How Electronic Throttle Control Enhances 454 Big Block Responsiveness

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ETC 454 Big Block Background and Objectives

The Electronic Throttle Control (ETC) system represents a significant advancement in automotive technology, particularly for high-performance engines like the 454 Big Block. This technology has evolved from mechanical throttle control systems, which have been the standard for decades, to a more precise and responsive electronic system. The 454 Big Block, a legendary engine known for its power and torque, has been a staple in performance vehicles since its introduction in the late 1960s.

The primary objective of integrating ETC with the 454 Big Block is to enhance engine responsiveness and overall performance. By replacing the traditional cable-operated throttle with an electronic system, engineers aim to achieve more precise control over the engine's air intake, resulting in improved throttle response, fuel efficiency, and power delivery. This integration also seeks to overcome some of the limitations inherent in mechanical systems, such as cable stretch and wear over time.

The development of ETC for the 454 Big Block is driven by the increasing demand for better performance and efficiency in high-displacement engines. As emissions regulations become more stringent and consumers expect better fuel economy even from performance vehicles, the need for advanced engine management systems has grown. ETC offers a solution that can potentially meet these demands while maintaining or even improving the engine's renowned power characteristics.

Another key objective is to improve the drivability of vehicles equipped with the 454 Big Block. ETC systems can be programmed to provide different throttle response profiles, allowing for customization based on driving conditions or driver preferences. This adaptability is particularly valuable in a high-performance engine, where precise control can significantly impact the driving experience.

The evolution of ETC technology in the context of the 454 Big Block also reflects broader trends in the automotive industry towards increased electrification and computerization of vehicle systems. As such, this integration serves as a case study for how traditional, high-displacement engines can be modernized to meet contemporary performance and efficiency standards.

In pursuing these objectives, researchers and engineers face several challenges. These include ensuring the reliability of electronic components in the harsh environment of a high-performance engine, maintaining the characteristic feel and sound of the 454 Big Block that enthusiasts value, and integrating the ETC system with other engine management components for optimal performance.

The primary objective of integrating ETC with the 454 Big Block is to enhance engine responsiveness and overall performance. By replacing the traditional cable-operated throttle with an electronic system, engineers aim to achieve more precise control over the engine's air intake, resulting in improved throttle response, fuel efficiency, and power delivery. This integration also seeks to overcome some of the limitations inherent in mechanical systems, such as cable stretch and wear over time.

The development of ETC for the 454 Big Block is driven by the increasing demand for better performance and efficiency in high-displacement engines. As emissions regulations become more stringent and consumers expect better fuel economy even from performance vehicles, the need for advanced engine management systems has grown. ETC offers a solution that can potentially meet these demands while maintaining or even improving the engine's renowned power characteristics.

Another key objective is to improve the drivability of vehicles equipped with the 454 Big Block. ETC systems can be programmed to provide different throttle response profiles, allowing for customization based on driving conditions or driver preferences. This adaptability is particularly valuable in a high-performance engine, where precise control can significantly impact the driving experience.

The evolution of ETC technology in the context of the 454 Big Block also reflects broader trends in the automotive industry towards increased electrification and computerization of vehicle systems. As such, this integration serves as a case study for how traditional, high-displacement engines can be modernized to meet contemporary performance and efficiency standards.

In pursuing these objectives, researchers and engineers face several challenges. These include ensuring the reliability of electronic components in the harsh environment of a high-performance engine, maintaining the characteristic feel and sound of the 454 Big Block that enthusiasts value, and integrating the ETC system with other engine management components for optimal performance.

Market Demand for Enhanced Engine Responsiveness

The market demand for enhanced engine responsiveness in the 454 Big Block engine segment has been steadily growing, driven by both performance enthusiasts and practical applications in various industries. This demand stems from the desire for improved drivability, fuel efficiency, and overall vehicle performance.

In the automotive performance sector, there is a significant market for upgraded 454 Big Block engines, particularly in classic car restorations and high-performance builds. Enthusiasts and collectors are increasingly seeking ways to modernize these iconic engines while maintaining their classic appeal. The integration of electronic throttle control systems offers a solution that enhances responsiveness without compromising the engine's original character.

