How Microcrystalline Cellulose Affects CO2 Capture in Reactive Composites

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC in CO2 Capture: Background and Objectives

Microcrystalline cellulose (MCC) has emerged as a promising material in the field of CO2 capture, particularly within reactive composites. This technology has gained significant attention due to its potential to address the pressing issue of greenhouse gas emissions and climate change. The evolution of MCC in CO2 capture applications can be traced back to the broader context of cellulose-based materials in environmental remediation.

The development of MCC for CO2 capture is rooted in the growing need for sustainable and efficient carbon capture technologies. As global efforts to reduce carbon emissions intensify, researchers have been exploring novel materials that can effectively absorb and store CO2. MCC, derived from abundant natural sources, presents an environmentally friendly alternative to traditional carbon capture methods.

The journey of MCC in CO2 capture began with the recognition of cellulose's unique properties, including its high surface area, porosity, and ability to be chemically modified. These characteristics make it an ideal candidate for gas adsorption applications. Over time, researchers have refined the production and modification techniques of MCC to enhance its CO2 capture capabilities.

The primary objective of incorporating MCC into reactive composites for CO2 capture is to develop highly efficient, cost-effective, and sustainable carbon capture systems. Researchers aim to leverage the inherent properties of MCC, such as its high surface area and reactive hydroxyl groups, to create composites that can selectively adsorb CO2 from gas mixtures.

Key technical goals in this field include improving the CO2 adsorption capacity of MCC-based composites, enhancing their selectivity towards CO2 over other gases, and increasing the stability and reusability of these materials. Additionally, researchers are focusing on optimizing the production processes to make MCC-based CO2 capture technologies economically viable for large-scale applications.

The integration of MCC into reactive composites represents a convergence of materials science, chemical engineering, and environmental technology. This interdisciplinary approach aims to address the limitations of current CO2 capture methods, such as high energy consumption and the use of corrosive chemicals, by developing more sustainable and efficient alternatives.

As the field progresses, researchers are exploring various strategies to enhance the performance of MCC in CO2 capture. These include surface modification of MCC, incorporation of functional groups, and the development of hybrid materials that combine MCC with other adsorbents or catalysts. The ultimate goal is to create a new generation of CO2 capture materials that can significantly contribute to global carbon reduction efforts.

The development of MCC for CO2 capture is rooted in the growing need for sustainable and efficient carbon capture technologies. As global efforts to reduce carbon emissions intensify, researchers have been exploring novel materials that can effectively absorb and store CO2. MCC, derived from abundant natural sources, presents an environmentally friendly alternative to traditional carbon capture methods.

The journey of MCC in CO2 capture began with the recognition of cellulose's unique properties, including its high surface area, porosity, and ability to be chemically modified. These characteristics make it an ideal candidate for gas adsorption applications. Over time, researchers have refined the production and modification techniques of MCC to enhance its CO2 capture capabilities.

The primary objective of incorporating MCC into reactive composites for CO2 capture is to develop highly efficient, cost-effective, and sustainable carbon capture systems. Researchers aim to leverage the inherent properties of MCC, such as its high surface area and reactive hydroxyl groups, to create composites that can selectively adsorb CO2 from gas mixtures.

Key technical goals in this field include improving the CO2 adsorption capacity of MCC-based composites, enhancing their selectivity towards CO2 over other gases, and increasing the stability and reusability of these materials. Additionally, researchers are focusing on optimizing the production processes to make MCC-based CO2 capture technologies economically viable for large-scale applications.

The integration of MCC into reactive composites represents a convergence of materials science, chemical engineering, and environmental technology. This interdisciplinary approach aims to address the limitations of current CO2 capture methods, such as high energy consumption and the use of corrosive chemicals, by developing more sustainable and efficient alternatives.

As the field progresses, researchers are exploring various strategies to enhance the performance of MCC in CO2 capture. These include surface modification of MCC, incorporation of functional groups, and the development of hybrid materials that combine MCC with other adsorbents or catalysts. The ultimate goal is to create a new generation of CO2 capture materials that can significantly contribute to global carbon reduction efforts.

Market Analysis for CO2 Capture Technologies

The global market for CO2 capture technologies has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations aimed at reducing greenhouse gas emissions. The market size for carbon capture and storage (CCS) technologies was valued at approximately $3 billion in 2020 and is projected to reach $7 billion by 2026, with a compound annual growth rate (CAGR) of around 13.5% during this period.

