Microcrystalline Cellulose as a Dispersing Agent in Ceramics Manufacturing

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellulose in Ceramics: Background and Objectives

Microcrystalline cellulose (MCC) has emerged as a promising dispersing agent in ceramics manufacturing, marking a significant advancement in the field. This natural, biodegradable polymer derived from cellulose has garnered attention due to its unique properties and potential to enhance ceramic production processes.

The use of cellulose in ceramics can be traced back to traditional pottery techniques, where plant fibers were often incorporated to improve the workability of clay. However, the application of MCC as a dispersing agent represents a modern, scientifically-driven approach to ceramic manufacturing.

The primary objective of this research is to explore the efficacy of MCC as a dispersing agent in ceramic production, with a focus on improving the dispersion of ceramic particles in suspensions. This investigation aims to address several key challenges in ceramic manufacturing, including the need for more environmentally friendly additives and the demand for enhanced control over ceramic particle distribution.

MCC's potential as a dispersing agent stems from its unique structural characteristics. Its high surface area, crystalline nature, and ability to form stable suspensions make it an ideal candidate for improving the rheological properties of ceramic slurries. By enhancing particle dispersion, MCC could potentially lead to more uniform ceramic bodies, reduced defects, and improved overall product quality.

The evolution of ceramic manufacturing techniques has been driven by the need for more precise control over material properties and production processes. Traditional dispersing agents, often synthetic and petroleum-based, have raised environmental concerns and may not meet the increasingly stringent sustainability requirements of modern industries. MCC, being a natural and renewable resource, aligns well with the growing trend towards eco-friendly manufacturing practices.

This research also aims to explore the broader implications of using MCC in ceramic production. Beyond its role as a dispersing agent, the integration of cellulose-based materials in ceramics opens up possibilities for creating novel composite materials with unique properties. Such innovations could potentially lead to new applications in fields ranging from construction to advanced electronics.

As the ceramics industry continues to evolve, driven by demands for higher performance materials and more sustainable production methods, the exploration of MCC as a dispersing agent represents a convergence of traditional materials science and modern green chemistry principles. This research seeks to contribute to this evolving landscape by providing insights into the fundamental mechanisms and practical applications of MCC in ceramic manufacturing processes.

The use of cellulose in ceramics can be traced back to traditional pottery techniques, where plant fibers were often incorporated to improve the workability of clay. However, the application of MCC as a dispersing agent represents a modern, scientifically-driven approach to ceramic manufacturing.

The primary objective of this research is to explore the efficacy of MCC as a dispersing agent in ceramic production, with a focus on improving the dispersion of ceramic particles in suspensions. This investigation aims to address several key challenges in ceramic manufacturing, including the need for more environmentally friendly additives and the demand for enhanced control over ceramic particle distribution.

MCC's potential as a dispersing agent stems from its unique structural characteristics. Its high surface area, crystalline nature, and ability to form stable suspensions make it an ideal candidate for improving the rheological properties of ceramic slurries. By enhancing particle dispersion, MCC could potentially lead to more uniform ceramic bodies, reduced defects, and improved overall product quality.

The evolution of ceramic manufacturing techniques has been driven by the need for more precise control over material properties and production processes. Traditional dispersing agents, often synthetic and petroleum-based, have raised environmental concerns and may not meet the increasingly stringent sustainability requirements of modern industries. MCC, being a natural and renewable resource, aligns well with the growing trend towards eco-friendly manufacturing practices.

This research also aims to explore the broader implications of using MCC in ceramic production. Beyond its role as a dispersing agent, the integration of cellulose-based materials in ceramics opens up possibilities for creating novel composite materials with unique properties. Such innovations could potentially lead to new applications in fields ranging from construction to advanced electronics.

As the ceramics industry continues to evolve, driven by demands for higher performance materials and more sustainable production methods, the exploration of MCC as a dispersing agent represents a convergence of traditional materials science and modern green chemistry principles. This research seeks to contribute to this evolving landscape by providing insights into the fundamental mechanisms and practical applications of MCC in ceramic manufacturing processes.

