Microcrystalline Cellulose in Plant-Based Edible Films: Mechanical Properties Analysis

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC in Edible Films: Background and Objectives

Microcrystalline cellulose (MCC) has emerged as a promising component in the development of plant-based edible films, addressing the growing demand for sustainable packaging solutions in the food industry. The evolution of this technology can be traced back to the early 2000s when researchers began exploring natural polymers as alternatives to synthetic plastics. MCC, derived from abundant cellulosic materials, has gained attention due to its biodegradability, non-toxicity, and potential to enhance mechanical properties of edible films.

The primary objective of incorporating MCC into plant-based edible films is to improve their mechanical strength, barrier properties, and overall functionality. This aligns with the broader goal of reducing environmental impact while meeting consumer expectations for food quality and safety. As the food packaging industry faces increasing pressure to adopt eco-friendly solutions, the development of MCC-enhanced edible films represents a significant technological advancement.

Recent years have witnessed a surge in research activities focused on optimizing MCC integration in various plant-based matrices. Scientists are exploring different sources of MCC, such as wood pulp, cotton, and agricultural residues, to identify the most effective and sustainable options. The mechanical properties analysis of these films is crucial in determining their viability for commercial applications, as it directly impacts their ability to protect food products during storage and transportation.

The technological trajectory of MCC in edible films is characterized by continuous improvements in processing techniques and formulation strategies. Researchers are investigating methods to enhance MCC dispersion within film matrices, optimize MCC concentration for maximum mechanical reinforcement, and develop hybrid systems that combine MCC with other bio-based materials. These efforts aim to create edible films with mechanical properties comparable to or surpassing those of conventional plastic packaging.

As the field progresses, there is a growing emphasis on understanding the fundamental mechanisms by which MCC influences the mechanical behavior of edible films. This includes studying the interactions between MCC and other film components at the molecular level, as well as examining the impact of MCC morphology and surface modifications on film performance. Such insights are essential for guiding future innovations and overcoming current limitations in mechanical properties.

The development of MCC-enhanced edible films is driven by both environmental concerns and market demands. Consumers are increasingly seeking sustainable packaging options, while regulatory bodies worldwide are implementing stricter policies on single-use plastics. This convergence of factors has created a favorable landscape for the advancement of MCC technology in food packaging applications, positioning it as a key player in the transition towards more sustainable food packaging solutions.

The primary objective of incorporating MCC into plant-based edible films is to improve their mechanical strength, barrier properties, and overall functionality. This aligns with the broader goal of reducing environmental impact while meeting consumer expectations for food quality and safety. As the food packaging industry faces increasing pressure to adopt eco-friendly solutions, the development of MCC-enhanced edible films represents a significant technological advancement.

Recent years have witnessed a surge in research activities focused on optimizing MCC integration in various plant-based matrices. Scientists are exploring different sources of MCC, such as wood pulp, cotton, and agricultural residues, to identify the most effective and sustainable options. The mechanical properties analysis of these films is crucial in determining their viability for commercial applications, as it directly impacts their ability to protect food products during storage and transportation.

The technological trajectory of MCC in edible films is characterized by continuous improvements in processing techniques and formulation strategies. Researchers are investigating methods to enhance MCC dispersion within film matrices, optimize MCC concentration for maximum mechanical reinforcement, and develop hybrid systems that combine MCC with other bio-based materials. These efforts aim to create edible films with mechanical properties comparable to or surpassing those of conventional plastic packaging.

As the field progresses, there is a growing emphasis on understanding the fundamental mechanisms by which MCC influences the mechanical behavior of edible films. This includes studying the interactions between MCC and other film components at the molecular level, as well as examining the impact of MCC morphology and surface modifications on film performance. Such insights are essential for guiding future innovations and overcoming current limitations in mechanical properties.

