How Microcrystalline Cellulose Affects the Mechanical Properties of Bioplastics

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC in Bioplastics: Background and Objectives

Microcrystalline cellulose (MCC) has emerged as a promising reinforcing agent in the development of bioplastics, addressing the growing demand for sustainable and biodegradable materials. The integration of MCC into bioplastic matrices represents a significant advancement in the field of eco-friendly polymers, aiming to enhance their mechanical properties while maintaining their environmental benefits.

The evolution of bioplastics can be traced back to the early 20th century, with the introduction of cellophane. However, it wasn't until the late 1980s and early 1990s that the development of biodegradable plastics gained momentum, driven by increasing environmental concerns and the need to reduce dependency on fossil-based resources. The incorporation of MCC into bioplastics is a more recent innovation, stemming from the broader trend of utilizing natural fibers and nanocellulose materials in composite structures.

MCC, derived from purified cellulose through acid hydrolysis, offers unique properties that make it an attractive additive for bioplastics. Its high crystallinity, large surface area, and strong hydrogen bonding capabilities contribute to its potential as a reinforcing agent. The primary objective of incorporating MCC into bioplastics is to enhance their mechanical properties, particularly strength, stiffness, and dimensional stability, without compromising their biodegradability.

The technological goals associated with MCC in bioplastics extend beyond mere mechanical enhancement. Researchers and industry professionals aim to optimize the interfacial compatibility between MCC and various biopolymer matrices, improve dispersion techniques, and develop scalable manufacturing processes. Additionally, there is a focus on understanding and controlling the impact of MCC on other material properties, such as barrier performance, thermal stability, and processability.

As the field progresses, the overarching aim is to create MCC-reinforced bioplastics that can compete with or surpass the performance of conventional petroleum-based plastics in specific applications. This involves tailoring the MCC-bioplastic composites to meet the requirements of diverse sectors, including packaging, automotive, construction, and consumer goods.

The integration of MCC into bioplastics aligns with broader sustainability initiatives and circular economy principles. By utilizing a renewable, biodegradable reinforcing agent, the industry seeks to reduce the environmental footprint of plastic products throughout their lifecycle. This approach not only addresses end-of-life concerns but also contributes to the conservation of non-renewable resources and the reduction of greenhouse gas emissions associated with traditional plastic production.

The evolution of bioplastics can be traced back to the early 20th century, with the introduction of cellophane. However, it wasn't until the late 1980s and early 1990s that the development of biodegradable plastics gained momentum, driven by increasing environmental concerns and the need to reduce dependency on fossil-based resources. The incorporation of MCC into bioplastics is a more recent innovation, stemming from the broader trend of utilizing natural fibers and nanocellulose materials in composite structures.

MCC, derived from purified cellulose through acid hydrolysis, offers unique properties that make it an attractive additive for bioplastics. Its high crystallinity, large surface area, and strong hydrogen bonding capabilities contribute to its potential as a reinforcing agent. The primary objective of incorporating MCC into bioplastics is to enhance their mechanical properties, particularly strength, stiffness, and dimensional stability, without compromising their biodegradability.

The technological goals associated with MCC in bioplastics extend beyond mere mechanical enhancement. Researchers and industry professionals aim to optimize the interfacial compatibility between MCC and various biopolymer matrices, improve dispersion techniques, and develop scalable manufacturing processes. Additionally, there is a focus on understanding and controlling the impact of MCC on other material properties, such as barrier performance, thermal stability, and processability.

As the field progresses, the overarching aim is to create MCC-reinforced bioplastics that can compete with or surpass the performance of conventional petroleum-based plastics in specific applications. This involves tailoring the MCC-bioplastic composites to meet the requirements of diverse sectors, including packaging, automotive, construction, and consumer goods.

The integration of MCC into bioplastics aligns with broader sustainability initiatives and circular economy principles. By utilizing a renewable, biodegradable reinforcing agent, the industry seeks to reduce the environmental footprint of plastic products throughout their lifecycle. This approach not only addresses end-of-life concerns but also contributes to the conservation of non-renewable resources and the reduction of greenhouse gas emissions associated with traditional plastic production.

Market Analysis for MCC-Enhanced Bioplastics

The market for MCC-enhanced bioplastics is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable alternatives to traditional plastics. The global bioplastics market, which includes MCC-enhanced products, is projected to expand at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is primarily fueled by stringent regulations on single-use plastics and rising consumer awareness about environmental issues.

