How Neoprene Aids in Advanced Weatherproofing Solutions?

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Weatherproofing Evolution and Objectives

Neoprene, a synthetic rubber developed in the 1930s, has played a pivotal role in the evolution of weatherproofing solutions. Initially created as an oil-resistant alternative to natural rubber, its unique properties quickly found applications in various industries, including construction and outdoor gear manufacturing. The journey of neoprene in weatherproofing began with its ability to withstand extreme temperatures and resist degradation from sunlight, ozone, and weathering.

Over the decades, the technology behind neoprene has continuously advanced, driven by the increasing demand for more effective and durable weatherproofing materials. The material's molecular structure has been fine-tuned to enhance its already impressive resistance to water, wind, and temperature fluctuations. This ongoing development has led to the creation of specialized neoprene formulations tailored for specific weatherproofing applications.

One of the key objectives in the evolution of neoprene weatherproofing has been to improve its longevity and performance under diverse environmental conditions. Researchers and manufacturers have focused on enhancing the material's UV resistance, thermal insulation properties, and overall durability. These efforts have resulted in neoprene variants that can maintain their protective qualities for extended periods, even when exposed to harsh weather elements.

Another significant goal in neoprene's development for weatherproofing has been to increase its versatility. Modern neoprene formulations can be engineered to possess varying degrees of flexibility, compression resistance, and adhesion properties. This adaptability allows neoprene to be used in a wide range of weatherproofing applications, from building seals and gaskets to protective coatings for outdoor structures.

The environmental impact of neoprene production and disposal has also become a crucial consideration in its evolution. Recent objectives include developing more sustainable manufacturing processes and exploring bio-based alternatives that maintain neoprene's superior weatherproofing characteristics while reducing its ecological footprint.

Looking ahead, the future objectives for neoprene in advanced weatherproofing solutions are focused on pushing the boundaries of its performance. This includes developing nanocomposite neoprene materials with enhanced barrier properties, exploring smart neoprene formulations that can adapt to changing environmental conditions, and integrating neoprene with other advanced materials to create hybrid weatherproofing systems with unprecedented levels of protection and durability.

Over the decades, the technology behind neoprene has continuously advanced, driven by the increasing demand for more effective and durable weatherproofing materials. The material's molecular structure has been fine-tuned to enhance its already impressive resistance to water, wind, and temperature fluctuations. This ongoing development has led to the creation of specialized neoprene formulations tailored for specific weatherproofing applications.

One of the key objectives in the evolution of neoprene weatherproofing has been to improve its longevity and performance under diverse environmental conditions. Researchers and manufacturers have focused on enhancing the material's UV resistance, thermal insulation properties, and overall durability. These efforts have resulted in neoprene variants that can maintain their protective qualities for extended periods, even when exposed to harsh weather elements.

Another significant goal in neoprene's development for weatherproofing has been to increase its versatility. Modern neoprene formulations can be engineered to possess varying degrees of flexibility, compression resistance, and adhesion properties. This adaptability allows neoprene to be used in a wide range of weatherproofing applications, from building seals and gaskets to protective coatings for outdoor structures.

The environmental impact of neoprene production and disposal has also become a crucial consideration in its evolution. Recent objectives include developing more sustainable manufacturing processes and exploring bio-based alternatives that maintain neoprene's superior weatherproofing characteristics while reducing its ecological footprint.

Looking ahead, the future objectives for neoprene in advanced weatherproofing solutions are focused on pushing the boundaries of its performance. This includes developing nanocomposite neoprene materials with enhanced barrier properties, exploring smart neoprene formulations that can adapt to changing environmental conditions, and integrating neoprene with other advanced materials to create hybrid weatherproofing systems with unprecedented levels of protection and durability.

Market Analysis for Advanced Weatherproofing Materials

The advanced weatherproofing materials market has experienced significant growth in recent years, driven by increasing demand for durable and high-performance construction solutions. This market segment encompasses a wide range of products, including sealants, membranes, coatings, and specialized fabrics, with neoprene playing a crucial role in many applications.

