Analyzing the Impact of Microcrystalline Cellulose on Sol-Gel Transitions

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sol-Gel Transition Background and Objectives

Sol-gel transitions represent a fundamental process in materials science, involving the transformation of a liquid solution (sol) into a solid, gel-like network. This phenomenon has been extensively studied and applied across various fields, including ceramics, pharmaceuticals, and advanced materials. The evolution of sol-gel technology can be traced back to the mid-19th century, with significant advancements occurring in the latter half of the 20th century.

The primary objective of analyzing the impact of microcrystalline cellulose on sol-gel transitions is to enhance our understanding of how this natural polymer influences the formation, structure, and properties of gel networks. Microcrystalline cellulose, derived from plant sources, has gained attention due to its unique properties and potential to modify sol-gel systems in novel ways.

Sol-gel transitions typically involve the hydrolysis and condensation of metal alkoxides or other precursors, leading to the formation of a three-dimensional network. The introduction of microcrystalline cellulose into this process can significantly alter the kinetics, morphology, and mechanical properties of the resulting gel. Understanding these effects is crucial for developing advanced materials with tailored characteristics.

The technological trajectory in this field has been driven by the need for more sustainable and biocompatible materials. Microcrystalline cellulose, being a renewable and biodegradable substance, aligns well with these objectives. Its incorporation into sol-gel systems opens up possibilities for creating hybrid organic-inorganic materials with enhanced properties and reduced environmental impact.

Current research aims to elucidate the mechanisms by which microcrystalline cellulose interacts with sol-gel precursors and influences the gelation process. This includes investigating how the cellulose particles affect nucleation, growth, and aggregation of the gel network, as well as studying the resulting changes in porosity, surface area, and mechanical strength.

The potential applications of microcrystalline cellulose-modified sol-gel materials are diverse and promising. They range from advanced drug delivery systems and tissue engineering scaffolds in the biomedical field to high-performance coatings and catalysts in industrial applications. The ability to fine-tune material properties through the careful control of microcrystalline cellulose content and sol-gel processing conditions offers exciting possibilities for innovation.

As we delve deeper into this research area, our goal is to develop a comprehensive understanding of the structure-property relationships in these hybrid systems. This knowledge will enable the rational design of new materials with optimized performance for specific applications, potentially revolutionizing fields such as biomaterials, energy storage, and environmental remediation.

The primary objective of analyzing the impact of microcrystalline cellulose on sol-gel transitions is to enhance our understanding of how this natural polymer influences the formation, structure, and properties of gel networks. Microcrystalline cellulose, derived from plant sources, has gained attention due to its unique properties and potential to modify sol-gel systems in novel ways.

Sol-gel transitions typically involve the hydrolysis and condensation of metal alkoxides or other precursors, leading to the formation of a three-dimensional network. The introduction of microcrystalline cellulose into this process can significantly alter the kinetics, morphology, and mechanical properties of the resulting gel. Understanding these effects is crucial for developing advanced materials with tailored characteristics.

The technological trajectory in this field has been driven by the need for more sustainable and biocompatible materials. Microcrystalline cellulose, being a renewable and biodegradable substance, aligns well with these objectives. Its incorporation into sol-gel systems opens up possibilities for creating hybrid organic-inorganic materials with enhanced properties and reduced environmental impact.

Current research aims to elucidate the mechanisms by which microcrystalline cellulose interacts with sol-gel precursors and influences the gelation process. This includes investigating how the cellulose particles affect nucleation, growth, and aggregation of the gel network, as well as studying the resulting changes in porosity, surface area, and mechanical strength.

The potential applications of microcrystalline cellulose-modified sol-gel materials are diverse and promising. They range from advanced drug delivery systems and tissue engineering scaffolds in the biomedical field to high-performance coatings and catalysts in industrial applications. The ability to fine-tune material properties through the careful control of microcrystalline cellulose content and sol-gel processing conditions offers exciting possibilities for innovation.