MCC-enhanced bioplastics are finding applications across various industries, with packaging being the largest segment. The food and beverage industry, in particular, is showing strong demand for these materials due to their improved barrier properties and biodegradability. Other key sectors include automotive, consumer goods, and agriculture, where the enhanced mechanical properties of MCC-bioplastics are highly valued.

Geographically, Europe leads the market for MCC-enhanced bioplastics, followed closely by North America. These regions have implemented strict regulations on plastic usage and have a high level of environmental consciousness among consumers. Asia-Pacific is emerging as the fastest-growing market, with countries like China and India investing heavily in bioplastic technologies and production capacities.

The market is characterized by intense competition and rapid technological advancements. Key players are focusing on research and development to improve the mechanical properties and reduce the production costs of MCC-enhanced bioplastics. Collaborations between material scientists, biopolymer manufacturers, and end-users are becoming increasingly common to drive innovation and market adoption.

Despite the positive outlook, challenges remain. The higher cost of production compared to conventional plastics is a significant barrier to widespread adoption. Additionally, there are concerns about the availability of raw materials and the potential impact on food security if agricultural resources are diverted for bioplastic production.

Looking ahead, the market for MCC-enhanced bioplastics is expected to continue its upward trajectory. Technological advancements in cellulose extraction and modification techniques are likely to improve the cost-effectiveness and performance of these materials. As governments worldwide implement more stringent environmental policies, the demand for sustainable packaging solutions is set to soar, further boosting the market for MCC-enhanced bioplastics.

MCC-enhanced bioplastics are finding applications across various industries, with packaging being the largest segment. The food and beverage industry, in particular, is showing strong demand for these materials due to their improved barrier properties and biodegradability. Other key sectors include automotive, consumer goods, and agriculture, where the enhanced mechanical properties of MCC-bioplastics are highly valued.

Geographically, Europe leads the market for MCC-enhanced bioplastics, followed closely by North America. These regions have implemented strict regulations on plastic usage and have a high level of environmental consciousness among consumers. Asia-Pacific is emerging as the fastest-growing market, with countries like China and India investing heavily in bioplastic technologies and production capacities.

The market is characterized by intense competition and rapid technological advancements. Key players are focusing on research and development to improve the mechanical properties and reduce the production costs of MCC-enhanced bioplastics. Collaborations between material scientists, biopolymer manufacturers, and end-users are becoming increasingly common to drive innovation and market adoption.

Despite the positive outlook, challenges remain. The higher cost of production compared to conventional plastics is a significant barrier to widespread adoption. Additionally, there are concerns about the availability of raw materials and the potential impact on food security if agricultural resources are diverted for bioplastic production.

Looking ahead, the market for MCC-enhanced bioplastics is expected to continue its upward trajectory. Technological advancements in cellulose extraction and modification techniques are likely to improve the cost-effectiveness and performance of these materials. As governments worldwide implement more stringent environmental policies, the demand for sustainable packaging solutions is set to soar, further boosting the market for MCC-enhanced bioplastics.

Current Challenges in MCC-Bioplastic Integration

The integration of microcrystalline cellulose (MCC) into bioplastics presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is achieving uniform dispersion of MCC within the bioplastic matrix. The hydrophilic nature of MCC often leads to agglomeration, resulting in poor distribution and inconsistent mechanical properties throughout the material.

Another major challenge lies in maintaining the biodegradability of the composite material. While both MCC and many bioplastics are biodegradable, the interaction between them can sometimes alter the degradation rate and mechanism. Ensuring that the final product maintains its environmentally friendly characteristics without compromising performance is a delicate balance that requires ongoing research and development.

The interface between MCC and the bioplastic matrix poses additional difficulties. Poor adhesion between these components can lead to reduced mechanical strength and decreased overall performance of the composite. Researchers are exploring various surface modification techniques for MCC to enhance its compatibility with different bioplastic matrices, but finding universally effective methods remains a challenge.

Scalability and cost-effectiveness in production represent significant hurdles in the widespread adoption of MCC-reinforced bioplastics. Current processes for incorporating MCC into bioplastics often involve complex steps that are difficult to scale up for industrial production. This complexity not only affects the consistency of the final product but also increases manufacturing costs, potentially limiting market competitiveness.

