How Metallocene Catalysts Revolutionize Polypropylene Production

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metallocene Catalysts Evolution and Objectives

Metallocene catalysts have revolutionized the production of polypropylene since their introduction in the 1980s. These single-site catalysts represent a significant leap forward from traditional Ziegler-Natta catalysts, offering unprecedented control over polymer structure and properties. The evolution of metallocene catalysts for polypropylene production has been driven by the need for enhanced product performance, improved process efficiency, and reduced environmental impact.

The journey of metallocene catalysts began with the discovery of cyclopentadienyl complexes of transition metals in the 1950s. However, it wasn't until the 1980s that researchers at Kaminsky and Sinn's laboratory in Germany developed the first metallocene catalysts capable of polymerizing olefins with high activity. This breakthrough paved the way for a new era in polyolefin production, particularly for polypropylene.

The primary objective of metallocene catalyst development has been to achieve precise control over polymer microstructure. This includes the ability to tailor molecular weight distribution, stereoregularity, and comonomer incorporation. By manipulating the ligand structure and metal center of the catalyst, researchers have been able to fine-tune these properties, resulting in polypropylene with superior mechanical and optical characteristics.

Another key goal in the evolution of metallocene catalysts has been to enhance catalytic activity and productivity. Early metallocene systems required high levels of methylaluminoxane (MAO) as a cocatalyst, which was both expensive and problematic for industrial-scale production. Subsequent research focused on developing more efficient catalyst systems with reduced cocatalyst requirements, leading to more economically viable processes.

The pursuit of broader temperature and pressure operating windows has also been a significant objective in metallocene catalyst development. This has enabled more flexible production conditions and improved process efficiency. Additionally, researchers have aimed to create catalysts capable of producing novel polypropylene architectures, such as long-chain branched polypropylene, which exhibits enhanced melt strength and processability.

Environmental considerations have played an increasingly important role in shaping the objectives of metallocene catalyst research. The drive towards more sustainable production methods has led to efforts in developing catalysts that operate efficiently at lower temperatures and pressures, thereby reducing energy consumption. Furthermore, the ability of metallocene catalysts to produce polymers with precise structures has enabled the creation of materials with improved recyclability and reduced material usage in end applications.

As the field continues to advance, current objectives include the development of catalysts capable of producing bimodal and multimodal polypropylene in a single reactor, further enhancing product performance and process efficiency. Additionally, there is ongoing research into catalysts that can incorporate functional comonomers, opening up new applications for polypropylene-based materials.

The journey of metallocene catalysts began with the discovery of cyclopentadienyl complexes of transition metals in the 1950s. However, it wasn't until the 1980s that researchers at Kaminsky and Sinn's laboratory in Germany developed the first metallocene catalysts capable of polymerizing olefins with high activity. This breakthrough paved the way for a new era in polyolefin production, particularly for polypropylene.

The primary objective of metallocene catalyst development has been to achieve precise control over polymer microstructure. This includes the ability to tailor molecular weight distribution, stereoregularity, and comonomer incorporation. By manipulating the ligand structure and metal center of the catalyst, researchers have been able to fine-tune these properties, resulting in polypropylene with superior mechanical and optical characteristics.

Another key goal in the evolution of metallocene catalysts has been to enhance catalytic activity and productivity. Early metallocene systems required high levels of methylaluminoxane (MAO) as a cocatalyst, which was both expensive and problematic for industrial-scale production. Subsequent research focused on developing more efficient catalyst systems with reduced cocatalyst requirements, leading to more economically viable processes.

The pursuit of broader temperature and pressure operating windows has also been a significant objective in metallocene catalyst development. This has enabled more flexible production conditions and improved process efficiency. Additionally, researchers have aimed to create catalysts capable of producing novel polypropylene architectures, such as long-chain branched polypropylene, which exhibits enhanced melt strength and processability.

