Microcrystalline Cellulose in High-Performance Separation Techniques for Proteins

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC in Protein Separation: Background and Objectives

Microcrystalline cellulose (MCC) has emerged as a promising material in high-performance separation techniques for proteins, attracting significant attention in the fields of biotechnology and pharmaceutical research. The development of MCC-based separation methods represents a convergence of advancements in material science and protein purification technologies, addressing the growing demand for more efficient and cost-effective protein separation processes.

The evolution of protein separation techniques has been driven by the increasing complexity of biopharmaceutical products and the need for higher purity standards in research and industrial applications. Traditional methods such as gel filtration, ion exchange chromatography, and affinity chromatography have long been the mainstay of protein purification. However, these techniques often face limitations in terms of capacity, selectivity, and scalability, particularly when dealing with complex protein mixtures or large-scale production requirements.

MCC, derived from natural cellulose through controlled depolymerization, offers unique properties that make it an attractive candidate for protein separation applications. Its high surface area, mechanical strength, and chemical stability provide a robust platform for developing advanced separation media. The hydroxyl-rich surface of MCC allows for various chemical modifications, enabling the creation of tailored separation matrices with enhanced selectivity and capacity for specific protein targets.

The primary objective of research on MCC in high-performance separation techniques for proteins is to develop novel separation media that overcome the limitations of conventional methods. This includes improving separation efficiency, increasing binding capacity, enhancing selectivity, and reducing processing times and costs. Additionally, researchers aim to exploit the biocompatibility and biodegradability of MCC to create more environmentally friendly separation processes.

Another key goal is to explore the potential of MCC-based separation techniques in emerging areas such as personalized medicine and point-of-care diagnostics. The ability to rapidly and efficiently separate proteins from complex biological samples could revolutionize disease diagnosis and treatment monitoring, particularly in resource-limited settings.

Furthermore, the research seeks to understand the fundamental interactions between MCC and proteins at the molecular level. This knowledge is crucial for optimizing separation conditions and designing next-generation separation media with predictable performance characteristics. By elucidating these mechanisms, scientists aim to develop a rational design approach for MCC-based separation systems tailored to specific protein separation challenges.

As the field progresses, there is also a focus on integrating MCC-based separation techniques with other emerging technologies, such as microfluidics and nanotechnology. This interdisciplinary approach holds promise for creating highly efficient, miniaturized separation systems capable of handling complex protein mixtures with unprecedented precision and speed.

The evolution of protein separation techniques has been driven by the increasing complexity of biopharmaceutical products and the need for higher purity standards in research and industrial applications. Traditional methods such as gel filtration, ion exchange chromatography, and affinity chromatography have long been the mainstay of protein purification. However, these techniques often face limitations in terms of capacity, selectivity, and scalability, particularly when dealing with complex protein mixtures or large-scale production requirements.

MCC, derived from natural cellulose through controlled depolymerization, offers unique properties that make it an attractive candidate for protein separation applications. Its high surface area, mechanical strength, and chemical stability provide a robust platform for developing advanced separation media. The hydroxyl-rich surface of MCC allows for various chemical modifications, enabling the creation of tailored separation matrices with enhanced selectivity and capacity for specific protein targets.

The primary objective of research on MCC in high-performance separation techniques for proteins is to develop novel separation media that overcome the limitations of conventional methods. This includes improving separation efficiency, increasing binding capacity, enhancing selectivity, and reducing processing times and costs. Additionally, researchers aim to exploit the biocompatibility and biodegradability of MCC to create more environmentally friendly separation processes.

Another key goal is to explore the potential of MCC-based separation techniques in emerging areas such as personalized medicine and point-of-care diagnostics. The ability to rapidly and efficiently separate proteins from complex biological samples could revolutionize disease diagnosis and treatment monitoring, particularly in resource-limited settings.

Furthermore, the research seeks to understand the fundamental interactions between MCC and proteins at the molecular level. This knowledge is crucial for optimizing separation conditions and designing next-generation separation media with predictable performance characteristics. By elucidating these mechanisms, scientists aim to develop a rational design approach for MCC-based separation systems tailored to specific protein separation challenges.

As the field progresses, there is also a focus on integrating MCC-based separation techniques with other emerging technologies, such as microfluidics and nanotechnology. This interdisciplinary approach holds promise for creating highly efficient, miniaturized separation systems capable of handling complex protein mixtures with unprecedented precision and speed.

