Microcrystalline Cellulose Integration in Electrospinning for Nanofiber Production

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC-Nanofiber Tech Evolution

The integration of microcrystalline cellulose (MCC) in electrospinning for nanofiber production has undergone significant evolution over the past decades. This technological journey began in the early 2000s when researchers first explored the potential of incorporating cellulose-based materials into electrospun fibers. Initially, the focus was on using dissolved cellulose derivatives, such as cellulose acetate, due to the challenges associated with processing pure cellulose.

As the field progressed, attention shifted towards utilizing MCC as a reinforcing agent in polymer-based nanofibers. This transition was driven by the growing interest in sustainable and biodegradable materials, as well as the superior mechanical properties offered by MCC. The early 2010s saw a surge in research activities aimed at optimizing MCC dispersion within polymer solutions and understanding the impact of MCC concentration on fiber morphology and properties.

A significant milestone was reached in the mid-2010s when researchers successfully developed methods to electrospin pure MCC nanofibers without the need for synthetic polymer carriers. This breakthrough was achieved through the use of advanced solvent systems and the optimization of electrospinning parameters. It opened up new possibilities for creating fully bio-based and biodegradable nanofiber materials with enhanced mechanical and thermal properties.

The late 2010s witnessed the emergence of hybrid MCC-based nanofibers, where MCC was combined with other nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles. These hybrid systems demonstrated synergistic effects, leading to nanofibers with multifunctional properties suitable for applications in areas like energy storage, water purification, and tissue engineering.

Recent advancements in the field have focused on scaling up MCC-based nanofiber production and improving process efficiency. This has involved the development of new electrospinning techniques, such as needleless electrospinning and solution blow spinning, which offer higher throughput and better control over fiber properties. Additionally, researchers have been exploring the use of ionic liquids and deep eutectic solvents as green alternatives for MCC dissolution and processing.

Looking towards the future, the integration of MCC in electrospinning for nanofiber production is expected to continue evolving. Emerging trends include the development of stimuli-responsive MCC-based nanofibers, the incorporation of functional groups onto MCC surfaces for enhanced compatibility and functionality, and the exploration of MCC nanofibers in advanced applications such as flexible electronics and smart textiles. As sustainability becomes increasingly important, the role of MCC in creating eco-friendly nanofiber materials is likely to expand, driving further innovation in this field.

As the field progressed, attention shifted towards utilizing MCC as a reinforcing agent in polymer-based nanofibers. This transition was driven by the growing interest in sustainable and biodegradable materials, as well as the superior mechanical properties offered by MCC. The early 2010s saw a surge in research activities aimed at optimizing MCC dispersion within polymer solutions and understanding the impact of MCC concentration on fiber morphology and properties.

A significant milestone was reached in the mid-2010s when researchers successfully developed methods to electrospin pure MCC nanofibers without the need for synthetic polymer carriers. This breakthrough was achieved through the use of advanced solvent systems and the optimization of electrospinning parameters. It opened up new possibilities for creating fully bio-based and biodegradable nanofiber materials with enhanced mechanical and thermal properties.

The late 2010s witnessed the emergence of hybrid MCC-based nanofibers, where MCC was combined with other nanomaterials such as graphene, carbon nanotubes, and metal nanoparticles. These hybrid systems demonstrated synergistic effects, leading to nanofibers with multifunctional properties suitable for applications in areas like energy storage, water purification, and tissue engineering.

Recent advancements in the field have focused on scaling up MCC-based nanofiber production and improving process efficiency. This has involved the development of new electrospinning techniques, such as needleless electrospinning and solution blow spinning, which offer higher throughput and better control over fiber properties. Additionally, researchers have been exploring the use of ionic liquids and deep eutectic solvents as green alternatives for MCC dissolution and processing.

Looking towards the future, the integration of MCC in electrospinning for nanofiber production is expected to continue evolving. Emerging trends include the development of stimuli-responsive MCC-based nanofibers, the incorporation of functional groups onto MCC surfaces for enhanced compatibility and functionality, and the exploration of MCC nanofibers in advanced applications such as flexible electronics and smart textiles. As sustainability becomes increasingly important, the role of MCC in creating eco-friendly nanofiber materials is likely to expand, driving further innovation in this field.

Market Demand Analysis

The integration of microcrystalline cellulose (MCC) in electrospinning for nanofiber production has garnered significant attention in recent years, driven by the growing demand for sustainable and high-performance materials across various industries. The market for nanofibers incorporating MCC is experiencing robust growth, with applications spanning from healthcare and pharmaceuticals to environmental remediation and energy storage.

