neuromorphic materials rely on rare earth elements with limited sourcing options, creating potential conflicts with automotive industry requirements for supply chain resilience and component availability guarantees extending 10+ years beyond production.

Radiation hardness presents an emerging concern as vehicles incorporate more autonomous features. Neuromorphic systems must maintain computational integrity under various radiation exposures, yet current materials show susceptibility to single-event upsets at rates exceeding automotive tolerance thresholds by approximately one order of magnitude.

These challenges necessitate collaborative development between material scientists and automotive engineers to create neuromorphic computing solutions that satisfy both the technological promise of brain-inspired computing and the stringent reliability requirements of automotive applications.

Memristive devices, particularly those based on metal oxides like HfO2 and TiO2, demonstrate promising synaptic behavior but struggle with temperature stability across the automotive range (-40°C to 125°C). Recent testing by automotive semiconductor manufacturers reveals performance degradation outside the 0-70°C range typically specified for consumer electronics, creating reliability concerns for critical automotive systems.

Phase-change materials (PCMs) such as Ge2Sb2Te5 offer excellent data retention characteristics but face challenges with power consumption and thermal management—critical factors in automotive environments where heat dissipation is already a significant design constraint. Current PCM implementations typically consume 30-50% more power than traditional computing architectures, creating efficiency barriers for battery-powered and energy-conscious vehicle systems.

Spintronic neuromorphic materials show promising energy efficiency but currently lack the maturity in manufacturing processes required by automotive qualification standards. The ISO 26262 functional safety requirements demand statistical evidence of reliability that emerging spintronic technologies have yet to accumulate, creating a certification bottleneck.

Material durability represents another critical compliance challenge. Automotive components must withstand 10-15 years of operation under harsh conditions including vibration, humidity, and chemical exposure. Current neuromorphic materials demonstrate accelerated degradation under these conditions, with write endurance typically falling below automotive requirements of 10^9 cycles over vehicle lifetime.

Supply chain considerations further complicate compliance efforts. Many advanced neuromorphic materials rely on rare earth elements with limited sourcing options, creating potential conflicts with automotive industry requirements for supply chain resilience and component availability guarantees extending 10+ years beyond production.

Radiation hardness presents an emerging concern as vehicles incorporate more autonomous features. Neuromorphic systems must maintain computational integrity under various radiation exposures, yet current materials show susceptibility to single-event upsets at rates exceeding automotive tolerance thresholds by approximately one order of magnitude.

These challenges necessitate collaborative development between material scientists and automotive engineers to create neuromorphic computing solutions that satisfy both the technological promise of brain-inspired computing and the stringent reliability requirements of automotive applications.

Current Compliance Solutions for Automotive-Grade Materials

01 Neuromorphic computing materials for hardware implementation

Various materials are being developed for neuromorphic computing hardware that mimics brain functionality. These materials enable the creation of artificial neural networks with properties like synaptic plasticity, low power consumption, and parallel processing capabilities. The hardware implementations include memristors, phase-change materials, and other novel materials that can efficiently perform neuromorphic operations while maintaining compliance with industry standards.- Materials for neuromorphic computing devices: Various materials can be used in neuromorphic computing devices to mimic the behavior of biological neurons and synapses. These materials include phase-change materials, resistive switching materials, and memristive materials that can change their properties in response to electrical stimuli. These materials enable the development of energy-efficient neuromorphic computing systems that can perform complex cognitive tasks with lower power consumption compared to traditional computing architectures.

- Compliance frameworks for neuromorphic computing systems: Compliance frameworks are essential for ensuring that neuromorphic computing systems meet regulatory requirements and industry standards. These frameworks address issues such as data security, privacy, and ethical considerations in the development and deployment of neuromorphic computing technologies. Compliance measures include encryption protocols, access controls, and audit mechanisms to protect sensitive information processed by neuromorphic systems.

