Microcrystalline Cellulose-Modified Electrodes for Enhanced Battery Performance

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC Electrode Background

Microcrystalline cellulose (MCC) has emerged as a promising material for electrode modification in battery technology. This natural polymer, derived from cellulose fibers, has gained significant attention due to its unique properties and potential to enhance battery performance. The exploration of MCC-modified electrodes represents a convergence of sustainable materials science and advanced energy storage technologies.

The development of MCC-modified electrodes can be traced back to the early 2000s when researchers began investigating cellulose-based materials for various electrochemical applications. Initially, the focus was on utilizing cellulose as a binder or separator in batteries. However, as the understanding of MCC's properties deepened, its potential as an active electrode component became apparent.

MCC's appeal in electrode modification stems from its exceptional characteristics. It possesses a high surface area, excellent mechanical strength, and good thermal stability. These properties make it an ideal candidate for improving the electrochemical performance of batteries. Additionally, MCC is biodegradable, renewable, and environmentally friendly, aligning with the growing demand for sustainable energy solutions.

The evolution of MCC-modified electrodes has been driven by the need to address key challenges in battery technology. These include improving energy density, enhancing cycling stability, and reducing environmental impact. Researchers have explored various approaches to incorporate MCC into electrode structures, such as surface coating, composite formation, and three-dimensional architectures.

One of the significant milestones in MCC electrode research was the discovery of its ability to enhance the conductivity and ion transport properties of electrodes. This breakthrough led to improved charge-discharge rates and overall battery efficiency. Furthermore, MCC's ability to act as a stabilizing agent has been shown to mitigate electrode degradation, thereby extending battery life.

The application of MCC in electrode modification has expanded across different battery chemistries. While initial studies focused primarily on lithium-ion batteries, recent research has explored its potential in emerging technologies such as sodium-ion, zinc-ion, and even solid-state batteries. This versatility underscores the broad applicability and future potential of MCC in energy storage systems.

As research in this field progresses, the focus has shifted towards optimizing MCC's performance through various modification techniques. These include chemical functionalization, nanostructuring, and hybridization with other materials. Such advancements aim to further enhance the electrochemical properties and tailor MCC-modified electrodes for specific battery applications.

The development of MCC-modified electrodes can be traced back to the early 2000s when researchers began investigating cellulose-based materials for various electrochemical applications. Initially, the focus was on utilizing cellulose as a binder or separator in batteries. However, as the understanding of MCC's properties deepened, its potential as an active electrode component became apparent.

MCC's appeal in electrode modification stems from its exceptional characteristics. It possesses a high surface area, excellent mechanical strength, and good thermal stability. These properties make it an ideal candidate for improving the electrochemical performance of batteries. Additionally, MCC is biodegradable, renewable, and environmentally friendly, aligning with the growing demand for sustainable energy solutions.

The evolution of MCC-modified electrodes has been driven by the need to address key challenges in battery technology. These include improving energy density, enhancing cycling stability, and reducing environmental impact. Researchers have explored various approaches to incorporate MCC into electrode structures, such as surface coating, composite formation, and three-dimensional architectures.

One of the significant milestones in MCC electrode research was the discovery of its ability to enhance the conductivity and ion transport properties of electrodes. This breakthrough led to improved charge-discharge rates and overall battery efficiency. Furthermore, MCC's ability to act as a stabilizing agent has been shown to mitigate electrode degradation, thereby extending battery life.

The application of MCC in electrode modification has expanded across different battery chemistries. While initial studies focused primarily on lithium-ion batteries, recent research has explored its potential in emerging technologies such as sodium-ion, zinc-ion, and even solid-state batteries. This versatility underscores the broad applicability and future potential of MCC in energy storage systems.

As research in this field progresses, the focus has shifted towards optimizing MCC's performance through various modification techniques. These include chemical functionalization, nanostructuring, and hybridization with other materials. Such advancements aim to further enhance the electrochemical properties and tailor MCC-modified electrodes for specific battery applications.