In the healthcare sector, there is a rising demand for advanced wound dressings and tissue engineering scaffolds that can leverage the biocompatibility and mechanical properties of MCC-enhanced nanofibers. The pharmaceutical industry is also showing increased interest in these materials for drug delivery systems, as they offer improved drug loading capacity and controlled release profiles.

The environmental sector presents another substantial market opportunity for MCC-integrated nanofibers. With growing concerns over water pollution and the need for efficient filtration systems, these nanofibers are being explored for their potential in developing high-performance membranes for water purification and air filtration applications.

In the textile industry, there is a notable trend towards sustainable and functional fabrics. MCC-enhanced nanofibers are being investigated for their potential to create lightweight, durable, and moisture-wicking textiles, catering to the increasing consumer demand for eco-friendly and high-performance clothing.

The energy storage sector is another area driving market demand for these innovative nanofibers. Researchers are exploring the use of MCC-integrated nanofibers in the development of advanced battery separators and supercapacitor electrodes, aiming to enhance energy storage capacity and efficiency.

The automotive and aerospace industries are also showing interest in these materials for lightweight composite applications, seeking to improve fuel efficiency and reduce environmental impact. The unique properties of MCC-enhanced nanofibers, such as high strength-to-weight ratio and thermal stability, make them attractive for these high-performance applications.

As sustainability becomes a key focus across industries, the biodegradability and renewability of MCC-based nanofibers are driving their adoption in packaging and disposable product applications. This aligns with the global push towards reducing plastic waste and embracing more environmentally friendly alternatives.

The market for MCC-integrated nanofibers is expected to continue its growth trajectory, fueled by ongoing research and development efforts to expand their applications and improve production processes. As manufacturing techniques become more refined and scalable, it is anticipated that these materials will find even broader adoption across various industrial sectors, further driving market demand and innovation in the field of nanofiber production.

In the healthcare sector, there is a rising demand for advanced wound dressings and tissue engineering scaffolds that can leverage the biocompatibility and mechanical properties of MCC-enhanced nanofibers. The pharmaceutical industry is also showing increased interest in these materials for drug delivery systems, as they offer improved drug loading capacity and controlled release profiles.

The environmental sector presents another substantial market opportunity for MCC-integrated nanofibers. With growing concerns over water pollution and the need for efficient filtration systems, these nanofibers are being explored for their potential in developing high-performance membranes for water purification and air filtration applications.

In the textile industry, there is a notable trend towards sustainable and functional fabrics. MCC-enhanced nanofibers are being investigated for their potential to create lightweight, durable, and moisture-wicking textiles, catering to the increasing consumer demand for eco-friendly and high-performance clothing.

The energy storage sector is another area driving market demand for these innovative nanofibers. Researchers are exploring the use of MCC-integrated nanofibers in the development of advanced battery separators and supercapacitor electrodes, aiming to enhance energy storage capacity and efficiency.

The automotive and aerospace industries are also showing interest in these materials for lightweight composite applications, seeking to improve fuel efficiency and reduce environmental impact. The unique properties of MCC-enhanced nanofibers, such as high strength-to-weight ratio and thermal stability, make them attractive for these high-performance applications.

As sustainability becomes a key focus across industries, the biodegradability and renewability of MCC-based nanofibers are driving their adoption in packaging and disposable product applications. This aligns with the global push towards reducing plastic waste and embracing more environmentally friendly alternatives.

The market for MCC-integrated nanofibers is expected to continue its growth trajectory, fueled by ongoing research and development efforts to expand their applications and improve production processes. As manufacturing techniques become more refined and scalable, it is anticipated that these materials will find even broader adoption across various industrial sectors, further driving market demand and innovation in the field of nanofiber production.

Current Challenges

The integration of microcrystalline cellulose (MCC) in electrospinning for nanofiber production faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the difficulty in achieving uniform dispersion of MCC particles within the polymer solution. The tendency of MCC to agglomerate due to strong hydrogen bonding between cellulose chains can lead to inconsistent fiber formation and potential clogging of the electrospinning nozzle.

Another critical challenge lies in maintaining the stability of the MCC-polymer suspension during the electrospinning process. The addition of MCC can alter the rheological properties of the spinning solution, potentially affecting its spinnability and the resulting fiber morphology. Achieving the right balance between MCC concentration and polymer viscosity is crucial for successful nanofiber production.