The global weatherproofing market size was valued at several billion dollars in 2020, with projections indicating steady growth over the next decade. Factors contributing to this growth include the rising frequency of extreme weather events, stringent building codes and regulations, and a growing awareness of energy efficiency in construction.

Neoprene, a synthetic rubber known for its excellent resistance to weathering, oil, and heat, has carved out a significant niche in the weatherproofing sector. Its versatility allows for applications in various forms, from liquid coatings to solid sheets, making it a preferred choice for architects, engineers, and contractors seeking reliable weatherproofing solutions.

The construction industry remains the primary driver of demand for advanced weatherproofing materials, including neoprene-based products. Residential, commercial, and industrial construction projects all contribute to market growth, with a particular emphasis on high-performance buildings that require superior protection against the elements.

Geographically, North America and Europe lead the market for advanced weatherproofing materials, owing to their mature construction industries and stringent building standards. However, rapid urbanization and infrastructure development in Asia-Pacific and emerging economies are creating new growth opportunities for weatherproofing solutions.

The automotive and aerospace industries also represent significant market segments for neoprene-based weatherproofing materials. These sectors demand high-performance solutions to protect vehicles and aircraft from harsh environmental conditions, further diversifying the application landscape for neoprene.

Market trends indicate a growing preference for eco-friendly and sustainable weatherproofing solutions. This shift is driving innovation in neoprene formulations and manufacturing processes to reduce environmental impact while maintaining or improving performance characteristics.

Competition in the advanced weatherproofing materials market is intense, with several major chemical and materials companies vying for market share. Key players are investing heavily in research and development to enhance product performance, durability, and ease of application, with neoprene remaining a focal point for many innovations.

The global weatherproofing market size was valued at several billion dollars in 2020, with projections indicating steady growth over the next decade. Factors contributing to this growth include the rising frequency of extreme weather events, stringent building codes and regulations, and a growing awareness of energy efficiency in construction.

Neoprene, a synthetic rubber known for its excellent resistance to weathering, oil, and heat, has carved out a significant niche in the weatherproofing sector. Its versatility allows for applications in various forms, from liquid coatings to solid sheets, making it a preferred choice for architects, engineers, and contractors seeking reliable weatherproofing solutions.

The construction industry remains the primary driver of demand for advanced weatherproofing materials, including neoprene-based products. Residential, commercial, and industrial construction projects all contribute to market growth, with a particular emphasis on high-performance buildings that require superior protection against the elements.

Geographically, North America and Europe lead the market for advanced weatherproofing materials, owing to their mature construction industries and stringent building standards. However, rapid urbanization and infrastructure development in Asia-Pacific and emerging economies are creating new growth opportunities for weatherproofing solutions.

The automotive and aerospace industries also represent significant market segments for neoprene-based weatherproofing materials. These sectors demand high-performance solutions to protect vehicles and aircraft from harsh environmental conditions, further diversifying the application landscape for neoprene.

Market trends indicate a growing preference for eco-friendly and sustainable weatherproofing solutions. This shift is driving innovation in neoprene formulations and manufacturing processes to reduce environmental impact while maintaining or improving performance characteristics.

Competition in the advanced weatherproofing materials market is intense, with several major chemical and materials companies vying for market share. Key players are investing heavily in research and development to enhance product performance, durability, and ease of application, with neoprene remaining a focal point for many innovations.

Current Neoprene Technology and Challenges

Neoprene, a synthetic rubber developed in the 1930s, has become a cornerstone in advanced weatherproofing solutions. Its unique properties, including excellent resistance to water, oils, and weathering, make it an ideal material for various applications. However, the current state of neoprene technology faces several challenges that need to be addressed to enhance its performance and sustainability.

One of the primary challenges in neoprene technology is improving its environmental impact. Traditional neoprene production involves the use of chloroprene, a potentially harmful chemical. Efforts are underway to develop more eco-friendly production methods, such as bio-based alternatives, but these are still in the early stages and require further research and development to become commercially viable.

