Microcrystalline Cellulose Nanocomposites in Flame Retardance Applications

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC Nanocomposites Background and Objectives

Microcrystalline cellulose (MCC) nanocomposites have emerged as a promising material in the field of flame retardance applications. This research area has gained significant attention due to the increasing demand for environmentally friendly and high-performance flame retardant materials. The development of MCC nanocomposites represents a convergence of nanotechnology and sustainable materials science, offering potential solutions to address the limitations of traditional flame retardants.

The evolution of flame retardant materials has been driven by the need to enhance fire safety in various industries, including construction, electronics, and transportation. Conventional flame retardants, while effective, often pose environmental and health concerns. This has led to a shift towards more sustainable alternatives, with cellulose-based materials becoming a focal point of research and development efforts.

MCC, derived from abundant and renewable cellulose sources, offers unique properties that make it an attractive candidate for flame retardance applications. Its nano-scale dimensions, high surface area, and ability to form strong interfacial interactions with polymer matrices contribute to its potential as an effective flame retardant additive. The incorporation of MCC into polymer systems can lead to improved thermal stability, reduced heat release rates, and enhanced char formation during combustion.

The primary objective of research in this field is to develop MCC nanocomposites that can effectively retard flame propagation while maintaining or enhancing the mechanical and physical properties of the host material. This involves optimizing the dispersion of MCC within polymer matrices, understanding the mechanisms of flame retardancy, and exploring synergistic effects with other flame retardant additives.

Another key goal is to investigate the scalability and cost-effectiveness of MCC nanocomposite production for commercial applications. This includes developing efficient methods for MCC extraction, modification, and incorporation into various polymer systems. Additionally, researchers aim to assess the long-term stability and performance of these nanocomposites under different environmental conditions.

The research also seeks to address regulatory challenges and meet increasingly stringent fire safety standards across different industries. This involves comprehensive testing and characterization of MCC nanocomposites to ensure compliance with relevant safety regulations and performance criteria.

As the field progresses, there is a growing emphasis on understanding the environmental impact and life cycle assessment of MCC nanocomposites. This includes evaluating their biodegradability, recyclability, and potential for end-of-life recovery and reuse. Such considerations are crucial for positioning MCC nanocomposites as a sustainable alternative to conventional flame retardants.

The evolution of flame retardant materials has been driven by the need to enhance fire safety in various industries, including construction, electronics, and transportation. Conventional flame retardants, while effective, often pose environmental and health concerns. This has led to a shift towards more sustainable alternatives, with cellulose-based materials becoming a focal point of research and development efforts.

MCC, derived from abundant and renewable cellulose sources, offers unique properties that make it an attractive candidate for flame retardance applications. Its nano-scale dimensions, high surface area, and ability to form strong interfacial interactions with polymer matrices contribute to its potential as an effective flame retardant additive. The incorporation of MCC into polymer systems can lead to improved thermal stability, reduced heat release rates, and enhanced char formation during combustion.

The primary objective of research in this field is to develop MCC nanocomposites that can effectively retard flame propagation while maintaining or enhancing the mechanical and physical properties of the host material. This involves optimizing the dispersion of MCC within polymer matrices, understanding the mechanisms of flame retardancy, and exploring synergistic effects with other flame retardant additives.

Another key goal is to investigate the scalability and cost-effectiveness of MCC nanocomposite production for commercial applications. This includes developing efficient methods for MCC extraction, modification, and incorporation into various polymer systems. Additionally, researchers aim to assess the long-term stability and performance of these nanocomposites under different environmental conditions.

The research also seeks to address regulatory challenges and meet increasingly stringent fire safety standards across different industries. This involves comprehensive testing and characterization of MCC nanocomposites to ensure compliance with relevant safety regulations and performance criteria.

As the field progresses, there is a growing emphasis on understanding the environmental impact and life cycle assessment of MCC nanocomposites. This includes evaluating their biodegradability, recyclability, and potential for end-of-life recovery and reuse. Such considerations are crucial for positioning MCC nanocomposites as a sustainable alternative to conventional flame retardants.

Market Analysis for Flame Retardant Materials

The global flame retardant materials market has been experiencing steady growth, driven by increasing safety regulations and growing awareness of fire hazards across various industries. The market for flame retardant materials is expected to continue its upward trajectory, with a particular focus on eco-friendly and sustainable solutions.