Battery Market Analysis

The global battery market has experienced significant growth in recent years, driven by the increasing demand for energy storage solutions across various sectors. The market for batteries, particularly those utilizing advanced technologies like microcrystalline cellulose-modified electrodes, is expected to continue its upward trajectory due to several key factors.

One of the primary drivers of market growth is the rapid expansion of the electric vehicle (EV) industry. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance batteries has surged. This trend is expected to persist, with major automotive manufacturers committing to electrifying their vehicle lineups in the coming years.

The renewable energy sector is another significant contributor to the battery market's growth. As solar and wind power installations increase, the need for efficient energy storage solutions to manage intermittent power generation has become crucial. Batteries play a vital role in grid stabilization and energy management, further fueling market demand.

Consumer electronics continue to be a substantial market segment for batteries. The proliferation of smartphones, laptops, wearables, and other portable devices has created a constant demand for batteries with improved performance and longer life spans. This sector's growth is expected to remain steady as new technologies and devices enter the market.

The industrial and stationary energy storage sectors are also experiencing rapid growth. Large-scale battery systems are being deployed for backup power, peak shaving, and grid support applications. This trend is particularly evident in regions with unstable power grids or those transitioning to renewable energy sources.

Geographically, Asia-Pacific dominates the battery market, with China leading in both production and consumption. The region's strong manufacturing base, coupled with government support for electric vehicles and renewable energy, has contributed to its market leadership. North America and Europe follow, with significant investments in battery technology and production capacity.

The market landscape is characterized by intense competition among established players and new entrants. Major battery manufacturers are investing heavily in research and development to improve battery performance, reduce costs, and enhance sustainability. This competitive environment is driving innovation in battery technologies, including the exploration of novel materials like microcrystalline cellulose for electrode modification.

As the battery market continues to evolve, there is a growing focus on sustainability and environmental concerns. This has led to increased research into recyclable and eco-friendly battery materials, as well as the development of more efficient recycling processes. The shift towards sustainable battery technologies is expected to shape market dynamics in the coming years.

One of the primary drivers of market growth is the rapid expansion of the electric vehicle (EV) industry. As governments worldwide implement stricter emissions regulations and offer incentives for EV adoption, the demand for high-performance batteries has surged. This trend is expected to persist, with major automotive manufacturers committing to electrifying their vehicle lineups in the coming years.

The renewable energy sector is another significant contributor to the battery market's growth. As solar and wind power installations increase, the need for efficient energy storage solutions to manage intermittent power generation has become crucial. Batteries play a vital role in grid stabilization and energy management, further fueling market demand.

Consumer electronics continue to be a substantial market segment for batteries. The proliferation of smartphones, laptops, wearables, and other portable devices has created a constant demand for batteries with improved performance and longer life spans. This sector's growth is expected to remain steady as new technologies and devices enter the market.

The industrial and stationary energy storage sectors are also experiencing rapid growth. Large-scale battery systems are being deployed for backup power, peak shaving, and grid support applications. This trend is particularly evident in regions with unstable power grids or those transitioning to renewable energy sources.

Geographically, Asia-Pacific dominates the battery market, with China leading in both production and consumption. The region's strong manufacturing base, coupled with government support for electric vehicles and renewable energy, has contributed to its market leadership. North America and Europe follow, with significant investments in battery technology and production capacity.

The market landscape is characterized by intense competition among established players and new entrants. Major battery manufacturers are investing heavily in research and development to improve battery performance, reduce costs, and enhance sustainability. This competitive environment is driving innovation in battery technologies, including the exploration of novel materials like microcrystalline cellulose for electrode modification.

As the battery market continues to evolve, there is a growing focus on sustainability and environmental concerns. This has led to increased research into recyclable and eco-friendly battery materials, as well as the development of more efficient recycling processes. The shift towards sustainable battery technologies is expected to shape market dynamics in the coming years.