As we delve deeper into this research area, our goal is to develop a comprehensive understanding of the structure-property relationships in these hybrid systems. This knowledge will enable the rational design of new materials with optimized performance for specific applications, potentially revolutionizing fields such as biomaterials, energy storage, and environmental remediation.

Market Analysis for MCC-Enhanced Sol-Gel Products

The market for microcrystalline cellulose (MCC)-enhanced sol-gel products is experiencing significant growth, driven by increasing demand across various industries. The unique properties of MCC, when incorporated into sol-gel systems, offer enhanced mechanical strength, improved thermal stability, and superior rheological characteristics, making these products highly attractive for a wide range of applications.

In the pharmaceutical industry, MCC-enhanced sol-gel products are gaining traction as excipients in drug delivery systems. The market for these products is expected to expand due to the growing emphasis on controlled release formulations and the need for more efficient drug delivery mechanisms. The food and beverage sector is another key market, where MCC-enhanced sol-gel products are utilized as stabilizers, thickeners, and texturizing agents, catering to the increasing consumer demand for clean label and natural ingredients.

The cosmetics and personal care industry represents a rapidly growing market segment for MCC-enhanced sol-gel products. These materials are being incorporated into various formulations, including creams, lotions, and gels, to improve texture, stability, and sensory properties. The market is driven by the rising consumer preference for natural and sustainable beauty products, aligning well with the eco-friendly nature of MCC.

In the construction and building materials sector, MCC-enhanced sol-gel products are finding applications in advanced insulation materials, coatings, and adhesives. The market growth in this segment is fueled by the increasing focus on energy-efficient buildings and sustainable construction practices. The automotive industry is also emerging as a promising market, with MCC-enhanced sol-gel products being used in lightweight composites and advanced coatings.

The global market for MCC-enhanced sol-gel products is characterized by regional variations in demand and adoption rates. North America and Europe currently lead in terms of market share, owing to their well-established pharmaceutical and personal care industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable incomes, and growing awareness of advanced materials in countries like China and India.

Key market trends include the development of novel MCC-based sol-gel composites with tailored properties for specific applications, increasing research and development activities focused on improving the performance of these materials, and growing collaborations between academic institutions and industry players to accelerate innovation in this field. The market is also seeing a shift towards more sustainable and bio-based sol-gel precursors, aligning with global sustainability goals.

In the pharmaceutical industry, MCC-enhanced sol-gel products are gaining traction as excipients in drug delivery systems. The market for these products is expected to expand due to the growing emphasis on controlled release formulations and the need for more efficient drug delivery mechanisms. The food and beverage sector is another key market, where MCC-enhanced sol-gel products are utilized as stabilizers, thickeners, and texturizing agents, catering to the increasing consumer demand for clean label and natural ingredients.

The cosmetics and personal care industry represents a rapidly growing market segment for MCC-enhanced sol-gel products. These materials are being incorporated into various formulations, including creams, lotions, and gels, to improve texture, stability, and sensory properties. The market is driven by the rising consumer preference for natural and sustainable beauty products, aligning well with the eco-friendly nature of MCC.

In the construction and building materials sector, MCC-enhanced sol-gel products are finding applications in advanced insulation materials, coatings, and adhesives. The market growth in this segment is fueled by the increasing focus on energy-efficient buildings and sustainable construction practices. The automotive industry is also emerging as a promising market, with MCC-enhanced sol-gel products being used in lightweight composites and advanced coatings.

The global market for MCC-enhanced sol-gel products is characterized by regional variations in demand and adoption rates. North America and Europe currently lead in terms of market share, owing to their well-established pharmaceutical and personal care industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable incomes, and growing awareness of advanced materials in countries like China and India.

Key market trends include the development of novel MCC-based sol-gel composites with tailored properties for specific applications, increasing research and development activities focused on improving the performance of these materials, and growing collaborations between academic institutions and industry players to accelerate innovation in this field. The market is also seeing a shift towards more sustainable and bio-based sol-gel precursors, aligning with global sustainability goals.