In recent years, there has been a significant shift towards more environmentally friendly flame retardant materials, as concerns over the toxicity and environmental impact of traditional halogenated flame retardants have grown. This trend has opened up new opportunities for bio-based flame retardants, such as microcrystalline cellulose nanocomposites, which offer a promising alternative to conventional synthetic flame retardants.

The construction industry remains the largest consumer of flame retardant materials, followed by the electronics and electrical sectors. The automotive and aerospace industries are also significant contributors to market demand. As urbanization continues and building safety standards become more stringent, the demand for flame retardant materials in construction is expected to rise further.

Asia-Pacific has emerged as the fastest-growing market for flame retardant materials, driven by rapid industrialization, increasing construction activities, and stringent safety regulations in countries like China and India. North America and Europe continue to be major markets, with a strong focus on developing advanced, sustainable flame retardant solutions.

The market for microcrystalline cellulose nanocomposites in flame retardance applications is still in its nascent stage but shows promising growth potential. These materials offer several advantages, including biodegradability, low toxicity, and improved mechanical properties when compared to traditional flame retardants. As research in this field progresses, it is anticipated that microcrystalline cellulose nanocomposites will gain a larger market share in the flame retardant materials sector.

Key market players are investing heavily in research and development to create innovative flame retardant solutions that meet both performance and environmental requirements. Collaborations between academic institutions and industry partners are becoming more common, accelerating the development and commercialization of novel flame retardant technologies, including microcrystalline cellulose nanocomposites.

The increasing focus on sustainable and green building practices is expected to further boost the demand for bio-based flame retardants like microcrystalline cellulose nanocomposites. As consumers and industries become more environmentally conscious, there is a growing preference for products that offer both safety and sustainability, creating a favorable market environment for these innovative materials.

In recent years, there has been a significant shift towards more environmentally friendly flame retardant materials, as concerns over the toxicity and environmental impact of traditional halogenated flame retardants have grown. This trend has opened up new opportunities for bio-based flame retardants, such as microcrystalline cellulose nanocomposites, which offer a promising alternative to conventional synthetic flame retardants.

The construction industry remains the largest consumer of flame retardant materials, followed by the electronics and electrical sectors. The automotive and aerospace industries are also significant contributors to market demand. As urbanization continues and building safety standards become more stringent, the demand for flame retardant materials in construction is expected to rise further.

Asia-Pacific has emerged as the fastest-growing market for flame retardant materials, driven by rapid industrialization, increasing construction activities, and stringent safety regulations in countries like China and India. North America and Europe continue to be major markets, with a strong focus on developing advanced, sustainable flame retardant solutions.

The market for microcrystalline cellulose nanocomposites in flame retardance applications is still in its nascent stage but shows promising growth potential. These materials offer several advantages, including biodegradability, low toxicity, and improved mechanical properties when compared to traditional flame retardants. As research in this field progresses, it is anticipated that microcrystalline cellulose nanocomposites will gain a larger market share in the flame retardant materials sector.

Key market players are investing heavily in research and development to create innovative flame retardant solutions that meet both performance and environmental requirements. Collaborations between academic institutions and industry partners are becoming more common, accelerating the development and commercialization of novel flame retardant technologies, including microcrystalline cellulose nanocomposites.

The increasing focus on sustainable and green building practices is expected to further boost the demand for bio-based flame retardants like microcrystalline cellulose nanocomposites. As consumers and industries become more environmentally conscious, there is a growing preference for products that offer both safety and sustainability, creating a favorable market environment for these innovative materials.

Current Challenges in MCC Nanocomposites

Despite the promising potential of microcrystalline cellulose (MCC) nanocomposites in flame retardance applications, several significant challenges persist in their development and implementation. One of the primary obstacles is achieving uniform dispersion of MCC nanoparticles within the polymer matrix. The high surface energy and strong hydrogen bonding between cellulose nanoparticles often lead to agglomeration, which can compromise the overall performance of the nanocomposite, including its flame retardant properties.

Another critical challenge lies in maintaining the thermal stability of MCC during processing and application. While cellulose-based materials offer excellent flame retardant characteristics, they are susceptible to thermal degradation at relatively low temperatures. This limitation can restrict the processing conditions and potential applications of MCC nanocomposites, particularly in high-temperature environments or during manufacturing processes that involve elevated temperatures.