Market Analysis for Ceramic Dispersants

The global market for ceramic dispersants has been experiencing steady growth, driven by the increasing demand for advanced ceramics in various industries. The ceramic dispersant market is closely tied to the overall ceramics industry, which has seen significant expansion due to the rising use of ceramics in electronics, automotive, healthcare, and construction sectors.

Microcrystalline cellulose (MCC) as a dispersing agent in ceramics manufacturing represents a novel and eco-friendly approach that has garnered attention in recent years. The market potential for MCC in this application is substantial, as the ceramics industry continues to seek more sustainable and efficient production methods.

The ceramic dispersant market is primarily dominated by synthetic dispersants, such as polyacrylates and polycarboxylates. However, there is a growing trend towards bio-based and environmentally friendly alternatives, which positions MCC favorably in this evolving landscape. The global ceramic dispersant market was valued at approximately $600 million in 2020 and is projected to reach $900 million by 2026, growing at a CAGR of around 6.5%.

Key factors driving the demand for ceramic dispersants, including MCC, include the increasing use of advanced ceramics in 3D printing, the growing automotive industry's need for ceramic components, and the rising adoption of ceramics in medical applications. The Asia-Pacific region, particularly China and Japan, leads the market due to their robust ceramics manufacturing sectors.

The potential market for MCC as a ceramic dispersant is further bolstered by the global push towards sustainability and environmentally friendly manufacturing processes. As industries face stricter regulations on emissions and waste, bio-based dispersants like MCC offer a compelling alternative to traditional synthetic options.

However, the adoption of MCC faces challenges such as the need for extensive research to optimize its performance across various ceramic formulations and manufacturing processes. Additionally, the cost-effectiveness of MCC compared to established synthetic dispersants will play a crucial role in its market penetration.

In conclusion, the market analysis for ceramic dispersants, particularly focusing on MCC, reveals a promising opportunity. The growing demand for advanced ceramics, coupled with the shift towards sustainable manufacturing practices, creates a favorable environment for the development and adoption of MCC as a dispersing agent in ceramics manufacturing.

Microcrystalline cellulose (MCC) as a dispersing agent in ceramics manufacturing represents a novel and eco-friendly approach that has garnered attention in recent years. The market potential for MCC in this application is substantial, as the ceramics industry continues to seek more sustainable and efficient production methods.

The ceramic dispersant market is primarily dominated by synthetic dispersants, such as polyacrylates and polycarboxylates. However, there is a growing trend towards bio-based and environmentally friendly alternatives, which positions MCC favorably in this evolving landscape. The global ceramic dispersant market was valued at approximately $600 million in 2020 and is projected to reach $900 million by 2026, growing at a CAGR of around 6.5%.

Key factors driving the demand for ceramic dispersants, including MCC, include the increasing use of advanced ceramics in 3D printing, the growing automotive industry's need for ceramic components, and the rising adoption of ceramics in medical applications. The Asia-Pacific region, particularly China and Japan, leads the market due to their robust ceramics manufacturing sectors.

The potential market for MCC as a ceramic dispersant is further bolstered by the global push towards sustainability and environmentally friendly manufacturing processes. As industries face stricter regulations on emissions and waste, bio-based dispersants like MCC offer a compelling alternative to traditional synthetic options.

However, the adoption of MCC faces challenges such as the need for extensive research to optimize its performance across various ceramic formulations and manufacturing processes. Additionally, the cost-effectiveness of MCC compared to established synthetic dispersants will play a crucial role in its market penetration.

In conclusion, the market analysis for ceramic dispersants, particularly focusing on MCC, reveals a promising opportunity. The growing demand for advanced ceramics, coupled with the shift towards sustainable manufacturing practices, creates a favorable environment for the development and adoption of MCC as a dispersing agent in ceramics manufacturing.