Environmental considerations have played an increasingly important role in shaping the objectives of metallocene catalyst research. The drive towards more sustainable production methods has led to efforts in developing catalysts that operate efficiently at lower temperatures and pressures, thereby reducing energy consumption. Furthermore, the ability of metallocene catalysts to produce polymers with precise structures has enabled the creation of materials with improved recyclability and reduced material usage in end applications.

As the field continues to advance, current objectives include the development of catalysts capable of producing bimodal and multimodal polypropylene in a single reactor, further enhancing product performance and process efficiency. Additionally, there is ongoing research into catalysts that can incorporate functional comonomers, opening up new applications for polypropylene-based materials.

Market Demand for Advanced Polypropylene

The global demand for advanced polypropylene has been steadily increasing, driven by its superior properties and versatile applications across various industries. Metallocene-catalyzed polypropylene, in particular, has gained significant traction due to its enhanced performance characteristics compared to traditional Ziegler-Natta catalyzed polypropylene.

The automotive sector represents a major market for advanced polypropylene, as manufacturers seek lightweight materials to improve fuel efficiency and reduce emissions. Metallocene polypropylene offers higher impact strength and better aesthetics, making it ideal for interior and exterior automotive components. The packaging industry also shows strong demand for metallocene polypropylene, valuing its improved clarity, stiffness, and barrier properties for food packaging and consumer goods.

In the healthcare sector, the demand for metallocene polypropylene is growing due to its purity and compatibility with medical applications. The material's enhanced sterilization resistance and clarity make it suitable for medical devices, pharmaceutical packaging, and laboratory equipment. The construction industry is another significant consumer, utilizing metallocene polypropylene for its durability and weather resistance in pipes, fittings, and geomembranes.

The electronics industry has also recognized the benefits of metallocene polypropylene, particularly in the production of high-performance capacitor films and insulation materials. Its superior dielectric properties and thermal stability make it an attractive choice for electronic components.

Market analysts project the global metallocene polypropylene market to experience robust growth in the coming years. This growth is attributed to the increasing adoption of metallocene technology in developing economies and the continuous innovation in catalyst systems. The Asia-Pacific region, led by China and India, is expected to be the fastest-growing market due to rapid industrialization and urbanization.

Environmental concerns and sustainability initiatives are further driving the demand for advanced polypropylene. Metallocene catalysts enable the production of polypropylene with improved recyclability and reduced material usage, aligning with the growing emphasis on circular economy principles.

Despite the positive outlook, challenges such as high production costs and the need for specialized equipment may hinder market growth to some extent. However, ongoing research and development efforts are focused on optimizing production processes and reducing costs, which is likely to mitigate these challenges in the long term.

The automotive sector represents a major market for advanced polypropylene, as manufacturers seek lightweight materials to improve fuel efficiency and reduce emissions. Metallocene polypropylene offers higher impact strength and better aesthetics, making it ideal for interior and exterior automotive components. The packaging industry also shows strong demand for metallocene polypropylene, valuing its improved clarity, stiffness, and barrier properties for food packaging and consumer goods.

In the healthcare sector, the demand for metallocene polypropylene is growing due to its purity and compatibility with medical applications. The material's enhanced sterilization resistance and clarity make it suitable for medical devices, pharmaceutical packaging, and laboratory equipment. The construction industry is another significant consumer, utilizing metallocene polypropylene for its durability and weather resistance in pipes, fittings, and geomembranes.

The electronics industry has also recognized the benefits of metallocene polypropylene, particularly in the production of high-performance capacitor films and insulation materials. Its superior dielectric properties and thermal stability make it an attractive choice for electronic components.

Market analysts project the global metallocene polypropylene market to experience robust growth in the coming years. This growth is attributed to the increasing adoption of metallocene technology in developing economies and the continuous innovation in catalyst systems. The Asia-Pacific region, led by China and India, is expected to be the fastest-growing market due to rapid industrialization and urbanization.

