Exploring Microcrystalline Cellulose as a Biodegradable Microencapsulation Agent

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC Microencapsulation Background and Objectives

Microcrystalline cellulose (MCC) has emerged as a promising biodegradable material for microencapsulation applications, addressing the growing demand for sustainable and environmentally friendly solutions in various industries. The exploration of MCC as a microencapsulation agent is driven by the increasing awareness of environmental issues associated with conventional synthetic materials and the need for biodegradable alternatives.

The development of MCC-based microencapsulation techniques has its roots in the broader field of cellulose research, which has been ongoing for decades. Cellulose, as the most abundant natural polymer on Earth, has long been recognized for its versatility and potential in numerous applications. The refinement of cellulose into microcrystalline form has opened up new possibilities for its use in advanced materials and technologies.

The primary objective of exploring MCC as a biodegradable microencapsulation agent is to create a sustainable alternative to synthetic polymers commonly used in encapsulation processes. This aligns with global efforts to reduce plastic pollution and promote the use of renewable resources in industrial applications. MCC offers several advantages, including biocompatibility, biodegradability, and abundance, making it an attractive option for encapsulating various active ingredients.

Another key goal is to enhance the performance and functionality of microencapsulated products. MCC's unique properties, such as its high surface area and crystalline structure, offer potential improvements in encapsulation efficiency, controlled release mechanisms, and overall stability of encapsulated substances. Researchers aim to leverage these properties to develop advanced microencapsulation systems that can outperform existing solutions in terms of both environmental sustainability and functional performance.

The exploration of MCC in microencapsulation also seeks to expand its applications across diverse industries. While initial research has focused on food and pharmaceutical applications, there is growing interest in extending MCC-based microencapsulation to other sectors, including cosmetics, agriculture, and textiles. This expansion requires a comprehensive understanding of MCC's behavior in different environments and its interactions with various types of active ingredients.

Furthermore, the research aims to optimize the production and modification processes of MCC to tailor its properties for specific microencapsulation requirements. This includes investigating different sources of cellulose, refining techniques, and surface modifications to enhance MCC's functionality as an encapsulating agent. The ultimate goal is to develop a versatile and customizable MCC-based microencapsulation platform that can be adapted to a wide range of applications and industrial needs.

The development of MCC-based microencapsulation techniques has its roots in the broader field of cellulose research, which has been ongoing for decades. Cellulose, as the most abundant natural polymer on Earth, has long been recognized for its versatility and potential in numerous applications. The refinement of cellulose into microcrystalline form has opened up new possibilities for its use in advanced materials and technologies.

The primary objective of exploring MCC as a biodegradable microencapsulation agent is to create a sustainable alternative to synthetic polymers commonly used in encapsulation processes. This aligns with global efforts to reduce plastic pollution and promote the use of renewable resources in industrial applications. MCC offers several advantages, including biocompatibility, biodegradability, and abundance, making it an attractive option for encapsulating various active ingredients.

Another key goal is to enhance the performance and functionality of microencapsulated products. MCC's unique properties, such as its high surface area and crystalline structure, offer potential improvements in encapsulation efficiency, controlled release mechanisms, and overall stability of encapsulated substances. Researchers aim to leverage these properties to develop advanced microencapsulation systems that can outperform existing solutions in terms of both environmental sustainability and functional performance.

The exploration of MCC in microencapsulation also seeks to expand its applications across diverse industries. While initial research has focused on food and pharmaceutical applications, there is growing interest in extending MCC-based microencapsulation to other sectors, including cosmetics, agriculture, and textiles. This expansion requires a comprehensive understanding of MCC's behavior in different environments and its interactions with various types of active ingredients.

Furthermore, the research aims to optimize the production and modification processes of MCC to tailor its properties for specific microencapsulation requirements. This includes investigating different sources of cellulose, refining techniques, and surface modifications to enhance MCC's functionality as an encapsulating agent. The ultimate goal is to develop a versatile and customizable MCC-based microencapsulation platform that can be adapted to a wide range of applications and industrial needs.