The development of MCC-enhanced edible films is driven by both environmental concerns and market demands. Consumers are increasingly seeking sustainable packaging options, while regulatory bodies worldwide are implementing stricter policies on single-use plastics. This convergence of factors has created a favorable landscape for the advancement of MCC technology in food packaging applications, positioning it as a key player in the transition towards more sustainable food packaging solutions.

Market Analysis for Plant-Based Packaging

The plant-based packaging market has experienced significant growth in recent years, driven by increasing consumer awareness of environmental issues and a shift towards sustainable alternatives. This trend is particularly evident in the food and beverage industry, where plant-based edible films incorporating microcrystalline cellulose (MCC) are gaining traction as a viable packaging solution.

The global market for plant-based packaging is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is fueled by stringent regulations on single-use plastics, rising demand for eco-friendly packaging materials, and changing consumer preferences towards sustainable products. The food and beverage sector accounts for the largest share of the plant-based packaging market, followed by personal care and cosmetics.

Microcrystalline cellulose, derived from plant sources such as wood pulp and cotton, is emerging as a key component in edible films due to its excellent mechanical properties and biodegradability. The MCC market is expected to grow steadily, with applications in food packaging being a major driver. The use of MCC in plant-based edible films addresses the increasing demand for packaging solutions that extend shelf life while reducing environmental impact.

Consumer demand for transparent and informative packaging is also influencing the market. Plant-based edible films with MCC offer the advantage of being clear and allowing consumers to see the product inside, which aligns with the growing trend of clean label and natural products. This transparency in both literal and figurative senses is becoming a key selling point for manufacturers adopting these packaging solutions.

Geographically, North America and Europe are leading the adoption of plant-based packaging, including edible films with MCC. However, Asia-Pacific is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing environmental consciousness in countries like China and India.

Despite the positive outlook, challenges remain in the widespread adoption of plant-based edible films with MCC. These include higher production costs compared to traditional packaging materials, limitations in barrier properties, and the need for further research to optimize mechanical strength and flexibility. Addressing these challenges will be crucial for market expansion and long-term success of MCC-based edible films in the plant-based packaging industry.

The global market for plant-based packaging is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is fueled by stringent regulations on single-use plastics, rising demand for eco-friendly packaging materials, and changing consumer preferences towards sustainable products. The food and beverage sector accounts for the largest share of the plant-based packaging market, followed by personal care and cosmetics.

Microcrystalline cellulose, derived from plant sources such as wood pulp and cotton, is emerging as a key component in edible films due to its excellent mechanical properties and biodegradability. The MCC market is expected to grow steadily, with applications in food packaging being a major driver. The use of MCC in plant-based edible films addresses the increasing demand for packaging solutions that extend shelf life while reducing environmental impact.

Consumer demand for transparent and informative packaging is also influencing the market. Plant-based edible films with MCC offer the advantage of being clear and allowing consumers to see the product inside, which aligns with the growing trend of clean label and natural products. This transparency in both literal and figurative senses is becoming a key selling point for manufacturers adopting these packaging solutions.

Geographically, North America and Europe are leading the adoption of plant-based packaging, including edible films with MCC. However, Asia-Pacific is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing environmental consciousness in countries like China and India.

Despite the positive outlook, challenges remain in the widespread adoption of plant-based edible films with MCC. These include higher production costs compared to traditional packaging materials, limitations in barrier properties, and the need for further research to optimize mechanical strength and flexibility. Addressing these challenges will be crucial for market expansion and long-term success of MCC-based edible films in the plant-based packaging industry.

Current Challenges in MCC-Enhanced Films

Despite the promising potential of microcrystalline cellulose (MCC) in enhancing plant-based edible films, several challenges persist in optimizing their mechanical properties. One of the primary obstacles is achieving uniform dispersion of MCC within the film matrix. The hydrophilic nature of MCC often leads to agglomeration, resulting in inconsistent mechanical strength across the film. This non-uniform distribution can create weak points, compromising the overall structural integrity of the film.