The impact of MCC on the electrical conductivity of the spinning solution presents an additional hurdle. As MCC is non-conductive, its incorporation may reduce the overall conductivity of the solution, potentially compromising the efficiency of the electrospinning process and the quality of the nanofibers produced.

Furthermore, the interaction between MCC and various polymer matrices poses a significant challenge. Different polymers exhibit varying degrees of compatibility with MCC, which can affect the mechanical properties, thermal stability, and overall performance of the resulting nanofibers. Optimizing these interactions to enhance fiber properties while maintaining processability remains a complex task.

The scalability of MCC-integrated electrospinning processes also presents a considerable challenge. While laboratory-scale production may yield promising results, translating these findings to industrial-scale manufacturing while maintaining consistent fiber quality and properties is a significant hurdle that requires further research and development.

Lastly, the environmental stability of MCC-containing nanofibers, particularly in high-humidity conditions, remains a concern. The hydrophilic nature of cellulose can lead to moisture absorption, potentially affecting the long-term performance and durability of the nanofiber products. Developing effective strategies to enhance the moisture resistance of these nanofibers without compromising their desirable properties is an ongoing challenge in the field.

Another critical challenge lies in maintaining the stability of the MCC-polymer suspension during the electrospinning process. The addition of MCC can alter the rheological properties of the spinning solution, potentially affecting its spinnability and the resulting fiber morphology. Achieving the right balance between MCC concentration and polymer viscosity is crucial for successful nanofiber production.

The impact of MCC on the electrical conductivity of the spinning solution presents an additional hurdle. As MCC is non-conductive, its incorporation may reduce the overall conductivity of the solution, potentially compromising the efficiency of the electrospinning process and the quality of the nanofibers produced.

Furthermore, the interaction between MCC and various polymer matrices poses a significant challenge. Different polymers exhibit varying degrees of compatibility with MCC, which can affect the mechanical properties, thermal stability, and overall performance of the resulting nanofibers. Optimizing these interactions to enhance fiber properties while maintaining processability remains a complex task.

The scalability of MCC-integrated electrospinning processes also presents a considerable challenge. While laboratory-scale production may yield promising results, translating these findings to industrial-scale manufacturing while maintaining consistent fiber quality and properties is a significant hurdle that requires further research and development.

Lastly, the environmental stability of MCC-containing nanofibers, particularly in high-humidity conditions, remains a concern. The hydrophilic nature of cellulose can lead to moisture absorption, potentially affecting the long-term performance and durability of the nanofiber products. Developing effective strategies to enhance the moisture resistance of these nanofibers without compromising their desirable properties is an ongoing challenge in the field.

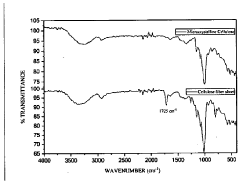

MCC Integration Methods

01 Production methods of microcrystalline cellulose nanofibers

Various methods are employed to produce microcrystalline cellulose nanofibers, including mechanical processing, chemical treatments, and enzymatic hydrolysis. These processes aim to break down cellulose fibers into nano-sized particles while maintaining their crystalline structure. The resulting nanofibers have unique properties that make them valuable in various applications.- Production methods of microcrystalline cellulose nanofibers: Various techniques are employed to produce microcrystalline cellulose nanofibers, including mechanical processing, chemical treatments, and enzymatic hydrolysis. These methods aim to break down cellulose fibers into nano-scale dimensions while maintaining their crystalline structure. The resulting nanofibers exhibit high strength, large surface area, and unique properties suitable for diverse applications.

- Applications in composite materials: Microcrystalline cellulose nanofibers are widely used as reinforcing agents in composite materials. They enhance mechanical properties, thermal stability, and barrier characteristics of polymers and other matrices. These nanofibers are particularly valuable in creating lightweight, strong, and environmentally friendly composites for various industries, including automotive, packaging, and construction.

- Use in pharmaceutical and biomedical applications: Microcrystalline cellulose nanofibers find applications in pharmaceutical and biomedical fields. They are used as excipients in drug formulations, scaffolds for tissue engineering, and components in wound dressings. The biocompatibility and unique properties of these nanofibers make them suitable for controlled drug release systems and regenerative medicine applications.

- Surface modification and functionalization: Various methods are employed to modify the surface of microcrystalline cellulose nanofibers, enhancing their compatibility with different matrices and expanding their application range. Surface treatments include chemical modifications, grafting of functional groups, and coating with other materials. These modifications improve dispersion, interfacial adhesion, and introduce new functionalities to the nanofibers.