- Integration of neuromorphic computing with existing technologies: Neuromorphic computing systems can be integrated with existing technologies such as cloud computing, edge devices, and Internet of Things (IoT) networks. This integration enables the deployment of neuromorphic computing capabilities in various applications while ensuring compliance with established technological standards. The integration approaches include hardware-software co-design, standardized interfaces, and compatibility layers that facilitate seamless operation with conventional computing systems.

- Environmental and sustainability compliance in neuromorphic materials: Environmental and sustainability considerations are important aspects of neuromorphic computing materials compliance. This includes the use of eco-friendly materials, reduction of hazardous substances, and implementation of sustainable manufacturing processes. Compliance with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) ensures that neuromorphic computing devices meet environmental standards throughout their lifecycle.

- Security and reliability standards for neuromorphic computing: Security and reliability standards are crucial for the widespread adoption of neuromorphic computing technologies. These standards address vulnerabilities specific to neuromorphic architectures, such as side-channel attacks and fault injection. Compliance with these standards involves implementing robust security measures, conducting thorough testing, and ensuring the reliability of neuromorphic computing systems under various operating conditions. This includes techniques for error detection and correction, secure boot processes, and resilience against hardware tampering.

02 Regulatory compliance frameworks for neuromorphic systems

Compliance frameworks are essential for neuromorphic computing systems to ensure they meet regulatory requirements across different jurisdictions. These frameworks address data protection, privacy concerns, ethical considerations, and industry-specific regulations. They provide guidelines for developers to ensure their neuromorphic computing materials and systems adhere to legal standards while maintaining innovation and technological advancement.Expand Specific Solutions03 Energy-efficient neuromorphic computing materials

Energy efficiency is a critical aspect of neuromorphic computing materials compliance. Researchers are developing materials that can perform complex computational tasks with minimal energy consumption, similar to the human brain. These materials include specialized semiconductors, nanoscale components, and novel architectures that optimize power usage while maintaining high computational performance, addressing both environmental compliance and practical deployment considerations.Expand Specific Solutions04 Security and reliability standards for neuromorphic materials

Security and reliability standards are being established for neuromorphic computing materials to ensure they can operate safely in various applications. These standards address concerns related to data integrity, system robustness, fault tolerance, and protection against adversarial attacks. Compliance with these standards is crucial for the adoption of neuromorphic computing in sensitive applications like healthcare, finance, and critical infrastructure.Expand Specific Solutions05 Integration of neuromorphic materials with conventional computing systems

The integration of neuromorphic computing materials with conventional computing systems requires compliance with existing hardware and software standards. This includes developing interface protocols, compatibility layers, and hybrid architectures that allow neuromorphic components to work seamlessly with traditional computing infrastructure. Such integration enables gradual adoption of neuromorphic computing while maintaining compliance with established industry practices and technical specifications.Expand Specific Solutions

Key Industry Players in Automotive Neuromorphic Computing

Neuromorphic Computing Materials for automotive applications is in an early development stage, with market growth driven by increasing demand for AI-powered automotive systems. The technology is still maturing, with key players demonstrating varying levels of readiness. IBM and Samsung lead in research and patent development, while automotive manufacturers like BMW, Bosch, and GM are exploring integration possibilities. Academic institutions including KAIST, Beijing Jiaotong University, and Imperial College collaborate with industry to advance material science aspects. Compliance with automotive standards remains a significant challenge, with companies like China Automotive Technology & Research Center and Ford Global Technologies working on certification frameworks. The market shows promise but requires further development to meet stringent automotive reliability and safety requirements.

International Business Machines Corp.

Technical Solution: IBM has pioneered neuromorphic computing materials specifically designed for automotive applications through their TrueNorth architecture. Their approach integrates phase-change memory (PCM) materials with CMOS technology to create energy-efficient neural networks that can operate under automotive temperature ranges (-40°C to 125°C). IBM's neuromorphic chips utilize resistive RAM (RRAM) and magnetoresistive RAM (MRAM) materials that have been tested to meet ISO 26262 functional safety standards for automotive applications. Their materials demonstrate resilience to electromagnetic interference (EMI) and vibration testing according to automotive standards LV 124 and ISO 16750. IBM has also developed specialized packaging solutions using materials that comply with automotive-grade reliability requirements, enabling their neuromorphic systems to achieve AEC-Q100 Grade 1 qualification for use in critical automotive systems.