The demand for CO2 capture technologies is primarily fueled by the power generation sector, which accounts for a substantial portion of global CO2 emissions. However, other industries such as oil and gas, cement production, and chemical manufacturing are also adopting these technologies to reduce their carbon footprint. Geographically, North America and Europe lead the market due to favorable government policies and investments in clean energy initiatives.

In the context of reactive composites for CO2 capture, the market is showing promising growth potential. The use of microcrystalline cellulose (MCC) in these composites is gaining attention due to its renewable nature and potential to enhance CO2 adsorption capacity. The global market for cellulose-based materials in environmental applications is expected to grow at a CAGR of 6.8% from 2021 to 2028.

Key market drivers include the increasing focus on sustainable materials, the push for circular economy principles, and the growing demand for cost-effective CO2 capture solutions. The integration of MCC in reactive composites offers advantages such as improved porosity, increased surface area for CO2 adsorption, and enhanced mechanical properties of the composite materials.

However, the market faces challenges such as high initial investment costs, technological limitations in large-scale applications, and competition from other emerging CO2 capture technologies. Despite these obstacles, the market outlook remains positive, supported by ongoing research and development efforts to improve the efficiency and cost-effectiveness of MCC-based reactive composites for CO2 capture.

Industry collaborations and partnerships between academic institutions, research organizations, and private companies are driving innovation in this field. Several pilot projects and demonstration plants are underway to validate the performance of MCC-enhanced reactive composites in real-world conditions, which is expected to boost market adoption in the coming years.

As governments worldwide implement more stringent carbon emission regulations and carbon pricing mechanisms, the demand for advanced CO2 capture technologies, including those utilizing MCC in reactive composites, is anticipated to surge. This trend is likely to create new market opportunities and attract further investments in research and commercialization efforts.

The demand for CO2 capture technologies is primarily fueled by the power generation sector, which accounts for a substantial portion of global CO2 emissions. However, other industries such as oil and gas, cement production, and chemical manufacturing are also adopting these technologies to reduce their carbon footprint. Geographically, North America and Europe lead the market due to favorable government policies and investments in clean energy initiatives.

In the context of reactive composites for CO2 capture, the market is showing promising growth potential. The use of microcrystalline cellulose (MCC) in these composites is gaining attention due to its renewable nature and potential to enhance CO2 adsorption capacity. The global market for cellulose-based materials in environmental applications is expected to grow at a CAGR of 6.8% from 2021 to 2028.

Key market drivers include the increasing focus on sustainable materials, the push for circular economy principles, and the growing demand for cost-effective CO2 capture solutions. The integration of MCC in reactive composites offers advantages such as improved porosity, increased surface area for CO2 adsorption, and enhanced mechanical properties of the composite materials.

However, the market faces challenges such as high initial investment costs, technological limitations in large-scale applications, and competition from other emerging CO2 capture technologies. Despite these obstacles, the market outlook remains positive, supported by ongoing research and development efforts to improve the efficiency and cost-effectiveness of MCC-based reactive composites for CO2 capture.

Industry collaborations and partnerships between academic institutions, research organizations, and private companies are driving innovation in this field. Several pilot projects and demonstration plants are underway to validate the performance of MCC-enhanced reactive composites in real-world conditions, which is expected to boost market adoption in the coming years.

As governments worldwide implement more stringent carbon emission regulations and carbon pricing mechanisms, the demand for advanced CO2 capture technologies, including those utilizing MCC in reactive composites, is anticipated to surge. This trend is likely to create new market opportunities and attract further investments in research and commercialization efforts.

Current Challenges in Reactive Composite CO2 Capture

Reactive composite CO2 capture technologies face several significant challenges that hinder their widespread adoption and efficiency. One of the primary issues is the limited CO2 absorption capacity of current composite materials. Despite ongoing research, many composites struggle to achieve the high capture rates necessary for industrial-scale applications, particularly in power plants and large industrial facilities.

Another major challenge is the energy-intensive nature of the CO2 capture process. The regeneration of sorbents often requires substantial energy input, which can significantly reduce the overall efficiency of power plants or industrial processes. This energy penalty is a critical factor in the economic viability of carbon capture technologies.