Environmental concerns and sustainability initiatives are further driving the demand for advanced polypropylene. Metallocene catalysts enable the production of polypropylene with improved recyclability and reduced material usage, aligning with the growing emphasis on circular economy principles.

Despite the positive outlook, challenges such as high production costs and the need for specialized equipment may hinder market growth to some extent. However, ongoing research and development efforts are focused on optimizing production processes and reducing costs, which is likely to mitigate these challenges in the long term.

Current State of Metallocene Catalyst Technology

Metallocene catalyst technology has revolutionized polypropylene production, offering significant advancements in polymer properties and process efficiency. Currently, this technology is widely adopted in the industry, with continuous improvements and innovations being made.

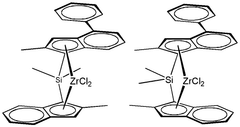

The state-of-the-art metallocene catalysts for polypropylene production are primarily based on group 4 transition metals, particularly zirconium and hafnium. These catalysts are characterized by their single-site nature, which allows for precise control over polymer microstructure, resulting in enhanced product properties and performance.

Recent developments in metallocene catalyst technology have focused on improving catalyst activity, stability, and selectivity. Researchers have made significant progress in designing novel ligand structures and fine-tuning the electronic and steric properties of the catalyst complexes. This has led to the development of catalysts capable of producing polypropylene with tailored molecular weight distributions, stereoregularity, and comonomer incorporation.

One of the key advancements in current metallocene catalyst technology is the development of supported catalyst systems. These systems offer improved morphology control and enhanced productivity in industrial-scale polymerization processes. Silica is commonly used as a support material, with various techniques employed to immobilize the metallocene complexes on the support surface.

The use of activators, particularly methylaluminoxane (MAO), remains crucial in metallocene-catalyzed polypropylene production. However, research efforts are ongoing to develop alternative activators that are more cost-effective and environmentally friendly. Some promising alternatives include boron-based compounds and modified aluminoxanes.

In terms of polymerization processes, both solution and gas-phase technologies have been successfully adapted for metallocene-catalyzed polypropylene production. Slurry processes are also employed, although to a lesser extent. Each process offers specific advantages in terms of product properties and production efficiency.

Current metallocene catalyst technology allows for the production of a wide range of polypropylene grades, including homopolymers, random copolymers, and impact copolymers. The ability to precisely control polymer architecture has enabled the development of specialty grades with enhanced properties, such as improved clarity, impact resistance, and heat resistance.

Despite the significant progress made in metallocene catalyst technology, challenges remain. These include the high cost of catalyst components, the need for specialized handling and storage procedures, and the complexity of catalyst synthesis. Ongoing research efforts are focused on addressing these challenges and further expanding the capabilities of metallocene catalysts in polypropylene production.

The state-of-the-art metallocene catalysts for polypropylene production are primarily based on group 4 transition metals, particularly zirconium and hafnium. These catalysts are characterized by their single-site nature, which allows for precise control over polymer microstructure, resulting in enhanced product properties and performance.

Recent developments in metallocene catalyst technology have focused on improving catalyst activity, stability, and selectivity. Researchers have made significant progress in designing novel ligand structures and fine-tuning the electronic and steric properties of the catalyst complexes. This has led to the development of catalysts capable of producing polypropylene with tailored molecular weight distributions, stereoregularity, and comonomer incorporation.

One of the key advancements in current metallocene catalyst technology is the development of supported catalyst systems. These systems offer improved morphology control and enhanced productivity in industrial-scale polymerization processes. Silica is commonly used as a support material, with various techniques employed to immobilize the metallocene complexes on the support surface.

The use of activators, particularly methylaluminoxane (MAO), remains crucial in metallocene-catalyzed polypropylene production. However, research efforts are ongoing to develop alternative activators that are more cost-effective and environmentally friendly. Some promising alternatives include boron-based compounds and modified aluminoxanes.