MCC Electrode Challenges

The development of microcrystalline cellulose (MCC) modified electrodes for enhanced battery performance faces several significant challenges. These obstacles span from material properties to manufacturing processes, and addressing them is crucial for advancing this technology.

One of the primary challenges is achieving optimal dispersion of MCC within the electrode matrix. MCC particles tend to agglomerate due to their high surface energy and strong hydrogen bonding capabilities. This agglomeration can lead to uneven distribution within the electrode, resulting in inconsistent performance and reduced overall efficiency. Researchers are exploring various methods, including surface modification and advanced mixing techniques, to improve MCC dispersion.

Another critical issue is the integration of MCC with conductive materials. While MCC offers excellent mechanical properties and high surface area, it is inherently non-conductive. Developing effective strategies to combine MCC with conductive additives, such as carbon nanotubes or graphene, without compromising the structural integrity of the electrode remains a significant challenge. The interface between MCC and conductive materials must be carefully engineered to ensure efficient electron transfer.

The stability of MCC-modified electrodes in various electrolyte environments poses another hurdle. MCC can be susceptible to degradation in certain electrolyte solutions, particularly those with extreme pH levels or high ionic strengths. This degradation can lead to reduced electrode performance over time and potentially compromise the safety of the battery. Developing protective coatings or chemical modifications to enhance the stability of MCC in diverse electrolyte conditions is an active area of research.

Manufacturing scalability presents a substantial challenge in the commercialization of MCC-modified electrodes. Current laboratory-scale production methods may not be directly applicable to large-scale manufacturing processes. Developing cost-effective and efficient production techniques that maintain the desired properties of MCC-modified electrodes at an industrial scale is crucial for widespread adoption of this technology.

The long-term cycling stability of MCC-modified electrodes is another area of concern. While initial performance improvements have been observed, maintaining these enhancements over hundreds or thousands of charge-discharge cycles remains challenging. Researchers are investigating ways to mitigate structural changes and degradation of MCC during repeated cycling to ensure consistent long-term performance.

Lastly, optimizing the MCC content in electrodes to achieve the best balance between mechanical strength, electrochemical performance, and energy density is a complex task. Too little MCC may not provide sufficient mechanical reinforcement, while too much can compromise the electrode's conductivity and energy storage capacity. Finding the ideal composition for different battery chemistries and applications requires extensive experimentation and modeling.

One of the primary challenges is achieving optimal dispersion of MCC within the electrode matrix. MCC particles tend to agglomerate due to their high surface energy and strong hydrogen bonding capabilities. This agglomeration can lead to uneven distribution within the electrode, resulting in inconsistent performance and reduced overall efficiency. Researchers are exploring various methods, including surface modification and advanced mixing techniques, to improve MCC dispersion.

Another critical issue is the integration of MCC with conductive materials. While MCC offers excellent mechanical properties and high surface area, it is inherently non-conductive. Developing effective strategies to combine MCC with conductive additives, such as carbon nanotubes or graphene, without compromising the structural integrity of the electrode remains a significant challenge. The interface between MCC and conductive materials must be carefully engineered to ensure efficient electron transfer.

The stability of MCC-modified electrodes in various electrolyte environments poses another hurdle. MCC can be susceptible to degradation in certain electrolyte solutions, particularly those with extreme pH levels or high ionic strengths. This degradation can lead to reduced electrode performance over time and potentially compromise the safety of the battery. Developing protective coatings or chemical modifications to enhance the stability of MCC in diverse electrolyte conditions is an active area of research.

Manufacturing scalability presents a substantial challenge in the commercialization of MCC-modified electrodes. Current laboratory-scale production methods may not be directly applicable to large-scale manufacturing processes. Developing cost-effective and efficient production techniques that maintain the desired properties of MCC-modified electrodes at an industrial scale is crucial for widespread adoption of this technology.