- Sustainable and eco-friendly material: Microcrystalline cellulose nanofibers are derived from renewable resources and are biodegradable, making them an environmentally friendly alternative to synthetic materials. Their production often involves the use of waste biomass or agricultural by-products, contributing to sustainability efforts. The eco-friendly nature of these nanofibers aligns with the growing demand for green materials in various industries.

02 Applications in composite materials

Microcrystalline cellulose nanofibers are widely used in composite materials to enhance mechanical properties, reduce weight, and improve thermal stability. They can be incorporated into polymers, resins, and other matrices to create high-performance materials for various industries, including automotive, aerospace, and construction.Expand Specific Solutions03 Use in pharmaceutical and biomedical applications

Microcrystalline cellulose nanofibers have found applications in pharmaceutical and biomedical fields. They can be used as excipients in drug formulations, as scaffolds for tissue engineering, and in wound healing materials. Their biocompatibility and unique properties make them suitable for various medical applications.Expand Specific Solutions04 Functionalization and surface modification

Microcrystalline cellulose nanofibers can be functionalized or surface-modified to enhance their properties or compatibility with different matrices. This can involve chemical treatments, grafting of functional groups, or coating with other materials to tailor the nanofibers for specific applications or improve their performance in various systems.Expand Specific Solutions05 Sustainable and eco-friendly material

Microcrystalline cellulose nanofibers are derived from renewable sources and are biodegradable, making them an environmentally friendly alternative to synthetic materials. Their production and use align with sustainability goals, and they are being explored as replacements for non-renewable materials in various applications, including packaging and consumer products.Expand Specific Solutions

Key Industry Players

The integration of microcrystalline cellulose in electrospinning for nanofiber production is an emerging field with significant potential. The market is in its early growth stage, characterized by increasing research activities and pilot-scale applications. While the market size is still relatively small, it is expected to expand rapidly due to the growing demand for advanced materials in various industries. Technologically, the process is evolving, with companies like Donghua University, Massachusetts Institute of Technology, and Fudan University leading research efforts. Henan China Fiber New Material Technology Co., Ltd. and Matregenix, Inc. are among the commercial entities exploring practical applications, indicating a gradual shift towards industrial-scale production and commercialization of this technology.

Donghua University

Technical Solution: Donghua University has pioneered a multi-step approach to incorporate microcrystalline cellulose into electrospun nanofibers. Their method involves pre-treating MCC to improve its dispersion in polymer solutions, followed by a modified electrospinning process. The university has developed a unique coaxial electrospinning technique that allows for the encapsulation of MCC within the core of the nanofibers, resulting in improved mechanical strength and thermal stability[2]. Additionally, they have explored the use of surface modification techniques to enhance the compatibility between MCC and various polymer matrices, leading to more uniform fiber formation[4].

Strengths: Innovative coaxial electrospinning technique, improved MCC dispersion through pre-treatment. Weaknesses: Complex multi-step process may increase production costs, limited to certain types of polymers.

Beijing University of Chemical Technology

Technical Solution: Beijing University of Chemical Technology has developed a green and sustainable approach to integrating microcrystalline cellulose into electrospun nanofibers. Their method focuses on using environmentally friendly solvents and optimizing the electrospinning parameters to achieve high-quality MCC-reinforced nanofibers. The university has successfully produced nanofibers with MCC content up to 30% by weight, significantly improving the mechanical and thermal properties of the fibers[5]. They have also explored the use of ionic liquids as solvents to enhance the dispersion of MCC in polymer solutions, resulting in more uniform fiber morphology[6].

Strengths: High MCC content in nanofibers, use of green solvents. Weaknesses: Potential high cost of ionic liquids, limited to specific polymer-solvent systems.

Innovative MCC-Nanofiber Patents

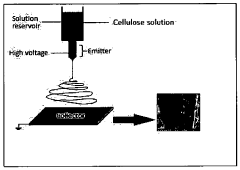

Synthesis of cellulose formate fiber sheets by electrospinning

PatentPendingIN202341016927A

Innovation

- A novel method for converting microcrystalline cellulose to cellulose nanofibers, nanofibersheets, and mats through electrospinning.

- Improved efficiency and cost-effectiveness in the synthesis of cellulose nanofibers, nanofiber sheets, and mats.

- Utilization of cellulose formate as an intermediate in the production of cellulose nanofibers via electrospinning.