Another significant challenge lies in maintaining the desired flexibility of the films while incorporating MCC. As the concentration of MCC increases, films tend to become more brittle, limiting their practical applications in food packaging where flexibility is crucial. Striking the right balance between enhanced strength and maintained flexibility remains a complex task for researchers and manufacturers alike.

The interaction between MCC and other film components presents another hurdle. Different plant-based materials used as film matrices (such as starch, pectin, or protein) interact uniquely with MCC, affecting the final mechanical properties. Understanding and controlling these interactions to achieve consistent and predictable mechanical enhancements across various film compositions is an ongoing challenge.

Moisture sensitivity is a persistent issue in MCC-enhanced films. The hydrophilic nature of both MCC and many plant-based film matrices makes the films susceptible to moisture absorption, which can significantly alter their mechanical properties over time. Developing strategies to improve moisture resistance without compromising the biodegradability or edibility of the films is a critical area of research.

Scale-up and manufacturing processes pose additional challenges. Techniques that work well in laboratory settings for producing small batches of MCC-enhanced films may not translate effectively to large-scale production. Ensuring consistent mechanical properties across large film areas and between production batches remains a significant industrial challenge.

Lastly, the variability in MCC sources and characteristics adds another layer of complexity. MCC derived from different plant sources or produced through varying processes can exhibit different properties, affecting their performance in films. Standardizing MCC characteristics or developing methods to adapt film formulations to different MCC types is crucial for consistent mechanical property enhancement.

Addressing these challenges requires interdisciplinary approaches, combining insights from materials science, polymer chemistry, and food technology. Innovative solutions in MCC modification, novel dispersion techniques, and advanced manufacturing processes are needed to fully harness the potential of MCC in enhancing the mechanical properties of plant-based edible films.

Another significant challenge lies in maintaining the desired flexibility of the films while incorporating MCC. As the concentration of MCC increases, films tend to become more brittle, limiting their practical applications in food packaging where flexibility is crucial. Striking the right balance between enhanced strength and maintained flexibility remains a complex task for researchers and manufacturers alike.

The interaction between MCC and other film components presents another hurdle. Different plant-based materials used as film matrices (such as starch, pectin, or protein) interact uniquely with MCC, affecting the final mechanical properties. Understanding and controlling these interactions to achieve consistent and predictable mechanical enhancements across various film compositions is an ongoing challenge.

Moisture sensitivity is a persistent issue in MCC-enhanced films. The hydrophilic nature of both MCC and many plant-based film matrices makes the films susceptible to moisture absorption, which can significantly alter their mechanical properties over time. Developing strategies to improve moisture resistance without compromising the biodegradability or edibility of the films is a critical area of research.

Scale-up and manufacturing processes pose additional challenges. Techniques that work well in laboratory settings for producing small batches of MCC-enhanced films may not translate effectively to large-scale production. Ensuring consistent mechanical properties across large film areas and between production batches remains a significant industrial challenge.

Lastly, the variability in MCC sources and characteristics adds another layer of complexity. MCC derived from different plant sources or produced through varying processes can exhibit different properties, affecting their performance in films. Standardizing MCC characteristics or developing methods to adapt film formulations to different MCC types is crucial for consistent mechanical property enhancement.

Addressing these challenges requires interdisciplinary approaches, combining insights from materials science, polymer chemistry, and food technology. Innovative solutions in MCC modification, novel dispersion techniques, and advanced manufacturing processes are needed to fully harness the potential of MCC in enhancing the mechanical properties of plant-based edible films.

Existing MCC Incorporation Methods

01 Improved mechanical strength and stability

Microcrystalline cellulose (MCC) exhibits enhanced mechanical properties, including improved strength and stability. These characteristics make it suitable for various applications in industries such as pharmaceuticals, food, and materials science. The improved mechanical properties are attributed to the crystalline structure and particle size of MCC.- Improved mechanical strength and stability: Microcrystalline cellulose (MCC) exhibits enhanced mechanical properties, including improved strength and stability. These characteristics make it suitable for various applications in industries such as pharmaceuticals, food, and materials science. The mechanical properties can be further enhanced through specific processing techniques or by combining MCC with other materials.