The compatibility between MCC and various polymer matrices presents an ongoing challenge. The hydrophilic nature of cellulose often conflicts with the hydrophobic character of many synthetic polymers, leading to poor interfacial adhesion. This incompatibility can result in reduced mechanical properties and diminished flame retardant effectiveness of the nanocomposite. Developing suitable surface modification techniques or compatibilizers to enhance the interaction between MCC and polymer matrices remains a key area of research.

Scalability and cost-effectiveness in the production of MCC nanocomposites pose significant hurdles for widespread industrial adoption. Current methods for producing high-quality MCC nanoparticles and incorporating them into polymer matrices are often complex, energy-intensive, and expensive. Developing more efficient and economically viable production processes is crucial for the commercial viability of these materials in flame retardance applications.

The long-term stability and durability of MCC nanocomposites in various environmental conditions are also areas of concern. Factors such as moisture absorption, UV exposure, and thermal cycling can potentially degrade the performance of these materials over time. Ensuring consistent flame retardant properties throughout the lifecycle of MCC nanocomposite products is essential for their reliable use in safety-critical applications.

Lastly, the regulatory landscape and environmental considerations surrounding flame retardant materials present additional challenges. As traditional halogenated flame retardants face increasing scrutiny due to environmental and health concerns, MCC nanocomposites must not only demonstrate superior flame retardant properties but also meet stringent safety and environmental standards. Comprehensive toxicological studies and life cycle assessments are necessary to fully understand the long-term impacts of these materials and ensure their sustainable use in flame retardance applications.

Another critical challenge lies in maintaining the thermal stability of MCC during processing and application. While cellulose-based materials offer excellent flame retardant characteristics, they are susceptible to thermal degradation at relatively low temperatures. This limitation can restrict the processing conditions and potential applications of MCC nanocomposites, particularly in high-temperature environments or during manufacturing processes that involve elevated temperatures.

The compatibility between MCC and various polymer matrices presents an ongoing challenge. The hydrophilic nature of cellulose often conflicts with the hydrophobic character of many synthetic polymers, leading to poor interfacial adhesion. This incompatibility can result in reduced mechanical properties and diminished flame retardant effectiveness of the nanocomposite. Developing suitable surface modification techniques or compatibilizers to enhance the interaction between MCC and polymer matrices remains a key area of research.

Scalability and cost-effectiveness in the production of MCC nanocomposites pose significant hurdles for widespread industrial adoption. Current methods for producing high-quality MCC nanoparticles and incorporating them into polymer matrices are often complex, energy-intensive, and expensive. Developing more efficient and economically viable production processes is crucial for the commercial viability of these materials in flame retardance applications.

The long-term stability and durability of MCC nanocomposites in various environmental conditions are also areas of concern. Factors such as moisture absorption, UV exposure, and thermal cycling can potentially degrade the performance of these materials over time. Ensuring consistent flame retardant properties throughout the lifecycle of MCC nanocomposite products is essential for their reliable use in safety-critical applications.

Lastly, the regulatory landscape and environmental considerations surrounding flame retardant materials present additional challenges. As traditional halogenated flame retardants face increasing scrutiny due to environmental and health concerns, MCC nanocomposites must not only demonstrate superior flame retardant properties but also meet stringent safety and environmental standards. Comprehensive toxicological studies and life cycle assessments are necessary to fully understand the long-term impacts of these materials and ensure their sustainable use in flame retardance applications.

Existing MCC Nanocomposite Solutions

01 Microcrystalline cellulose-based flame retardant composites

Microcrystalline cellulose is used as a base material for creating flame retardant nanocomposites. These composites incorporate various additives and treatments to enhance their fire-resistant properties, making them suitable for applications in construction, electronics, and textiles.- Microcrystalline cellulose-based flame retardant composites: Microcrystalline cellulose is used as a base material for developing flame retardant nanocomposites. These composites incorporate various additives and treatments to enhance their fire-resistant properties, making them suitable for applications in construction, electronics, and textiles.

- Flame retardant coatings using cellulose nanocomposites: Cellulose nanocomposites are utilized in the formulation of flame retardant coatings. These coatings can be applied to various substrates to improve their fire resistance. The nanocomposite structure enhances the effectiveness of the flame retardant properties while maintaining other desirable characteristics of the coating.