In terms of polymerization processes, both solution and gas-phase technologies have been successfully adapted for metallocene-catalyzed polypropylene production. Slurry processes are also employed, although to a lesser extent. Each process offers specific advantages in terms of product properties and production efficiency.

Current metallocene catalyst technology allows for the production of a wide range of polypropylene grades, including homopolymers, random copolymers, and impact copolymers. The ability to precisely control polymer architecture has enabled the development of specialty grades with enhanced properties, such as improved clarity, impact resistance, and heat resistance.

Despite the significant progress made in metallocene catalyst technology, challenges remain. These include the high cost of catalyst components, the need for specialized handling and storage procedures, and the complexity of catalyst synthesis. Ongoing research efforts are focused on addressing these challenges and further expanding the capabilities of metallocene catalysts in polypropylene production.

Existing Metallocene Catalyst Solutions

01 Improved polymerization catalysts

Metallocene catalysts revolutionize polymerization processes by offering superior control over polymer properties, including molecular weight distribution, stereoregularity, and comonomer incorporation. These catalysts enable the production of polymers with enhanced mechanical and optical properties, making them suitable for a wide range of applications.- Improved polymerization control: Metallocene catalysts revolutionize polymerization processes by offering superior control over polymer structure, molecular weight distribution, and stereochemistry. This results in the production of polymers with enhanced properties and performance characteristics, enabling the development of tailored materials for specific applications.

- Enhanced copolymerization capabilities: Metallocene catalysts enable the efficient copolymerization of different monomers, allowing for the creation of novel copolymers with unique properties. This capability expands the range of possible polymer compositions and facilitates the development of materials with improved mechanical, thermal, and chemical properties.

- Increased catalytic activity and efficiency: Metallocene catalysts demonstrate significantly higher catalytic activity compared to traditional Ziegler-Natta catalysts. This increased efficiency leads to improved polymer yields, reduced catalyst residues in the final product, and potential cost savings in industrial polymerization processes.

- Production of specialty polymers: The unique properties of metallocene catalysts enable the production of specialty polymers with tailored characteristics, such as ultra-high molecular weight polyethylene, cyclic olefin copolymers, and elastomers with improved properties. These specialty polymers find applications in various industries, including automotive, packaging, and medical devices.

- Environmental and economic benefits: Metallocene catalysts contribute to more sustainable polymer production by reducing energy consumption, improving resource efficiency, and minimizing waste generation. The ability to produce polymers with enhanced properties using less material also leads to economic benefits in various applications, such as lightweight automotive components and improved packaging materials.

02 Novel catalyst compositions

Researchers have developed new metallocene catalyst compositions that incorporate various support materials, activators, and co-catalysts. These innovations improve catalyst activity, stability, and selectivity, leading to more efficient polymerization processes and the ability to produce tailored polymer structures.Expand Specific Solutions03 Polyolefin production advancements

Metallocene catalysts have significantly impacted polyolefin production, enabling the synthesis of polymers with unique properties and improved performance characteristics. These catalysts allow for the production of polyethylene and polypropylene with controlled tacticity, narrow molecular weight distribution, and enhanced copolymerization capabilities.Expand Specific Solutions04 Catalyst immobilization techniques

Advancements in metallocene catalyst immobilization techniques have led to improved heterogeneous catalysts for industrial-scale polymerization processes. These methods enhance catalyst stability, recyclability, and polymer morphology control, resulting in more efficient and cost-effective production of polyolefins.Expand Specific Solutions05 Specialized polymer applications

Metallocene catalysts enable the production of specialized polymers for advanced applications. These include high-performance elastomers, thermoplastic olefins with improved impact resistance, and polymers with tailored optical properties. The unique capabilities of metallocene catalysts have opened up new possibilities in various industries, including automotive, packaging, and medical devices.Expand Specific Solutions