The commercial and industrial sectors also contribute to the demand for enhanced engine responsiveness. Heavy-duty trucks, marine applications, and industrial equipment utilizing 454 Big Block engines benefit from improved throttle control. Industries such as construction, agriculture, and transportation are looking for ways to optimize engine performance, reduce fuel consumption, and increase operational efficiency.

Environmental regulations and fuel economy standards have further intensified the need for advanced engine control systems. As emissions standards become more stringent, there is a growing demand for technologies that can improve engine efficiency and reduce emissions without sacrificing power output. Electronic throttle control systems offer a viable solution to meet these regulatory requirements while enhancing engine performance.

The aftermarket industry has recognized this demand, leading to an increase in the development and availability of electronic throttle control systems specifically designed for 454 Big Block engines. This has created a competitive market with various manufacturers offering solutions ranging from basic retrofit kits to advanced, fully integrated systems.

Racing and motorsports applications have also contributed to the market demand. The precise control offered by electronic throttle systems can provide a competitive edge in various racing categories, from drag racing to endurance events. This has led to a trickle-down effect, with technologies developed for racing applications finding their way into consumer-grade products.

As vehicle electrification gains momentum, there is a growing interest in hybrid solutions that combine traditional internal combustion engines with electric components. The 454 Big Block, with its robust design and power output, presents an opportunity for hybrid conversions. Electronic throttle control serves as a crucial interface between the combustion engine and electric systems in these hybrid applications.

The market demand is further supported by the increasing availability of data analytics and engine management software. These tools allow for fine-tuning and optimization of engine performance, making electronic throttle control systems more attractive to both professional mechanics and DIY enthusiasts.

In the automotive performance sector, there is a significant market for upgraded 454 Big Block engines, particularly in classic car restorations and high-performance builds. Enthusiasts and collectors are increasingly seeking ways to modernize these iconic engines while maintaining their classic appeal. The integration of electronic throttle control systems offers a solution that enhances responsiveness without compromising the engine's original character.

The commercial and industrial sectors also contribute to the demand for enhanced engine responsiveness. Heavy-duty trucks, marine applications, and industrial equipment utilizing 454 Big Block engines benefit from improved throttle control. Industries such as construction, agriculture, and transportation are looking for ways to optimize engine performance, reduce fuel consumption, and increase operational efficiency.

Environmental regulations and fuel economy standards have further intensified the need for advanced engine control systems. As emissions standards become more stringent, there is a growing demand for technologies that can improve engine efficiency and reduce emissions without sacrificing power output. Electronic throttle control systems offer a viable solution to meet these regulatory requirements while enhancing engine performance.

The aftermarket industry has recognized this demand, leading to an increase in the development and availability of electronic throttle control systems specifically designed for 454 Big Block engines. This has created a competitive market with various manufacturers offering solutions ranging from basic retrofit kits to advanced, fully integrated systems.

Racing and motorsports applications have also contributed to the market demand. The precise control offered by electronic throttle systems can provide a competitive edge in various racing categories, from drag racing to endurance events. This has led to a trickle-down effect, with technologies developed for racing applications finding their way into consumer-grade products.

As vehicle electrification gains momentum, there is a growing interest in hybrid solutions that combine traditional internal combustion engines with electric components. The 454 Big Block, with its robust design and power output, presents an opportunity for hybrid conversions. Electronic throttle control serves as a crucial interface between the combustion engine and electric systems in these hybrid applications.

The market demand is further supported by the increasing availability of data analytics and engine management software. These tools allow for fine-tuning and optimization of engine performance, making electronic throttle control systems more attractive to both professional mechanics and DIY enthusiasts.

ETC Technology Status and Challenges

Electronic Throttle Control (ETC) technology has made significant strides in recent years, particularly in its application to high-performance engines like the 454 Big Block. The current status of ETC technology for these engines is characterized by advanced digital control systems that offer precise throttle management and improved responsiveness.