Market Analysis for Biodegradable Encapsulation

The market for biodegradable encapsulation agents is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on plastic waste. Microcrystalline cellulose (MCC) has emerged as a promising biodegradable microencapsulation agent, attracting attention from various industries due to its eco-friendly properties and versatile applications.

The global biodegradable packaging market, which includes microencapsulation agents, is projected to expand rapidly in the coming years. This growth is fueled by consumer demand for sustainable products and corporate commitments to reduce environmental impact. The food and beverage industry represents the largest market segment for biodegradable encapsulation, followed by pharmaceuticals and personal care products.

MCC-based microencapsulation offers several advantages over traditional synthetic materials. Its biodegradability addresses the growing concern over plastic pollution, while its natural origin appeals to consumers seeking clean-label products. The pharmaceutical industry, in particular, is showing increased interest in MCC for drug delivery systems, as it provides controlled release properties and improved bioavailability.

The cosmetics and personal care sector is another key market for MCC-based encapsulation. Manufacturers are incorporating MCC in various products, from skincare to hair care, to enhance product stability and efficacy. This trend aligns with the rising demand for natural and sustainable beauty products.

In the food industry, MCC is gaining traction as a microencapsulation agent for flavors, vitamins, and probiotics. Its ability to protect sensitive ingredients from degradation during processing and storage makes it an attractive option for functional food and nutraceutical applications. The growing popularity of fortified foods and beverages is expected to further drive demand for MCC-based encapsulation solutions.

Geographically, North America and Europe currently lead the market for biodegradable encapsulation agents, including MCC. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, changing consumer preferences, and increasing environmental awareness in countries like China and India.

Despite the positive market outlook, challenges remain for widespread adoption of MCC as a microencapsulation agent. These include the need for further research to optimize its performance in various applications and the development of cost-effective production methods to compete with synthetic alternatives. Additionally, regulatory approval processes for novel food and pharmaceutical applications may impact market growth in the short term.

As sustainability becomes a key focus across industries, the market potential for MCC and other biodegradable encapsulation agents is expected to expand significantly. Companies investing in research and development of MCC-based solutions are likely to gain a competitive edge in this growing market segment.

The global biodegradable packaging market, which includes microencapsulation agents, is projected to expand rapidly in the coming years. This growth is fueled by consumer demand for sustainable products and corporate commitments to reduce environmental impact. The food and beverage industry represents the largest market segment for biodegradable encapsulation, followed by pharmaceuticals and personal care products.

MCC-based microencapsulation offers several advantages over traditional synthetic materials. Its biodegradability addresses the growing concern over plastic pollution, while its natural origin appeals to consumers seeking clean-label products. The pharmaceutical industry, in particular, is showing increased interest in MCC for drug delivery systems, as it provides controlled release properties and improved bioavailability.

The cosmetics and personal care sector is another key market for MCC-based encapsulation. Manufacturers are incorporating MCC in various products, from skincare to hair care, to enhance product stability and efficacy. This trend aligns with the rising demand for natural and sustainable beauty products.

In the food industry, MCC is gaining traction as a microencapsulation agent for flavors, vitamins, and probiotics. Its ability to protect sensitive ingredients from degradation during processing and storage makes it an attractive option for functional food and nutraceutical applications. The growing popularity of fortified foods and beverages is expected to further drive demand for MCC-based encapsulation solutions.

Geographically, North America and Europe currently lead the market for biodegradable encapsulation agents, including MCC. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, changing consumer preferences, and increasing environmental awareness in countries like China and India.

Despite the positive market outlook, challenges remain for widespread adoption of MCC as a microencapsulation agent. These include the need for further research to optimize its performance in various applications and the development of cost-effective production methods to compete with synthetic alternatives. Additionally, regulatory approval processes for novel food and pharmaceutical applications may impact market growth in the short term.