Key Players in Metallocene Catalyst Industry

The metallocene catalyst technology for polypropylene production is in a mature growth stage, with a global market size estimated to exceed $100 billion by 2025. Major players like ExxonMobil, LyondellBasell, and LG Chem have commercialized metallocene-based polypropylene processes, indicating high technological readiness. The competitive landscape is characterized by ongoing innovation and patent activity among petrochemical giants and specialized catalyst companies such as Univation Technologies. Asian firms, particularly from China and Japan, are increasingly active in research and development, challenging the traditional dominance of Western companies in this field.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed advanced metallocene catalysts for polypropylene production, focusing on improving polymer properties and process efficiency. Their ACHIEVE™ Advanced Polypropylene technology utilizes single-site metallocene catalysts to produce polypropylene with enhanced clarity, impact strength, and stiffness[1]. The company's metallocene catalysts enable precise control over molecular weight distribution and comonomer incorporation, resulting in tailored polymer architectures. ExxonMobil's process innovations include gas-phase polymerization reactors optimized for metallocene catalysts, allowing for higher productivity and reduced energy consumption[2]. They have also developed catalyst systems that can produce both isotactic and syndiotactic polypropylene, expanding the range of achievable material properties[3].

Strengths: Superior polymer properties, precise control over molecular structure, versatility in product range. Weaknesses: Higher catalyst costs, potential need for specialized equipment.

Borealis AG

Technical Solution: Borealis has pioneered the use of Ziegler-Natta and metallocene catalysts in their Borstar® technology platform for polypropylene production. Their metallocene-based process allows for the production of bimodal polypropylene with a wide range of molecular weights and improved mechanical properties[4]. Borealis has developed proprietary single-site metallocene catalysts that enable the production of highly isotactic polypropylene with narrow molecular weight distribution. Their technology incorporates a dual reactor system, combining loop and gas-phase reactors, to optimize the polymerization process for metallocene catalysts[5]. This approach results in polypropylene with enhanced transparency, impact resistance, and processing characteristics.

Strengths: Bimodal polymer production, excellent polymer properties, efficient reactor design. Weaknesses: Complex process control, higher initial investment costs.

Core Innovations in Metallocene Catalysis

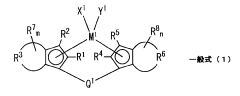

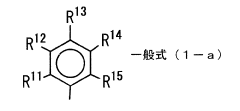

Metallocenes for the manufacture of polypropylene

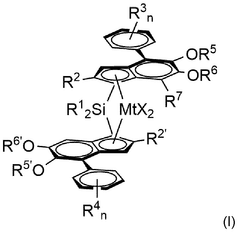

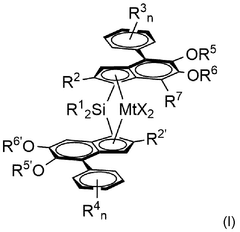

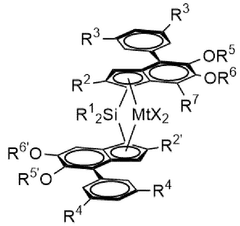

PatentWO2025016564A1

Innovation

- Development of new metallocene complexes with specific dioxo-substituents in both indene moieties, which provide high isoselectivity and high molecular weight without compromising productivity, especially in homopolymerization of propylene or copolymerization with ethylene.

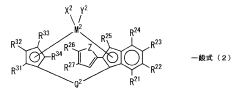

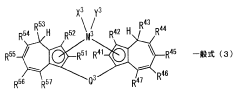

Polymerization catalyst using metallocene complex and production method of propylene polymer using the catalyst

PatentInactiveJP2012188603A

Innovation

- A polymerization catalyst system using a combination of two transition metal compounds with specific steric structures, along with an aluminum oxy compound, ionic compound, solid acid fine particles, and ion-exchange layered silicate, to control the coordination fields independently, allowing for balanced polymerization properties and enhanced stereoregularity.