Current Challenges in MCC-Sol-Gel Systems

The integration of microcrystalline cellulose (MCC) into sol-gel systems presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary issues is achieving uniform dispersion of MCC particles within the sol-gel matrix. The hydrophilic nature of MCC often leads to agglomeration, which can result in inhomogeneous structures and compromised mechanical properties of the final material.

Another challenge lies in controlling the kinetics of the sol-gel transition in the presence of MCC. The addition of MCC can significantly alter the gelation time and the overall network formation process. This unpredictability makes it difficult to optimize processing conditions and achieve consistent product quality. Researchers are still working to develop robust models that can accurately predict the impact of MCC concentration on sol-gel transition rates.

The interaction between MCC and the precursor molecules in the sol-gel system is another area of concern. MCC's hydroxyl groups can potentially interfere with the hydrolysis and condensation reactions that are fundamental to the sol-gel process. This interference may lead to incomplete network formation or undesired modifications to the final material's properties. Understanding and controlling these interactions at the molecular level remains a significant challenge.

Porosity control is also a critical issue in MCC-sol-gel systems. While MCC can be used to introduce porosity, precisely tailoring the pore size distribution and interconnectivity is challenging. This is particularly important for applications requiring specific surface areas or controlled release properties. Current research is focused on developing methods to fine-tune the porosity without compromising the structural integrity of the material.

Scalability and reproducibility of MCC-sol-gel systems pose additional challenges. Laboratory-scale successes often face difficulties when translated to industrial production. Maintaining consistent quality and properties across larger batch sizes is problematic due to the complex interplay of factors influencing the sol-gel transition. This scaling issue is a significant barrier to the widespread adoption of MCC-sol-gel technologies in commercial applications.

Lastly, the long-term stability of MCC-sol-gel composites is an ongoing concern. Environmental factors such as humidity and temperature can affect the material's properties over time. Understanding and mitigating these aging effects is crucial for developing products with reliable performance throughout their intended lifespan. Current research efforts are directed towards improving the durability and stability of these composite materials under various environmental conditions.

Another challenge lies in controlling the kinetics of the sol-gel transition in the presence of MCC. The addition of MCC can significantly alter the gelation time and the overall network formation process. This unpredictability makes it difficult to optimize processing conditions and achieve consistent product quality. Researchers are still working to develop robust models that can accurately predict the impact of MCC concentration on sol-gel transition rates.

The interaction between MCC and the precursor molecules in the sol-gel system is another area of concern. MCC's hydroxyl groups can potentially interfere with the hydrolysis and condensation reactions that are fundamental to the sol-gel process. This interference may lead to incomplete network formation or undesired modifications to the final material's properties. Understanding and controlling these interactions at the molecular level remains a significant challenge.

Porosity control is also a critical issue in MCC-sol-gel systems. While MCC can be used to introduce porosity, precisely tailoring the pore size distribution and interconnectivity is challenging. This is particularly important for applications requiring specific surface areas or controlled release properties. Current research is focused on developing methods to fine-tune the porosity without compromising the structural integrity of the material.

Scalability and reproducibility of MCC-sol-gel systems pose additional challenges. Laboratory-scale successes often face difficulties when translated to industrial production. Maintaining consistent quality and properties across larger batch sizes is problematic due to the complex interplay of factors influencing the sol-gel transition. This scaling issue is a significant barrier to the widespread adoption of MCC-sol-gel technologies in commercial applications.

Lastly, the long-term stability of MCC-sol-gel composites is an ongoing concern. Environmental factors such as humidity and temperature can affect the material's properties over time. Understanding and mitigating these aging effects is crucial for developing products with reliable performance throughout their intended lifespan. Current research efforts are directed towards improving the durability and stability of these composite materials under various environmental conditions.