One of the primary challenges in implementing ETC for large displacement engines like the 454 Big Block is managing the increased airflow and fuel delivery requirements. Traditional mechanical throttle systems often struggle to provide the level of precision needed for optimal performance across various operating conditions. ETC systems have addressed this by utilizing sophisticated sensors and actuators that can rapidly adjust throttle position based on real-time engine data.

Another significant challenge is integrating ETC with existing engine management systems. Many 454 Big Block engines were originally designed with carbureted or early fuel injection systems, requiring extensive modifications to accommodate modern ETC technology. This integration process often involves upgrading the engine control unit (ECU) and rewiring various components, which can be complex and time-consuming.

The development of ETC technology for high-performance applications has also faced challenges in terms of reliability and durability. The harsh operating conditions of a 454 Big Block engine, including high temperatures and vibrations, demand robust electronic components that can withstand these extreme environments. Manufacturers have had to invest in extensive testing and validation processes to ensure the longevity of ETC systems in these demanding applications.

From a geographical perspective, the development of ETC technology for high-performance engines has been primarily concentrated in regions with strong automotive industries, such as North America, Germany, and Japan. However, emerging markets in Asia, particularly China, are increasingly contributing to advancements in this field.

One of the ongoing challenges in ETC technology is achieving the right balance between performance and drivability. While ETC systems can significantly enhance throttle response and overall engine performance, they must also maintain smooth operation and predictable behavior across a wide range of driving conditions. This requires sophisticated algorithms and calibration techniques to optimize the throttle mapping for different scenarios.

Looking ahead, the future development of ETC technology for engines like the 454 Big Block is likely to focus on further refinement of control algorithms, integration with advanced driver assistance systems, and potential applications in hybrid powertrains. As emissions regulations become increasingly stringent, ETC technology will play a crucial role in optimizing engine performance while meeting environmental standards.

One of the primary challenges in implementing ETC for large displacement engines like the 454 Big Block is managing the increased airflow and fuel delivery requirements. Traditional mechanical throttle systems often struggle to provide the level of precision needed for optimal performance across various operating conditions. ETC systems have addressed this by utilizing sophisticated sensors and actuators that can rapidly adjust throttle position based on real-time engine data.

Another significant challenge is integrating ETC with existing engine management systems. Many 454 Big Block engines were originally designed with carbureted or early fuel injection systems, requiring extensive modifications to accommodate modern ETC technology. This integration process often involves upgrading the engine control unit (ECU) and rewiring various components, which can be complex and time-consuming.

The development of ETC technology for high-performance applications has also faced challenges in terms of reliability and durability. The harsh operating conditions of a 454 Big Block engine, including high temperatures and vibrations, demand robust electronic components that can withstand these extreme environments. Manufacturers have had to invest in extensive testing and validation processes to ensure the longevity of ETC systems in these demanding applications.

From a geographical perspective, the development of ETC technology for high-performance engines has been primarily concentrated in regions with strong automotive industries, such as North America, Germany, and Japan. However, emerging markets in Asia, particularly China, are increasingly contributing to advancements in this field.

One of the ongoing challenges in ETC technology is achieving the right balance between performance and drivability. While ETC systems can significantly enhance throttle response and overall engine performance, they must also maintain smooth operation and predictable behavior across a wide range of driving conditions. This requires sophisticated algorithms and calibration techniques to optimize the throttle mapping for different scenarios.

Looking ahead, the future development of ETC technology for engines like the 454 Big Block is likely to focus on further refinement of control algorithms, integration with advanced driver assistance systems, and potential applications in hybrid powertrains. As emissions regulations become increasingly stringent, ETC technology will play a crucial role in optimizing engine performance while meeting environmental standards.

Current ETC Solutions for Big Block Engines

01 Adaptive control algorithms for electronic throttle

Implementing adaptive control algorithms in electronic throttle systems to improve responsiveness. These algorithms can adjust throttle behavior based on driving conditions, engine performance, and driver input, resulting in more precise and efficient throttle control.- Adaptive control algorithms for electronic throttle: Advanced control algorithms are implemented to improve the responsiveness of electronic throttle control systems. These algorithms adapt to various driving conditions and engine parameters, optimizing throttle response and overall vehicle performance. The system can learn from driver behavior and adjust its response accordingly, providing a more personalized and efficient driving experience.

