Microcrystalline Cellulose in Aerosolized Drug Delivery Systems

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCC in Aerosol Drug Delivery: Background and Objectives

Microcrystalline cellulose (MCC) has emerged as a pivotal excipient in the field of aerosolized drug delivery systems, marking a significant advancement in pharmaceutical technology. The evolution of MCC in this domain can be traced back to the mid-20th century when its potential as a versatile pharmaceutical excipient was first recognized. Since then, its application in aerosol formulations has grown exponentially, driven by the increasing demand for efficient pulmonary drug delivery methods.

The primary objective of incorporating MCC in aerosolized drug delivery systems is to enhance the performance and stability of inhaled medications. MCC's unique physicochemical properties, including its high surface area, low bulk density, and excellent compressibility, make it an ideal candidate for improving the dispersibility and aerosolization of drug particles. These characteristics contribute to the formation of stable suspensions and the generation of fine aerosol particles, crucial for effective deep lung deposition.

In recent years, the focus has shifted towards developing novel MCC-based formulations that can address the challenges associated with traditional aerosol delivery systems. These challenges include poor drug solubility, inadequate lung deposition, and limited bioavailability of inhaled medications. Researchers are exploring various modifications of MCC, such as surface functionalization and particle engineering, to tailor its properties for specific drug delivery applications.

The technological trajectory of MCC in aerosol drug delivery is closely aligned with the broader trends in personalized medicine and targeted therapies. As the pharmaceutical industry moves towards more precise and patient-centric treatments, the role of MCC in enabling controlled release and targeted delivery of inhaled drugs is becoming increasingly important. This has led to a surge in research activities aimed at optimizing MCC-based formulations for a wide range of respiratory conditions, from asthma and COPD to more complex diseases like cystic fibrosis and pulmonary hypertension.

Looking ahead, the development of MCC in aerosolized drug delivery systems is expected to focus on several key areas. These include the integration of MCC with advanced drug delivery technologies, such as nanocarriers and smart polymers, to achieve prolonged drug release and improved therapeutic efficacy. Additionally, there is growing interest in exploring the potential of MCC in the delivery of biologics and gene therapies via the pulmonary route, opening up new avenues for treating previously intractable respiratory diseases.

As we delve deeper into the research on MCC in aerosolized drug delivery systems, it becomes evident that this field is at the cusp of significant breakthroughs. The convergence of material science, pharmaceutical engineering, and respiratory medicine is driving innovation in MCC-based formulations, promising to revolutionize the landscape of inhaled therapies in the coming years.

The primary objective of incorporating MCC in aerosolized drug delivery systems is to enhance the performance and stability of inhaled medications. MCC's unique physicochemical properties, including its high surface area, low bulk density, and excellent compressibility, make it an ideal candidate for improving the dispersibility and aerosolization of drug particles. These characteristics contribute to the formation of stable suspensions and the generation of fine aerosol particles, crucial for effective deep lung deposition.

In recent years, the focus has shifted towards developing novel MCC-based formulations that can address the challenges associated with traditional aerosol delivery systems. These challenges include poor drug solubility, inadequate lung deposition, and limited bioavailability of inhaled medications. Researchers are exploring various modifications of MCC, such as surface functionalization and particle engineering, to tailor its properties for specific drug delivery applications.

The technological trajectory of MCC in aerosol drug delivery is closely aligned with the broader trends in personalized medicine and targeted therapies. As the pharmaceutical industry moves towards more precise and patient-centric treatments, the role of MCC in enabling controlled release and targeted delivery of inhaled drugs is becoming increasingly important. This has led to a surge in research activities aimed at optimizing MCC-based formulations for a wide range of respiratory conditions, from asthma and COPD to more complex diseases like cystic fibrosis and pulmonary hypertension.

Looking ahead, the development of MCC in aerosolized drug delivery systems is expected to focus on several key areas. These include the integration of MCC with advanced drug delivery technologies, such as nanocarriers and smart polymers, to achieve prolonged drug release and improved therapeutic efficacy. Additionally, there is growing interest in exploring the potential of MCC in the delivery of biologics and gene therapies via the pulmonary route, opening up new avenues for treating previously intractable respiratory diseases.