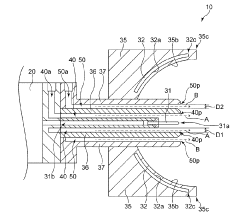

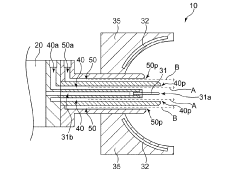

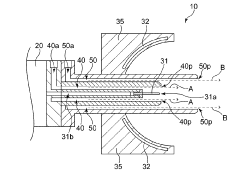

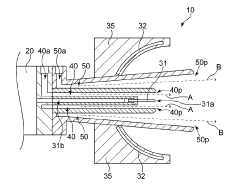

Electrospinning apparatus and method for producing nanofiber

PatentActiveJP2021011665A

Innovation

- An electrospinning apparatus with a nozzle, electrode, and gas injection units is designed to inject heated gas flows from multiple directions, enhancing the drawing and cooling control of molten resin to produce finer fibers efficiently.

Regulatory Considerations

The integration of microcrystalline cellulose (MCC) in electrospinning for nanofiber production presents several regulatory considerations that must be addressed to ensure compliance with relevant standards and guidelines. As this technology finds applications in various industries, including pharmaceuticals, food packaging, and medical devices, it falls under the purview of multiple regulatory bodies.

In the pharmaceutical sector, the use of MCC-integrated nanofibers must comply with Good Manufacturing Practice (GMP) regulations set forth by agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). These regulations ensure the quality, safety, and efficacy of drug products. Manufacturers must demonstrate that the incorporation of MCC does not adversely affect the drug's stability, bioavailability, or therapeutic efficacy.

For food packaging applications, regulatory bodies such as the FDA and the European Food Safety Authority (EFSA) have established guidelines for food contact materials. The use of MCC-integrated nanofibers in food packaging must adhere to these regulations, which typically involve migration testing to ensure that no harmful substances leach into food products. Manufacturers must provide evidence that the nanofibers do not pose any health risks to consumers.

In the medical device industry, regulatory frameworks such as the FDA's 510(k) clearance process and the European Union's Medical Device Regulation (MDR) govern the approval of new materials and technologies. Manufacturers incorporating MCC-integrated nanofibers into medical devices must conduct thorough biocompatibility testing and risk assessments to demonstrate the safety and effectiveness of their products.

Environmental regulations also play a crucial role in the development and commercialization of MCC-integrated nanofibers. As these materials are often biodegradable, manufacturers must comply with waste management and disposal regulations set by environmental protection agencies. Additionally, the sourcing of cellulose raw materials may be subject to sustainability certifications and forest management regulations.

Occupational health and safety regulations must be considered during the production process of MCC-integrated nanofibers. Agencies such as the Occupational Safety and Health Administration (OSHA) in the United States provide guidelines for handling nanomaterials and ensuring worker safety in manufacturing environments.

As nanotechnology continues to evolve, regulatory frameworks are likely to adapt and become more specific to address the unique properties and potential risks associated with nanofibers. Manufacturers and researchers working with MCC-integrated nanofibers must stay informed about emerging regulations and participate in industry discussions to shape future guidelines. Proactive engagement with regulatory bodies and adherence to current good practices will be essential for successful commercialization and widespread adoption of this technology.

In the pharmaceutical sector, the use of MCC-integrated nanofibers must comply with Good Manufacturing Practice (GMP) regulations set forth by agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). These regulations ensure the quality, safety, and efficacy of drug products. Manufacturers must demonstrate that the incorporation of MCC does not adversely affect the drug's stability, bioavailability, or therapeutic efficacy.

For food packaging applications, regulatory bodies such as the FDA and the European Food Safety Authority (EFSA) have established guidelines for food contact materials. The use of MCC-integrated nanofibers in food packaging must adhere to these regulations, which typically involve migration testing to ensure that no harmful substances leach into food products. Manufacturers must provide evidence that the nanofibers do not pose any health risks to consumers.

In the medical device industry, regulatory frameworks such as the FDA's 510(k) clearance process and the European Union's Medical Device Regulation (MDR) govern the approval of new materials and technologies. Manufacturers incorporating MCC-integrated nanofibers into medical devices must conduct thorough biocompatibility testing and risk assessments to demonstrate the safety and effectiveness of their products.

Environmental regulations also play a crucial role in the development and commercialization of MCC-integrated nanofibers. As these materials are often biodegradable, manufacturers must comply with waste management and disposal regulations set by environmental protection agencies. Additionally, the sourcing of cellulose raw materials may be subject to sustainability certifications and forest management regulations.