- Particle size and morphology effects: The mechanical properties of microcrystalline cellulose are significantly influenced by its particle size and morphology. Controlling these parameters during production can lead to tailored mechanical characteristics, such as improved compressibility, flowability, and binding properties. This is particularly important in pharmaceutical tablet formulations and other applications requiring specific physical attributes.

- Composite materials and blends: Microcrystalline cellulose can be combined with other materials to create composites or blends with enhanced mechanical properties. These combinations can result in materials with improved strength, flexibility, or other desirable characteristics. Such composites find applications in various fields, including packaging, construction, and automotive industries.

- Surface modification and functionalization: The mechanical properties of microcrystalline cellulose can be modified through surface treatments or functionalization. These processes can alter the surface chemistry of MCC particles, leading to improved compatibility with other materials, enhanced dispersibility, or modified mechanical behavior. Such modifications expand the range of potential applications for MCC-based materials.

- Processing techniques and conditions: Various processing techniques and conditions can significantly impact the mechanical properties of microcrystalline cellulose. These include methods such as spray-drying, freeze-drying, or mechanical treatments like milling or homogenization. The choice of processing method and parameters can be tailored to achieve specific mechanical characteristics required for different applications.

02 Particle size and morphology effects

The particle size and morphology of microcrystalline cellulose significantly influence its mechanical properties. Smaller particle sizes and specific morphologies can lead to improved compressibility, flowability, and binding properties. These characteristics are crucial for applications in tablet formulation and as a reinforcing agent in composite materials.Expand Specific Solutions03 Moisture content and hygroscopicity

The moisture content and hygroscopic nature of microcrystalline cellulose play a crucial role in its mechanical properties. Controlled moisture levels can affect the material's compressibility, tensile strength, and overall performance in various applications. Understanding and managing these factors are essential for optimizing MCC's mechanical properties in different environmental conditions.Expand Specific Solutions04 Surface modification and functionalization

Surface modification and functionalization of microcrystalline cellulose can enhance its mechanical properties. Techniques such as chemical treatment, coating, or grafting can improve the material's compatibility with other substances, increase its strength, and modify its surface characteristics. These modifications expand the range of applications for MCC in various industries.Expand Specific Solutions05 Composite reinforcement capabilities

Microcrystalline cellulose demonstrates excellent potential as a reinforcing agent in composite materials. Its high strength-to-weight ratio, biodegradability, and ability to form strong interfacial bonds with various matrices make it an attractive option for enhancing the mechanical properties of composites. This capability is particularly valuable in the development of sustainable and high-performance materials.Expand Specific Solutions

Key Players in Biopolymer Film Industry

The microcrystalline cellulose market in plant-based edible films is in a growth phase, driven by increasing demand for sustainable packaging solutions. The market size is expanding due to rising consumer awareness of eco-friendly alternatives and stringent regulations on plastic use. Technologically, the field is advancing rapidly, with companies like CP Kelco, Stora Enso, and FMC Corp leading innovation. These firms are developing improved formulations to enhance mechanical properties of edible films. Academic institutions such as Nanjing University and South China University of Technology are also contributing to research advancements. The collaboration between industry and academia is accelerating the technology's maturity, positioning microcrystalline cellulose as a promising material for future food packaging applications.

CP Kelco US, Inc.