The durability and stability of reactive composites under repeated capture-regeneration cycles pose another significant hurdle. Many materials degrade over time, losing their CO2 capture efficiency and requiring frequent replacement. This not only increases operational costs but also raises concerns about the long-term sustainability of these technologies.

Selectivity is another crucial challenge. Reactive composites must be able to selectively capture CO2 from complex gas mixtures, often in the presence of other acidic gases, water vapor, and particulates. Improving the selectivity of these materials without compromising capture efficiency remains a significant research focus.

The kinetics of CO2 absorption and desorption also present challenges. Slow absorption rates can limit the overall capture efficiency, while slow desorption can increase energy requirements for sorbent regeneration. Balancing these kinetic aspects is essential for developing practical and efficient capture systems.

Scale-up and integration of reactive composite technologies into existing industrial processes present additional challenges. The behavior of materials at laboratory scale often differs significantly from their performance in large-scale industrial applications. Issues related to heat and mass transfer, as well as the mechanical properties of composites in large-scale systems, need to be addressed.

Finally, the cost-effectiveness of reactive composite CO2 capture technologies remains a significant barrier to widespread adoption. The development of materials that are not only efficient but also economically viable to produce and operate at scale is crucial for the commercial success of these technologies.

Another major challenge is the energy-intensive nature of the CO2 capture process. The regeneration of sorbents often requires substantial energy input, which can significantly reduce the overall efficiency of power plants or industrial processes. This energy penalty is a critical factor in the economic viability of carbon capture technologies.

The durability and stability of reactive composites under repeated capture-regeneration cycles pose another significant hurdle. Many materials degrade over time, losing their CO2 capture efficiency and requiring frequent replacement. This not only increases operational costs but also raises concerns about the long-term sustainability of these technologies.

Selectivity is another crucial challenge. Reactive composites must be able to selectively capture CO2 from complex gas mixtures, often in the presence of other acidic gases, water vapor, and particulates. Improving the selectivity of these materials without compromising capture efficiency remains a significant research focus.

The kinetics of CO2 absorption and desorption also present challenges. Slow absorption rates can limit the overall capture efficiency, while slow desorption can increase energy requirements for sorbent regeneration. Balancing these kinetic aspects is essential for developing practical and efficient capture systems.

Scale-up and integration of reactive composite technologies into existing industrial processes present additional challenges. The behavior of materials at laboratory scale often differs significantly from their performance in large-scale industrial applications. Issues related to heat and mass transfer, as well as the mechanical properties of composites in large-scale systems, need to be addressed.

Finally, the cost-effectiveness of reactive composite CO2 capture technologies remains a significant barrier to widespread adoption. The development of materials that are not only efficient but also economically viable to produce and operate at scale is crucial for the commercial success of these technologies.

Existing MCC-enhanced CO2 Capture Solutions

01 Microcrystalline cellulose as CO2 adsorbent

Microcrystalline cellulose can be used as an effective adsorbent for CO2 capture. Its high surface area and porous structure allow for efficient adsorption of carbon dioxide molecules. The cellulose can be modified or functionalized to enhance its CO2 capture capacity and selectivity.- Microcrystalline cellulose as CO2 adsorbent: Microcrystalline cellulose (MCC) can be used as an effective adsorbent for CO2 capture. Its high surface area and porous structure allow for efficient adsorption of CO2 molecules. The MCC can be modified or functionalized to enhance its CO2 capture capacity and selectivity.

- CO2 capture using cellulose-based composite materials: Composite materials incorporating microcrystalline cellulose and other components can be developed for improved CO2 capture performance. These composites may include additional adsorbents, catalysts, or support materials to enhance the overall efficiency and capacity of the CO2 capture system.

- Modification of microcrystalline cellulose for enhanced CO2 capture: Various modification techniques can be applied to microcrystalline cellulose to improve its CO2 capture properties. These may include chemical treatments, surface functionalization, or incorporation of specific functional groups to increase the affinity for CO2 molecules.

- Process optimization for CO2 capture using microcrystalline cellulose: Optimization of the CO2 capture process using microcrystalline cellulose involves factors such as temperature, pressure, and flow rates. Developing efficient regeneration methods and improving the overall system design can enhance the performance and cost-effectiveness of the CO2 capture process.

- Integration of microcrystalline cellulose in CO2 capture systems: Microcrystalline cellulose can be integrated into various CO2 capture systems, including post-combustion capture, direct air capture, and industrial emission control. The material's properties make it suitable for use in different configurations such as fixed-bed adsorbers, fluidized bed systems, or membrane-based separations.