Current Challenges in Ceramic Dispersion

The ceramic industry faces several significant challenges in achieving effective dispersion, which is crucial for producing high-quality ceramic products. One of the primary issues is the tendency of ceramic particles to agglomerate due to strong inter-particle forces, including van der Waals attractions and electrostatic interactions. This agglomeration can lead to inhomogeneous particle distribution, resulting in defects and reduced mechanical properties in the final ceramic products.

Another challenge is the difficulty in maintaining stable suspensions of ceramic particles in liquid media. The high specific surface area of ceramic powders often leads to rapid sedimentation, which can cause inconsistencies in the ceramic slurry and affect the uniformity of the final product. This issue is particularly pronounced when dealing with nanoscale ceramic particles, where the surface forces become even more dominant.

The selection of appropriate dispersing agents presents its own set of challenges. Traditional dispersants may not be effective for all types of ceramic materials, and finding a universal dispersant that works across various ceramic compositions remains elusive. Moreover, the effectiveness of dispersants can be highly sensitive to pH, temperature, and ionic strength of the suspension, requiring careful control of these parameters during the manufacturing process.

Environmental concerns and regulatory pressures add another layer of complexity to ceramic dispersion. Many conventional dispersants are petroleum-based and may pose environmental risks. There is a growing need for eco-friendly, biodegradable dispersants that can match or exceed the performance of traditional options while meeting stringent environmental standards.

The processing of advanced ceramics with complex compositions further complicates dispersion efforts. These materials often require precise control over particle size distribution and homogeneity to achieve desired properties. Achieving uniform dispersion becomes increasingly challenging as the complexity of the ceramic composition increases, particularly in multi-component systems.

Scalability of dispersion techniques from laboratory to industrial production scales presents additional hurdles. Methods that work well in small-scale experiments may not translate effectively to large-scale manufacturing processes, necessitating the development of robust and scalable dispersion technologies.

Lastly, the integration of new dispersing agents, such as microcrystalline cellulose, into existing ceramic manufacturing processes poses its own set of challenges. These include potential incompatibilities with current equipment, the need for process optimization, and the requirement for extensive testing to ensure that the new dispersant does not adversely affect the final ceramic properties or introduce unforeseen issues in downstream processing steps.

Another challenge is the difficulty in maintaining stable suspensions of ceramic particles in liquid media. The high specific surface area of ceramic powders often leads to rapid sedimentation, which can cause inconsistencies in the ceramic slurry and affect the uniformity of the final product. This issue is particularly pronounced when dealing with nanoscale ceramic particles, where the surface forces become even more dominant.

The selection of appropriate dispersing agents presents its own set of challenges. Traditional dispersants may not be effective for all types of ceramic materials, and finding a universal dispersant that works across various ceramic compositions remains elusive. Moreover, the effectiveness of dispersants can be highly sensitive to pH, temperature, and ionic strength of the suspension, requiring careful control of these parameters during the manufacturing process.

Environmental concerns and regulatory pressures add another layer of complexity to ceramic dispersion. Many conventional dispersants are petroleum-based and may pose environmental risks. There is a growing need for eco-friendly, biodegradable dispersants that can match or exceed the performance of traditional options while meeting stringent environmental standards.

The processing of advanced ceramics with complex compositions further complicates dispersion efforts. These materials often require precise control over particle size distribution and homogeneity to achieve desired properties. Achieving uniform dispersion becomes increasingly challenging as the complexity of the ceramic composition increases, particularly in multi-component systems.

Scalability of dispersion techniques from laboratory to industrial production scales presents additional hurdles. Methods that work well in small-scale experiments may not translate effectively to large-scale manufacturing processes, necessitating the development of robust and scalable dispersion technologies.

Lastly, the integration of new dispersing agents, such as microcrystalline cellulose, into existing ceramic manufacturing processes poses its own set of challenges. These include potential incompatibilities with current equipment, the need for process optimization, and the requirement for extensive testing to ensure that the new dispersant does not adversely affect the final ceramic properties or introduce unforeseen issues in downstream processing steps.