As we delve deeper into the research on MCC in aerosolized drug delivery systems, it becomes evident that this field is at the cusp of significant breakthroughs. The convergence of material science, pharmaceutical engineering, and respiratory medicine is driving innovation in MCC-based formulations, promising to revolutionize the landscape of inhaled therapies in the coming years.

Market Analysis for MCC-based Inhalation Therapies

The market for microcrystalline cellulose (MCC) in aerosolized drug delivery systems, particularly for inhalation therapies, has been experiencing significant growth in recent years. This trend is driven by the increasing prevalence of respiratory diseases, such as asthma and chronic obstructive pulmonary disease (COPD), coupled with the growing demand for more efficient and targeted drug delivery methods.

The global market for MCC-based inhalation therapies is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2026. This growth is primarily attributed to the rising adoption of dry powder inhalers (DPIs) and metered-dose inhalers (MDIs), where MCC serves as a crucial excipient. The North American region currently holds the largest market share, followed by Europe and Asia-Pacific.

One of the key factors driving market growth is the superior properties of MCC as an excipient in inhalation formulations. MCC offers excellent flow properties, low moisture content, and high compressibility, making it an ideal carrier for active pharmaceutical ingredients (APIs) in dry powder inhalers. These characteristics contribute to improved drug dispersion and enhanced lung deposition, ultimately leading to better therapeutic outcomes for patients.

The pharmaceutical industry's increasing focus on developing innovative inhalation therapies for both existing and emerging respiratory conditions is another significant driver for the MCC market. As more companies invest in research and development of novel inhaled medications, the demand for high-quality excipients like MCC continues to rise.

Furthermore, the growing preference for non-invasive drug delivery methods among patients and healthcare providers is boosting the adoption of inhalation therapies. This trend is particularly evident in the treatment of chronic respiratory diseases, where long-term medication adherence is crucial for effective management.

However, the market also faces certain challenges. Stringent regulatory requirements for inhalation drug products and the complex manufacturing processes associated with MCC-based formulations can potentially hinder market growth. Additionally, the emergence of alternative excipients and carrier systems may pose a threat to the dominance of MCC in certain applications.

Despite these challenges, the overall market outlook for MCC in aerosolized drug delivery systems remains positive. The ongoing technological advancements in particle engineering and formulation techniques are expected to further enhance the performance of MCC-based inhalation therapies, driving continued market expansion in the coming years.

The global market for MCC-based inhalation therapies is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2026. This growth is primarily attributed to the rising adoption of dry powder inhalers (DPIs) and metered-dose inhalers (MDIs), where MCC serves as a crucial excipient. The North American region currently holds the largest market share, followed by Europe and Asia-Pacific.

One of the key factors driving market growth is the superior properties of MCC as an excipient in inhalation formulations. MCC offers excellent flow properties, low moisture content, and high compressibility, making it an ideal carrier for active pharmaceutical ingredients (APIs) in dry powder inhalers. These characteristics contribute to improved drug dispersion and enhanced lung deposition, ultimately leading to better therapeutic outcomes for patients.

The pharmaceutical industry's increasing focus on developing innovative inhalation therapies for both existing and emerging respiratory conditions is another significant driver for the MCC market. As more companies invest in research and development of novel inhaled medications, the demand for high-quality excipients like MCC continues to rise.

Furthermore, the growing preference for non-invasive drug delivery methods among patients and healthcare providers is boosting the adoption of inhalation therapies. This trend is particularly evident in the treatment of chronic respiratory diseases, where long-term medication adherence is crucial for effective management.

However, the market also faces certain challenges. Stringent regulatory requirements for inhalation drug products and the complex manufacturing processes associated with MCC-based formulations can potentially hinder market growth. Additionally, the emergence of alternative excipients and carrier systems may pose a threat to the dominance of MCC in certain applications.

Despite these challenges, the overall market outlook for MCC in aerosolized drug delivery systems remains positive. The ongoing technological advancements in particle engineering and formulation techniques are expected to further enhance the performance of MCC-based inhalation therapies, driving continued market expansion in the coming years.