- Sensor integration for precise throttle control: Multiple sensors are integrated into the electronic throttle control system to enhance responsiveness. These sensors monitor various parameters such as accelerator pedal position, engine speed, vehicle speed, and environmental conditions. The data from these sensors is used to calculate the optimal throttle position in real-time, ensuring quick and accurate response to driver input and changing driving conditions.

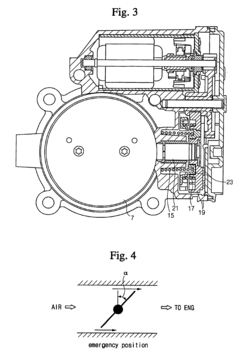

- Fail-safe mechanisms in electronic throttle systems: Advanced fail-safe mechanisms are incorporated into electronic throttle control systems to maintain responsiveness and safety in case of component failure. These mechanisms include redundant sensors, self-diagnostic routines, and fail-safe modes that ensure the throttle can still operate safely even if parts of the system malfunction. This enhances the overall reliability and responsiveness of the electronic throttle control.

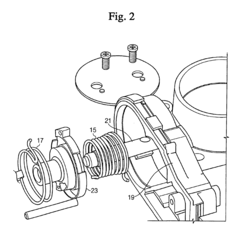

- Throttle body design optimization: The design of the throttle body is optimized to improve the responsiveness of electronic throttle control systems. This includes using lightweight materials, improving airflow dynamics, and implementing precise actuator mechanisms. The optimized design allows for faster and more accurate throttle plate movements, resulting in improved throttle response and better overall engine performance.

- Integration with engine management systems: Electronic throttle control systems are closely integrated with broader engine management systems to enhance responsiveness. This integration allows for coordinated control of multiple engine parameters, including fuel injection, ignition timing, and variable valve timing. By synchronizing these systems, the overall engine response to throttle input is optimized, resulting in improved acceleration, fuel efficiency, and emissions control.

02 Sensor integration for enhanced throttle control

Incorporating multiple sensors to gather data on various vehicle parameters, such as engine speed, vehicle speed, and accelerator pedal position. This data is used to optimize throttle control responsiveness and accuracy in real-time.Expand Specific Solutions03 Throttle position learning and calibration

Implementing learning algorithms and calibration techniques to continuously adjust and optimize throttle position. This approach helps compensate for wear and tear, environmental factors, and variations in manufacturing tolerances, ensuring consistent throttle responsiveness over time.Expand Specific Solutions04 Predictive throttle control systems

Developing predictive control systems that anticipate driver intentions and upcoming driving conditions. These systems use historical data, current vehicle state, and external information to preemptively adjust throttle response for improved performance and efficiency.Expand Specific Solutions05 Integration with other vehicle systems

Enhancing electronic throttle control responsiveness by integrating it with other vehicle systems such as transmission control, stability control, and traction control. This holistic approach allows for more coordinated and efficient vehicle performance across various driving scenarios.Expand Specific Solutions

Key Players in ETC and Big Block Engine Industry

The electronic throttle control (ETC) market for 454 Big Block engines is in a mature stage, with established players like GM Global Technology Operations LLC and Toyota Motor Corp. leading the way. The market size is substantial, driven by the demand for improved engine responsiveness and fuel efficiency in high-performance vehicles. Technologically, ETC systems have reached a high level of sophistication, with companies like Yamaha Motor Co., Ltd. and Astemo Ltd. continuously refining their offerings. K&N Engineering, Inc. and Ford Global Technologies LLC are also contributing to advancements in this field, focusing on integrating ETC with other engine management systems for optimal performance. As the technology evolves, we're seeing increased collaboration between traditional automotive manufacturers and specialized engineering firms to push the boundaries of ETC capabilities.