The long-term cycling stability of MCC-modified electrodes is another area of concern. While initial performance improvements have been observed, maintaining these enhancements over hundreds or thousands of charge-discharge cycles remains challenging. Researchers are investigating ways to mitigate structural changes and degradation of MCC during repeated cycling to ensure consistent long-term performance.

Lastly, optimizing the MCC content in electrodes to achieve the best balance between mechanical strength, electrochemical performance, and energy density is a complex task. Too little MCC may not provide sufficient mechanical reinforcement, while too much can compromise the electrode's conductivity and energy storage capacity. Finding the ideal composition for different battery chemistries and applications requires extensive experimentation and modeling.

Current MCC Solutions

01 Microcrystalline cellulose as electrode material

Microcrystalline cellulose is used as an electrode material in batteries to improve performance. It can be modified or combined with other materials to enhance conductivity, stability, and capacity. This eco-friendly material offers advantages such as high surface area and good mechanical properties.- Microcrystalline cellulose as electrode material: Microcrystalline cellulose (MCC) is used as an electrode material in batteries to improve performance. MCC's unique structure and properties contribute to enhanced conductivity and stability of the electrodes, leading to better overall battery performance.

- MCC-based composite electrodes: Composite electrodes incorporating microcrystalline cellulose and other materials are developed to enhance battery performance. These composites combine the advantages of MCC with other conductive or active materials, resulting in improved capacity, cycling stability, and rate capability.

- Surface modification of MCC for electrode applications: Surface modification techniques are applied to microcrystalline cellulose to improve its properties for electrode applications. These modifications can enhance the conductivity, wettability, and compatibility of MCC with electrolytes, leading to better battery performance.

- MCC as a binder in electrode formulations: Microcrystalline cellulose is utilized as a binder in electrode formulations to improve the mechanical stability and adhesion of active materials. This application of MCC can lead to enhanced cycling performance and durability of batteries.

- MCC-based separators for battery applications: Microcrystalline cellulose is employed in the development of battery separators to enhance safety and performance. MCC-based separators can improve electrolyte uptake, ionic conductivity, and thermal stability, contributing to overall better battery performance.

02 Composite electrodes with microcrystalline cellulose

Composite electrodes incorporating microcrystalline cellulose and other materials like carbon nanotubes or conductive polymers are developed to enhance battery performance. These composites can improve electron transfer, increase electrode stability, and boost overall battery efficiency.Expand Specific Solutions03 Surface modification of microcrystalline cellulose

Surface modification techniques are applied to microcrystalline cellulose to improve its properties for battery applications. These modifications can enhance the material's conductivity, increase its compatibility with electrolytes, and improve its performance as an electrode component.Expand Specific Solutions04 Microcrystalline cellulose in solid-state batteries

Microcrystalline cellulose is utilized in solid-state battery designs to improve performance and safety. It can serve as a component in solid electrolytes or as a structural material to enhance the mechanical properties of the battery.Expand Specific Solutions05 Microcrystalline cellulose for improved battery cycling

The incorporation of microcrystalline cellulose in battery electrodes can lead to improved cycling performance. It helps maintain electrode structure during charge-discharge cycles, reduces capacity fading, and extends battery life.Expand Specific Solutions