Existing MCC-Sol-Gel Integration Methods

01 Sol-gel transition mechanisms of microcrystalline cellulose

The sol-gel transition of microcrystalline cellulose involves the transformation from a liquid suspension to a solid-like gel state. This process is influenced by factors such as concentration, temperature, and pH. Understanding these mechanisms is crucial for controlling the properties of the resulting gel and its applications in various industries.- Sol-gel transition mechanisms of microcrystalline cellulose: The sol-gel transition of microcrystalline cellulose involves the transformation from a liquid-like sol state to a solid-like gel state. This process is influenced by factors such as concentration, temperature, and pH. Understanding these mechanisms is crucial for controlling the properties of MCC-based materials in various applications.

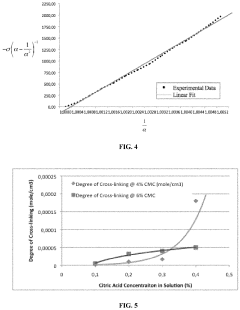

- Modification of microcrystalline cellulose for improved sol-gel properties: Chemical or physical modifications of microcrystalline cellulose can enhance its sol-gel transition behavior. These modifications may include surface treatments, crosslinking, or incorporation of additives to improve stability, mechanical properties, or responsiveness to external stimuli.

- Applications of microcrystalline cellulose sol-gel systems: Microcrystalline cellulose sol-gel systems find applications in various fields such as pharmaceuticals, food industry, cosmetics, and materials science. These applications leverage the unique properties of MCC gels, including their biocompatibility, biodegradability, and tunable mechanical characteristics.

- Characterization techniques for microcrystalline cellulose sol-gel transitions: Various analytical methods are employed to study the sol-gel transitions of microcrystalline cellulose. These techniques may include rheology, spectroscopy, microscopy, and thermal analysis, which provide insights into the structural changes, kinetics, and properties of the sol-gel system during the transition process.

- Composite materials incorporating microcrystalline cellulose sol-gels: Microcrystalline cellulose sol-gels can be combined with other materials to create composite systems with enhanced properties. These composites may exhibit improved mechanical strength, thermal stability, or functional characteristics, making them suitable for advanced applications in areas such as tissue engineering, drug delivery, and smart materials.

02 Modification of microcrystalline cellulose for enhanced sol-gel properties

Chemical and physical modifications of microcrystalline cellulose can enhance its sol-gel transition properties. These modifications may include surface treatments, crosslinking, or incorporation of additives to improve gel strength, stability, and functionality. Such modifications expand the potential applications of microcrystalline cellulose in areas like drug delivery and material science.Expand Specific Solutions03 Applications of microcrystalline cellulose sol-gel in pharmaceuticals

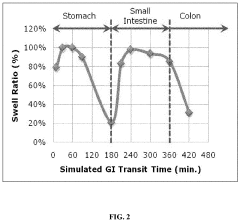

Microcrystalline cellulose sol-gel systems have significant applications in the pharmaceutical industry. They can be used as drug carriers, controlled release matrices, and excipients in various dosage forms. The unique properties of these sol-gel systems allow for improved drug stability, bioavailability, and targeted delivery.Expand Specific Solutions04 Characterization techniques for microcrystalline cellulose sol-gel transitions

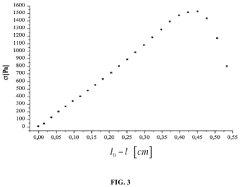

Various analytical techniques are employed to characterize the sol-gel transitions of microcrystalline cellulose. These may include rheological measurements, microscopy, spectroscopy, and thermal analysis. Such characterization is essential for understanding the structure-property relationships and optimizing the sol-gel systems for specific applications.Expand Specific Solutions05 Environmental and sustainability aspects of microcrystalline cellulose sol-gels