Technical Solution: CP Kelco has developed an innovative approach to incorporating MCC in plant-based edible films through their CELLULON™ Cellulose Liquid technology. This unique form of MCC is produced through bacterial fermentation, resulting in a highly pure, three-dimensional network of cellulose fibrils. When incorporated into edible films, CELLULON™ provides exceptional strength and flexibility due to its high aspect ratio and ability to form a continuous network within the film matrix[9]. CP Kelco's research has shown that films containing as little as 0.1% CELLULON™ can exhibit up to 200% increase in tensile strength and 150% improvement in elongation at break compared to films without it[10]. The company has also developed a patented process for creating hybrid films that combine CELLULON™ with other hydrocolloids, resulting in films with tailored mechanical and barrier properties for specific applications.

Strengths: Unique bacterial cellulose technology, significant improvements in mechanical properties at low concentrations, versatility in combination with other hydrocolloids. Weaknesses: Potentially higher production costs compared to plant-derived MCC, may require specialized handling and processing techniques.

Stora Enso Oyj

Technical Solution: Stora Enso has developed a novel approach to incorporating MCC in plant-based edible films through their MicroFibrillar Cellulose (MFC) technology. Their process involves mechanical fibrillation of cellulose fibers to produce nano-scale fibrils, which are then integrated into film formulations. This MFC-enhanced film exhibits significantly improved tensile strength and barrier properties compared to conventional MCC-based films[2]. Stora Enso's research has shown that MFC can increase the Young's modulus of starch-based films by up to 5000% at low loading levels (1-5%)[4]. Additionally, they have developed a patented surface treatment process for MFC that enhances its compatibility with hydrophobic polymers, further expanding its application in diverse film matrices.

Strengths: Innovative MFC technology, significant improvements in mechanical properties, versatility in various film matrices. Weaknesses: Potentially energy-intensive production process, may require modifications to existing film manufacturing lines.

Mechanical Property Enhancement Techniques

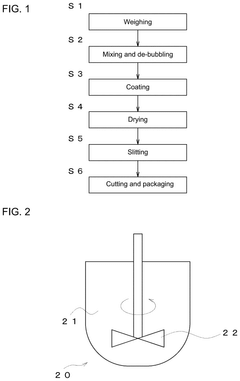

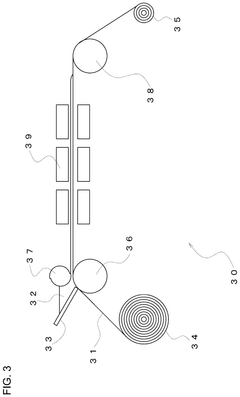

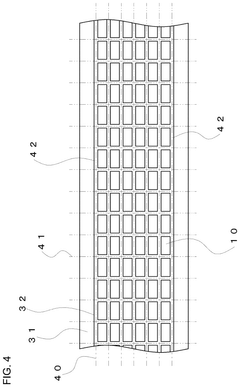

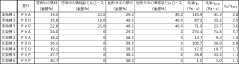

Edible film and method for manufacturing edible film

PatentPendingUS20250177536A1

Innovation

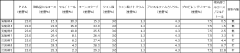

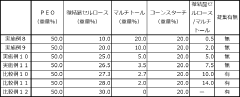

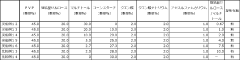

- Incorporating microcrystalline cellulose at a content of 5 to 50 wt% and maltitol, with specific ratios of microcrystalline cellulose to maltitol, into the edible film composition to enhance thixotropy, ensuring easy coating and uniform ingredient distribution.

Edible film and method for manufacturing same

PatentWO2024024185A1

Innovation

- Incorporating microcrystalline cellulose as a component in the edible film, with a content of 5-50% by weight, and optionally maltitol, to achieve thixotropy, allowing the solution to flow easily during coating and prevent convection during drying, ensuring uniform distribution of components.

Environmental Impact Assessment

The environmental impact assessment of microcrystalline cellulose (MCC) in plant-based edible films is a crucial aspect of evaluating the sustainability and eco-friendliness of this technology. MCC, derived from natural cellulose sources, offers a promising alternative to synthetic polymers in food packaging applications.