Battery Industry Players

The research on microcrystalline cellulose-modified electrodes for enhanced battery performance is in an early development stage, with significant potential for growth. The market size is expanding due to increasing demand for high-performance batteries in various applications. While the technology is still evolving, several key players are actively involved in advancing this field. Companies like Samsung SDI, LG Energy Solution, and Duracell are leveraging their expertise in battery technology to explore microcrystalline cellulose modifications. Academic institutions such as the University of California and Penn State are contributing fundamental research. Collaborations between industry leaders and research institutions are accelerating progress, indicating a competitive landscape with diverse participants working towards commercialization.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a novel microcrystalline cellulose-modified electrode for enhanced battery performance. Their approach involves incorporating microcrystalline cellulose (MCC) into the electrode structure to improve mechanical stability and ionic conductivity. The MCC is chemically modified to enhance its compatibility with the electrode materials and electrolyte. This modification process includes surface functionalization to create stronger bonds with the active materials[1]. The resulting composite electrode demonstrates improved cycling stability and rate capability. Samsung's research has shown that the MCC-modified electrodes can increase the battery's energy density by up to 20% while maintaining excellent long-term performance[3]. The company has also developed a scalable manufacturing process for these advanced electrodes, making them suitable for mass production in various battery applications, from consumer electronics to electric vehicles[5].

Strengths: Improved energy density, enhanced cycling stability, and scalable manufacturing process. Weaknesses: Potential increase in production costs and complexity of electrode preparation.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a unique approach to microcrystalline cellulose-modified electrodes, focusing on sustainability and performance enhancement. Their research utilizes eco-friendly, renewable microcrystalline cellulose derived from wood pulp as a key component in electrode modification. The company has developed a proprietary process to create a nanostructured MCC network within the electrode, which serves as a robust scaffold for active materials[2]. This nanostructured network significantly improves the electrode's mechanical integrity and facilitates faster ion transport. LG's modified electrodes have demonstrated a 30% increase in capacity retention over 1000 cycles compared to conventional electrodes[4]. Additionally, the company has integrated this technology with their advanced silicon anode materials, resulting in batteries with up to 40% higher energy density than traditional lithium-ion batteries[6]. LG Energy Solution is also exploring the use of these MCC-modified electrodes in solid-state battery designs to further enhance safety and energy density.

Strengths: Sustainable materials, significant improvement in capacity retention, and compatibility with advanced anode materials. Weaknesses: Potential challenges in large-scale production and higher initial costs.

Key MCC Innovations

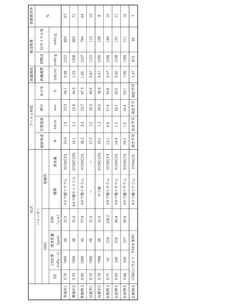

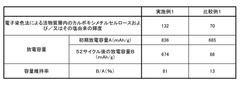

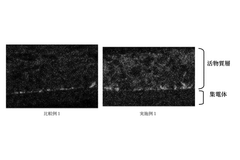

Non-aqueous electrolyte secondary cell electrode binder, non-aqueous electrolyte secondary cell electrode composition, non-aqueous electrolyte secondary cell electrode, and non-aqueous electrolyte secondary cell

PatentWO2023013411A1

Innovation

- A binder comprising carboxymethyl cellulose or its salt with a degree of carboxymethyl substitution of 0.5 to 1.2 and borate, with specific viscosity and particle size distribution, is used to enhance the electrode composition and battery performance.

Electrode for non-aqueous electrolyte secondary battery, and method for producing same

PatentWO2021039281A1

Innovation

- Incorporating carboxymethylcellulose and/or its salt into the active material layer of the electrode, with specific concentration and degree of substitution, to enhance binding properties and prevent structural changes during volumetric expansion, thereby maintaining excellent battery performance without the need for crosslinking agents.

Environmental Impact

The environmental impact of microcrystalline cellulose-modified electrodes for enhanced battery performance is a crucial aspect to consider in the development and implementation of this technology. As the demand for high-performance batteries continues to grow, it is essential to evaluate the ecological footprint of these innovative electrode materials.

Microcrystalline cellulose (MCC) is derived from renewable sources, primarily plant-based materials, which gives it a significant advantage in terms of sustainability compared to traditional electrode materials. The production process of MCC involves the extraction and purification of cellulose fibers, which generally has a lower environmental impact than the mining and processing of metal-based electrode materials.