As sustainability becomes a key focus across industries, the market potential for MCC and other biodegradable encapsulation agents is expected to expand significantly. Companies investing in research and development of MCC-based solutions are likely to gain a competitive edge in this growing market segment.

Current Challenges in MCC Microencapsulation

Despite the promising potential of microcrystalline cellulose (MCC) as a biodegradable microencapsulation agent, several challenges currently hinder its widespread adoption and optimal performance. One of the primary obstacles is the inherent hydrophilicity of MCC, which can lead to poor encapsulation efficiency for hydrophobic compounds. This characteristic limits its application in certain industries, particularly in the encapsulation of lipophilic active ingredients commonly used in pharmaceuticals and food products.

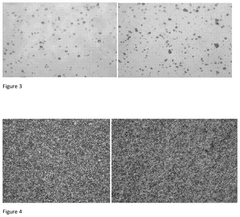

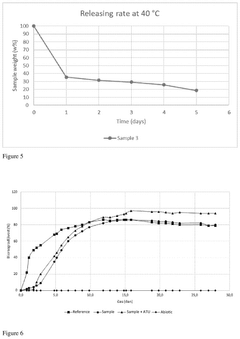

Another significant challenge lies in controlling the release kinetics of encapsulated substances from MCC-based microcapsules. The porous structure of MCC can sometimes result in rapid or uncontrolled release of the encapsulated material, which may not be desirable for applications requiring sustained or targeted release profiles. Achieving precise control over the release rate and duration remains a complex task that requires further research and development.

The mechanical strength and stability of MCC microcapsules also present challenges, especially in applications involving high shear forces or extreme environmental conditions. While MCC offers good biodegradability, enhancing its robustness without compromising its eco-friendly nature is a delicate balance that researchers are still working to optimize.

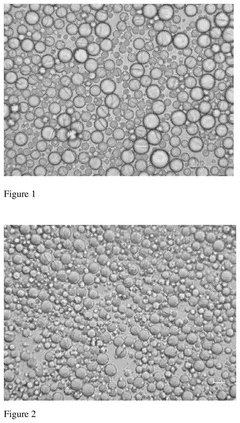

Scale-up and industrial production of MCC-based microencapsulation systems pose additional challenges. Maintaining consistent particle size distribution, encapsulation efficiency, and product quality during large-scale manufacturing processes can be difficult. The development of cost-effective and scalable production methods that preserve the desired properties of MCC microcapsules is crucial for commercial viability.

Furthermore, the compatibility of MCC with various active ingredients and its interaction with other excipients in complex formulations require extensive study. Some active compounds may not be suitable for encapsulation with MCC due to chemical incompatibilities or adverse effects on the stability of the encapsulated material.

Regulatory considerations also present challenges, particularly in the food and pharmaceutical industries. While MCC is generally recognized as safe (GRAS), its use as a microencapsulation agent may require additional safety assessments and regulatory approvals, depending on the specific application and jurisdiction.

Lastly, optimizing the surface modification of MCC to enhance its functionality as a microencapsulation agent remains an ongoing challenge. Researchers are exploring various chemical and physical modification techniques to improve MCC's encapsulation efficiency, controlled release properties, and compatibility with diverse active ingredients. However, developing modification methods that are both effective and environmentally friendly adds another layer of complexity to the research efforts in this field.

Another significant challenge lies in controlling the release kinetics of encapsulated substances from MCC-based microcapsules. The porous structure of MCC can sometimes result in rapid or uncontrolled release of the encapsulated material, which may not be desirable for applications requiring sustained or targeted release profiles. Achieving precise control over the release rate and duration remains a complex task that requires further research and development.

The mechanical strength and stability of MCC microcapsules also present challenges, especially in applications involving high shear forces or extreme environmental conditions. While MCC offers good biodegradability, enhancing its robustness without compromising its eco-friendly nature is a delicate balance that researchers are still working to optimize.