Market Analysis for High-Performance Protein Separation

The market for high-performance protein separation techniques is experiencing significant growth, driven by advancements in biotechnology, pharmaceuticals, and life sciences research. The global protein separation and purification market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily fueled by the increasing demand for purified proteins in various applications, including drug development, diagnostics, and academic research.

Microcrystalline cellulose (MCC) has emerged as a promising material in high-performance separation techniques for proteins, attracting attention from both industry and academia. The unique properties of MCC, such as its high surface area, mechanical strength, and biocompatibility, make it an excellent candidate for protein separation applications. As a result, the market for MCC-based separation technologies is expected to grow rapidly within the broader protein separation market.

The pharmaceutical and biotechnology sectors are the largest consumers of high-performance protein separation techniques, accounting for a significant portion of the market share. These industries rely heavily on efficient protein separation methods for drug discovery, development, and production processes. The increasing focus on personalized medicine and biopharmaceuticals is further driving the demand for advanced separation technologies, including those utilizing MCC.

Academic and research institutions also contribute substantially to the market demand, as they require high-performance separation techniques for various studies in proteomics, genomics, and other life science fields. The food and beverage industry is another growing segment, particularly in the development of functional foods and nutraceuticals, where protein separation plays a crucial role.

Geographically, North America and Europe dominate the market for high-performance protein separation techniques, owing to their well-established biotechnology and pharmaceutical industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in life sciences research and the rapid expansion of the biopharmaceutical sector in countries like China and India.

The market is characterized by intense competition among key players, including major life sciences companies and specialized separation technology providers. These companies are investing heavily in research and development to improve existing technologies and introduce innovative solutions, such as MCC-based separation techniques. Collaborations between academic institutions and industry partners are also becoming more common, accelerating the development and commercialization of novel separation technologies.

As environmental concerns grow, there is an increasing demand for sustainable and eco-friendly separation techniques. MCC, being a renewable and biodegradable material, aligns well with this trend, potentially giving it a competitive edge in the market. This shift towards green technologies is expected to create new opportunities for MCC-based separation methods in the coming years.

Microcrystalline cellulose (MCC) has emerged as a promising material in high-performance separation techniques for proteins, attracting attention from both industry and academia. The unique properties of MCC, such as its high surface area, mechanical strength, and biocompatibility, make it an excellent candidate for protein separation applications. As a result, the market for MCC-based separation technologies is expected to grow rapidly within the broader protein separation market.

The pharmaceutical and biotechnology sectors are the largest consumers of high-performance protein separation techniques, accounting for a significant portion of the market share. These industries rely heavily on efficient protein separation methods for drug discovery, development, and production processes. The increasing focus on personalized medicine and biopharmaceuticals is further driving the demand for advanced separation technologies, including those utilizing MCC.

Academic and research institutions also contribute substantially to the market demand, as they require high-performance separation techniques for various studies in proteomics, genomics, and other life science fields. The food and beverage industry is another growing segment, particularly in the development of functional foods and nutraceuticals, where protein separation plays a crucial role.

Geographically, North America and Europe dominate the market for high-performance protein separation techniques, owing to their well-established biotechnology and pharmaceutical industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in life sciences research and the rapid expansion of the biopharmaceutical sector in countries like China and India.

The market is characterized by intense competition among key players, including major life sciences companies and specialized separation technology providers. These companies are investing heavily in research and development to improve existing technologies and introduce innovative solutions, such as MCC-based separation techniques. Collaborations between academic institutions and industry partners are also becoming more common, accelerating the development and commercialization of novel separation technologies.

As environmental concerns grow, there is an increasing demand for sustainable and eco-friendly separation techniques. MCC, being a renewable and biodegradable material, aligns well with this trend, potentially giving it a competitive edge in the market. This shift towards green technologies is expected to create new opportunities for MCC-based separation methods in the coming years.

Current Challenges in MCC-Based Protein Separation

Despite the promising potential of microcrystalline cellulose (MCC) in protein separation techniques, several challenges persist in its application. One of the primary issues is the variability in MCC quality and consistency across different batches and sources. This inconsistency can lead to unpredictable separation performance and reduced reproducibility of results, which is critical in analytical and preparative protein separations.

Another significant challenge is the limited understanding of the interaction mechanisms between MCC and various protein types. While MCC has shown effectiveness in separating certain proteins, its behavior with a broader range of protein molecules, especially those with complex structures or post-translational modifications, remains unclear. This knowledge gap hinders the optimization of MCC-based separation protocols for diverse protein samples.