Microcrystalline Cellulose Dispersion Mechanisms

01 Dispersion methods for microcrystalline cellulose

Various methods are employed to disperse microcrystalline cellulose effectively. These include mechanical dispersion techniques such as high-shear mixing, ultrasonic treatment, and homogenization. Chemical methods involving the use of dispersing agents or surfactants are also utilized to improve the dispersion of microcrystalline cellulose in different mediums.- Dispersion methods for microcrystalline cellulose: Various methods are employed to disperse microcrystalline cellulose effectively. These include mechanical dispersion techniques such as high-shear mixing, ultrasonic treatment, and homogenization. Chemical methods involving the use of dispersing agents or surfactants are also utilized to improve the dispersion of microcrystalline cellulose in different mediums.

- Modification of microcrystalline cellulose for improved dispersion: Chemical modification of microcrystalline cellulose is performed to enhance its dispersibility. This includes surface modification techniques, grafting of hydrophilic or hydrophobic groups, and the creation of composite materials. These modifications aim to improve the compatibility of microcrystalline cellulose with various matrices and solvents.

- Formulation of microcrystalline cellulose dispersions for specific applications: Microcrystalline cellulose dispersions are formulated for use in various industries such as pharmaceuticals, food, cosmetics, and paper manufacturing. These formulations often involve the combination of microcrystalline cellulose with other ingredients to achieve desired properties such as stability, viscosity, and functionality in the final product.

- Stabilization of microcrystalline cellulose dispersions: Techniques are developed to stabilize microcrystalline cellulose dispersions and prevent aggregation or sedimentation. This includes the use of stabilizing agents, pH adjustment, and the optimization of particle size distribution. The goal is to maintain the dispersion's stability over time and under various environmental conditions.

- Characterization and quality control of microcrystalline cellulose dispersions: Methods for characterizing and controlling the quality of microcrystalline cellulose dispersions are developed. This includes techniques for measuring particle size, zeta potential, and rheological properties. Quality control procedures are implemented to ensure consistency and performance of the dispersions in various applications.

02 Modification of microcrystalline cellulose for improved dispersion

Chemical modification of microcrystalline cellulose can enhance its dispersibility. This includes surface modification techniques, grafting of hydrophilic or hydrophobic groups, and the creation of composite materials. These modifications alter the surface properties of microcrystalline cellulose, making it more compatible with various dispersion mediums.Expand Specific Solutions03 Use of additives to enhance microcrystalline cellulose dispersion

Various additives are used to improve the dispersion of microcrystalline cellulose. These include surfactants, stabilizers, and co-solvents. The selection of appropriate additives depends on the intended application and the properties of the dispersion medium. Some additives work by reducing surface tension, while others prevent agglomeration of cellulose particles.Expand Specific Solutions04 Application-specific dispersion techniques for microcrystalline cellulose

Different industries employ specialized dispersion techniques for microcrystalline cellulose based on their specific requirements. For example, in pharmaceutical applications, controlled dispersion is crucial for drug delivery systems. In the food industry, dispersion techniques focus on achieving uniform distribution without affecting taste or texture. The paper industry uses specific dispersion methods to enhance paper strength and quality.Expand Specific Solutions05 Characterization and quality control of dispersed microcrystalline cellulose

Various analytical techniques are used to characterize and control the quality of dispersed microcrystalline cellulose. These include particle size analysis, zeta potential measurements, rheological studies, and microscopy techniques. Quality control measures ensure consistent dispersion properties across different batches and applications, which is crucial for product performance and regulatory compliance.Expand Specific Solutions

Key Players in Ceramic Additives Industry

The research on microcrystalline cellulose as a dispersing agent in ceramics manufacturing is in an emerging stage, with growing market potential due to increasing demand for advanced ceramic materials. The global market for ceramic dispersants is expected to expand significantly in the coming years, driven by applications in various industries. While the technology is still developing, several key players are actively involved in research and development. Companies like FMC Corp., Henkel AG & Co. KGaA, and Nippon Paper Industries Co., Ltd. are leveraging their expertise in cellulose-based materials to explore innovative applications in ceramic manufacturing. The competitive landscape is diverse, with both established chemical companies and specialized materials firms contributing to advancements in this field.