Microcrystalline cellulose sol-gels are gaining attention for their potential in developing sustainable and environmentally friendly materials. Being derived from renewable resources, these sol-gels offer advantages in terms of biodegradability and reduced environmental impact. Research is ongoing to explore their use in eco-friendly packaging, water treatment, and other green technologies.Expand Specific Solutions

Key Players in MCC and Sol-Gel Research

The analysis of microcrystalline cellulose's impact on sol-gel transitions is in an early developmental stage, with a growing market potential due to its applications in pharmaceuticals, cosmetics, and materials science. The global market size for microcrystalline cellulose is expanding, driven by increasing demand in various industries. Technologically, the field is advancing rapidly, with companies like FMC Corp., DuPont de Nemours, and Merck Millipore leading research efforts. Academic institutions such as Vanderbilt University and South China University of Technology are also contributing significantly to the knowledge base, indicating a collaborative approach between industry and academia in pushing the boundaries of this technology.

FMC Corp.

Technical Solution: FMC Corp. has developed advanced microcrystalline cellulose (MCC) products specifically designed to influence sol-gel transitions. Their proprietary MCC technology, known as FMC BioPolymer, utilizes a unique particle size distribution and surface modification process to enhance the stability and rheological properties of sol-gel systems[1]. This technology allows for precise control over the gelation process, enabling the creation of gels with tailored mechanical properties and release profiles. FMC's MCC products have been shown to significantly impact the sol-gel transition temperature, gelation kinetics, and final gel strength in various applications, including pharmaceuticals, food, and personal care products[2][3].

Strengths: Extensive experience in MCC production, proprietary surface modification techniques, and a wide range of MCC grades for different applications. Weaknesses: Potential limitations in extreme pH conditions or high-temperature applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel approach to utilizing microcrystalline cellulose in sol-gel transitions, focusing on nanocellulose-based materials. Their research has led to the creation of cellulose nanocrystals (CNCs) and cellulose nanofibrils (CNFs) that can significantly influence sol-gel behavior[4]. These nanoscale cellulose particles exhibit unique properties, including high surface area and strong hydrogen bonding capabilities, which allow for enhanced control over sol-gel transitions. DuPont's technology enables the formation of highly stable and responsive hydrogels with improved mechanical properties and stimuli-responsive characteristics[5]. The company has successfully applied this technology in various fields, including drug delivery systems, tissue engineering scaffolds, and advanced coating materials[6].

Strengths: Cutting-edge nanocellulose technology, diverse application potential, and strong R&D capabilities. Weaknesses: Higher production costs compared to traditional MCC, and potential scalability challenges for certain applications.

Core Innovations in MCC-Sol-Gel Interactions

Method for producing hydrogels

PatentInactiveUS20220073651A1

Innovation

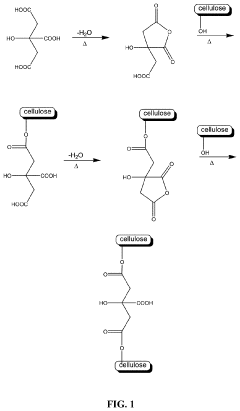

- Cross-linking water-soluble cellulose derivatives like carboxymethylcellulose with low levels of polycarboxylic acids, specifically citric acid, to form highly absorbent and mechanically stable polymer hydrogels through a chemical cross-linking process involving heating and agitation, resulting in improved water absorption and retention properties.

Environmental Impact of MCC-Sol-Gel Materials

The environmental impact of microcrystalline cellulose (MCC) and sol-gel materials is a crucial consideration in their development and application. As these materials gain prominence in various industries, understanding their ecological footprint becomes increasingly important.

MCC-sol-gel composites offer several environmental advantages. Being derived from cellulose, a renewable resource, MCC contributes to the sustainability of these materials. The production process of MCC typically involves less energy consumption compared to synthetic alternatives, potentially reducing carbon emissions. Furthermore, the biodegradability of MCC enhances the overall eco-friendliness of the composite materials.