Technical Challenges in MCC Aerosolization

The aerosolization of Microcrystalline Cellulose (MCC) in drug delivery systems presents several technical challenges that researchers and manufacturers must overcome. One of the primary difficulties lies in achieving consistent particle size distribution. MCC particles tend to agglomerate due to their high surface area and intermolecular forces, making it challenging to produce aerosols with uniform particle sizes within the respirable range (1-5 μm).

Another significant hurdle is maintaining the stability of MCC-based formulations during the aerosolization process. The high shear forces involved in aerosolization can potentially alter the physical properties of MCC, affecting its performance as a carrier or stabilizer for active pharmaceutical ingredients (APIs). This instability may lead to reduced drug delivery efficiency and compromised therapeutic outcomes.

The hygroscopic nature of MCC poses additional challenges in aerosolization. Moisture absorption can cause particle swelling and changes in aerodynamic behavior, potentially impacting the deposition pattern of the drug in the respiratory tract. Controlling environmental conditions during manufacturing, storage, and administration becomes crucial to maintain the desired aerosolization characteristics.

Furthermore, the interaction between MCC and different APIs presents complexities in formulation development. Some drugs may adhere strongly to MCC particles, while others may not bind sufficiently, affecting the overall performance of the aerosolized drug delivery system. Optimizing these interactions requires extensive research and formulation studies.

The choice of aerosolization device also plays a critical role in overcoming technical challenges. Different devices (e.g., dry powder inhalers, nebulizers, pressurized metered-dose inhalers) may require specific MCC properties or formulation adjustments to achieve optimal aerosolization. Developing MCC-based formulations that are compatible with a wide range of devices while maintaining consistent performance is a significant technical challenge.

Scalability and reproducibility in manufacturing processes present additional hurdles. Translating laboratory-scale formulations to industrial production while maintaining the desired MCC aerosolization properties requires careful process optimization and quality control measures. Ensuring batch-to-batch consistency in terms of particle size distribution, flow properties, and aerosolization performance is essential for commercial viability.

Regulatory considerations add another layer of complexity to MCC aerosolization challenges. Meeting stringent quality and safety standards for inhalation products, including demonstrating the long-term stability of MCC-based formulations and their performance consistency, requires extensive testing and documentation.

Another significant hurdle is maintaining the stability of MCC-based formulations during the aerosolization process. The high shear forces involved in aerosolization can potentially alter the physical properties of MCC, affecting its performance as a carrier or stabilizer for active pharmaceutical ingredients (APIs). This instability may lead to reduced drug delivery efficiency and compromised therapeutic outcomes.

The hygroscopic nature of MCC poses additional challenges in aerosolization. Moisture absorption can cause particle swelling and changes in aerodynamic behavior, potentially impacting the deposition pattern of the drug in the respiratory tract. Controlling environmental conditions during manufacturing, storage, and administration becomes crucial to maintain the desired aerosolization characteristics.

Furthermore, the interaction between MCC and different APIs presents complexities in formulation development. Some drugs may adhere strongly to MCC particles, while others may not bind sufficiently, affecting the overall performance of the aerosolized drug delivery system. Optimizing these interactions requires extensive research and formulation studies.

The choice of aerosolization device also plays a critical role in overcoming technical challenges. Different devices (e.g., dry powder inhalers, nebulizers, pressurized metered-dose inhalers) may require specific MCC properties or formulation adjustments to achieve optimal aerosolization. Developing MCC-based formulations that are compatible with a wide range of devices while maintaining consistent performance is a significant technical challenge.

Scalability and reproducibility in manufacturing processes present additional hurdles. Translating laboratory-scale formulations to industrial production while maintaining the desired MCC aerosolization properties requires careful process optimization and quality control measures. Ensuring batch-to-batch consistency in terms of particle size distribution, flow properties, and aerosolization performance is essential for commercial viability.

Regulatory considerations add another layer of complexity to MCC aerosolization challenges. Meeting stringent quality and safety standards for inhalation products, including demonstrating the long-term stability of MCC-based formulations and their performance consistency, requires extensive testing and documentation.