The scalability of MCC-based separation techniques also presents a considerable hurdle. While MCC performs well in small-scale laboratory settings, translating these successes to industrial-scale protein purification processes has proven challenging. Issues such as column clogging, pressure build-up, and decreased efficiency at larger scales need to be addressed to make MCC a viable option for large-scale protein separation.

Furthermore, the modification and functionalization of MCC to enhance its separation capabilities pose technical difficulties. While chemical modifications can potentially improve MCC's selectivity and capacity for protein binding, achieving uniform and reproducible modifications across the MCC surface remains challenging. The development of cost-effective and scalable modification techniques is crucial for advancing MCC-based protein separation methods.

The environmental impact and sustainability of MCC production and use in protein separation also present challenges. As the demand for high-performance separation techniques grows, ensuring a sustainable supply of MCC without compromising natural resources becomes increasingly important. Additionally, the disposal or recycling of used MCC materials needs to be addressed to minimize environmental impact.

Lastly, the integration of MCC-based separation techniques with existing protein purification workflows and technologies poses compatibility issues. Adapting current protocols and equipment to accommodate MCC-based methods without compromising efficiency or increasing costs is a significant challenge that requires innovative solutions and potentially new equipment designs.

Another significant challenge is the limited understanding of the interaction mechanisms between MCC and various protein types. While MCC has shown effectiveness in separating certain proteins, its behavior with a broader range of protein molecules, especially those with complex structures or post-translational modifications, remains unclear. This knowledge gap hinders the optimization of MCC-based separation protocols for diverse protein samples.

The scalability of MCC-based separation techniques also presents a considerable hurdle. While MCC performs well in small-scale laboratory settings, translating these successes to industrial-scale protein purification processes has proven challenging. Issues such as column clogging, pressure build-up, and decreased efficiency at larger scales need to be addressed to make MCC a viable option for large-scale protein separation.

Furthermore, the modification and functionalization of MCC to enhance its separation capabilities pose technical difficulties. While chemical modifications can potentially improve MCC's selectivity and capacity for protein binding, achieving uniform and reproducible modifications across the MCC surface remains challenging. The development of cost-effective and scalable modification techniques is crucial for advancing MCC-based protein separation methods.

The environmental impact and sustainability of MCC production and use in protein separation also present challenges. As the demand for high-performance separation techniques grows, ensuring a sustainable supply of MCC without compromising natural resources becomes increasingly important. Additionally, the disposal or recycling of used MCC materials needs to be addressed to minimize environmental impact.

Lastly, the integration of MCC-based separation techniques with existing protein purification workflows and technologies poses compatibility issues. Adapting current protocols and equipment to accommodate MCC-based methods without compromising efficiency or increasing costs is a significant challenge that requires innovative solutions and potentially new equipment designs.

Existing MCC-Based Protein Separation Methods

01 Mechanical separation methods

Various mechanical methods are employed for separating microcrystalline cellulose, including centrifugation, filtration, and sieving. These techniques rely on differences in particle size, density, or other physical properties to achieve separation. Mechanical separation is often used as a primary step in the purification process of microcrystalline cellulose.- Mechanical separation methods: Various mechanical methods are employed for separating microcrystalline cellulose, including centrifugation, filtration, and sieving. These techniques exploit differences in particle size, density, or other physical properties to achieve separation. Mechanical separation is often used as a primary step in the purification process of microcrystalline cellulose.

- Chemical treatment for separation: Chemical treatments are utilized to separate microcrystalline cellulose from other components. This may involve acid hydrolysis, alkaline treatments, or the use of specific solvents to dissolve or modify non-cellulosic materials. Chemical methods can enhance the purity of the separated microcrystalline cellulose by removing lignin, hemicellulose, and other impurities.

- Enzymatic separation techniques: Enzymatic methods employ specific enzymes to break down or modify cellulose and other plant materials, facilitating the separation of microcrystalline cellulose. These biological approaches can be more selective and environmentally friendly compared to chemical methods. Enzymes such as cellulases and hemicellulases are commonly used in this process.

- Combination of physical and chemical methods: Hybrid approaches combining physical and chemical separation techniques are often employed to improve efficiency and yield. This may involve a sequence of mechanical processing followed by chemical treatments, or vice versa. Such combined methods can optimize the separation process by leveraging the strengths of different techniques.