Durability and longevity remain areas of focus for neoprene technology. While neoprene exhibits good resistance to weathering, prolonged exposure to extreme conditions can lead to degradation. Researchers are exploring ways to enhance neoprene's UV resistance and overall lifespan, particularly for outdoor applications where it is subjected to harsh environmental factors.

Another significant challenge lies in improving neoprene's thermal insulation properties. While it provides adequate insulation in many applications, there is a growing demand for materials with superior thermal performance. This has led to the development of neoprene composites and hybrid materials that combine the weatherproofing benefits of neoprene with enhanced insulation capabilities.

The manufacturing process of neoprene also presents challenges in terms of energy consumption and waste generation. Current production methods are energy-intensive, contributing to a higher carbon footprint. Efforts are being made to optimize manufacturing processes, reduce energy consumption, and minimize waste through recycling and reuse initiatives.

Advancements in nanotech-enhanced neoprene formulations show promise in addressing some of these challenges. By incorporating nanoparticles or nanostructures into neoprene, researchers aim to enhance its mechanical properties, chemical resistance, and overall performance. However, scaling up these technologies for mass production remains a hurdle.

The cost of high-performance neoprene formulations is another challenge facing the industry. As demand for more advanced weatherproofing solutions grows, balancing performance improvements with cost-effectiveness becomes crucial. This has spurred research into more efficient production methods and alternative raw materials to reduce overall costs.

Lastly, the integration of smart technologies with neoprene presents both opportunities and challenges. There is growing interest in developing neoprene-based materials with embedded sensors or adaptive properties for enhanced weatherproofing. However, ensuring the durability and reliability of these smart materials in harsh environments poses significant technical challenges that require innovative solutions.

One of the primary challenges in neoprene technology is improving its environmental impact. Traditional neoprene production involves the use of chloroprene, a potentially harmful chemical. Efforts are underway to develop more eco-friendly production methods, such as bio-based alternatives, but these are still in the early stages and require further research and development to become commercially viable.

Durability and longevity remain areas of focus for neoprene technology. While neoprene exhibits good resistance to weathering, prolonged exposure to extreme conditions can lead to degradation. Researchers are exploring ways to enhance neoprene's UV resistance and overall lifespan, particularly for outdoor applications where it is subjected to harsh environmental factors.

Another significant challenge lies in improving neoprene's thermal insulation properties. While it provides adequate insulation in many applications, there is a growing demand for materials with superior thermal performance. This has led to the development of neoprene composites and hybrid materials that combine the weatherproofing benefits of neoprene with enhanced insulation capabilities.

The manufacturing process of neoprene also presents challenges in terms of energy consumption and waste generation. Current production methods are energy-intensive, contributing to a higher carbon footprint. Efforts are being made to optimize manufacturing processes, reduce energy consumption, and minimize waste through recycling and reuse initiatives.

Advancements in nanotech-enhanced neoprene formulations show promise in addressing some of these challenges. By incorporating nanoparticles or nanostructures into neoprene, researchers aim to enhance its mechanical properties, chemical resistance, and overall performance. However, scaling up these technologies for mass production remains a hurdle.

The cost of high-performance neoprene formulations is another challenge facing the industry. As demand for more advanced weatherproofing solutions grows, balancing performance improvements with cost-effectiveness becomes crucial. This has spurred research into more efficient production methods and alternative raw materials to reduce overall costs.

Lastly, the integration of smart technologies with neoprene presents both opportunities and challenges. There is growing interest in developing neoprene-based materials with embedded sensors or adaptive properties for enhanced weatherproofing. However, ensuring the durability and reliability of these smart materials in harsh environments poses significant technical challenges that require innovative solutions.