Scale-up and industrial production of MCC-based microencapsulation systems pose additional challenges. Maintaining consistent particle size distribution, encapsulation efficiency, and product quality during large-scale manufacturing processes can be difficult. The development of cost-effective and scalable production methods that preserve the desired properties of MCC microcapsules is crucial for commercial viability.

Furthermore, the compatibility of MCC with various active ingredients and its interaction with other excipients in complex formulations require extensive study. Some active compounds may not be suitable for encapsulation with MCC due to chemical incompatibilities or adverse effects on the stability of the encapsulated material.

Regulatory considerations also present challenges, particularly in the food and pharmaceutical industries. While MCC is generally recognized as safe (GRAS), its use as a microencapsulation agent may require additional safety assessments and regulatory approvals, depending on the specific application and jurisdiction.

Lastly, optimizing the surface modification of MCC to enhance its functionality as a microencapsulation agent remains an ongoing challenge. Researchers are exploring various chemical and physical modification techniques to improve MCC's encapsulation efficiency, controlled release properties, and compatibility with diverse active ingredients. However, developing modification methods that are both effective and environmentally friendly adds another layer of complexity to the research efforts in this field.

Existing MCC Microencapsulation Techniques

01 Production and modification of microcrystalline cellulose

Various methods are employed to produce and modify microcrystalline cellulose, including acid hydrolysis, enzymatic treatments, and mechanical processes. These techniques aim to improve the properties of microcrystalline cellulose for specific applications, such as enhancing its stability, particle size distribution, or surface characteristics.- Production and modification of microcrystalline cellulose: Various methods are employed to produce and modify microcrystalline cellulose, including acid hydrolysis, enzymatic treatments, and mechanical processes. These techniques aim to improve the properties of microcrystalline cellulose for specific applications, such as enhancing its stability, particle size distribution, or functionality.

- Applications in pharmaceutical formulations: Microcrystalline cellulose is widely used in pharmaceutical formulations as an excipient. It serves various functions, including as a binder, disintegrant, and filler in tablet and capsule formulations. Its properties contribute to improved drug release, stability, and overall performance of pharmaceutical products.

- Use in food and beverage industry: Microcrystalline cellulose finds applications in the food and beverage industry as a stabilizer, thickener, and texturizing agent. It is used in various products to improve consistency, mouthfeel, and shelf life. The material's unique properties make it suitable for use in low-fat and reduced-calorie food formulations.

- Applications in personal care and cosmetics: Microcrystalline cellulose is utilized in personal care and cosmetic products for its absorbent and texturizing properties. It is incorporated into formulations such as creams, lotions, and powders to improve stability, spreadability, and sensory characteristics. The material also acts as a mild abrasive in some products.

- Industrial and specialty applications: Microcrystalline cellulose has various industrial and specialty applications, including use in paints, coatings, adhesives, and as a reinforcing agent in composites. It is also employed in water treatment processes, as a filtration aid, and in the production of specialty papers. The material's versatility allows for its incorporation in diverse industrial processes and products.

02 Applications in pharmaceutical formulations

Microcrystalline cellulose is widely used in pharmaceutical formulations as an excipient. It serves various functions, including as a binder, disintegrant, and filler in tablet and capsule formulations. Its properties contribute to improved drug release, stability, and overall performance of pharmaceutical products.Expand Specific Solutions03 Use in food and cosmetic industries

Microcrystalline cellulose finds applications in food and cosmetic products as a stabilizer, thickener, and texturizing agent. It is used to improve the consistency, mouthfeel, and shelf-life of various food items and personal care products.Expand Specific Solutions04 Composite materials and reinforcement

Microcrystalline cellulose is utilized in the development of composite materials, where it acts as a reinforcing agent. It can enhance the mechanical properties, thermal stability, and biodegradability of various polymer-based composites, finding applications in packaging, construction, and automotive industries.Expand Specific Solutions05 Sustainable and eco-friendly applications