Environmental Impact of Metallocene Catalysts

The introduction of metallocene catalysts in polypropylene production has significantly reduced the environmental impact of the manufacturing process. These catalysts offer superior control over polymer structure and properties, leading to more efficient production methods and reduced waste generation.

One of the primary environmental benefits of metallocene catalysts is their ability to produce polypropylene with enhanced physical properties at lower temperatures and pressures compared to traditional Ziegler-Natta catalysts. This results in reduced energy consumption during the polymerization process, contributing to lower greenhouse gas emissions and a smaller carbon footprint for polypropylene production facilities.

Metallocene catalysts also enable the production of polypropylene with improved strength-to-weight ratios, allowing for the manufacture of thinner and lighter products. This translates to reduced material usage and lower transportation costs, further decreasing the overall environmental impact throughout the product lifecycle.

The increased precision in polymer chain formation afforded by metallocene catalysts leads to a significant reduction in the generation of atactic polypropylene, a by-product that often requires disposal. This reduction in waste not only improves resource efficiency but also minimizes the need for landfill space and associated environmental concerns.

Furthermore, the enhanced properties of metallocene-catalyzed polypropylene often result in products with longer lifespans and improved recyclability. This contributes to a more circular economy approach, reducing the demand for virgin materials and decreasing the environmental burden associated with end-of-life disposal.

Metallocene catalysts also facilitate the production of polypropylene grades with improved barrier properties, which can lead to extended shelf life for packaged goods. This has the potential to reduce food waste and the associated environmental impacts of premature spoilage.

However, it is important to note that the production of metallocene catalysts themselves involves complex synthesis processes that may have their own environmental considerations. Ongoing research is focused on developing more sustainable methods for catalyst production and recovery to further enhance the overall environmental profile of metallocene-catalyzed polypropylene manufacturing.

In conclusion, while there are still areas for improvement, the adoption of metallocene catalysts in polypropylene production represents a significant step towards more environmentally friendly plastic manufacturing processes, offering benefits in energy efficiency, waste reduction, and product performance that contribute to a reduced ecological footprint.

One of the primary environmental benefits of metallocene catalysts is their ability to produce polypropylene with enhanced physical properties at lower temperatures and pressures compared to traditional Ziegler-Natta catalysts. This results in reduced energy consumption during the polymerization process, contributing to lower greenhouse gas emissions and a smaller carbon footprint for polypropylene production facilities.

Metallocene catalysts also enable the production of polypropylene with improved strength-to-weight ratios, allowing for the manufacture of thinner and lighter products. This translates to reduced material usage and lower transportation costs, further decreasing the overall environmental impact throughout the product lifecycle.

The increased precision in polymer chain formation afforded by metallocene catalysts leads to a significant reduction in the generation of atactic polypropylene, a by-product that often requires disposal. This reduction in waste not only improves resource efficiency but also minimizes the need for landfill space and associated environmental concerns.

Furthermore, the enhanced properties of metallocene-catalyzed polypropylene often result in products with longer lifespans and improved recyclability. This contributes to a more circular economy approach, reducing the demand for virgin materials and decreasing the environmental burden associated with end-of-life disposal.

Metallocene catalysts also facilitate the production of polypropylene grades with improved barrier properties, which can lead to extended shelf life for packaged goods. This has the potential to reduce food waste and the associated environmental impacts of premature spoilage.

However, it is important to note that the production of metallocene catalysts themselves involves complex synthesis processes that may have their own environmental considerations. Ongoing research is focused on developing more sustainable methods for catalyst production and recovery to further enhance the overall environmental profile of metallocene-catalyzed polypropylene manufacturing.

In conclusion, while there are still areas for improvement, the adoption of metallocene catalysts in polypropylene production represents a significant step towards more environmentally friendly plastic manufacturing processes, offering benefits in energy efficiency, waste reduction, and product performance that contribute to a reduced ecological footprint.