Strengths: Superior energy efficiency (100x more efficient than conventional processors for pattern recognition tasks); proven compliance with automotive safety standards; extensive testing in real-world automotive environments. Weaknesses: Higher initial implementation costs; requires specialized programming paradigms different from traditional computing approaches; integration challenges with existing automotive electronic architectures.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced neuromorphic computing materials through their "Auto Brain" initiative specifically targeting automotive applications. Their approach utilizes specialized magnetoresistive RAM (MRAM) and phase-change memory (PCM) materials that maintain stable performance across automotive temperature ranges (-40°C to 125°C) while offering radiation hardness for EMI protection. Samsung's neuromorphic materials feature self-monitoring capabilities that continuously assess material integrity and performance, enabling predictive maintenance aligned with automotive reliability requirements. Their materials have undergone comprehensive qualification testing according to AEC-Q100 Grade 1 standards, including temperature cycling, humidity testing, and mechanical shock resistance. Samsung has developed specialized packaging solutions using automotive-grade polymers and ceramics that protect their neuromorphic components while enabling efficient thermal management. Their neuromorphic computing materials are designed with redundancy mechanisms and error correction capabilities to ensure functional safety compliance with ISO 26262 ASIL C requirements, making them suitable for advanced driver assistance systems and in-vehicle infotainment applications.

Strengths: Vertical integration capabilities from material development to chip manufacturing; extensive experience with automotive memory requirements; established presence in automotive supply chains. Weaknesses: Less specialized in neuromorphic architectures compared to pure-play neuromorphic companies; balancing between consumer electronics and automotive requirements may create design compromises; relatively new entrant to automotive-specific neuromorphic computing.

Critical Patents in Automotive-Compliant Neuromorphic Materials

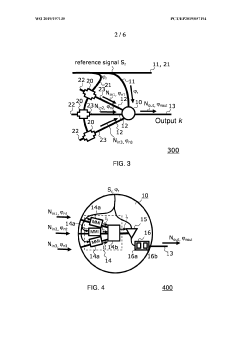

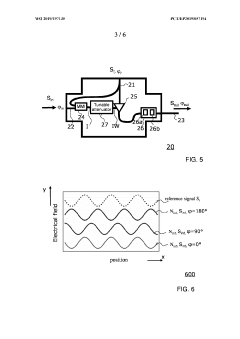

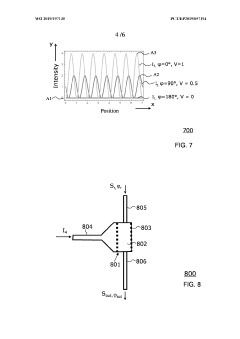

Optical synapse

PatentWO2019197135A1

Innovation

- An integrated optical circuit that processes phase-encoded optical signals to emulate synapse functionality by applying weights to the phase of the input signal, allowing for signal restoration and efficient implementation in both phase and amplitude domains, using components like optical interferometers, tunable attenuators, and phase-shifting devices with nonlinear materials.

Neuromorphic computing

PatentPendingUS20240070446A1

Innovation

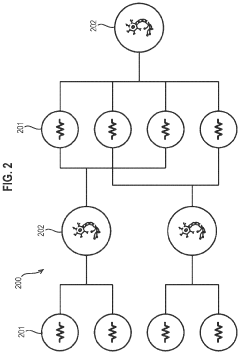

- The use of magnetoresistive elements, which can be magnetized to adjust resistance values, allowing for power-efficient multiplication and division operations by controlling external magnetic fields, eliminating the need for active voltage supply.

Safety Certification Requirements for Automotive AI Systems

The integration of neuromorphic computing materials into automotive systems necessitates rigorous compliance with established safety certification frameworks. ISO 26262, the international standard for functional safety in road vehicles, serves as the primary regulatory guideline for automotive electronic systems. Neuromorphic computing materials must undergo comprehensive hazard analysis and risk assessment (HARA) to identify potential failure modes and their consequences on vehicle operation and passenger safety.