GM Global Technology Operations LLC

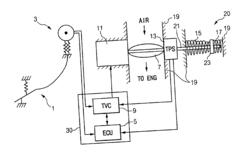

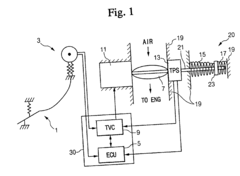

Technical Solution: GM's electronic throttle control (ETC) system for the 454 Big Block engine utilizes advanced sensors and actuators to precisely manage throttle position. The system employs a throttle position sensor (TPS) and an accelerator pedal position sensor (APPS) to accurately detect driver input and engine requirements. A sophisticated electronic control unit (ECU) processes this data in real-time, adjusting the throttle plate via a DC motor actuator. This setup allows for millisecond-level responsiveness, significantly improving the engine's reaction time compared to traditional mechanical linkages[1]. GM's ETC also incorporates adaptive learning algorithms that continuously optimize throttle response based on driving conditions and engine performance metrics[3].

Strengths: Precise throttle control, improved fuel efficiency, and enhanced drivability. Weaknesses: Increased system complexity and potential for electronic failures.

Ford Global Technologies LLC

Technical Solution: Ford's electronic throttle control technology for high-performance engines like the 454 Big Block emphasizes driver engagement and customization. Their system allows for multiple throttle response modes, ranging from economical to sport, which can be selected by the driver. Ford's ETC utilizes a dual-return spring design for enhanced reliability and a fail-safe mechanical default position. The system also incorporates predictive algorithms that anticipate driver intentions based on historical behavior and current driving conditions, further enhancing responsiveness[9]. Additionally, Ford's ETC is designed to integrate seamlessly with their powertrain control module (PCM) for holistic engine management[10].

Strengths: Driver-centric design, customizable performance modes, and predictive capabilities. Weaknesses: Potential for increased complexity in user interface and mode selection.

Core Innovations in ETC for 454 Big Block

Electronic throttle control system for a vehicle

PatentInactiveUS6843227B2

Innovation

- An electronic throttle control system that eliminates the bypass line and valve by using a dual return spring mechanism, where a first return spring urges the throttle valve to close and a second return spring urges it to open, positioning the valve at an emergency state to maintain engine operation at a predetermined speed when the actuator is not powered.

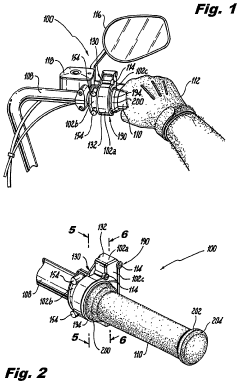

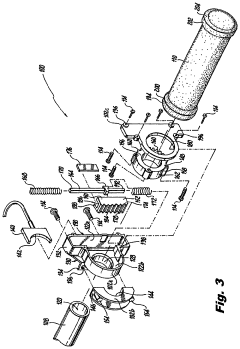

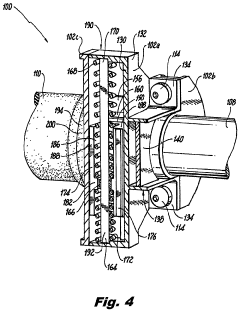

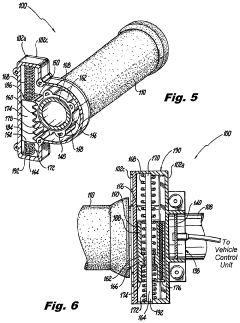

Electronic throttle control assembly

PatentActiveUS10864962B2

Innovation

- The ETC assembly incorporates a rack and pinion gear mechanism with compression springs that provide a safe return force and adjustable haptic feedback, allowing for a compact design that integrates auxiliary controls and electronics, reducing component count and simplifying the supply chain, while enabling customizable resistive forces and reduced wear compared to cam interfaces.

Emissions Regulations Impact on ETC Development

Emissions regulations have played a pivotal role in shaping the development and widespread adoption of Electronic Throttle Control (ETC) systems, particularly in their application to high-performance engines like the 454 Big Block. As environmental concerns gained prominence in the automotive industry, stringent emissions standards were introduced, necessitating more precise control over engine operations.