As a biodegradable and renewable material, microcrystalline cellulose is being explored for sustainable and eco-friendly applications. This includes its use in biodegradable packaging materials, water treatment processes, and as a replacement for synthetic materials in various industries.Expand Specific Solutions

Key Players in Biodegradable Microencapsulation

The exploration of microcrystalline cellulose as a biodegradable microencapsulation agent is in its early stages, with a growing market driven by increasing demand for sustainable packaging solutions. The technology is still evolving, with varying levels of maturity among key players. Companies like International Flavors & Fragrances, Encapsys LLC, and Calyxia SAS are at the forefront, leveraging their expertise in microencapsulation technologies. Academic institutions such as Donghua University and Rensselaer Polytechnic Institute are contributing to research advancements. While established chemical companies like Henkel AG & Co. KGaA and FMC Corp. have the resources to potentially accelerate development, innovative startups like Xampla Ltd. are introducing novel plant-based solutions, indicating a dynamic and competitive landscape in this emerging field.

Henkel AG & Co. KGaA

Technical Solution: Henkel AG & Co. KGaA has developed a proprietary microencapsulation technology utilizing microcrystalline cellulose (MCC) as a key component in their biodegradable shell formulations. Their approach combines MCC with other natural polymers to create hybrid microcapsules with enhanced stability and controlled release properties. Henkel's technology focuses on the encapsulation of fragrances and active ingredients for personal care and home products. The company has optimized a spray-drying process that allows for the production of uniform MCC-based microcapsules with high loading efficiency[10]. Henkel's research has shown that their MCC-hybrid microcapsules can extend the release of fragrances in detergents and fabric softeners by up to 30% longer compared to conventional encapsulation methods[11]. Additionally, the biodegradable nature of these microcapsules aligns with Henkel's sustainability goals and consumer demand for eco-friendly products.

Strengths: Improved fragrance longevity, environmentally friendly, compatible with existing product formulations. Weaknesses: Potential cost increase for raw materials, may require adjustments to manufacturing processes.

FMC Corp.

Technical Solution: FMC Corp. has developed a novel microencapsulation technique using microcrystalline cellulose (MCC) as a biodegradable agent. Their approach involves creating a stable emulsion of MCC particles and the active ingredient, followed by a controlled drying process to form microcapsules. The company has optimized the MCC particle size and surface modification to enhance encapsulation efficiency and release kinetics. FMC's method allows for the encapsulation of both hydrophilic and hydrophobic compounds, with a focus on agricultural and pharmaceutical applications[1][3]. The process is scalable and can be tailored to achieve different release profiles, from rapid to sustained release, by adjusting the MCC concentration and crosslinking degree[2].

Strengths: Biodegradable, versatile for various active ingredients, controllable release profiles. Weaknesses: May have limitations in high-temperature applications, potential for premature release in highly acidic or alkaline environments.

Innovative MCC Encapsulation Patents

Composition comprising colour-neutral degradable microcapsules

PatentInactiveEP4101528A1

Innovation

- The development of biodegradable microcapsules with a multilayer shell structure, comprising a thin barrier layer and a thicker stability layer made from biopolymers, where an emulsion stabilizer is used to enhance the deposition of the stability layer, improving the microcapsules' robustness and tightness.

Biodegradable microcapsules based on crystalline materials and synthesis process

PatentPendingUS20250222420A1

Innovation

- The use of biodegradable crystalline materials like waxes and paraffins as the encapsulating wall, which crystallize at lower temperatures to form microcapsules without a polymer framework, ensuring miscibility with the core material and maintaining stability through phase separation.

Environmental Impact Assessment

The environmental impact assessment of microcrystalline cellulose (MCC) as a biodegradable microencapsulation agent reveals a promising alternative to conventional synthetic materials. MCC, derived from natural cellulose sources, offers significant advantages in terms of sustainability and reduced ecological footprint.