Current MCC Formulation Strategies for Inhalers

01 Production and modification of microcrystalline cellulose

Various methods are employed to produce and modify microcrystalline cellulose, including acid hydrolysis, enzymatic treatment, and mechanical processing. These techniques aim to improve the properties of microcrystalline cellulose for specific applications, such as enhancing its stability, particle size distribution, or surface characteristics.- Production and modification of microcrystalline cellulose: Various methods are employed to produce and modify microcrystalline cellulose, including acid hydrolysis, enzymatic treatment, and mechanical processing. These techniques aim to improve the properties of microcrystalline cellulose for specific applications, such as enhancing its stability, particle size distribution, or functionality.

- Applications in pharmaceutical formulations: Microcrystalline cellulose is widely used in pharmaceutical formulations as an excipient. It serves various functions, including as a binder, disintegrant, and filler in tablet and capsule formulations. Its properties contribute to improved drug release, stability, and overall performance of pharmaceutical products.

- Use in food and cosmetic industries: Microcrystalline cellulose finds applications in food and cosmetic products as a stabilizer, thickener, and texturizing agent. It is used to improve the consistency, mouthfeel, and shelf-life of various food products, as well as in cosmetic formulations for its rheological properties and as a bulking agent.

- Composite materials and reinforcement applications: Microcrystalline cellulose is utilized in the development of composite materials, where it acts as a reinforcing agent. It can enhance the mechanical properties, thermal stability, and biodegradability of various materials, including plastics, paper, and construction materials.

- Nanotechnology and advanced applications: Research is ongoing in the field of nanocellulose derived from microcrystalline cellulose. These nanostructures have potential applications in areas such as drug delivery systems, advanced materials, and environmental remediation. The unique properties of nanocellulose open up new possibilities for innovative products and technologies.

02 Applications in pharmaceutical formulations

Microcrystalline cellulose is widely used in pharmaceutical formulations as an excipient. It serves various functions, including as a binder, disintegrant, and filler in tablet and capsule formulations. Its unique properties contribute to improved drug release, stability, and overall performance of pharmaceutical products.Expand Specific Solutions03 Use in food and cosmetic industries

Microcrystalline cellulose finds applications in food and cosmetic products as a stabilizer, thickener, and texturizing agent. It is used to improve the consistency, mouthfeel, and shelf-life of various food products. In cosmetics, it serves as a bulking agent and helps control viscosity in creams and lotions.Expand Specific Solutions04 Composite materials and reinforcement applications

Microcrystalline cellulose is utilized in the development of composite materials, where it acts as a reinforcing agent. It can enhance the mechanical properties, thermal stability, and biodegradability of various polymers and materials. This has applications in packaging, construction, and automotive industries.Expand Specific Solutions05 Sustainable and eco-friendly material

As a naturally derived and biodegradable material, microcrystalline cellulose is increasingly being explored for sustainable and eco-friendly applications. It is used in the development of biodegradable plastics, packaging materials, and as a replacement for synthetic additives in various industries, aligning with the growing demand for environmentally friendly products.Expand Specific Solutions

Key Players in MCC-based Inhaler Technology

The research on microcrystalline cellulose in aerosolized drug delivery systems is in a growth phase, with increasing market potential due to the rising demand for innovative drug delivery methods. The global market for this technology is expanding, driven by the need for more efficient and targeted drug administration. Companies like Insmed, Inc., Bristol Myers Squibb Co., and 3M Innovative Properties Co. are at the forefront of developing advanced formulations and devices for aerosolized drug delivery. The technology's maturity is progressing, with ongoing research and development efforts by academic institutions such as the University of Copenhagen and Rutgers State University, alongside industry players, indicating a collaborative approach to advancing this field.

Insmed, Inc.

Technical Solution: Insmed has developed a proprietary technology platform called PULMOSPHERE™ for the delivery of inhaled drugs. This technology utilizes microcrystalline cellulose (MCC) as a carrier for aerosolized drug delivery. The PULMOSPHERE™ particles are engineered to have a specific size and density that allows for optimal lung deposition[1]. The company has applied this technology to develop ARIKAYCE®, an inhaled liposomal amikacin for the treatment of lung infections caused by Mycobacterium avium complex (MAC)[2]. The MCC-based particles are designed to improve drug stability, enhance lung penetration, and provide sustained release of the active ingredient[3].