Moisture sensitivity is another critical issue facing MCC-bioplastic composites. The hydrophilic nature of MCC can lead to increased water absorption in the final product, potentially compromising its dimensional stability and mechanical properties over time. Developing effective moisture barriers or treatments to mitigate this issue without negatively impacting other desirable properties is an ongoing area of research.

Furthermore, the impact of MCC on the processing characteristics of bioplastics presents challenges in manufacturing. The addition of MCC can alter the melt flow behavior, affecting processes such as extrusion and injection molding. Optimizing processing parameters to accommodate these changes without sacrificing production efficiency or product quality requires significant experimentation and expertise.

Lastly, achieving a balance between improved mechanical properties and maintaining other desirable characteristics of bioplastics, such as transparency or flexibility, remains a complex task. The addition of MCC often enhances strength and stiffness but may negatively impact other properties, necessitating careful formulation and processing strategies to meet diverse application requirements.

Another major challenge lies in maintaining the biodegradability of the composite material. While both MCC and many bioplastics are biodegradable, the interaction between them can sometimes alter the degradation rate and mechanism. Ensuring that the final product maintains its environmentally friendly characteristics without compromising performance is a delicate balance that requires ongoing research and development.

The interface between MCC and the bioplastic matrix poses additional difficulties. Poor adhesion between these components can lead to reduced mechanical strength and decreased overall performance of the composite. Researchers are exploring various surface modification techniques for MCC to enhance its compatibility with different bioplastic matrices, but finding universally effective methods remains a challenge.

Scalability and cost-effectiveness in production represent significant hurdles in the widespread adoption of MCC-reinforced bioplastics. Current processes for incorporating MCC into bioplastics often involve complex steps that are difficult to scale up for industrial production. This complexity not only affects the consistency of the final product but also increases manufacturing costs, potentially limiting market competitiveness.

Moisture sensitivity is another critical issue facing MCC-bioplastic composites. The hydrophilic nature of MCC can lead to increased water absorption in the final product, potentially compromising its dimensional stability and mechanical properties over time. Developing effective moisture barriers or treatments to mitigate this issue without negatively impacting other desirable properties is an ongoing area of research.

Furthermore, the impact of MCC on the processing characteristics of bioplastics presents challenges in manufacturing. The addition of MCC can alter the melt flow behavior, affecting processes such as extrusion and injection molding. Optimizing processing parameters to accommodate these changes without sacrificing production efficiency or product quality requires significant experimentation and expertise.

Lastly, achieving a balance between improved mechanical properties and maintaining other desirable characteristics of bioplastics, such as transparency or flexibility, remains a complex task. The addition of MCC often enhances strength and stiffness but may negatively impact other properties, necessitating careful formulation and processing strategies to meet diverse application requirements.

Existing MCC-Bioplastic Composite Solutions

01 Improved mechanical properties through processing techniques

Various processing techniques can be employed to enhance the mechanical properties of microcrystalline cellulose. These methods include specific drying processes, particle size control, and surface modifications. Such techniques can lead to improved strength, stiffness, and durability of the material.- Improved mechanical strength and stability: Microcrystalline cellulose (MCC) exhibits enhanced mechanical properties, including improved strength and stability. These characteristics make it suitable for various applications in industries such as pharmaceuticals, food, and materials science. The mechanical properties can be further enhanced through specific processing techniques and modifications.

- Particle size and morphology effects: The particle size and morphology of microcrystalline cellulose significantly influence its mechanical properties. Controlling these parameters during production can lead to tailored mechanical characteristics, such as improved compressibility, flowability, and binding properties. This is particularly important in pharmaceutical tablet formulations and other applications requiring specific physical attributes.

- Composite materials and blends: Microcrystalline cellulose can be used in composite materials and blends to enhance mechanical properties. When combined with other materials, MCC can improve tensile strength, flexural modulus, and impact resistance. This makes it valuable in the development of biodegradable composites and high-performance materials for various industries.

- Surface modification and functionalization: Surface modification and functionalization of microcrystalline cellulose can significantly alter its mechanical properties. Techniques such as chemical treatments, grafting, and coating can enhance properties like water resistance, adhesion, and compatibility with other materials. This allows for the customization of MCC for specific applications and performance requirements.