- Modification of cellulose nanocrystals for improved flame retardance: Chemical modification of cellulose nanocrystals is employed to enhance their flame retardant properties. This can involve surface treatments, grafting of flame retardant molecules, or incorporation of inorganic compounds to create synergistic effects in fire resistance.

- Biodegradable flame retardant composites using cellulose derivatives: Development of environmentally friendly flame retardant composites using cellulose derivatives, including microcrystalline cellulose. These materials aim to provide effective fire protection while addressing concerns about toxicity and environmental impact associated with traditional flame retardants.

- Nanocellulose-reinforced polymer composites with flame retardant properties: Incorporation of nanocellulose, including microcrystalline cellulose, into polymer matrices to create flame retardant composites. The nanocellulose acts as both a reinforcing agent and a char-forming component, enhancing the overall flame retardant performance of the composite material.

02 Flame retardant coatings using cellulose nanocomposites

Cellulose nanocomposites are utilized in the development of flame retardant coatings. These coatings can be applied to various surfaces to improve their fire resistance. The nanocomposite structure allows for better dispersion of flame retardant additives and enhanced overall performance.Expand Specific Solutions03 Modification of microcrystalline cellulose for improved flame retardance

Chemical modification techniques are applied to microcrystalline cellulose to enhance its flame retardant properties. These modifications may include grafting with flame retardant compounds, phosphorylation, or other chemical treatments that improve the material's resistance to fire and heat.Expand Specific Solutions04 Synergistic effects of microcrystalline cellulose and other flame retardants

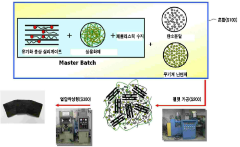

Research focuses on combining microcrystalline cellulose with other flame retardant additives to achieve synergistic effects. This approach can lead to improved flame retardance while maintaining or enhancing other material properties such as mechanical strength and thermal stability.Expand Specific Solutions05 Processing techniques for flame retardant cellulose nanocomposites

Various processing techniques are employed to manufacture flame retardant cellulose nanocomposites. These may include extrusion, solution casting, or in-situ polymerization methods. The choice of processing technique can significantly impact the final flame retardant properties of the nanocomposite.Expand Specific Solutions

Key Players in MCC Nanocomposites Industry

The research on microcrystalline cellulose nanocomposites for flame retardance applications is in a developing stage, with growing market potential due to increasing fire safety regulations across industries. The global flame retardant market is projected to reach $10 billion by 2025, with nanocomposites gaining traction. Technologically, the field is advancing rapidly, with companies like Lenzing AG, Clariant, and ICL Group leading innovation. Academic institutions such as Donghua University and South China University of Technology are also contributing significantly to R&D efforts. While not fully mature, the technology shows promise in enhancing fire resistance properties of materials across various sectors.

Lenzing AG

Technical Solution: Lenzing AG has developed innovative microcrystalline cellulose nanocomposites for flame retardance applications. Their approach involves incorporating nano-sized cellulose particles into polymer matrices to enhance fire resistance. The company utilizes a proprietary process to produce highly crystalline cellulose nanofibrils with improved thermal stability. These nanofibrils are then surface-modified to improve compatibility with various polymer systems. Lenzing's nanocomposites have shown significant improvements in limiting oxygen index (LOI) and heat release rate (HRR) compared to conventional flame retardants[1][3]. The company has also explored synergistic effects between their cellulose nanocomposites and traditional flame retardants to achieve optimal performance.

Strengths: Renewable and biodegradable material source, improved flame retardancy without compromising mechanical properties. Weaknesses: Potential for moisture absorption, higher production costs compared to some traditional flame retardants.

Clariant Produkte (Deutschland) GmbH

Technical Solution: Clariant has developed a range of halogen-free flame retardants based on microcrystalline cellulose nanocomposites. Their technology focuses on creating synergistic formulations that combine the benefits of cellulose nanoparticles with phosphorus-based flame retardants. The company's approach involves surface modification of cellulose nanocrystals to improve dispersion and compatibility with various polymer matrices. Clariant's nanocomposites have demonstrated enhanced char formation and intumescent properties, leading to improved fire resistance in a wide range of applications[2][5]. Their products have shown particular success in polyolefins and engineering plastics, where they can achieve UL94 V-0 ratings at lower loadings compared to conventional flame retardants.