Economic Implications for Polypropylene Industry

The introduction of metallocene catalysts has had profound economic implications for the polypropylene industry. These catalysts have significantly improved production efficiency, leading to reduced manufacturing costs and increased profit margins for producers. The ability to create polypropylene with enhanced properties has opened up new market opportunities, particularly in high-performance applications such as automotive parts, medical devices, and packaging materials.

The improved control over polymer structure afforded by metallocene catalysts has resulted in higher-quality products with more consistent properties. This has led to increased customer satisfaction and brand loyalty, potentially commanding premium prices in certain market segments. Additionally, the ability to produce specialized grades of polypropylene has allowed manufacturers to differentiate their products, potentially capturing larger market shares in niche applications.

From a supply chain perspective, the use of metallocene catalysts has enabled more flexible production processes. Manufacturers can now more easily switch between different grades of polypropylene, allowing for better inventory management and faster response to market demands. This flexibility has the potential to reduce overall operational costs and improve supply chain efficiency.

The economic impact extends beyond individual companies to the broader polypropylene market. The increased production efficiency has contributed to a general downward pressure on polypropylene prices, benefiting end-users across various industries. This price competitiveness has also helped polypropylene maintain its market position against alternative materials, potentially expanding its overall market share in the plastics industry.

However, the adoption of metallocene catalyst technology also presents economic challenges. The initial investment required for implementing this technology can be substantial, potentially creating barriers to entry for smaller manufacturers. This could lead to industry consolidation, with larger players gaining competitive advantages through economies of scale.

Furthermore, the intellectual property landscape surrounding metallocene catalysts is complex, with numerous patents held by different companies. This situation may result in licensing costs or legal disputes, potentially impacting the economic dynamics of the industry. Companies must carefully navigate these intellectual property issues to fully capitalize on the benefits of metallocene catalyst technology.

In conclusion, the economic implications of metallocene catalysts in polypropylene production are far-reaching, affecting production costs, product quality, market opportunities, and industry structure. While presenting significant opportunities for growth and innovation, they also introduce new economic challenges that industry players must address to remain competitive in the evolving polypropylene market.

The improved control over polymer structure afforded by metallocene catalysts has resulted in higher-quality products with more consistent properties. This has led to increased customer satisfaction and brand loyalty, potentially commanding premium prices in certain market segments. Additionally, the ability to produce specialized grades of polypropylene has allowed manufacturers to differentiate their products, potentially capturing larger market shares in niche applications.

From a supply chain perspective, the use of metallocene catalysts has enabled more flexible production processes. Manufacturers can now more easily switch between different grades of polypropylene, allowing for better inventory management and faster response to market demands. This flexibility has the potential to reduce overall operational costs and improve supply chain efficiency.

The economic impact extends beyond individual companies to the broader polypropylene market. The increased production efficiency has contributed to a general downward pressure on polypropylene prices, benefiting end-users across various industries. This price competitiveness has also helped polypropylene maintain its market position against alternative materials, potentially expanding its overall market share in the plastics industry.

However, the adoption of metallocene catalyst technology also presents economic challenges. The initial investment required for implementing this technology can be substantial, potentially creating barriers to entry for smaller manufacturers. This could lead to industry consolidation, with larger players gaining competitive advantages through economies of scale.

Furthermore, the intellectual property landscape surrounding metallocene catalysts is complex, with numerous patents held by different companies. This situation may result in licensing costs or legal disputes, potentially impacting the economic dynamics of the industry. Companies must carefully navigate these intellectual property issues to fully capitalize on the benefits of metallocene catalyst technology.

In conclusion, the economic implications of metallocene catalysts in polypropylene production are far-reaching, affecting production costs, product quality, market opportunities, and industry structure. While presenting significant opportunities for growth and innovation, they also introduce new economic challenges that industry players must address to remain competitive in the evolving polypropylene market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!