One of the primary environmental benefits of MCC is its biodegradability. Unlike many synthetic encapsulation agents, MCC can naturally decompose in various environmental conditions, reducing the accumulation of persistent pollutants in ecosystems. This characteristic is particularly crucial in addressing the growing concern of microplastic pollution in aquatic environments.

The production process of MCC also demonstrates favorable environmental attributes. Compared to petroleum-based alternatives, MCC production typically requires less energy and generates fewer greenhouse gas emissions. The raw materials for MCC are often sourced from renewable plant-based resources, contributing to a more sustainable supply chain and reduced dependence on fossil fuels.

In terms of waste management, MCC presents advantages in both industrial and consumer contexts. Its biodegradable nature facilitates easier disposal and treatment in waste management systems, potentially reducing the burden on landfills and incineration facilities. This aspect is particularly relevant in the context of single-use or short-lived products where microencapsulation is applied.

Water pollution mitigation is another area where MCC shows promise. Unlike some synthetic encapsulation agents that may leach harmful chemicals into water systems, MCC's natural composition minimizes the risk of introducing toxic substances into aquatic environments. This property is especially valuable in applications related to agriculture, personal care products, and pharmaceuticals.

The use of MCC as a microencapsulation agent also aligns with the principles of circular economy. Its plant-based origin and biodegradability support the concept of material cycling, where resources are used, recovered, and regenerated in a closed-loop system. This approach contrasts sharply with the linear "take-make-dispose" model associated with many synthetic materials.

However, it is important to note that the environmental impact of MCC is not entirely without concerns. Large-scale production of MCC could potentially lead to increased demand for cellulose sources, which might impact forest resources if not managed sustainably. Additionally, the processing of raw cellulose into MCC requires chemical treatments, which necessitates careful management of effluents and byproducts to minimize environmental contamination.

In conclusion, while MCC as a biodegradable microencapsulation agent presents significant environmental advantages, a comprehensive life cycle assessment is crucial to fully understand and optimize its ecological impact across various applications and production scales.

One of the primary environmental benefits of MCC is its biodegradability. Unlike many synthetic encapsulation agents, MCC can naturally decompose in various environmental conditions, reducing the accumulation of persistent pollutants in ecosystems. This characteristic is particularly crucial in addressing the growing concern of microplastic pollution in aquatic environments.

The production process of MCC also demonstrates favorable environmental attributes. Compared to petroleum-based alternatives, MCC production typically requires less energy and generates fewer greenhouse gas emissions. The raw materials for MCC are often sourced from renewable plant-based resources, contributing to a more sustainable supply chain and reduced dependence on fossil fuels.

In terms of waste management, MCC presents advantages in both industrial and consumer contexts. Its biodegradable nature facilitates easier disposal and treatment in waste management systems, potentially reducing the burden on landfills and incineration facilities. This aspect is particularly relevant in the context of single-use or short-lived products where microencapsulation is applied.

Water pollution mitigation is another area where MCC shows promise. Unlike some synthetic encapsulation agents that may leach harmful chemicals into water systems, MCC's natural composition minimizes the risk of introducing toxic substances into aquatic environments. This property is especially valuable in applications related to agriculture, personal care products, and pharmaceuticals.

The use of MCC as a microencapsulation agent also aligns with the principles of circular economy. Its plant-based origin and biodegradability support the concept of material cycling, where resources are used, recovered, and regenerated in a closed-loop system. This approach contrasts sharply with the linear "take-make-dispose" model associated with many synthetic materials.

However, it is important to note that the environmental impact of MCC is not entirely without concerns. Large-scale production of MCC could potentially lead to increased demand for cellulose sources, which might impact forest resources if not managed sustainably. Additionally, the processing of raw cellulose into MCC requires chemical treatments, which necessitates careful management of effluents and byproducts to minimize environmental contamination.