ASIL (Automotive Safety Integrity Level) classification, ranging from A (lowest) to D (highest), must be determined for neuromorphic computing applications based on severity, exposure, and controllability factors. Materials and systems implementing brain-inspired computing architectures require verification through fault injection testing to demonstrate resilience against random hardware failures and systematic errors that could compromise safety-critical functions.

The certification process demands extensive documentation of design specifications, verification methods, and validation results. Manufacturers must establish traceability between safety requirements and implementation, particularly challenging for neuromorphic systems whose emergent behaviors may not always follow deterministic patterns. This necessitates the development of specialized testing methodologies that can adequately assess the reliability of these novel computing paradigms.

Functional safety management systems must be implemented throughout the development lifecycle, from concept phase through decommissioning. For neuromorphic materials, this includes specialized considerations for hardware-software integration, as these systems often blur traditional boundaries between physical components and computational processes. Safety cases must demonstrate that residual risks have been reduced to acceptable levels through appropriate safety mechanisms.

Compliance with cybersecurity standards (ISO/SAE 21434) represents another critical dimension, as neuromorphic systems may present unique attack vectors. Materials and architectures must incorporate security-by-design principles to prevent unauthorized access or manipulation that could compromise safety functions. This includes protection against both physical tampering and remote exploitation.

Environmental qualification testing presents particular challenges for neuromorphic materials, which must maintain consistent performance across the extreme temperature ranges, vibration profiles, and electromagnetic environments typical in automotive applications. Accelerated aging tests must verify that neuromorphic properties remain stable throughout the vehicle's operational lifetime, typically 10-15 years under harsh conditions.

Certification bodies increasingly require evidence of predictable degradation modes, where systems fail in safe, controlled manners rather than exhibiting catastrophic failures. This "graceful degradation" requirement poses unique challenges for neuromorphic computing materials, whose failure characteristics may differ significantly from conventional semiconductor technologies.

ASIL (Automotive Safety Integrity Level) classification, ranging from A (lowest) to D (highest), must be determined for neuromorphic computing applications based on severity, exposure, and controllability factors. Materials and systems implementing brain-inspired computing architectures require verification through fault injection testing to demonstrate resilience against random hardware failures and systematic errors that could compromise safety-critical functions.

The certification process demands extensive documentation of design specifications, verification methods, and validation results. Manufacturers must establish traceability between safety requirements and implementation, particularly challenging for neuromorphic systems whose emergent behaviors may not always follow deterministic patterns. This necessitates the development of specialized testing methodologies that can adequately assess the reliability of these novel computing paradigms.

Functional safety management systems must be implemented throughout the development lifecycle, from concept phase through decommissioning. For neuromorphic materials, this includes specialized considerations for hardware-software integration, as these systems often blur traditional boundaries between physical components and computational processes. Safety cases must demonstrate that residual risks have been reduced to acceptable levels through appropriate safety mechanisms.

Compliance with cybersecurity standards (ISO/SAE 21434) represents another critical dimension, as neuromorphic systems may present unique attack vectors. Materials and architectures must incorporate security-by-design principles to prevent unauthorized access or manipulation that could compromise safety functions. This includes protection against both physical tampering and remote exploitation.

Environmental qualification testing presents particular challenges for neuromorphic materials, which must maintain consistent performance across the extreme temperature ranges, vibration profiles, and electromagnetic environments typical in automotive applications. Accelerated aging tests must verify that neuromorphic properties remain stable throughout the vehicle's operational lifetime, typically 10-15 years under harsh conditions.

Certification bodies increasingly require evidence of predictable degradation modes, where systems fail in safe, controlled manners rather than exhibiting catastrophic failures. This "graceful degradation" requirement poses unique challenges for neuromorphic computing materials, whose failure characteristics may differ significantly from conventional semiconductor technologies.