Strengths: Improved drug stability and lung deposition, potential for sustained release. Weaknesses: May require specialized inhalation devices, potential for particle aggregation.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced microcrystalline cellulose-based technologies for aerosolized drug delivery systems. Their approach involves creating MCC particles with specific morphologies and surface properties to enhance drug loading and aerosolization performance[4]. The company has patented methods for producing MCC particles with high specific surface area and controlled porosity, which can improve drug absorption and release kinetics in the lungs[5]. 3M's technology also incorporates surface modification of MCC particles to enhance their compatibility with various drug molecules and improve dispersion in aerosol formulations[6].

Strengths: Customizable particle properties, improved drug loading capacity. Weaknesses: Potential for batch-to-batch variability, may require specialized manufacturing processes.

Innovations in MCC Particle Engineering

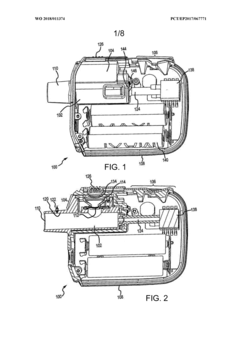

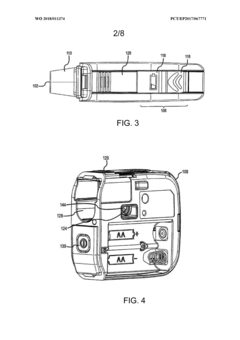

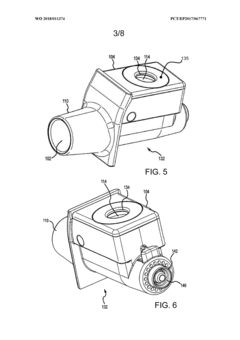

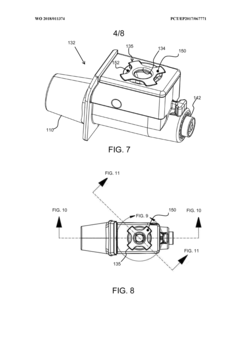

Aerosolizaton device and an aerosol drug delivery device

PatentWO2018011374A1

Innovation

- The aerosolization device features a tapered fluid receiving chamber with a spoked top cover design that reduces liquid trapping and ribbed or channelled surfaces to minimize air bubbles, combined with a vibratable mesh aerosol generator and a mouthpiece cartridge with a controller and batteries for precise dose delivery.

Treating cystic fibrosis with antibiotics via an aerosol drug

PatentWO2007145868A1

Innovation

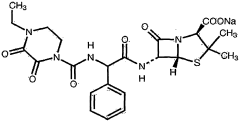

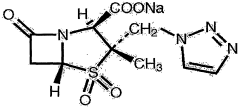

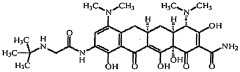

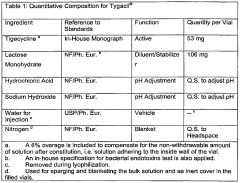

- An aerosol drug delivery system that produces at least 90% of antibiotic particles in the size range of 1-3 microns or less, allowing for effective delivery to the lung alveoli, using devices such as unit dose dry-powder inhalers, nebulizers, and metered-dose inhalers, with antibiotics like ZOSYN, Piperacillin, Tazobactam, and TYGACIL administered in combination with diluents to achieve optimal particle size distribution.

Regulatory Framework for Inhaled MCC Formulations

The regulatory framework for inhaled microcrystalline cellulose (MCC) formulations is a critical aspect of the development and approval process for aerosolized drug delivery systems. Regulatory agencies, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have established specific guidelines and requirements for inhaled drug products containing MCC as an excipient.

These regulatory bodies primarily focus on ensuring the safety and efficacy of inhaled MCC formulations. They require comprehensive data on the physicochemical properties of MCC, its interaction with active pharmaceutical ingredients, and its impact on drug delivery performance. Manufacturers must demonstrate that the use of MCC in inhaled formulations does not adversely affect the stability, aerodynamic properties, or bioavailability of the drug product.