- Novel separation technologies: Emerging technologies are being developed for more efficient and sustainable separation of microcrystalline cellulose. These may include advanced membrane filtration systems, supercritical fluid extraction, or innovative biotechnological approaches. These novel methods aim to improve separation efficiency, reduce environmental impact, and enhance the quality of the obtained microcrystalline cellulose.

02 Chemical treatment for separation

Chemical treatments are utilized to separate microcrystalline cellulose from other components. This may involve acid hydrolysis, alkaline treatments, or the use of specific solvents to dissolve non-cellulosic materials. Chemical separation methods can be highly effective in isolating pure microcrystalline cellulose from complex mixtures.Expand Specific Solutions03 Enzymatic separation techniques

Enzymatic methods employ specific enzymes to break down non-cellulosic components, facilitating the separation of microcrystalline cellulose. This approach offers a more selective and environmentally friendly alternative to chemical treatments. Enzymes such as cellulases and hemicellulases are commonly used in these processes.Expand Specific Solutions04 Combination of physical and chemical methods

Many separation processes for microcrystalline cellulose involve a combination of physical and chemical methods. This may include initial mechanical processing followed by chemical treatments, or vice versa. The combination approach often yields higher purity and efficiency in separating microcrystalline cellulose from complex raw materials.Expand Specific Solutions05 Novel separation technologies

Emerging technologies are being developed for more efficient separation of microcrystalline cellulose. These may include advanced membrane filtration systems, supercritical fluid extraction, or novel biomass fractionation techniques. These innovative methods aim to improve yield, reduce environmental impact, and enhance the quality of the separated microcrystalline cellulose.Expand Specific Solutions

Key Players in MCC and Protein Separation Industry

The research on microcrystalline cellulose in high-performance separation techniques for proteins is in a growth phase, with increasing market potential due to rising demand for advanced protein purification methods. The global market for protein separation and purification is expanding, driven by biopharmaceutical and biotechnology industries. Technologically, the field is advancing rapidly, with companies like Sartorius Stedim Biotech GmbH, Cytiva BioProcess R&D AB, and Merck Millipore Ltd. leading innovation. Academic institutions such as Yale University and Northwestern University are contributing significantly to fundamental research, while collaborations between industry and academia are accelerating the development of novel applications and improving existing techniques.

Cytiva BioProcess R&D AB

Technical Solution: Cytiva BioProcess R&D AB has developed advanced microcrystalline cellulose (MCC) based separation techniques for protein purification. Their approach utilizes MCC as a stationary phase in chromatography columns, offering enhanced protein binding capacity and selectivity. The company has engineered MCC particles with controlled porosity and surface modifications to optimize protein separation[1]. Their technology incorporates a unique cross-linking process that improves the mechanical stability of MCC, allowing for higher flow rates and pressure resistance in chromatographic applications[2]. Cytiva's MCC-based columns have demonstrated superior resolution in separating complex protein mixtures, particularly for monoclonal antibodies and recombinant proteins[3].

Strengths: High binding capacity, improved selectivity, and mechanical stability. Weaknesses: Potential higher cost compared to traditional resins, may require specialized equipment for optimal performance.

Sartorius Stedim Biotech GmbH

Technical Solution: Sartorius Stedim Biotech GmbH has pioneered the use of MCC in membrane adsorbers for protein separation. Their technology combines MCC with nanofiber membranes to create high-performance separation matrices. The company has developed a proprietary process to incorporate MCC into the membrane structure, resulting in increased surface area and improved protein binding kinetics[4]. Sartorius' MCC-enhanced membranes exhibit rapid mass transfer and reduced diffusion limitations, enabling faster separations and higher throughput in protein purification processes[5]. The company has also introduced MCC-based disposable chromatography devices, addressing the growing demand for single-use technologies in biopharmaceutical manufacturing[6].

Strengths: Rapid mass transfer, high throughput, and single-use options. Weaknesses: Limited scalability for very large-scale purifications, potential for increased cost per unit of protein purified.

Innovations in MCC for Enhanced Protein Separation

Method for separating and purifying protein from plants using cellulose and cellulose binding domain

PatentWO2014054865A1

Innovation

- A method utilizing various forms of cellulose, such as microcrystalline and amorphous cellulose, to bind and separate proteins containing a cellulose binding domain from plant extracts through a protein binding, washing, and elution process, using specific buffer solutions to achieve high-purity protein isolation.