- Processing techniques and property optimization: Various processing techniques can be employed to optimize the mechanical properties of microcrystalline cellulose. These include methods such as spray-drying, freeze-drying, and mechanical treatments. By controlling processing parameters, it is possible to achieve desired mechanical characteristics such as improved compressibility, tensile strength, and elastic modulus, tailoring the MCC for specific end-use applications.

02 Composite materials incorporating microcrystalline cellulose

Microcrystalline cellulose can be used as a reinforcing agent in composite materials. When combined with other substances, it can significantly enhance the mechanical properties of the resulting composite, including tensile strength, flexural modulus, and impact resistance.Expand Specific Solutions03 Effect of crystallinity on mechanical properties

The degree of crystallinity in microcrystalline cellulose plays a crucial role in determining its mechanical properties. Higher crystallinity generally results in improved strength and stiffness. Techniques to control and enhance crystallinity can be employed to tailor the mechanical characteristics of the material.Expand Specific Solutions04 Influence of moisture content on mechanical behavior

The moisture content of microcrystalline cellulose significantly affects its mechanical properties. Controlling moisture levels during processing and storage is crucial for maintaining desired mechanical characteristics. Proper moisture management can lead to improved strength, dimensional stability, and overall performance.Expand Specific Solutions05 Nanocellulose and its impact on mechanical properties

Nanocellulose, derived from microcrystalline cellulose, exhibits exceptional mechanical properties due to its nanoscale dimensions. Incorporating nanocellulose into materials can lead to significant improvements in strength, stiffness, and toughness. Various methods of nanocellulose production and integration are being explored to enhance mechanical performance.Expand Specific Solutions

Key Players in MCC and Bioplastic Industries

The development of microcrystalline cellulose's impact on bioplastics' mechanical properties is in an early growth stage, with increasing market potential due to sustainability trends. The global bioplastics market is expanding, projected to reach $19.93 billion by 2026. Technologically, the field is advancing rapidly, with companies like NEC Corp., Donghua University, and South China University of Technology leading research efforts. However, the technology is not yet fully mature, as evidenced by ongoing studies at institutions such as Aalto University and Columbia University, indicating room for further innovation and optimization in enhancing bioplastics' performance through microcrystalline cellulose incorporation.

Nano-Green Biorefineries, Inc.

Technical Solution: Nano-Green Biorefineries, Inc. has developed a novel approach to enhancing the mechanical properties of bioplastics using microcrystalline cellulose (MCC). Their technology focuses on the production of nano-scale MCC particles through a proprietary biorefinery process, which allows for better integration into bioplastic matrices. The company's method involves a combination of mechanical and enzymatic treatments to produce highly crystalline MCC with optimized aspect ratios[8]. These nano-MCC particles are then surface-modified to improve compatibility with various biopolymers. Nano-Green's research has demonstrated that their nano-MCC can significantly enhance the tensile strength, Young's modulus, and thermal stability of bioplastics at lower filler loadings compared to conventional MCC[9]. The company has also developed a scalable production process for their nano-MCC, making it suitable for industrial applications.

Strengths: Enhanced mechanical properties at lower filler loadings; improved thermal stability; scalable production process. Weaknesses: Potentially higher production costs due to specialized nano-MCC production; may require modifications to existing bioplastic manufacturing processes.

FMC Corp.

Technical Solution: FMC Corp. has developed innovative approaches to incorporate microcrystalline cellulose (MCC) into bioplastics to enhance their mechanical properties. Their research focuses on optimizing the dispersion of MCC within the biopolymer matrix, utilizing surface modification techniques to improve compatibility. FMC's method involves a proprietary process of MCC functionalization, which allows for better interfacial adhesion between the cellulose fibers and the bioplastic matrix[1]. This results in improved tensile strength and modulus of the composite material. Additionally, FMC has explored the use of different MCC particle sizes and concentrations to tailor the mechanical properties of the bioplastic composites for specific applications[3]. Their technology also addresses the moisture sensitivity issues often associated with cellulose-based fillers in bioplastics.

Strengths: Improved tensile strength and modulus; tailored mechanical properties for specific applications; reduced moisture sensitivity. Weaknesses: Potential increase in production costs due to MCC modification process; may affect biodegradability depending on modifications made.