Occupational health and safety regulations must be considered during the production process of MCC-integrated nanofibers. Agencies such as the Occupational Safety and Health Administration (OSHA) in the United States provide guidelines for handling nanomaterials and ensuring worker safety in manufacturing environments.

As nanotechnology continues to evolve, regulatory frameworks are likely to adapt and become more specific to address the unique properties and potential risks associated with nanofibers. Manufacturers and researchers working with MCC-integrated nanofibers must stay informed about emerging regulations and participate in industry discussions to shape future guidelines. Proactive engagement with regulatory bodies and adherence to current good practices will be essential for successful commercialization and widespread adoption of this technology.

Sustainability Aspects

The integration of microcrystalline cellulose (MCC) in electrospinning for nanofiber production presents significant sustainability advantages. MCC, derived from renewable plant sources, offers a biodegradable and eco-friendly alternative to synthetic polymers commonly used in nanofiber fabrication. This approach aligns with the growing demand for sustainable materials in various industries, including textiles, filtration, and biomedical applications.

The use of MCC in electrospinning contributes to reduced environmental impact throughout the product lifecycle. Unlike petroleum-based polymers, MCC production requires less energy and generates fewer greenhouse gas emissions. Additionally, the biodegradability of MCC-based nanofibers ensures that they can decompose naturally at the end of their useful life, minimizing waste accumulation in landfills and oceans.

From a resource conservation perspective, MCC integration promotes the efficient use of cellulose, one of the most abundant natural polymers on Earth. This helps to decrease reliance on non-renewable resources and supports the circular economy concept. Furthermore, the versatility of MCC allows for the development of multifunctional nanofibers with enhanced properties, potentially reducing the need for additional chemical treatments or coatings.

The sustainability benefits extend to the electrospinning process itself. MCC-based solutions often require less toxic solvents compared to synthetic polymer alternatives, leading to safer working conditions and reduced environmental hazards. This aspect is particularly crucial in scaling up production for industrial applications, where large volumes of solvents may be used.

In terms of energy efficiency, the incorporation of MCC can potentially lower the energy requirements of the electrospinning process. The unique properties of MCC, such as its high surface area and crystalline structure, may facilitate fiber formation at lower voltages or flow rates, thereby optimizing energy consumption during production.

The adoption of MCC in nanofiber production also supports sustainable agriculture practices. As demand for cellulose-based materials grows, it incentivizes responsible forest management and the cultivation of fast-growing plant species for cellulose extraction. This can lead to increased carbon sequestration and the development of sustainable supply chains in the long term.

Moreover, the biocompatibility of MCC-based nanofibers opens up new possibilities for sustainable applications in healthcare and environmental remediation. These nanofibers can be used in wound dressings, drug delivery systems, and water filtration membranes, offering eco-friendly solutions to critical global challenges.

The use of MCC in electrospinning contributes to reduced environmental impact throughout the product lifecycle. Unlike petroleum-based polymers, MCC production requires less energy and generates fewer greenhouse gas emissions. Additionally, the biodegradability of MCC-based nanofibers ensures that they can decompose naturally at the end of their useful life, minimizing waste accumulation in landfills and oceans.

From a resource conservation perspective, MCC integration promotes the efficient use of cellulose, one of the most abundant natural polymers on Earth. This helps to decrease reliance on non-renewable resources and supports the circular economy concept. Furthermore, the versatility of MCC allows for the development of multifunctional nanofibers with enhanced properties, potentially reducing the need for additional chemical treatments or coatings.

The sustainability benefits extend to the electrospinning process itself. MCC-based solutions often require less toxic solvents compared to synthetic polymer alternatives, leading to safer working conditions and reduced environmental hazards. This aspect is particularly crucial in scaling up production for industrial applications, where large volumes of solvents may be used.

In terms of energy efficiency, the incorporation of MCC can potentially lower the energy requirements of the electrospinning process. The unique properties of MCC, such as its high surface area and crystalline structure, may facilitate fiber formation at lower voltages or flow rates, thereby optimizing energy consumption during production.

The adoption of MCC in nanofiber production also supports sustainable agriculture practices. As demand for cellulose-based materials grows, it incentivizes responsible forest management and the cultivation of fast-growing plant species for cellulose extraction. This can lead to increased carbon sequestration and the development of sustainable supply chains in the long term.

Moreover, the biocompatibility of MCC-based nanofibers opens up new possibilities for sustainable applications in healthcare and environmental remediation. These nanofibers can be used in wound dressings, drug delivery systems, and water filtration membranes, offering eco-friendly solutions to critical global challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!