One of the primary environmental benefits of using MCC in edible films is its biodegradability. Unlike conventional plastic packaging materials, MCC-based films can decompose naturally in the environment, significantly reducing the accumulation of plastic waste in landfills and oceans. This characteristic aligns with global efforts to mitigate plastic pollution and promote circular economy principles.

The production process of MCC from plant sources generally has a lower carbon footprint compared to the manufacture of petroleum-based plastics. The renewable nature of cellulose sources, such as wood pulp or agricultural residues, contributes to the overall sustainability of MCC-based films. However, it is essential to consider the energy consumption and chemical processes involved in MCC extraction and film production to accurately assess the net environmental impact.

Water usage is another critical factor in the environmental assessment of MCC-based edible films. While the production of MCC may require significant water resources, the potential for water recycling and the use of eco-friendly extraction methods can help mitigate this impact. Additionally, the water-soluble nature of many MCC-based films can potentially reduce water consumption in cleaning and recycling processes compared to conventional packaging materials.

The use of MCC in edible films also presents opportunities for reducing food waste. By extending the shelf life of perishable products and providing better barrier properties against moisture and gases, these films can help minimize food spoilage and the associated environmental impacts of food production and disposal.

Land use considerations are also relevant in the environmental impact assessment of MCC-based edible films. The sourcing of cellulose from sustainable forestry practices or agricultural by-products can help minimize negative impacts on land use and biodiversity. However, careful management is necessary to prevent potential competition with food crops or deforestation.

In terms of end-of-life scenarios, MCC-based edible films offer advantages in waste management. Their biodegradability and potential for composting align with sustainable waste disposal practices. This characteristic can contribute to reducing the environmental burden associated with packaging waste in municipal solid waste streams.

Overall, while MCC in plant-based edible films presents numerous environmental benefits, a comprehensive life cycle assessment is necessary to fully quantify its environmental impact. This assessment should consider factors such as raw material sourcing, production processes, transportation, use phase, and end-of-life disposal to provide a holistic view of the technology's environmental footprint.

One of the primary environmental benefits of using MCC in edible films is its biodegradability. Unlike conventional plastic packaging materials, MCC-based films can decompose naturally in the environment, significantly reducing the accumulation of plastic waste in landfills and oceans. This characteristic aligns with global efforts to mitigate plastic pollution and promote circular economy principles.

The production process of MCC from plant sources generally has a lower carbon footprint compared to the manufacture of petroleum-based plastics. The renewable nature of cellulose sources, such as wood pulp or agricultural residues, contributes to the overall sustainability of MCC-based films. However, it is essential to consider the energy consumption and chemical processes involved in MCC extraction and film production to accurately assess the net environmental impact.

Water usage is another critical factor in the environmental assessment of MCC-based edible films. While the production of MCC may require significant water resources, the potential for water recycling and the use of eco-friendly extraction methods can help mitigate this impact. Additionally, the water-soluble nature of many MCC-based films can potentially reduce water consumption in cleaning and recycling processes compared to conventional packaging materials.

The use of MCC in edible films also presents opportunities for reducing food waste. By extending the shelf life of perishable products and providing better barrier properties against moisture and gases, these films can help minimize food spoilage and the associated environmental impacts of food production and disposal.

Land use considerations are also relevant in the environmental impact assessment of MCC-based edible films. The sourcing of cellulose from sustainable forestry practices or agricultural by-products can help minimize negative impacts on land use and biodiversity. However, careful management is necessary to prevent potential competition with food crops or deforestation.

In terms of end-of-life scenarios, MCC-based edible films offer advantages in waste management. Their biodegradability and potential for composting align with sustainable waste disposal practices. This characteristic can contribute to reducing the environmental burden associated with packaging waste in municipal solid waste streams.

Overall, while MCC in plant-based edible films presents numerous environmental benefits, a comprehensive life cycle assessment is necessary to fully quantify its environmental impact. This assessment should consider factors such as raw material sourcing, production processes, transportation, use phase, and end-of-life disposal to provide a holistic view of the technology's environmental footprint.