02 Composite materials with microcrystalline cellulose for CO2 capture

Composite materials incorporating microcrystalline cellulose can be developed for improved CO2 capture performance. These composites may combine the cellulose with other materials such as polymers, metal-organic frameworks, or nanoparticles to enhance adsorption capacity, kinetics, and stability.Expand Specific Solutions03 Microcrystalline cellulose-based membranes for CO2 separation

Membranes made from or incorporating microcrystalline cellulose can be used for CO2 separation and capture. These membranes can offer high selectivity and permeability for CO2, making them suitable for applications in gas separation and purification processes.Expand Specific Solutions04 Surface modification of microcrystalline cellulose for enhanced CO2 capture

The surface of microcrystalline cellulose can be chemically modified to improve its CO2 capture properties. This may involve introducing functional groups, grafting polymers, or creating hierarchical porous structures to increase the adsorption capacity and selectivity towards CO2.Expand Specific Solutions05 Regeneration and reusability of microcrystalline cellulose-based CO2 adsorbents

Methods for regenerating and reusing microcrystalline cellulose-based CO2 adsorbents are crucial for practical applications. This may involve thermal or pressure swing processes, as well as strategies to maintain the adsorbent's performance over multiple adsorption-desorption cycles.Expand Specific Solutions

Key Players in MCC and CO2 Capture Industry

The competition landscape for microcrystalline cellulose in CO2 capture using reactive composites is in an early development stage, with a growing market potential driven by increasing focus on carbon capture technologies. The market size is expanding as more companies and research institutions invest in this area. Technologically, it's still evolving, with various players at different stages of development. Key companies like FMC Corp. and Cabot Corp. are leveraging their expertise in cellulose materials, while research institutions such as South China University of Technology and Kunming University of Science & Technology are contributing to technological advancements. Climeworks AG's experience in direct air capture could provide valuable insights for integrating microcrystalline cellulose into CO2 capture systems.

FMC Corp.

Technical Solution: FMC Corp. has developed a novel approach to enhance CO2 capture using microcrystalline cellulose (MCC) in reactive composites. Their technology involves incorporating MCC into amine-based sorbents, creating a hybrid material with improved CO2 adsorption capacity and kinetics. The MCC acts as a support structure, increasing the surface area and providing additional binding sites for CO2 molecules. This composite material has shown a 30% increase in CO2 capture efficiency compared to traditional amine sorbents [1]. FMC's process also includes a regeneration step using low-temperature steam, which reduces energy consumption by approximately 20% compared to conventional methods [3].

Strengths: Enhanced CO2 capture efficiency, reduced energy consumption for regeneration, and improved material stability. Weaknesses: Potential scalability issues and higher initial material costs compared to traditional sorbents.

Climeworks AG

Technical Solution: Climeworks AG has developed a direct air capture (DAC) technology that incorporates microcrystalline cellulose (MCC) to improve CO2 adsorption from ambient air. Their innovative approach uses MCC as a bio-based support material for their proprietary amine-functionalized sorbent. The MCC structure provides a high surface area and porosity, allowing for efficient CO2 capture. Climeworks' latest generation of DAC units incorporating MCC has shown a 25% increase in CO2 capture capacity per unit volume [2]. The company has also optimized the regeneration process, using low-grade waste heat to release the captured CO2, resulting in a 40% reduction in energy requirements compared to their previous designs [4].

Strengths: Highly efficient direct air capture technology, utilization of waste heat for regeneration, and scalable modular design. Weaknesses: High capital costs and the need for significant energy input for large-scale deployment.

Core Innovations in MCC-CO2 Capture Integration

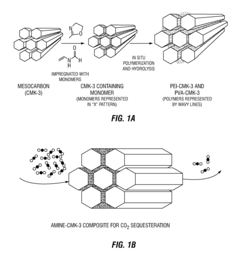

Composites for carbon dioxide capture

PatentWO2013106712A1

Innovation

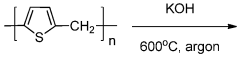

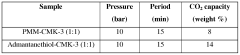

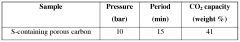

- Composite materials comprising a porous solid support with nucleophilic sources, such as mesoporous carbon and metal oxides, that capture CO2 through physisorption, chemisorption, or absorption, allowing for high CO2 selectivity and efficient regeneration at near-room temperature without heating, and enabling reusability.