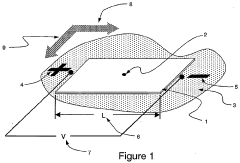

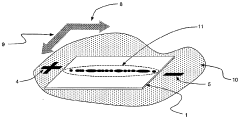

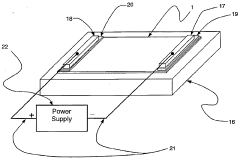

Separations platform based upon electroosmosis-driven planar chromatography

PatentWO2005092013A2

Innovation

- A high-resolution protein, peptide, and glycan separation system using electroosmosis-driven planar chromatography with an amphiphilic solid phase support and a combination of organic and aqueous mobile phases, facilitating electrophoretic and chromatographic mechanisms for stable and efficient separation of hydrophobic analytes and large molecular complexes.

Environmental Impact of MCC in Separation Processes

The use of microcrystalline cellulose (MCC) in high-performance separation techniques for proteins has gained significant attention due to its effectiveness and potential environmental benefits. As a natural, biodegradable material derived from renewable sources, MCC offers a more sustainable alternative to traditional synthetic materials used in separation processes.

One of the primary environmental advantages of MCC in protein separation is its reduced carbon footprint compared to synthetic alternatives. The production of MCC typically requires less energy and generates fewer greenhouse gas emissions than the manufacture of synthetic materials. This aligns with the growing emphasis on sustainable practices in the biotechnology and pharmaceutical industries.

MCC's biodegradability is another crucial environmental benefit. Unlike many synthetic materials used in separation processes, MCC can naturally decompose without leaving persistent pollutants in the environment. This characteristic significantly reduces the long-term environmental impact of protein separation techniques and aligns with circular economy principles.

The use of MCC in separation processes also contributes to reduced chemical waste. Many traditional separation methods rely on harsh chemicals or solvents that can be environmentally harmful. MCC-based techniques often require fewer or less toxic chemicals, minimizing the environmental impact of waste disposal and reducing the risk of contamination.

Water consumption is a critical environmental concern in many industrial processes. MCC-based separation techniques have shown potential for improved water efficiency compared to some conventional methods. This reduction in water usage not only conserves a vital resource but also decreases the volume of wastewater that requires treatment and disposal.

The renewable nature of MCC sources, primarily from plant-based materials, supports sustainable resource management. Unlike finite synthetic materials, MCC can be continuously produced from managed forests or agricultural byproducts, promoting a more sustainable supply chain for separation technologies.

However, it is important to consider the potential environmental trade-offs associated with increased MCC production. Large-scale cultivation of cellulose sources could lead to land-use changes or compete with food production. Careful management and sourcing strategies are necessary to mitigate these risks and ensure that the environmental benefits of MCC in separation processes are not offset by negative impacts in other areas.

In conclusion, the adoption of MCC in high-performance separation techniques for proteins offers several environmental advantages, including reduced carbon emissions, improved biodegradability, decreased chemical waste, and enhanced water efficiency. As research in this field progresses, further optimization of MCC-based separation processes may lead to even greater environmental benefits, contributing to more sustainable practices in biotechnology and related industries.

One of the primary environmental advantages of MCC in protein separation is its reduced carbon footprint compared to synthetic alternatives. The production of MCC typically requires less energy and generates fewer greenhouse gas emissions than the manufacture of synthetic materials. This aligns with the growing emphasis on sustainable practices in the biotechnology and pharmaceutical industries.

MCC's biodegradability is another crucial environmental benefit. Unlike many synthetic materials used in separation processes, MCC can naturally decompose without leaving persistent pollutants in the environment. This characteristic significantly reduces the long-term environmental impact of protein separation techniques and aligns with circular economy principles.

The use of MCC in separation processes also contributes to reduced chemical waste. Many traditional separation methods rely on harsh chemicals or solvents that can be environmentally harmful. MCC-based techniques often require fewer or less toxic chemicals, minimizing the environmental impact of waste disposal and reducing the risk of contamination.

Water consumption is a critical environmental concern in many industrial processes. MCC-based separation techniques have shown potential for improved water efficiency compared to some conventional methods. This reduction in water usage not only conserves a vital resource but also decreases the volume of wastewater that requires treatment and disposal.

The renewable nature of MCC sources, primarily from plant-based materials, supports sustainable resource management. Unlike finite synthetic materials, MCC can be continuously produced from managed forests or agricultural byproducts, promoting a more sustainable supply chain for separation technologies.