FMC Corp.

Technical Solution: FMC Corp. has developed a proprietary microcrystalline cellulose (MCC) technology for use as a dispersing agent in ceramics manufacturing. Their MCC-based dispersant, known as Avicel®, is engineered to provide superior dispersion and stability in ceramic slurries. The company has optimized the particle size distribution and surface modification of MCC to enhance its performance in ceramic applications. FMC's research has shown that their MCC dispersant can improve the rheological properties of ceramic slurries, resulting in better flow characteristics and reduced sedimentation[1]. The company has also developed a patented process for producing MCC with controlled porosity, which allows for better interaction with ceramic particles and improved dispersion efficiency[2].

Strengths: Extensive experience in MCC production, proprietary technology for surface modification, and proven performance in ceramic applications. Weaknesses: May be more expensive than traditional dispersants, and potential limitations in high-temperature ceramic processes.

Nippon Paper Industries Co., Ltd.

Technical Solution: Nippon Paper Industries has developed an innovative approach to using microcrystalline cellulose (MCC) as a dispersing agent in ceramics manufacturing. Their research focuses on creating MCC with specific surface characteristics that enhance its dispersing capabilities in ceramic slurries. The company has patented a method for producing MCC with controlled aspect ratios and surface charges, which allows for better interaction with ceramic particles[3]. Nippon Paper's MCC dispersant has been shown to improve the stability of ceramic suspensions and reduce the viscosity of slurries, leading to better casting and forming processes. Their technology also incorporates a unique surface treatment that enhances the thermal stability of MCC, making it suitable for use in high-temperature ceramic applications[4]. The company has conducted extensive testing to demonstrate the effectiveness of their MCC dispersant in various ceramic systems, including porcelain, stoneware, and technical ceramics.

Strengths: Specialized MCC production for ceramic applications, improved thermal stability, and demonstrated effectiveness in various ceramic systems. Weaknesses: May require specific formulation adjustments for different ceramic compositions, and potential scalability challenges for large-scale production.

Innovations in Cellulose-based Ceramic Dispersants

Ultra-fine microcrystalline cellulose compositions and process

PatentInactiveUS6037380A

Innovation

- A process involving high-shear wet grinding of hydrolyzed cellulose wetcake with an attriting aid and optional protective colloid to produce microcrystalline cellulose compositions with up to 100% of particles less than 1 micron, ensuring colloidally stable dispersions that resist centrifugation and provide improved suspension and stabilization properties.

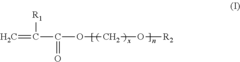

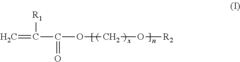

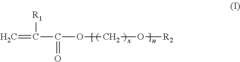

Dispersing agent, a method for manufacturing a dispersing agent, an ink, and a method for forming an electrically conductive pattern

PatentInactiveUS20160354744A1

Innovation

- A dispersing agent with a structural unit from a compound represented by a specific general formula, including an ionic group, is used to disperse metal particles, allowing for low volume resistivity in electrically conductive patterns by polymerizing a composition with a monomer that has an ionic group, ensuring effective solubility and adsorption onto metal particles, thereby preventing aggregation and facilitating curing.

Environmental Impact of Cellulose in Ceramics

The use of microcrystalline cellulose (MCC) as a dispersing agent in ceramics manufacturing has significant environmental implications. As a natural, biodegradable material derived from renewable sources, MCC offers a more sustainable alternative to traditional synthetic dispersants. This shift towards bio-based additives aligns with the growing emphasis on environmentally friendly production processes in the ceramics industry.

One of the primary environmental benefits of using MCC in ceramics manufacturing is the reduction of harmful chemical emissions. Unlike some synthetic dispersants that may release volatile organic compounds (VOCs) during processing, MCC is non-toxic and does not contribute to air pollution. This characteristic not only improves workplace safety but also minimizes the overall environmental footprint of ceramic production.