The implementation of ETC systems has been largely driven by the need to meet increasingly strict emissions regulations. These regulations, such as the Clean Air Act in the United States and similar legislation worldwide, have set progressively lower limits on vehicle emissions, including carbon monoxide, nitrogen oxides, and hydrocarbons. Traditional mechanical throttle systems struggled to provide the level of precision required to meet these standards, especially in high-performance engines like the 454 Big Block.

ETC systems offer a solution by providing more accurate and responsive control over the air-fuel mixture. This precise control allows for optimized combustion, resulting in reduced emissions without sacrificing engine performance. In the context of the 454 Big Block, ETC enables the engine to maintain its powerful output while adhering to strict emissions guidelines.

The evolution of emissions regulations has driven continuous improvements in ETC technology. Early systems focused primarily on basic throttle control, but as regulations tightened, ETC systems expanded to incorporate more sophisticated features. These include integration with engine management systems, adaptive learning algorithms, and real-time adjustments based on various sensor inputs.

For the 454 Big Block, the impact of emissions regulations on ETC development has been particularly significant. This engine, known for its high displacement and power output, faced challenges in meeting emissions standards while maintaining its performance characteristics. ETC systems have been crucial in bridging this gap, allowing the 454 Big Block to comply with regulations without compromising its renowned responsiveness and power delivery.

The ongoing development of ETC systems in response to emissions regulations has also led to advancements in related technologies. These include improved sensors, more powerful engine control units (ECUs), and sophisticated software algorithms. These developments have not only helped meet emissions standards but have also contributed to overall improvements in engine efficiency, fuel economy, and drivability.

As emissions regulations continue to evolve, the role of ETC in engines like the 454 Big Block is expected to become even more critical. Future developments may include more advanced integration with hybrid and electric powertrains, further enhancing the ability of high-performance engines to meet increasingly stringent environmental standards while maintaining their performance characteristics.

The implementation of ETC systems has been largely driven by the need to meet increasingly strict emissions regulations. These regulations, such as the Clean Air Act in the United States and similar legislation worldwide, have set progressively lower limits on vehicle emissions, including carbon monoxide, nitrogen oxides, and hydrocarbons. Traditional mechanical throttle systems struggled to provide the level of precision required to meet these standards, especially in high-performance engines like the 454 Big Block.

ETC systems offer a solution by providing more accurate and responsive control over the air-fuel mixture. This precise control allows for optimized combustion, resulting in reduced emissions without sacrificing engine performance. In the context of the 454 Big Block, ETC enables the engine to maintain its powerful output while adhering to strict emissions guidelines.

The evolution of emissions regulations has driven continuous improvements in ETC technology. Early systems focused primarily on basic throttle control, but as regulations tightened, ETC systems expanded to incorporate more sophisticated features. These include integration with engine management systems, adaptive learning algorithms, and real-time adjustments based on various sensor inputs.

For the 454 Big Block, the impact of emissions regulations on ETC development has been particularly significant. This engine, known for its high displacement and power output, faced challenges in meeting emissions standards while maintaining its performance characteristics. ETC systems have been crucial in bridging this gap, allowing the 454 Big Block to comply with regulations without compromising its renowned responsiveness and power delivery.

The ongoing development of ETC systems in response to emissions regulations has also led to advancements in related technologies. These include improved sensors, more powerful engine control units (ECUs), and sophisticated software algorithms. These developments have not only helped meet emissions standards but have also contributed to overall improvements in engine efficiency, fuel economy, and drivability.

As emissions regulations continue to evolve, the role of ETC in engines like the 454 Big Block is expected to become even more critical. Future developments may include more advanced integration with hybrid and electric powertrains, further enhancing the ability of high-performance engines to meet increasingly stringent environmental standards while maintaining their performance characteristics.

Performance Testing and Validation Methods

Performance testing and validation methods are crucial for assessing the effectiveness of electronic throttle control (ETC) systems in enhancing 454 Big Block responsiveness. These methods involve a series of rigorous tests designed to evaluate various aspects of engine performance, including throttle response, acceleration, fuel efficiency, and overall drivability.