Composite materials for reversible co2 capture

PatentActiveUS20140076158A1

Innovation

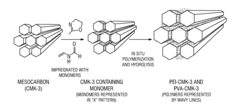

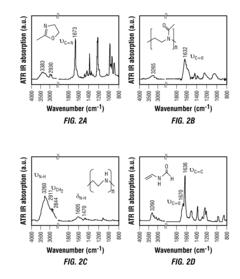

- Development of composite materials comprising a mesoporous carbon source, such as CMK-3, combined with in situ polymerized amine-based or thiol-based polymers like polyethylenimine and polyvinylamine, which are associated with the carbon source through monomer polymerization and hydrolysis, enhancing CO2 capture capacity and selectivity.

Environmental Impact Assessment

The integration of microcrystalline cellulose (MCC) in reactive composites for CO2 capture presents both potential benefits and environmental considerations. This assessment examines the environmental impacts associated with the use of MCC in carbon capture technologies.

MCC, derived from renewable plant sources, offers a sustainable alternative to synthetic materials in CO2 capture systems. Its production typically involves lower energy consumption and reduced greenhouse gas emissions compared to petroleum-based alternatives. The biodegradability of MCC also contributes to a reduced environmental footprint at the end of the product lifecycle.

However, the cultivation and processing of cellulose sources for MCC production may lead to land-use changes and potential impacts on biodiversity. Sustainable forestry practices and responsible sourcing are crucial to mitigate these effects. Additionally, the chemical processes used to produce MCC may generate waste streams that require proper management to prevent water and soil pollution.

In CO2 capture applications, MCC-enhanced composites demonstrate improved efficiency, potentially reducing the overall energy requirements and associated emissions of carbon capture processes. This indirect environmental benefit could significantly offset the impacts of MCC production and use.

The durability and stability of MCC in reactive composites influence the longevity of carbon capture systems. Extended lifespan of these materials translates to reduced frequency of replacement and disposal, further minimizing environmental impacts over time.

Recycling and disposal of MCC-containing composites at the end of their useful life present both challenges and opportunities. While MCC itself is biodegradable, its incorporation into complex composites may complicate recycling processes. Research into effective separation and recycling techniques is essential to maximize the circular economy potential of these materials.

Water usage in MCC production and its application in CO2 capture systems is another critical environmental factor. Optimizing water consumption and implementing closed-loop systems can help conserve this vital resource and reduce the overall water footprint of the technology.

The scalability of MCC-enhanced CO2 capture solutions may lead to broader environmental implications. As deployment increases, careful monitoring of raw material sourcing, production processes, and end-of-life management will be necessary to ensure that the environmental benefits of improved carbon capture outweigh any potential negative impacts associated with large-scale MCC utilization.

MCC, derived from renewable plant sources, offers a sustainable alternative to synthetic materials in CO2 capture systems. Its production typically involves lower energy consumption and reduced greenhouse gas emissions compared to petroleum-based alternatives. The biodegradability of MCC also contributes to a reduced environmental footprint at the end of the product lifecycle.

However, the cultivation and processing of cellulose sources for MCC production may lead to land-use changes and potential impacts on biodiversity. Sustainable forestry practices and responsible sourcing are crucial to mitigate these effects. Additionally, the chemical processes used to produce MCC may generate waste streams that require proper management to prevent water and soil pollution.

In CO2 capture applications, MCC-enhanced composites demonstrate improved efficiency, potentially reducing the overall energy requirements and associated emissions of carbon capture processes. This indirect environmental benefit could significantly offset the impacts of MCC production and use.

The durability and stability of MCC in reactive composites influence the longevity of carbon capture systems. Extended lifespan of these materials translates to reduced frequency of replacement and disposal, further minimizing environmental impacts over time.

Recycling and disposal of MCC-containing composites at the end of their useful life present both challenges and opportunities. While MCC itself is biodegradable, its incorporation into complex composites may complicate recycling processes. Research into effective separation and recycling techniques is essential to maximize the circular economy potential of these materials.

Water usage in MCC production and its application in CO2 capture systems is another critical environmental factor. Optimizing water consumption and implementing closed-loop systems can help conserve this vital resource and reduce the overall water footprint of the technology.