Existing Neoprene-based Weatherproofing Solutions

01 Neoprene-based weatherproofing materials

Neoprene is used as a key component in weatherproofing materials due to its excellent resistance to water, UV radiation, and temperature fluctuations. These materials are often applied as coatings or sealants to protect various surfaces from environmental damage.- Neoprene-based weatherproofing materials: Neoprene is used as a key component in weatherproofing materials due to its excellent resistance to water, UV radiation, and temperature fluctuations. These materials are often applied as coatings or sealants to protect various surfaces from environmental damage.

- Neoprene in electrical weatherproofing: Neoprene is utilized in electrical applications for weatherproofing connectors, cables, and other components. Its insulating properties and durability make it ideal for protecting electrical systems from moisture and environmental factors.

- Neoprene-based adhesives and sealants: Specialized adhesives and sealants incorporating neoprene are developed for weatherproofing applications. These products offer strong bonding capabilities and flexibility, making them suitable for sealing joints and gaps in various structures.

- Neoprene in construction weatherproofing: Neoprene is employed in construction materials and techniques for weatherproofing buildings and structures. It is used in roofing membranes, window seals, and expansion joints to prevent water infiltration and improve energy efficiency.

- Neoprene composites for enhanced weatherproofing: Advanced composites incorporating neoprene and other materials are developed to enhance weatherproofing performance. These composites may include additives or be combined with other polymers to improve specific properties such as UV resistance or thermal insulation.

02 Weatherproofing applications for buildings and structures

Neoprene-based weatherproofing solutions are employed in construction to protect buildings and structures from moisture infiltration and weather-related damage. These applications include sealing joints, roofing membranes, and waterproofing foundations.Expand Specific Solutions03 Electrical and electronic weatherproofing

Neoprene is utilized in weatherproofing electrical and electronic components, providing protection against moisture, dust, and other environmental factors. This includes weatherproof enclosures, cable insulation, and sealing systems for outdoor electrical installations.Expand Specific Solutions04 Neoprene-based adhesives and sealants

Specialized adhesives and sealants incorporating neoprene are developed for weatherproofing applications. These products offer strong bonding properties and flexibility, making them suitable for sealing joints and gaps in various structures exposed to the elements.Expand Specific Solutions05 Neoprene weatherproofing for automotive and transportation

Neoprene-based weatherproofing solutions are applied in the automotive and transportation industries to protect vehicles and components from environmental damage. This includes weatherstripping, gaskets, and seals for doors, windows, and other openings.Expand Specific Solutions

Key Manufacturers and Suppliers in Neoprene Industry

The market for advanced weatherproofing solutions utilizing neoprene is in a growth phase, driven by increasing demand for durable and high-performance materials in various industries. The global market size for neoprene-based weatherproofing products is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is moderately mature, with ongoing innovations focused on enhancing performance and sustainability. Key players like Tianjin Pengling Group, Kolon Industries, and Toray Industries are investing in R&D to develop advanced neoprene formulations and application techniques. Emerging companies such as Zhik Pty Ltd. and Changsha Zichen Technology are also contributing to the competitive landscape with specialized solutions, indicating a dynamic and evolving market.

Zhik Pty Ltd.

Technical Solution: Zhik Pty Ltd. has developed innovative neoprene-based solutions specifically for marine weatherproofing. Their technology focuses on enhancing the performance of neoprene in high-stress, wet environments. Zhik's approach involves a unique lamination process that combines neoprene with high-stretch, water-repellent fabrics. This creates a composite material that offers superior flexibility and comfort while maintaining excellent waterproofing properties. The company has also developed a proprietary seam-sealing technology that uses heat-welded, waterproof tapes to reinforce all joints, significantly reducing water ingress at vulnerable points[6]. Additionally, Zhik has incorporated antimicrobial treatments into their neoprene composites to prevent odor and degradation in marine environments[7].

Strengths: Excellent performance in marine environments, superior flexibility and comfort, innovative seam-sealing technology. Weaknesses: Specialized for marine use, potentially less versatile for other applications. Higher cost due to specialized materials and processes.