Furthermore, the biodegradability of MCC addresses concerns related to waste management in the ceramics industry. When ceramic products reach the end of their lifecycle, the presence of MCC as a dispersing agent ensures that the material can decompose naturally, reducing the burden on landfills and potentially facilitating recycling processes. This aspect is particularly crucial as the industry seeks to adopt more circular economy principles.

The production of MCC itself has a relatively low environmental impact compared to synthetic alternatives. Cellulose is abundant in nature and can be sourced from various plant materials, including agricultural by-products. This not only reduces dependence on non-renewable resources but also provides an opportunity to valorize waste streams from other industries, promoting a more integrated and sustainable approach to resource utilization.

Water consumption is another critical environmental factor in ceramics manufacturing. MCC's ability to improve the dispersion of ceramic particles in aqueous systems can lead to more efficient use of water in the production process. By enhancing the stability of ceramic slurries, MCC may reduce the need for excessive water addition, potentially resulting in energy savings during drying stages and decreased wastewater generation.

However, it is important to consider the potential environmental trade-offs associated with MCC use. The extraction and processing of cellulose to produce MCC require energy and resources, which must be factored into a comprehensive environmental assessment. Additionally, the sourcing of raw materials for MCC production should be carefully managed to prevent deforestation or competition with food crops.

In conclusion, the incorporation of MCC as a dispersing agent in ceramics manufacturing presents a promising avenue for enhancing the environmental sustainability of the industry. While challenges remain in optimizing its production and application, the potential benefits in terms of reduced emissions, improved waste management, and more efficient resource use make MCC an attractive option for environmentally conscious ceramic manufacturers.

One of the primary environmental benefits of using MCC in ceramics manufacturing is the reduction of harmful chemical emissions. Unlike some synthetic dispersants that may release volatile organic compounds (VOCs) during processing, MCC is non-toxic and does not contribute to air pollution. This characteristic not only improves workplace safety but also minimizes the overall environmental footprint of ceramic production.

Furthermore, the biodegradability of MCC addresses concerns related to waste management in the ceramics industry. When ceramic products reach the end of their lifecycle, the presence of MCC as a dispersing agent ensures that the material can decompose naturally, reducing the burden on landfills and potentially facilitating recycling processes. This aspect is particularly crucial as the industry seeks to adopt more circular economy principles.

The production of MCC itself has a relatively low environmental impact compared to synthetic alternatives. Cellulose is abundant in nature and can be sourced from various plant materials, including agricultural by-products. This not only reduces dependence on non-renewable resources but also provides an opportunity to valorize waste streams from other industries, promoting a more integrated and sustainable approach to resource utilization.

Water consumption is another critical environmental factor in ceramics manufacturing. MCC's ability to improve the dispersion of ceramic particles in aqueous systems can lead to more efficient use of water in the production process. By enhancing the stability of ceramic slurries, MCC may reduce the need for excessive water addition, potentially resulting in energy savings during drying stages and decreased wastewater generation.

However, it is important to consider the potential environmental trade-offs associated with MCC use. The extraction and processing of cellulose to produce MCC require energy and resources, which must be factored into a comprehensive environmental assessment. Additionally, the sourcing of raw materials for MCC production should be carefully managed to prevent deforestation or competition with food crops.

In conclusion, the incorporation of MCC as a dispersing agent in ceramics manufacturing presents a promising avenue for enhancing the environmental sustainability of the industry. While challenges remain in optimizing its production and application, the potential benefits in terms of reduced emissions, improved waste management, and more efficient resource use make MCC an attractive option for environmentally conscious ceramic manufacturers.

Scalability and Cost Analysis

The scalability and cost analysis of using microcrystalline cellulose (MCC) as a dispersing agent in ceramics manufacturing is crucial for assessing its potential for widespread industrial adoption. MCC offers several advantages in terms of scalability due to its natural abundance and renewable nature. As a cellulose-derived product, MCC can be sourced from various plant materials, including wood pulp, cotton, and agricultural residues, ensuring a stable and potentially expandable supply chain.