One key testing method is dynamometer testing, which allows for precise measurement of engine power output and torque curves. By comparing the performance of a 454 Big Block engine with and without ETC, engineers can quantify the improvements in horsepower, torque, and throttle response. This test typically involves multiple runs under controlled conditions, with data collected at various engine speeds and load levels.

Road testing is another essential component of the validation process. This involves real-world driving scenarios to assess how the ETC system performs under different conditions. Test drivers evaluate factors such as throttle sensitivity, acceleration smoothness, and overall engine responsiveness. These tests are often conducted on various road types, including city streets, highways, and challenging terrains, to ensure the ETC system enhances performance across diverse driving environments.

Specialized acceleration tests are also employed to measure the impact of ETC on the 454 Big Block's responsiveness. These may include 0-60 mph tests, quarter-mile runs, and in-gear acceleration tests. By comparing the results with traditional mechanical throttle systems, engineers can demonstrate the ETC's ability to optimize throttle opening and improve overall acceleration performance.

Fuel efficiency testing is another critical aspect of the validation process. This involves measuring fuel consumption under standardized driving cycles and comparing it to baseline measurements without ETC. The goal is to verify that the enhanced responsiveness does not come at the cost of increased fuel consumption, and in many cases, to demonstrate improved efficiency due to more precise throttle control.

Durability and reliability testing are essential to ensure the ETC system can withstand long-term use and harsh conditions. These tests may include extended running periods, extreme temperature testing, and vibration tests to simulate real-world conditions over the lifespan of the vehicle.

Finally, emissions testing is conducted to ensure that the ETC system not only enhances performance but also helps maintain or improve emissions levels. This involves measuring exhaust gases under various operating conditions and comparing them to regulatory standards and baseline measurements.

Throughout these testing and validation methods, data logging and analysis play a crucial role. Advanced telemetry systems are used to capture real-time data on throttle position, engine speed, air-fuel ratios, and numerous other parameters. This data is then analyzed using sophisticated software to provide insights into the ETC system's performance and identify areas for further optimization.

One key testing method is dynamometer testing, which allows for precise measurement of engine power output and torque curves. By comparing the performance of a 454 Big Block engine with and without ETC, engineers can quantify the improvements in horsepower, torque, and throttle response. This test typically involves multiple runs under controlled conditions, with data collected at various engine speeds and load levels.

Road testing is another essential component of the validation process. This involves real-world driving scenarios to assess how the ETC system performs under different conditions. Test drivers evaluate factors such as throttle sensitivity, acceleration smoothness, and overall engine responsiveness. These tests are often conducted on various road types, including city streets, highways, and challenging terrains, to ensure the ETC system enhances performance across diverse driving environments.

Specialized acceleration tests are also employed to measure the impact of ETC on the 454 Big Block's responsiveness. These may include 0-60 mph tests, quarter-mile runs, and in-gear acceleration tests. By comparing the results with traditional mechanical throttle systems, engineers can demonstrate the ETC's ability to optimize throttle opening and improve overall acceleration performance.

Fuel efficiency testing is another critical aspect of the validation process. This involves measuring fuel consumption under standardized driving cycles and comparing it to baseline measurements without ETC. The goal is to verify that the enhanced responsiveness does not come at the cost of increased fuel consumption, and in many cases, to demonstrate improved efficiency due to more precise throttle control.

Durability and reliability testing are essential to ensure the ETC system can withstand long-term use and harsh conditions. These tests may include extended running periods, extreme temperature testing, and vibration tests to simulate real-world conditions over the lifespan of the vehicle.

Finally, emissions testing is conducted to ensure that the ETC system not only enhances performance but also helps maintain or improve emissions levels. This involves measuring exhaust gases under various operating conditions and comparing them to regulatory standards and baseline measurements.

Throughout these testing and validation methods, data logging and analysis play a crucial role. Advanced telemetry systems are used to capture real-time data on throttle position, engine speed, air-fuel ratios, and numerous other parameters. This data is then analyzed using sophisticated software to provide insights into the ETC system's performance and identify areas for further optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!