However, the environmental impact is not uniformly positive. The extraction and processing of cellulose to produce MCC may involve chemical treatments that generate waste products. The disposal or treatment of these byproducts requires careful management to prevent environmental contamination. Additionally, the energy requirements for the sol-gel process itself must be considered in the overall environmental assessment.

The use of MCC-sol-gel materials in various applications can have both positive and negative environmental implications. In water treatment applications, these materials show promise for removing pollutants, potentially improving water quality and reducing the need for harsher chemical treatments. However, the long-term effects of introducing these materials into aquatic ecosystems are not yet fully understood and require further investigation.

In the context of packaging and construction materials, MCC-sol-gel composites offer potential benefits such as improved biodegradability and reduced reliance on petroleum-based products. This could lead to a decrease in plastic waste and associated environmental issues. However, the durability and recyclability of these materials in practical applications need to be carefully evaluated to ensure they do not create new environmental challenges.

The end-of-life considerations for MCC-sol-gel materials are also significant. While the biodegradability of MCC is advantageous, the complete breakdown of the composite materials and their potential to release nanoparticles into the environment must be studied. The impact of these materials on soil ecosystems and their potential for bioaccumulation in food chains are areas that require thorough research.

As the development of MCC-sol-gel materials progresses, life cycle assessments will be crucial in comprehensively evaluating their environmental impact. These assessments should consider raw material sourcing, production processes, use-phase performance, and end-of-life scenarios. Such holistic evaluations will guide the optimization of these materials for minimal environmental impact while maximizing their functional benefits.

MCC-sol-gel composites offer several environmental advantages. Being derived from cellulose, a renewable resource, MCC contributes to the sustainability of these materials. The production process of MCC typically involves less energy consumption compared to synthetic alternatives, potentially reducing carbon emissions. Furthermore, the biodegradability of MCC enhances the overall eco-friendliness of the composite materials.

However, the environmental impact is not uniformly positive. The extraction and processing of cellulose to produce MCC may involve chemical treatments that generate waste products. The disposal or treatment of these byproducts requires careful management to prevent environmental contamination. Additionally, the energy requirements for the sol-gel process itself must be considered in the overall environmental assessment.

The use of MCC-sol-gel materials in various applications can have both positive and negative environmental implications. In water treatment applications, these materials show promise for removing pollutants, potentially improving water quality and reducing the need for harsher chemical treatments. However, the long-term effects of introducing these materials into aquatic ecosystems are not yet fully understood and require further investigation.

In the context of packaging and construction materials, MCC-sol-gel composites offer potential benefits such as improved biodegradability and reduced reliance on petroleum-based products. This could lead to a decrease in plastic waste and associated environmental issues. However, the durability and recyclability of these materials in practical applications need to be carefully evaluated to ensure they do not create new environmental challenges.

The end-of-life considerations for MCC-sol-gel materials are also significant. While the biodegradability of MCC is advantageous, the complete breakdown of the composite materials and their potential to release nanoparticles into the environment must be studied. The impact of these materials on soil ecosystems and their potential for bioaccumulation in food chains are areas that require thorough research.

As the development of MCC-sol-gel materials progresses, life cycle assessments will be crucial in comprehensively evaluating their environmental impact. These assessments should consider raw material sourcing, production processes, use-phase performance, and end-of-life scenarios. Such holistic evaluations will guide the optimization of these materials for minimal environmental impact while maximizing their functional benefits.

Scalability and Industrial Applications

The scalability and industrial applications of microcrystalline cellulose (MCC) in sol-gel transitions present significant opportunities for various sectors. MCC's unique properties, including its high surface area, biodegradability, and ability to form stable suspensions, make it an attractive candidate for large-scale production and diverse industrial uses.

In terms of scalability, MCC production has seen substantial advancements in recent years. Traditional methods of acid hydrolysis have been optimized for industrial-scale production, allowing for higher yields and more consistent quality. Emerging technologies, such as enzymatic hydrolysis and mechanochemical processes, show promise for even more efficient and environmentally friendly large-scale MCC production.