Taiwan Textile Research Institute

Technical Solution: The Taiwan Textile Research Institute (TTRI) has made significant advancements in neoprene-based weatherproofing solutions through their research into nanocomposite materials. Their approach involves incorporating nanoparticles into neoprene to enhance its weatherproofing properties. TTRI has developed a process for dispersing nano-scale clay particles throughout the neoprene matrix, which significantly improves its barrier properties against water and gases[10]. This nanocomposite structure also enhances the material's mechanical strength and thermal stability. Additionally, TTRI has explored the use of carbon nanotubes in neoprene, which has shown promising results in improving the material's electrical conductivity and thermal management properties[11]. These innovations have potential applications in advanced protective clothing and industrial weatherproofing solutions.

Strengths: Significantly improved barrier properties, enhanced mechanical strength and thermal stability, potential for multifunctional materials. Weaknesses: Higher production costs, potential challenges in large-scale manufacturing, possible environmental concerns related to nanomaterials.

Innovative Neoprene Formulations for Weatherproofing

Improvements in or relating to neoprene solutions

PatentInactiveGB580190A

Innovation

- Incorporating cis-isomerides of unsaturated dicarboxylic acids, such as maleic acid, into Neoprene solutions in organic solvents to inhibit gelling caused by iron contamination, which maintains solution stability even when exposed to iron or elevated temperatures.

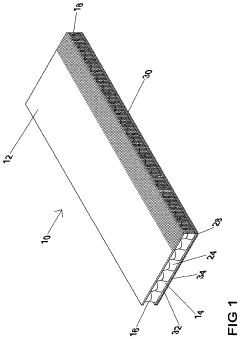

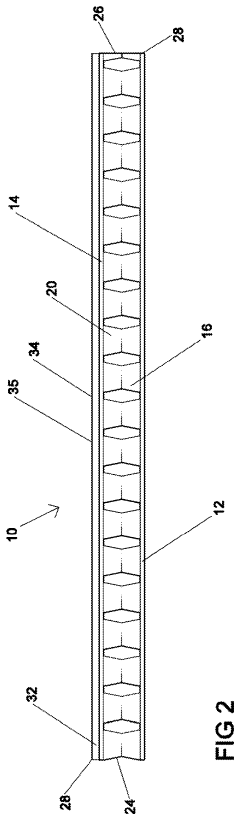

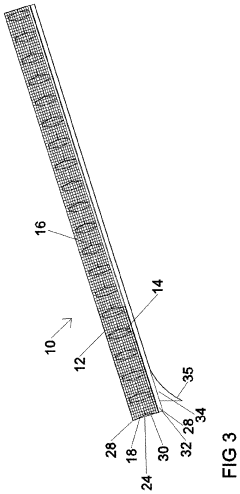

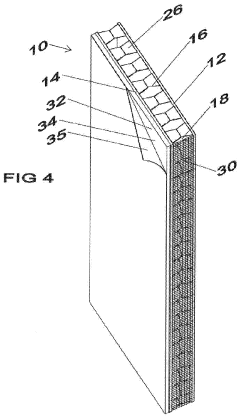

Moisture porous building furring strip

PatentPendingUS20230304296A1

Innovation

- A rigid, moisture and air porous furring strip with an elongate outer and inner facer sheet and an open cellular core, featuring a self-sealing butyl-like adhesive layer and optional stainless-steel screen to prevent insect and rodent entry, and a Neoprene-type adhesive for secure attachment with reduced hole damage.

Environmental Impact of Neoprene in Weatherproofing

The environmental impact of neoprene in weatherproofing applications is a complex issue that requires careful consideration. Neoprene, a synthetic rubber, has been widely used in weatherproofing solutions due to its excellent resistance to water, oils, and weathering. However, its production and disposal processes raise significant environmental concerns.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and energy consumption. The production process releases chloroprene, a potentially harmful compound, into the atmosphere. This can lead to air pollution and potential health risks for workers and nearby communities if not properly managed.