The use of MCC-modified electrodes can potentially reduce the reliance on rare earth elements and toxic metals commonly used in battery production. This shift towards more abundant and environmentally friendly materials can help mitigate the negative impacts associated with resource extraction and processing. Additionally, the biodegradable nature of MCC contributes to easier end-of-life management for batteries, potentially reducing electronic waste and associated environmental hazards.

However, it is important to consider the entire life cycle of MCC-modified electrodes. The cultivation and harvesting of plant materials for MCC production may require land use changes and agricultural inputs, which could have implications for biodiversity and soil health. The energy consumption and chemical processes involved in MCC extraction and modification should also be carefully assessed to ensure they do not offset the environmental benefits gained from using this material.

The improved performance of batteries utilizing MCC-modified electrodes may lead to longer battery lifespans and increased energy efficiency. This could result in a reduction of overall battery production and replacement rates, thereby decreasing the environmental impact associated with battery manufacturing and disposal. Furthermore, enhanced battery performance could support the wider adoption of renewable energy systems and electric vehicles, contributing to a reduction in greenhouse gas emissions from fossil fuel-based energy sources.

Water usage and potential contamination during the production and modification of MCC electrodes should be carefully monitored and managed. Implementing closed-loop systems and efficient water treatment processes can help minimize the environmental impact on local water resources. Additionally, the development of eco-friendly modification techniques for MCC electrodes should be prioritized to further reduce the use of harmful chemicals and solvents in the production process.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments to quantify the environmental impacts of MCC-modified electrodes compared to conventional alternatives. This will help identify areas for improvement and ensure that the technology truly delivers on its promise of enhanced battery performance with reduced environmental consequences.

Microcrystalline cellulose (MCC) is derived from renewable sources, primarily plant-based materials, which gives it a significant advantage in terms of sustainability compared to traditional electrode materials. The production process of MCC involves the extraction and purification of cellulose fibers, which generally has a lower environmental impact than the mining and processing of metal-based electrode materials.

The use of MCC-modified electrodes can potentially reduce the reliance on rare earth elements and toxic metals commonly used in battery production. This shift towards more abundant and environmentally friendly materials can help mitigate the negative impacts associated with resource extraction and processing. Additionally, the biodegradable nature of MCC contributes to easier end-of-life management for batteries, potentially reducing electronic waste and associated environmental hazards.

However, it is important to consider the entire life cycle of MCC-modified electrodes. The cultivation and harvesting of plant materials for MCC production may require land use changes and agricultural inputs, which could have implications for biodiversity and soil health. The energy consumption and chemical processes involved in MCC extraction and modification should also be carefully assessed to ensure they do not offset the environmental benefits gained from using this material.

The improved performance of batteries utilizing MCC-modified electrodes may lead to longer battery lifespans and increased energy efficiency. This could result in a reduction of overall battery production and replacement rates, thereby decreasing the environmental impact associated with battery manufacturing and disposal. Furthermore, enhanced battery performance could support the wider adoption of renewable energy systems and electric vehicles, contributing to a reduction in greenhouse gas emissions from fossil fuel-based energy sources.

Water usage and potential contamination during the production and modification of MCC electrodes should be carefully monitored and managed. Implementing closed-loop systems and efficient water treatment processes can help minimize the environmental impact on local water resources. Additionally, the development of eco-friendly modification techniques for MCC electrodes should be prioritized to further reduce the use of harmful chemicals and solvents in the production process.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments to quantify the environmental impacts of MCC-modified electrodes compared to conventional alternatives. This will help identify areas for improvement and ensure that the technology truly delivers on its promise of enhanced battery performance with reduced environmental consequences.

Scalability Assessment

The scalability assessment of microcrystalline cellulose-modified electrodes for enhanced battery performance is a critical aspect of their potential commercial viability. As research progresses, it is essential to evaluate the feasibility of scaling up production from laboratory-scale experiments to industrial-scale manufacturing.