However, it is important to consider the potential environmental trade-offs associated with increased MCC production. Large-scale cultivation of cellulose sources could lead to land-use changes or compete with food production. Careful management and sourcing strategies are necessary to mitigate these risks and ensure that the environmental benefits of MCC in separation processes are not offset by negative impacts in other areas.

In conclusion, the adoption of MCC in high-performance separation techniques for proteins offers several environmental advantages, including reduced carbon emissions, improved biodegradability, decreased chemical waste, and enhanced water efficiency. As research in this field progresses, further optimization of MCC-based separation processes may lead to even greater environmental benefits, contributing to more sustainable practices in biotechnology and related industries.

Scalability and Industrial Applications of MCC Techniques

The scalability and industrial applications of microcrystalline cellulose (MCC) techniques in high-performance protein separation represent a crucial aspect of their practical implementation. As research progresses, the potential for large-scale production and diverse industrial uses of MCC-based separation methods continues to expand.

In terms of scalability, MCC techniques have shown promising results in laboratory settings, but transitioning to industrial-scale operations presents both challenges and opportunities. The production of MCC itself can be scaled up through various methods, including acid hydrolysis of cellulose sources and mechanical processing. However, ensuring consistent quality and particle size distribution at larger scales remains a key consideration.

For protein separation applications, the scalability of MCC-based techniques depends on factors such as column design, flow rates, and loading capacity. Recent advancements in column chromatography have demonstrated the feasibility of using MCC as a stationary phase in larger-diameter columns, potentially allowing for increased throughput in industrial settings.

The industrial applications of MCC techniques for protein separation span multiple sectors. In the pharmaceutical industry, MCC-based methods show promise for the purification of therapeutic proteins and antibodies. The biocompatibility and low cost of MCC make it an attractive alternative to traditional chromatography resins, potentially reducing production costs for biopharmaceuticals.

In the food industry, MCC techniques are being explored for the isolation and purification of functional proteins from various sources, including plant-based materials. This application aligns with the growing demand for plant-based protein alternatives and clean-label ingredients.

The biotechnology sector is another area where MCC-based separation techniques find potential applications. From enzyme purification to the isolation of recombinant proteins, MCC offers a versatile platform for various bioprocessing needs. Its ability to maintain protein stability during separation processes makes it particularly valuable in this field.

Environmental applications are also emerging, with MCC techniques being investigated for the removal of proteins and other contaminants from wastewater streams. This could have significant implications for industries such as food processing and biofuel production, where protein-rich effluents require treatment.

As research continues, the development of hybrid materials combining MCC with other functional components may further expand its industrial applications. These innovations could lead to enhanced separation performance, improved selectivity, and broader applicability across different protein types and separation conditions.

In terms of scalability, MCC techniques have shown promising results in laboratory settings, but transitioning to industrial-scale operations presents both challenges and opportunities. The production of MCC itself can be scaled up through various methods, including acid hydrolysis of cellulose sources and mechanical processing. However, ensuring consistent quality and particle size distribution at larger scales remains a key consideration.

For protein separation applications, the scalability of MCC-based techniques depends on factors such as column design, flow rates, and loading capacity. Recent advancements in column chromatography have demonstrated the feasibility of using MCC as a stationary phase in larger-diameter columns, potentially allowing for increased throughput in industrial settings.

The industrial applications of MCC techniques for protein separation span multiple sectors. In the pharmaceutical industry, MCC-based methods show promise for the purification of therapeutic proteins and antibodies. The biocompatibility and low cost of MCC make it an attractive alternative to traditional chromatography resins, potentially reducing production costs for biopharmaceuticals.

In the food industry, MCC techniques are being explored for the isolation and purification of functional proteins from various sources, including plant-based materials. This application aligns with the growing demand for plant-based protein alternatives and clean-label ingredients.

The biotechnology sector is another area where MCC-based separation techniques find potential applications. From enzyme purification to the isolation of recombinant proteins, MCC offers a versatile platform for various bioprocessing needs. Its ability to maintain protein stability during separation processes makes it particularly valuable in this field.

Environmental applications are also emerging, with MCC techniques being investigated for the removal of proteins and other contaminants from wastewater streams. This could have significant implications for industries such as food processing and biofuel production, where protein-rich effluents require treatment.

As research continues, the development of hybrid materials combining MCC with other functional components may further expand its industrial applications. These innovations could lead to enhanced separation performance, improved selectivity, and broader applicability across different protein types and separation conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!