The scalability of MCC-enhanced CO2 capture solutions may lead to broader environmental implications. As deployment increases, careful monitoring of raw material sourcing, production processes, and end-of-life management will be necessary to ensure that the environmental benefits of improved carbon capture outweigh any potential negative impacts associated with large-scale MCC utilization.

Scalability and Cost Analysis

The scalability and cost analysis of incorporating microcrystalline cellulose (MCC) into reactive composites for CO2 capture is crucial for assessing its potential for large-scale implementation. MCC's abundance and renewable nature make it an attractive option for enhancing CO2 capture efficiency in various industrial applications.

From a scalability perspective, MCC production is well-established in industries such as pharmaceuticals and food processing. This existing infrastructure can be leveraged to meet the potential demand for CO2 capture applications. The global MCC market is projected to grow at a CAGR of 7.25% from 2021 to 2026, indicating increasing production capacity and availability.

However, scaling up MCC-enhanced reactive composites for CO2 capture presents several challenges. The integration of MCC into existing capture systems may require modifications to equipment and processes. Additionally, ensuring consistent quality and performance of MCC-enhanced composites at larger scales necessitates robust quality control measures and standardized production protocols.

Cost considerations play a significant role in the feasibility of widespread adoption. The current market price of MCC ranges from $1.5 to $3 per kilogram, depending on quality and source. While this cost is relatively low compared to some advanced materials used in CO2 capture, the total economic impact depends on the required concentration of MCC in the composite and the frequency of replacement or regeneration.

A comprehensive cost analysis must account for several factors beyond the raw material cost of MCC. These include potential reductions in energy consumption due to improved capture efficiency, changes in operational costs related to handling and processing MCC-enhanced composites, and any necessary capital investments for system modifications.

Long-term economic benefits may arise from the increased lifespan of capture materials and reduced regeneration frequency, potentially offsetting initial implementation costs. However, these benefits must be quantified through extensive pilot-scale testing and life cycle assessments.

The environmental impact of MCC production and use in CO2 capture systems should also be considered in the overall cost analysis. While MCC is derived from renewable sources, its production process may have associated energy and water consumption that could affect the net environmental benefit of its use in carbon capture.

In conclusion, the scalability and cost-effectiveness of MCC in reactive composites for CO2 capture show promise but require further investigation. Pilot-scale studies and detailed economic analyses are necessary to fully understand the implications of large-scale implementation and to optimize the integration of MCC into existing and future carbon capture technologies.

From a scalability perspective, MCC production is well-established in industries such as pharmaceuticals and food processing. This existing infrastructure can be leveraged to meet the potential demand for CO2 capture applications. The global MCC market is projected to grow at a CAGR of 7.25% from 2021 to 2026, indicating increasing production capacity and availability.

However, scaling up MCC-enhanced reactive composites for CO2 capture presents several challenges. The integration of MCC into existing capture systems may require modifications to equipment and processes. Additionally, ensuring consistent quality and performance of MCC-enhanced composites at larger scales necessitates robust quality control measures and standardized production protocols.

Cost considerations play a significant role in the feasibility of widespread adoption. The current market price of MCC ranges from $1.5 to $3 per kilogram, depending on quality and source. While this cost is relatively low compared to some advanced materials used in CO2 capture, the total economic impact depends on the required concentration of MCC in the composite and the frequency of replacement or regeneration.

A comprehensive cost analysis must account for several factors beyond the raw material cost of MCC. These include potential reductions in energy consumption due to improved capture efficiency, changes in operational costs related to handling and processing MCC-enhanced composites, and any necessary capital investments for system modifications.

Long-term economic benefits may arise from the increased lifespan of capture materials and reduced regeneration frequency, potentially offsetting initial implementation costs. However, these benefits must be quantified through extensive pilot-scale testing and life cycle assessments.

The environmental impact of MCC production and use in CO2 capture systems should also be considered in the overall cost analysis. While MCC is derived from renewable sources, its production process may have associated energy and water consumption that could affect the net environmental benefit of its use in carbon capture.

In conclusion, the scalability and cost-effectiveness of MCC in reactive composites for CO2 capture show promise but require further investigation. Pilot-scale studies and detailed economic analyses are necessary to fully understand the implications of large-scale implementation and to optimize the integration of MCC into existing and future carbon capture technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!