One key regulatory consideration is the characterization of MCC particles used in inhaled formulations. Regulatory agencies typically require detailed information on particle size distribution, morphology, and surface properties. This is crucial because these characteristics can significantly influence the deposition pattern of the drug in the respiratory tract and, consequently, its therapeutic efficacy.

Safety assessments for inhaled MCC formulations are particularly stringent. Regulatory bodies demand extensive toxicological studies to evaluate the potential long-term effects of MCC inhalation on lung function and overall respiratory health. These studies often include in vitro and in vivo experiments to assess the impact of MCC on mucociliary clearance, lung inflammation, and potential immunogenic responses.

The manufacturing process for inhaled MCC formulations is subject to rigorous quality control measures. Regulatory agencies require adherence to Good Manufacturing Practices (GMP) and the implementation of robust quality management systems. This includes validation of the production process, establishment of appropriate specifications for raw materials and finished products, and implementation of effective analytical methods for quality control.

Stability testing is another critical component of the regulatory framework. Manufacturers must provide data demonstrating the long-term stability of inhaled MCC formulations under various environmental conditions. This includes evaluating the potential for moisture uptake, which can affect the aerodynamic properties of the formulation and, consequently, its therapeutic efficacy.

Regulatory agencies also focus on the performance of inhaled MCC formulations in terms of drug delivery efficiency. They require in vitro studies using cascade impactors to assess the aerodynamic particle size distribution and fine particle fraction of the drug product. Additionally, in vivo pharmacokinetic and pharmacodynamic studies are necessary to demonstrate the bioequivalence of MCC-containing formulations compared to reference products.

These regulatory bodies primarily focus on ensuring the safety and efficacy of inhaled MCC formulations. They require comprehensive data on the physicochemical properties of MCC, its interaction with active pharmaceutical ingredients, and its impact on drug delivery performance. Manufacturers must demonstrate that the use of MCC in inhaled formulations does not adversely affect the stability, aerodynamic properties, or bioavailability of the drug product.

One key regulatory consideration is the characterization of MCC particles used in inhaled formulations. Regulatory agencies typically require detailed information on particle size distribution, morphology, and surface properties. This is crucial because these characteristics can significantly influence the deposition pattern of the drug in the respiratory tract and, consequently, its therapeutic efficacy.

Safety assessments for inhaled MCC formulations are particularly stringent. Regulatory bodies demand extensive toxicological studies to evaluate the potential long-term effects of MCC inhalation on lung function and overall respiratory health. These studies often include in vitro and in vivo experiments to assess the impact of MCC on mucociliary clearance, lung inflammation, and potential immunogenic responses.

The manufacturing process for inhaled MCC formulations is subject to rigorous quality control measures. Regulatory agencies require adherence to Good Manufacturing Practices (GMP) and the implementation of robust quality management systems. This includes validation of the production process, establishment of appropriate specifications for raw materials and finished products, and implementation of effective analytical methods for quality control.

Stability testing is another critical component of the regulatory framework. Manufacturers must provide data demonstrating the long-term stability of inhaled MCC formulations under various environmental conditions. This includes evaluating the potential for moisture uptake, which can affect the aerodynamic properties of the formulation and, consequently, its therapeutic efficacy.

Regulatory agencies also focus on the performance of inhaled MCC formulations in terms of drug delivery efficiency. They require in vitro studies using cascade impactors to assess the aerodynamic particle size distribution and fine particle fraction of the drug product. Additionally, in vivo pharmacokinetic and pharmacodynamic studies are necessary to demonstrate the bioequivalence of MCC-containing formulations compared to reference products.

Environmental Impact of MCC-based Inhalers

The environmental impact of microcrystalline cellulose (MCC)-based inhalers is an important consideration in the development and use of aerosolized drug delivery systems. As a naturally derived excipient, MCC offers several environmental advantages over traditional propellant-based inhalers.

MCC-based dry powder inhalers (DPIs) eliminate the need for chlorofluorocarbon (CFC) or hydrofluoroalkane (HFA) propellants, which have been associated with ozone depletion and greenhouse gas emissions. This shift towards propellant-free inhalers significantly reduces the carbon footprint of inhaler production and use.