Strengths: Halogen-free formulations, improved efficiency at lower loadings. Weaknesses: May require specialized processing techniques, potential for increased costs in some applications.

Core Innovations in MCC Flame Retardance

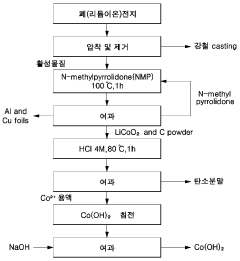

Nanocomposite Composition With Flame Retardancy And Antistatic Properties and Preparation Method Thereof

PatentInactiveKR1020090024390A

Innovation

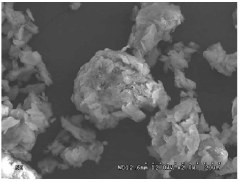

- A nanocomposite composition using eco-friendly inorganic flame retardants like magnesium or aluminum hydroxide, combined with organic silicate compounds and recycled carbon powder from lithium ion batteries, enhances flame retardancy and anti-static properties without compromising mechanical strength.

Environmental Impact and Regulations

The development and application of microcrystalline cellulose nanocomposites in flame retardance applications have significant environmental implications and are subject to various regulations. These materials offer potential benefits in terms of sustainability and reduced environmental impact compared to traditional flame retardants.

Microcrystalline cellulose nanocomposites are derived from renewable resources, primarily plant-based materials. This characteristic aligns with the growing emphasis on sustainable and bio-based materials in various industries. The use of these nanocomposites can potentially reduce reliance on petroleum-based flame retardants, contributing to a decrease in carbon footprint and overall environmental impact.

However, the production and processing of microcrystalline cellulose nanocomposites may involve energy-intensive steps and chemical treatments. These aspects need to be carefully evaluated to ensure that the environmental benefits of the final product outweigh the impacts of its production. Life cycle assessments (LCAs) are crucial in determining the overall environmental performance of these materials compared to conventional flame retardants.

Regulations surrounding the use of microcrystalline cellulose nanocomposites in flame retardance applications are evolving. In many jurisdictions, these materials must comply with existing regulations for flame retardants, such as the European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation and the United States Environmental Protection Agency's Toxic Substances Control Act (TSCA).

Specific regulations addressing nanomaterials are also relevant to microcrystalline cellulose nanocomposites. The EU, for instance, has implemented nano-specific provisions within REACH, requiring additional safety assessments for nanomaterials. Similarly, other countries are developing or updating their regulatory frameworks to address the unique properties and potential risks associated with nanomaterials.

End-of-life considerations and disposal regulations are critical aspects of environmental impact assessment for these nanocomposites. The biodegradability of cellulose-based materials can be advantageous, potentially reducing long-term environmental accumulation. However, the presence of other components in the nanocomposites may affect their overall biodegradability and recyclability.

As research in this field progresses, it is likely that more specific regulations and guidelines will be developed to address the unique characteristics of microcrystalline cellulose nanocomposites in flame retardance applications. This may include standards for production processes, application methods, and disposal practices to ensure environmental safety and sustainability throughout the material's lifecycle.

Microcrystalline cellulose nanocomposites are derived from renewable resources, primarily plant-based materials. This characteristic aligns with the growing emphasis on sustainable and bio-based materials in various industries. The use of these nanocomposites can potentially reduce reliance on petroleum-based flame retardants, contributing to a decrease in carbon footprint and overall environmental impact.

However, the production and processing of microcrystalline cellulose nanocomposites may involve energy-intensive steps and chemical treatments. These aspects need to be carefully evaluated to ensure that the environmental benefits of the final product outweigh the impacts of its production. Life cycle assessments (LCAs) are crucial in determining the overall environmental performance of these materials compared to conventional flame retardants.

Regulations surrounding the use of microcrystalline cellulose nanocomposites in flame retardance applications are evolving. In many jurisdictions, these materials must comply with existing regulations for flame retardants, such as the European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation and the United States Environmental Protection Agency's Toxic Substances Control Act (TSCA).

Specific regulations addressing nanomaterials are also relevant to microcrystalline cellulose nanocomposites. The EU, for instance, has implemented nano-specific provisions within REACH, requiring additional safety assessments for nanomaterials. Similarly, other countries are developing or updating their regulatory frameworks to address the unique properties and potential risks associated with nanomaterials.