Core Innovations in MCC-Bioplastic Mechanics

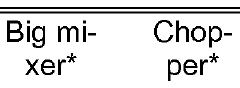

Microcrystalline cellulose product

PatentWO2022229511A1

Innovation

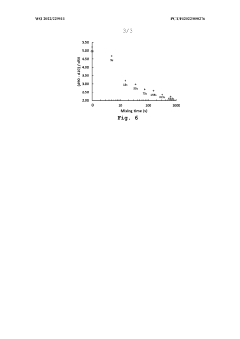

- The method involves mixing a hydrolyzed pulp mixture with controlled energy dissipation (0.01 - 15.0 x 10^6 W/m^3 for 0.1 - 180 s) and adding acid in multiple stages during the acid hydrolysis process, using one or two reactors, to achieve a uniform and adjustable MCC product with a narrow particle size distribution.

Environmental Impact of MCC-Enhanced Bioplastics

The incorporation of Microcrystalline Cellulose (MCC) into bioplastics not only enhances their mechanical properties but also significantly impacts their environmental footprint. As the demand for sustainable materials grows, understanding the ecological implications of MCC-enhanced bioplastics becomes crucial for informed decision-making in product development and environmental policy.

MCC-enhanced bioplastics generally exhibit improved biodegradability compared to conventional plastics. The cellulose component, being naturally derived, can be broken down by microorganisms in various environments, potentially reducing the persistence of plastic waste in ecosystems. However, the rate of biodegradation can vary depending on the specific formulation and environmental conditions, necessitating careful consideration in disposal and waste management strategies.

The production of MCC itself presents both advantages and challenges from an environmental perspective. On one hand, MCC is derived from renewable resources, primarily wood pulp or cotton linters, which can be sustainably sourced. This reduces reliance on fossil fuel-based raw materials, contributing to a lower carbon footprint. On the other hand, the extraction and processing of MCC may involve energy-intensive steps and chemical treatments, which could offset some of the environmental benefits if not managed efficiently.

Water usage and potential chemical runoff during MCC production are additional environmental concerns that warrant attention. Implementing closed-loop systems and water recycling technologies in manufacturing facilities can help mitigate these impacts. Furthermore, the use of eco-friendly extraction methods and green chemistry principles in MCC production can significantly reduce the environmental burden associated with this component of bioplastics.

The end-of-life scenario for MCC-enhanced bioplastics is a critical aspect of their environmental impact. While these materials offer improved biodegradability, the infrastructure for proper composting or recycling may not be universally available. This highlights the need for developing comprehensive waste management systems that can effectively handle these advanced materials, ensuring that their potential environmental benefits are fully realized.

Life cycle assessments (LCAs) of MCC-enhanced bioplastics have shown promising results in terms of reduced greenhouse gas emissions and energy consumption compared to traditional plastics. However, these benefits can vary depending on factors such as raw material sourcing, production methods, and end-of-life management. Continuous research and optimization of these factors are essential to maximize the positive environmental impact of MCC-enhanced bioplastics.

MCC-enhanced bioplastics generally exhibit improved biodegradability compared to conventional plastics. The cellulose component, being naturally derived, can be broken down by microorganisms in various environments, potentially reducing the persistence of plastic waste in ecosystems. However, the rate of biodegradation can vary depending on the specific formulation and environmental conditions, necessitating careful consideration in disposal and waste management strategies.

The production of MCC itself presents both advantages and challenges from an environmental perspective. On one hand, MCC is derived from renewable resources, primarily wood pulp or cotton linters, which can be sustainably sourced. This reduces reliance on fossil fuel-based raw materials, contributing to a lower carbon footprint. On the other hand, the extraction and processing of MCC may involve energy-intensive steps and chemical treatments, which could offset some of the environmental benefits if not managed efficiently.

Water usage and potential chemical runoff during MCC production are additional environmental concerns that warrant attention. Implementing closed-loop systems and water recycling technologies in manufacturing facilities can help mitigate these impacts. Furthermore, the use of eco-friendly extraction methods and green chemistry principles in MCC production can significantly reduce the environmental burden associated with this component of bioplastics.

The end-of-life scenario for MCC-enhanced bioplastics is a critical aspect of their environmental impact. While these materials offer improved biodegradability, the infrastructure for proper composting or recycling may not be universally available. This highlights the need for developing comprehensive waste management systems that can effectively handle these advanced materials, ensuring that their potential environmental benefits are fully realized.