The biodegradability of MCC is another key environmental benefit. Unlike synthetic polymers used in some inhaler components, MCC can naturally decompose in the environment without leaving persistent pollutants. This characteristic reduces the long-term environmental impact of discarded inhalers and their components.

However, the production of MCC does have some environmental considerations. The process of extracting cellulose from wood pulp and converting it to microcrystalline form requires energy and chemical inputs. Sustainable forestry practices and efficient manufacturing processes are crucial to minimizing the environmental impact of MCC production.

The disposal of used MCC-based inhalers also presents environmental challenges. While the MCC itself is biodegradable, other components of the inhaler, such as plastics and metals, may not be. Proper recycling and waste management systems are necessary to ensure that these materials are appropriately handled at the end of the inhaler's life cycle.

In terms of drug delivery efficiency, MCC-based DPIs can potentially reduce medication waste compared to pressurized metered-dose inhalers (pMDIs). This improved efficiency means less active pharmaceutical ingredient (API) is required per dose, potentially reducing the environmental impact of drug manufacturing and disposal.

The particle engineering capabilities of MCC in inhaler formulations can lead to improved lung deposition of drugs. This enhanced targeting may result in lower required doses, further reducing the environmental footprint of drug production and potential environmental contamination through patient excretion.

As regulations around environmental impact become more stringent, the use of MCC in inhalers may provide pharmaceutical companies with a competitive advantage. The shift towards more environmentally friendly drug delivery systems aligns with global sustainability goals and may influence prescribing practices and patient preferences.

In conclusion, while MCC-based inhalers offer significant environmental benefits, particularly in terms of eliminating propellants and improving biodegradability, there are still areas for improvement in the overall lifecycle environmental impact of these devices. Ongoing research and development efforts are focused on further enhancing the sustainability of MCC production, optimizing inhaler design for recyclability, and improving drug delivery efficiency to minimize waste and environmental contamination.

MCC-based dry powder inhalers (DPIs) eliminate the need for chlorofluorocarbon (CFC) or hydrofluoroalkane (HFA) propellants, which have been associated with ozone depletion and greenhouse gas emissions. This shift towards propellant-free inhalers significantly reduces the carbon footprint of inhaler production and use.

The biodegradability of MCC is another key environmental benefit. Unlike synthetic polymers used in some inhaler components, MCC can naturally decompose in the environment without leaving persistent pollutants. This characteristic reduces the long-term environmental impact of discarded inhalers and their components.

However, the production of MCC does have some environmental considerations. The process of extracting cellulose from wood pulp and converting it to microcrystalline form requires energy and chemical inputs. Sustainable forestry practices and efficient manufacturing processes are crucial to minimizing the environmental impact of MCC production.

The disposal of used MCC-based inhalers also presents environmental challenges. While the MCC itself is biodegradable, other components of the inhaler, such as plastics and metals, may not be. Proper recycling and waste management systems are necessary to ensure that these materials are appropriately handled at the end of the inhaler's life cycle.

In terms of drug delivery efficiency, MCC-based DPIs can potentially reduce medication waste compared to pressurized metered-dose inhalers (pMDIs). This improved efficiency means less active pharmaceutical ingredient (API) is required per dose, potentially reducing the environmental impact of drug manufacturing and disposal.

The particle engineering capabilities of MCC in inhaler formulations can lead to improved lung deposition of drugs. This enhanced targeting may result in lower required doses, further reducing the environmental footprint of drug production and potential environmental contamination through patient excretion.

As regulations around environmental impact become more stringent, the use of MCC in inhalers may provide pharmaceutical companies with a competitive advantage. The shift towards more environmentally friendly drug delivery systems aligns with global sustainability goals and may influence prescribing practices and patient preferences.

In conclusion, while MCC-based inhalers offer significant environmental benefits, particularly in terms of eliminating propellants and improving biodegradability, there are still areas for improvement in the overall lifecycle environmental impact of these devices. Ongoing research and development efforts are focused on further enhancing the sustainability of MCC production, optimizing inhaler design for recyclability, and improving drug delivery efficiency to minimize waste and environmental contamination.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!