One of the primary considerations in scaling up the production of microcrystalline cellulose-modified electrodes is the availability and cost of raw materials. Microcrystalline cellulose is derived from abundant natural sources, such as wood pulp and cotton, which suggests a potentially sustainable supply chain. However, the purification and processing of these materials to achieve the desired properties for electrode modification may present challenges in large-scale production.

The manufacturing processes involved in creating microcrystalline cellulose-modified electrodes must also be assessed for scalability. This includes evaluating the efficiency and reproducibility of techniques such as electrode coating, drying, and assembly. Automated production lines may need to be developed to ensure consistent quality and high throughput. Additionally, the integration of these modified electrodes into existing battery manufacturing processes must be carefully considered to minimize disruptions to established production workflows.

Environmental and safety considerations play a crucial role in scalability assessment. The use of microcrystalline cellulose as an electrode modifier may offer advantages in terms of reduced environmental impact compared to some synthetic materials. However, the potential generation of cellulose dust during manufacturing processes must be addressed to ensure worker safety and prevent contamination of the production environment.

Quality control and characterization methods must be adapted for large-scale production. Techniques used in laboratory settings, such as scanning electron microscopy or X-ray diffraction, may not be practical for inline quality assurance in a high-volume manufacturing environment. Therefore, the development of rapid, non-destructive testing methods is essential for maintaining product consistency and performance at scale.

The economic viability of scaling up production is another critical factor. A comprehensive cost analysis must be conducted, considering factors such as raw material costs, equipment investments, energy consumption, and labor requirements. This analysis should be compared against the potential performance improvements and market demand for batteries with enhanced characteristics to determine the overall feasibility of large-scale production.

Regulatory compliance and standardization are also important aspects of scalability assessment. As production scales up, adherence to industry standards and regulations becomes increasingly critical. This may involve obtaining certifications, conducting extensive safety testing, and ensuring that the scaled-up production processes meet all relevant environmental and quality standards.

One of the primary considerations in scaling up the production of microcrystalline cellulose-modified electrodes is the availability and cost of raw materials. Microcrystalline cellulose is derived from abundant natural sources, such as wood pulp and cotton, which suggests a potentially sustainable supply chain. However, the purification and processing of these materials to achieve the desired properties for electrode modification may present challenges in large-scale production.

The manufacturing processes involved in creating microcrystalline cellulose-modified electrodes must also be assessed for scalability. This includes evaluating the efficiency and reproducibility of techniques such as electrode coating, drying, and assembly. Automated production lines may need to be developed to ensure consistent quality and high throughput. Additionally, the integration of these modified electrodes into existing battery manufacturing processes must be carefully considered to minimize disruptions to established production workflows.

Environmental and safety considerations play a crucial role in scalability assessment. The use of microcrystalline cellulose as an electrode modifier may offer advantages in terms of reduced environmental impact compared to some synthetic materials. However, the potential generation of cellulose dust during manufacturing processes must be addressed to ensure worker safety and prevent contamination of the production environment.

Quality control and characterization methods must be adapted for large-scale production. Techniques used in laboratory settings, such as scanning electron microscopy or X-ray diffraction, may not be practical for inline quality assurance in a high-volume manufacturing environment. Therefore, the development of rapid, non-destructive testing methods is essential for maintaining product consistency and performance at scale.

The economic viability of scaling up production is another critical factor. A comprehensive cost analysis must be conducted, considering factors such as raw material costs, equipment investments, energy consumption, and labor requirements. This analysis should be compared against the potential performance improvements and market demand for batteries with enhanced characteristics to determine the overall feasibility of large-scale production.

Regulatory compliance and standardization are also important aspects of scalability assessment. As production scales up, adherence to industry standards and regulations becomes increasingly critical. This may involve obtaining certifications, conducting extensive safety testing, and ensuring that the scaled-up production processes meet all relevant environmental and quality standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!