The food industry has been at the forefront of MCC adoption, utilizing its sol-gel properties for texture modification and stabilization in a wide range of products. As production scales up, MCC is increasingly being incorporated into low-fat and reduced-calorie foods, where it can mimic the mouthfeel of fats while reducing overall caloric content. This application is particularly relevant given the growing consumer demand for healthier food options.

In the pharmaceutical sector, MCC's role in sol-gel transitions is being leveraged for controlled drug release systems. The scalability of MCC production has enabled its widespread use as an excipient in tablet formulations. Research is ongoing to develop more sophisticated drug delivery systems that take advantage of MCC's sol-gel behavior, potentially leading to novel formulations with improved bioavailability and targeted release profiles.

The personal care and cosmetics industry is another area where MCC's sol-gel properties are finding increased application. As production scales up, MCC is being incorporated into a broader range of products, from creams and lotions to more complex formulations like sunscreens and anti-aging products. Its ability to form stable gels and act as a thickening agent without synthetic additives aligns well with the growing consumer preference for natural and sustainable ingredients.

In the field of materials science, MCC's sol-gel transitions are being explored for the development of advanced materials. The scalability of MCC production is enabling research into areas such as biodegradable packaging, where MCC-based films and coatings could offer environmentally friendly alternatives to traditional plastics. Additionally, the potential for MCC in composite materials is being investigated, with applications ranging from lightweight structural materials to advanced filtration systems.

As industrial applications expand, there is a growing focus on optimizing MCC's performance in sol-gel systems across different environments and conditions. This includes research into modifying MCC to enhance its stability, improve its compatibility with other materials, and tailor its sol-gel transition properties for specific applications. Such advancements are crucial for broadening MCC's industrial applicability and ensuring its effectiveness in diverse product formulations.

In terms of scalability, MCC production has seen substantial advancements in recent years. Traditional methods of acid hydrolysis have been optimized for industrial-scale production, allowing for higher yields and more consistent quality. Emerging technologies, such as enzymatic hydrolysis and mechanochemical processes, show promise for even more efficient and environmentally friendly large-scale MCC production.

The food industry has been at the forefront of MCC adoption, utilizing its sol-gel properties for texture modification and stabilization in a wide range of products. As production scales up, MCC is increasingly being incorporated into low-fat and reduced-calorie foods, where it can mimic the mouthfeel of fats while reducing overall caloric content. This application is particularly relevant given the growing consumer demand for healthier food options.

In the pharmaceutical sector, MCC's role in sol-gel transitions is being leveraged for controlled drug release systems. The scalability of MCC production has enabled its widespread use as an excipient in tablet formulations. Research is ongoing to develop more sophisticated drug delivery systems that take advantage of MCC's sol-gel behavior, potentially leading to novel formulations with improved bioavailability and targeted release profiles.

The personal care and cosmetics industry is another area where MCC's sol-gel properties are finding increased application. As production scales up, MCC is being incorporated into a broader range of products, from creams and lotions to more complex formulations like sunscreens and anti-aging products. Its ability to form stable gels and act as a thickening agent without synthetic additives aligns well with the growing consumer preference for natural and sustainable ingredients.

In the field of materials science, MCC's sol-gel transitions are being explored for the development of advanced materials. The scalability of MCC production is enabling research into areas such as biodegradable packaging, where MCC-based films and coatings could offer environmentally friendly alternatives to traditional plastics. Additionally, the potential for MCC in composite materials is being investigated, with applications ranging from lightweight structural materials to advanced filtration systems.

As industrial applications expand, there is a growing focus on optimizing MCC's performance in sol-gel systems across different environments and conditions. This includes research into modifying MCC to enhance its stability, improve its compatibility with other materials, and tailor its sol-gel transition properties for specific applications. Such advancements are crucial for broadening MCC's industrial applicability and ensuring its effectiveness in diverse product formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!