In terms of production scalability, MCC can be manufactured through well-established processes such as acid hydrolysis or enzymatic treatment of cellulose sources. These methods are amenable to large-scale production, allowing for the potential to meet increasing demand in the ceramics industry. However, the scalability of MCC production may be influenced by factors such as raw material availability, processing efficiency, and quality control measures.

From a cost perspective, the use of MCC as a dispersing agent in ceramics manufacturing presents a mixed picture. On one hand, the raw materials for MCC production are generally inexpensive and widely available, which can contribute to lower overall costs. Additionally, the renewable nature of MCC aligns with sustainability goals, potentially offering long-term cost benefits as environmental regulations become more stringent.

However, the processing and purification steps required to produce high-quality MCC suitable for ceramics applications can add significant costs. The level of purity and specific properties required for effective dispersion in ceramic slurries may necessitate additional processing steps, potentially increasing production expenses. Furthermore, the integration of MCC into existing ceramics manufacturing processes may require modifications to equipment or procedures, which could incur initial implementation costs.

When comparing MCC to traditional dispersing agents used in ceramics manufacturing, such as synthetic polymers or inorganic additives, the cost-effectiveness becomes a critical consideration. While MCC may offer environmental and performance advantages, its economic viability will depend on factors such as production efficiency, required dosage, and overall impact on the final ceramic product quality.

Scaling up the use of MCC in ceramics manufacturing also involves considerations of supply chain logistics and storage. As an organic material, MCC may require specific storage conditions to maintain its properties and prevent degradation, which could add to overall costs. However, its non-toxic nature may simplify handling and transportation requirements compared to some synthetic alternatives.

In conclusion, the scalability of MCC as a dispersing agent in ceramics manufacturing appears promising due to its renewable source and established production methods. However, the cost analysis reveals a complex interplay of factors, including raw material costs, processing requirements, and implementation expenses. Further research and optimization of production processes, as well as comprehensive cost-benefit analyses in specific ceramics applications, will be crucial in determining the long-term economic viability of MCC as a dispersing agent in large-scale ceramics manufacturing.

In terms of production scalability, MCC can be manufactured through well-established processes such as acid hydrolysis or enzymatic treatment of cellulose sources. These methods are amenable to large-scale production, allowing for the potential to meet increasing demand in the ceramics industry. However, the scalability of MCC production may be influenced by factors such as raw material availability, processing efficiency, and quality control measures.

From a cost perspective, the use of MCC as a dispersing agent in ceramics manufacturing presents a mixed picture. On one hand, the raw materials for MCC production are generally inexpensive and widely available, which can contribute to lower overall costs. Additionally, the renewable nature of MCC aligns with sustainability goals, potentially offering long-term cost benefits as environmental regulations become more stringent.

However, the processing and purification steps required to produce high-quality MCC suitable for ceramics applications can add significant costs. The level of purity and specific properties required for effective dispersion in ceramic slurries may necessitate additional processing steps, potentially increasing production expenses. Furthermore, the integration of MCC into existing ceramics manufacturing processes may require modifications to equipment or procedures, which could incur initial implementation costs.

When comparing MCC to traditional dispersing agents used in ceramics manufacturing, such as synthetic polymers or inorganic additives, the cost-effectiveness becomes a critical consideration. While MCC may offer environmental and performance advantages, its economic viability will depend on factors such as production efficiency, required dosage, and overall impact on the final ceramic product quality.

Scaling up the use of MCC in ceramics manufacturing also involves considerations of supply chain logistics and storage. As an organic material, MCC may require specific storage conditions to maintain its properties and prevent degradation, which could add to overall costs. However, its non-toxic nature may simplify handling and transportation requirements compared to some synthetic alternatives.

In conclusion, the scalability of MCC as a dispersing agent in ceramics manufacturing appears promising due to its renewable source and established production methods. However, the cost analysis reveals a complex interplay of factors, including raw material costs, processing requirements, and implementation expenses. Further research and optimization of production processes, as well as comprehensive cost-benefit analyses in specific ceramics applications, will be crucial in determining the long-term economic viability of MCC as a dispersing agent in large-scale ceramics manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!