Environmental Sustainability of Neuromorphic Materials

The environmental sustainability of neuromorphic computing materials represents a critical consideration in their development and deployment for automotive applications. Current neuromorphic systems predominantly utilize rare earth elements and heavy metals, raising significant concerns regarding resource depletion and environmental impact throughout their lifecycle. The extraction processes for these materials often involve energy-intensive mining operations that contribute to habitat destruction, water pollution, and carbon emissions.

Manufacturing neuromorphic components typically requires specialized cleanroom environments with substantial energy consumption and chemical usage. These processes generate hazardous waste streams containing etching chemicals, solvents, and metal residues that require careful management to prevent environmental contamination. Additionally, the fabrication of neuromorphic materials often involves high-temperature processes that further increase their carbon footprint.

Recent sustainability assessments reveal that neuromorphic computing materials have varying environmental profiles. Silicon-based neuromorphic chips generally align with conventional semiconductor manufacturing impacts, while emerging memristive materials incorporating hafnium, tantalum, and other specialized metals present unique recycling challenges. Phase-change materials containing germanium and tellurium compounds raise particular concerns due to their limited global supply and extraction impacts.

The automotive industry's push toward circular economy principles has spurred research into more sustainable neuromorphic materials. Biodegradable substrates, reduced toxic element content, and designs facilitating end-of-life recovery are emerging as promising approaches. Several research institutions have demonstrated prototype neuromorphic systems using carbon-based materials and organic semiconductors that offer significantly improved environmental profiles while maintaining performance characteristics necessary for automotive applications.

Lifecycle assessment studies indicate that the environmental benefits of neuromorphic computing may outweigh production impacts when considering operational efficiency. These systems typically consume 10-100 times less power than conventional computing architectures for equivalent tasks, potentially reducing vehicle energy consumption over extended service periods. This operational advantage creates a sustainability trade-off that must be carefully evaluated when considering material selection and design approaches.

Regulatory frameworks addressing electronic waste management are increasingly influencing neuromorphic material selection for automotive applications. The European Union's Restriction of Hazardous Substances (RoHS) and End-of-Life Vehicle (ELV) directives specifically limit certain substances commonly found in neuromorphic materials, driving innovation toward more environmentally compatible alternatives that maintain required performance characteristics while reducing environmental impact.

Manufacturing neuromorphic components typically requires specialized cleanroom environments with substantial energy consumption and chemical usage. These processes generate hazardous waste streams containing etching chemicals, solvents, and metal residues that require careful management to prevent environmental contamination. Additionally, the fabrication of neuromorphic materials often involves high-temperature processes that further increase their carbon footprint.

Recent sustainability assessments reveal that neuromorphic computing materials have varying environmental profiles. Silicon-based neuromorphic chips generally align with conventional semiconductor manufacturing impacts, while emerging memristive materials incorporating hafnium, tantalum, and other specialized metals present unique recycling challenges. Phase-change materials containing germanium and tellurium compounds raise particular concerns due to their limited global supply and extraction impacts.

The automotive industry's push toward circular economy principles has spurred research into more sustainable neuromorphic materials. Biodegradable substrates, reduced toxic element content, and designs facilitating end-of-life recovery are emerging as promising approaches. Several research institutions have demonstrated prototype neuromorphic systems using carbon-based materials and organic semiconductors that offer significantly improved environmental profiles while maintaining performance characteristics necessary for automotive applications.

Lifecycle assessment studies indicate that the environmental benefits of neuromorphic computing may outweigh production impacts when considering operational efficiency. These systems typically consume 10-100 times less power than conventional computing architectures for equivalent tasks, potentially reducing vehicle energy consumption over extended service periods. This operational advantage creates a sustainability trade-off that must be carefully evaluated when considering material selection and design approaches.

Regulatory frameworks addressing electronic waste management are increasingly influencing neuromorphic material selection for automotive applications. The European Union's Restriction of Hazardous Substances (RoHS) and End-of-Life Vehicle (ELV) directives specifically limit certain substances commonly found in neuromorphic materials, driving innovation toward more environmentally compatible alternatives that maintain required performance characteristics while reducing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!