Regulatory Framework for Food Packaging

The regulatory framework for food packaging plays a crucial role in ensuring the safety and quality of edible films containing microcrystalline cellulose (MCC). Various international and national regulatory bodies have established guidelines and standards to govern the use of MCC in plant-based edible films.

In the United States, the Food and Drug Administration (FDA) regulates the use of MCC in food packaging under the Federal Food, Drug, and Cosmetic Act. MCC is generally recognized as safe (GRAS) for use in food applications, including edible films. The FDA has set specific limits on the amount of MCC that can be used in food packaging materials, ensuring that it does not exceed levels that could potentially affect food safety or quality.

The European Food Safety Authority (EFSA) has also evaluated the safety of MCC for use in food packaging. EFSA has established specific migration limits for MCC, which define the maximum amount of the substance that can migrate from the packaging material into food. These limits are based on toxicological assessments and are designed to protect consumer health.

In addition to regulatory bodies, international standards organizations such as the International Organization for Standardization (ISO) have developed standards for food packaging materials. ISO 22000, for example, provides guidelines for food safety management systems, which include requirements for packaging materials used in the food industry.

The Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), has also developed international food standards that address the use of packaging materials, including those containing MCC. These standards aim to ensure food safety and facilitate international trade.

Many countries have adopted their own regulatory frameworks for food packaging, often based on or harmonized with international standards. For instance, Japan's Ministry of Health, Labour and Welfare has established regulations for food packaging materials, including specific requirements for the use of cellulose-based materials like MCC.

Compliance with these regulatory frameworks is essential for manufacturers developing plant-based edible films containing MCC. This includes conducting safety assessments, ensuring proper labeling, and adhering to specified limits and migration thresholds. Manufacturers must also consider the intended use of the packaging and the type of food it will come into contact with, as different regulations may apply depending on these factors.

As research in the field of plant-based edible films progresses, regulatory frameworks are likely to evolve to address new findings and potential applications. This may include updates to existing regulations or the development of new standards specifically tailored to novel packaging technologies incorporating MCC.

In the United States, the Food and Drug Administration (FDA) regulates the use of MCC in food packaging under the Federal Food, Drug, and Cosmetic Act. MCC is generally recognized as safe (GRAS) for use in food applications, including edible films. The FDA has set specific limits on the amount of MCC that can be used in food packaging materials, ensuring that it does not exceed levels that could potentially affect food safety or quality.

The European Food Safety Authority (EFSA) has also evaluated the safety of MCC for use in food packaging. EFSA has established specific migration limits for MCC, which define the maximum amount of the substance that can migrate from the packaging material into food. These limits are based on toxicological assessments and are designed to protect consumer health.

In addition to regulatory bodies, international standards organizations such as the International Organization for Standardization (ISO) have developed standards for food packaging materials. ISO 22000, for example, provides guidelines for food safety management systems, which include requirements for packaging materials used in the food industry.

The Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), has also developed international food standards that address the use of packaging materials, including those containing MCC. These standards aim to ensure food safety and facilitate international trade.

Many countries have adopted their own regulatory frameworks for food packaging, often based on or harmonized with international standards. For instance, Japan's Ministry of Health, Labour and Welfare has established regulations for food packaging materials, including specific requirements for the use of cellulose-based materials like MCC.

Compliance with these regulatory frameworks is essential for manufacturers developing plant-based edible films containing MCC. This includes conducting safety assessments, ensuring proper labeling, and adhering to specified limits and migration thresholds. Manufacturers must also consider the intended use of the packaging and the type of food it will come into contact with, as different regulations may apply depending on these factors.

As research in the field of plant-based edible films progresses, regulatory frameworks are likely to evolve to address new findings and potential applications. This may include updates to existing regulations or the development of new standards specifically tailored to novel packaging technologies incorporating MCC.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!