End-of-life considerations and disposal regulations are critical aspects of environmental impact assessment for these nanocomposites. The biodegradability of cellulose-based materials can be advantageous, potentially reducing long-term environmental accumulation. However, the presence of other components in the nanocomposites may affect their overall biodegradability and recyclability.

As research in this field progresses, it is likely that more specific regulations and guidelines will be developed to address the unique characteristics of microcrystalline cellulose nanocomposites in flame retardance applications. This may include standards for production processes, application methods, and disposal practices to ensure environmental safety and sustainability throughout the material's lifecycle.

Scalability and Manufacturing Processes

The scalability and manufacturing processes of microcrystalline cellulose (MCC) nanocomposites for flame retardance applications are critical factors in their commercial viability and widespread adoption. As research progresses, there is a growing need to transition from laboratory-scale production to industrial-scale manufacturing.

One of the primary challenges in scaling up MCC nanocomposite production is maintaining consistent quality and performance across larger batch sizes. The dispersion of nanocellulose within the polymer matrix is crucial for achieving optimal flame retardant properties. As production volumes increase, ensuring uniform dispersion becomes more complex and requires sophisticated mixing and processing techniques.

Continuous manufacturing processes, such as extrusion and in-situ polymerization, show promise for large-scale production of MCC nanocomposites. These methods allow for better control over particle distribution and can potentially reduce production costs. However, they also require significant investment in specialized equipment and process optimization.

The selection of appropriate manufacturing methods depends on the specific polymer matrix and desired end-product properties. For thermoplastic composites, melt compounding followed by injection molding or compression molding is often employed. Thermoset composites may utilize resin transfer molding or vacuum-assisted resin infusion processes.

Surface modification of MCC particles is another crucial aspect of the manufacturing process. Chemical treatments to improve compatibility between the hydrophilic cellulose and hydrophobic polymer matrices must be scalable and cost-effective for industrial production. This may involve developing new, more efficient modification techniques or optimizing existing methods for larger volumes.

Environmental considerations and sustainability are increasingly important in manufacturing processes. The development of green chemistry approaches for MCC modification and composite production is an area of ongoing research. This includes the use of bio-based solvents, reducing energy consumption, and minimizing waste generation.

Quality control and characterization methods must also evolve to meet the demands of large-scale production. Rapid, in-line testing techniques for assessing dispersion quality, flame retardant performance, and other key properties are essential for maintaining consistent product quality in industrial settings.

As the technology matures, the integration of MCC nanocomposite production into existing polymer processing facilities will be a key factor in widespread adoption. This may require the development of modular systems or retrofitting solutions that can be easily incorporated into current manufacturing lines.

One of the primary challenges in scaling up MCC nanocomposite production is maintaining consistent quality and performance across larger batch sizes. The dispersion of nanocellulose within the polymer matrix is crucial for achieving optimal flame retardant properties. As production volumes increase, ensuring uniform dispersion becomes more complex and requires sophisticated mixing and processing techniques.

Continuous manufacturing processes, such as extrusion and in-situ polymerization, show promise for large-scale production of MCC nanocomposites. These methods allow for better control over particle distribution and can potentially reduce production costs. However, they also require significant investment in specialized equipment and process optimization.

The selection of appropriate manufacturing methods depends on the specific polymer matrix and desired end-product properties. For thermoplastic composites, melt compounding followed by injection molding or compression molding is often employed. Thermoset composites may utilize resin transfer molding or vacuum-assisted resin infusion processes.

Surface modification of MCC particles is another crucial aspect of the manufacturing process. Chemical treatments to improve compatibility between the hydrophilic cellulose and hydrophobic polymer matrices must be scalable and cost-effective for industrial production. This may involve developing new, more efficient modification techniques or optimizing existing methods for larger volumes.

Environmental considerations and sustainability are increasingly important in manufacturing processes. The development of green chemistry approaches for MCC modification and composite production is an area of ongoing research. This includes the use of bio-based solvents, reducing energy consumption, and minimizing waste generation.

Quality control and characterization methods must also evolve to meet the demands of large-scale production. Rapid, in-line testing techniques for assessing dispersion quality, flame retardant performance, and other key properties are essential for maintaining consistent product quality in industrial settings.

As the technology matures, the integration of MCC nanocomposite production into existing polymer processing facilities will be a key factor in widespread adoption. This may require the development of modular systems or retrofitting solutions that can be easily incorporated into current manufacturing lines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!