Life cycle assessments (LCAs) of MCC-enhanced bioplastics have shown promising results in terms of reduced greenhouse gas emissions and energy consumption compared to traditional plastics. However, these benefits can vary depending on factors such as raw material sourcing, production methods, and end-of-life management. Continuous research and optimization of these factors are essential to maximize the positive environmental impact of MCC-enhanced bioplastics.

Scalability and Cost Analysis of MCC Integration

The integration of Microcrystalline Cellulose (MCC) into bioplastic production processes presents both opportunities and challenges in terms of scalability and cost-effectiveness. As the demand for sustainable packaging solutions continues to grow, understanding these factors is crucial for industry stakeholders.

From a scalability perspective, MCC integration shows promising potential. The raw material for MCC, cellulose, is abundantly available from various plant sources, ensuring a stable supply chain. However, the extraction and processing of MCC require specialized equipment and techniques, which may pose initial barriers to large-scale production.

The production capacity of MCC-enhanced bioplastics can be significantly increased through process optimization and automation. Continuous flow reactors and advanced extrusion technologies can improve throughput and consistency in MCC dispersion within the bioplastic matrix. These advancements can potentially reduce production times and increase output volumes, making MCC integration more feasible for large-scale manufacturing.

Cost analysis of MCC integration reveals a complex picture. While the raw material costs for cellulose are relatively low, the processing and purification of MCC can be expensive. The additional steps required to incorporate MCC into bioplastics, such as surface modification or compatibilization, may also add to the overall production costs.

However, the enhanced mechanical properties imparted by MCC can potentially reduce the amount of other, more expensive additives or plasticizers needed in bioplastic formulations. This trade-off could lead to cost savings in the long run, especially as production scales up and economies of scale come into play.

The environmental benefits of MCC-enhanced bioplastics, such as improved biodegradability and reduced carbon footprint, may also translate into economic advantages. As regulations around plastic use become stricter, products incorporating MCC could command premium prices or gain market share, offsetting higher production costs.

Investments in research and development are crucial for improving the cost-effectiveness of MCC integration. Innovations in MCC production methods, such as enzyme-assisted processes or green chemistry approaches, could significantly reduce processing costs. Similarly, advancements in bioplastic formulation techniques could optimize MCC usage, further improving the cost-benefit ratio.

In conclusion, while the scalability and cost analysis of MCC integration in bioplastics production reveals some challenges, the long-term prospects appear promising. As technology advances and market demand for sustainable materials grows, the economic viability of MCC-enhanced bioplastics is likely to improve, paving the way for wider adoption in various industries.

From a scalability perspective, MCC integration shows promising potential. The raw material for MCC, cellulose, is abundantly available from various plant sources, ensuring a stable supply chain. However, the extraction and processing of MCC require specialized equipment and techniques, which may pose initial barriers to large-scale production.

The production capacity of MCC-enhanced bioplastics can be significantly increased through process optimization and automation. Continuous flow reactors and advanced extrusion technologies can improve throughput and consistency in MCC dispersion within the bioplastic matrix. These advancements can potentially reduce production times and increase output volumes, making MCC integration more feasible for large-scale manufacturing.

Cost analysis of MCC integration reveals a complex picture. While the raw material costs for cellulose are relatively low, the processing and purification of MCC can be expensive. The additional steps required to incorporate MCC into bioplastics, such as surface modification or compatibilization, may also add to the overall production costs.

However, the enhanced mechanical properties imparted by MCC can potentially reduce the amount of other, more expensive additives or plasticizers needed in bioplastic formulations. This trade-off could lead to cost savings in the long run, especially as production scales up and economies of scale come into play.

The environmental benefits of MCC-enhanced bioplastics, such as improved biodegradability and reduced carbon footprint, may also translate into economic advantages. As regulations around plastic use become stricter, products incorporating MCC could command premium prices or gain market share, offsetting higher production costs.

Investments in research and development are crucial for improving the cost-effectiveness of MCC integration. Innovations in MCC production methods, such as enzyme-assisted processes or green chemistry approaches, could significantly reduce processing costs. Similarly, advancements in bioplastic formulation techniques could optimize MCC usage, further improving the cost-benefit ratio.

In conclusion, while the scalability and cost analysis of MCC integration in bioplastics production reveals some challenges, the long-term prospects appear promising. As technology advances and market demand for sustainable materials grows, the economic viability of MCC-enhanced bioplastics is likely to improve, paving the way for wider adoption in various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!