In conclusion, while MCC as a biodegradable microencapsulation agent presents significant environmental advantages, a comprehensive life cycle assessment is crucial to fully understand and optimize its ecological impact across various applications and production scales.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials, particularly in the context of microcrystalline cellulose (MCC) as a microencapsulation agent, is a complex and evolving landscape. Various international bodies and national governments have established guidelines and standards to ensure the safety and efficacy of biodegradable materials in different applications.

At the forefront of this regulatory framework is the European Union (EU), which has implemented comprehensive regulations through the European Chemicals Agency (ECHA). The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers and importers to register substances, including biodegradable materials like MCC, and provide safety data before they can be marketed.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating biodegradable materials used in food packaging and pharmaceutical applications. The FDA has established specific guidelines for the use of MCC in food contact materials and as an inactive ingredient in drug formulations.

The International Organization for Standardization (ISO) has developed several standards relevant to biodegradable materials, including ISO 17088 for compostable plastics and ISO 14851 for determining the aerobic biodegradability of plastic materials in an aqueous medium.

Specific to microencapsulation, regulatory bodies often require manufacturers to demonstrate the safety and biodegradability of both the encapsulating agent (in this case, MCC) and the encapsulated substance. This involves providing data on degradation rates, potential environmental impacts, and toxicological assessments.

Many countries have implemented their own regulatory frameworks for biodegradable materials. For instance, Japan's Biodegradable Plastics Society (BPS) has established certification standards for biodegradable plastics, which could be applicable to MCC-based microencapsulation systems.

As environmental concerns grow, there is an increasing trend towards stricter regulations on biodegradable materials. This includes requirements for lifecycle assessments, end-of-life disposal considerations, and potential impacts on waste management systems.

Regulatory compliance for MCC as a biodegradable microencapsulation agent may also involve adherence to Good Manufacturing Practices (GMP) and quality control standards, especially when used in pharmaceutical or food applications.

The regulatory landscape is continually evolving, with ongoing research and policy developments shaping future guidelines. Companies exploring MCC for microencapsulation must stay abreast of these changes and engage proactively with regulatory bodies to ensure compliance and market acceptance.

At the forefront of this regulatory framework is the European Union (EU), which has implemented comprehensive regulations through the European Chemicals Agency (ECHA). The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers and importers to register substances, including biodegradable materials like MCC, and provide safety data before they can be marketed.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating biodegradable materials used in food packaging and pharmaceutical applications. The FDA has established specific guidelines for the use of MCC in food contact materials and as an inactive ingredient in drug formulations.

The International Organization for Standardization (ISO) has developed several standards relevant to biodegradable materials, including ISO 17088 for compostable plastics and ISO 14851 for determining the aerobic biodegradability of plastic materials in an aqueous medium.

Specific to microencapsulation, regulatory bodies often require manufacturers to demonstrate the safety and biodegradability of both the encapsulating agent (in this case, MCC) and the encapsulated substance. This involves providing data on degradation rates, potential environmental impacts, and toxicological assessments.

Many countries have implemented their own regulatory frameworks for biodegradable materials. For instance, Japan's Biodegradable Plastics Society (BPS) has established certification standards for biodegradable plastics, which could be applicable to MCC-based microencapsulation systems.

As environmental concerns grow, there is an increasing trend towards stricter regulations on biodegradable materials. This includes requirements for lifecycle assessments, end-of-life disposal considerations, and potential impacts on waste management systems.

Regulatory compliance for MCC as a biodegradable microencapsulation agent may also involve adherence to Good Manufacturing Practices (GMP) and quality control standards, especially when used in pharmaceutical or food applications.

The regulatory landscape is continually evolving, with ongoing research and policy developments shaping future guidelines. Companies exploring MCC for microencapsulation must stay abreast of these changes and engage proactively with regulatory bodies to ensure compliance and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!