Neoprene's durability, while beneficial for weatherproofing applications, presents challenges in terms of disposal. The material is not biodegradable and can persist in the environment for extended periods. When neoprene products reach the end of their lifecycle, they often end up in landfills, contributing to the growing problem of non-biodegradable waste accumulation.

Water pollution is another concern associated with neoprene production and use. The manufacturing process can result in the release of chemical effluents into water bodies if not properly treated. Additionally, the breakdown of neoprene products over time may lead to the leaching of harmful substances into soil and water systems.

On the positive side, neoprene's longevity in weatherproofing applications can reduce the need for frequent replacements, potentially lowering overall material consumption and waste generation. Some manufacturers have also begun exploring more sustainable production methods and recycling initiatives for neoprene products.

Efforts to mitigate the environmental impact of neoprene in weatherproofing include the development of bio-based alternatives and improved recycling technologies. Some companies are investigating plant-based precursors for neoprene production, which could reduce reliance on petroleum-derived materials. Advancements in recycling techniques aim to break down neoprene into its component parts for reuse, potentially creating a more circular economy for this material.

The weatherproofing industry is also exploring alternative materials with similar performance characteristics but lower environmental footprints. These include natural rubber compounds, silicone-based materials, and advanced synthetic polymers designed for easier recycling and reduced environmental persistence.

In conclusion, while neoprene offers significant benefits in weatherproofing applications, its environmental impact remains a concern. Balancing the material's performance advantages with ecological considerations will be crucial for the sustainable development of weatherproofing solutions in the future.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and energy consumption. The production process releases chloroprene, a potentially harmful compound, into the atmosphere. This can lead to air pollution and potential health risks for workers and nearby communities if not properly managed.

Neoprene's durability, while beneficial for weatherproofing applications, presents challenges in terms of disposal. The material is not biodegradable and can persist in the environment for extended periods. When neoprene products reach the end of their lifecycle, they often end up in landfills, contributing to the growing problem of non-biodegradable waste accumulation.

Water pollution is another concern associated with neoprene production and use. The manufacturing process can result in the release of chemical effluents into water bodies if not properly treated. Additionally, the breakdown of neoprene products over time may lead to the leaching of harmful substances into soil and water systems.

On the positive side, neoprene's longevity in weatherproofing applications can reduce the need for frequent replacements, potentially lowering overall material consumption and waste generation. Some manufacturers have also begun exploring more sustainable production methods and recycling initiatives for neoprene products.

Efforts to mitigate the environmental impact of neoprene in weatherproofing include the development of bio-based alternatives and improved recycling technologies. Some companies are investigating plant-based precursors for neoprene production, which could reduce reliance on petroleum-derived materials. Advancements in recycling techniques aim to break down neoprene into its component parts for reuse, potentially creating a more circular economy for this material.

The weatherproofing industry is also exploring alternative materials with similar performance characteristics but lower environmental footprints. These include natural rubber compounds, silicone-based materials, and advanced synthetic polymers designed for easier recycling and reduced environmental persistence.

In conclusion, while neoprene offers significant benefits in weatherproofing applications, its environmental impact remains a concern. Balancing the material's performance advantages with ecological considerations will be crucial for the sustainable development of weatherproofing solutions in the future.

Comparative Analysis with Alternative Materials

Neoprene, a synthetic rubber known for its exceptional weatherproofing properties, has become a staple in advanced weatherproofing solutions. To fully appreciate its value, it is essential to compare it with alternative materials commonly used in weatherproofing applications.

One of the primary competitors to neoprene is silicone rubber. While silicone offers excellent temperature resistance and flexibility, it falls short in terms of durability and tear resistance compared to neoprene. Neoprene maintains its structural integrity under harsh weather conditions for extended periods, making it a preferred choice for long-term weatherproofing solutions.

Another alternative is EPDM (Ethylene Propylene Diene Monomer) rubber. EPDM is known for its resistance to ozone and weathering, but it lacks the oil and chemical resistance that neoprene provides. This makes neoprene a superior option for applications where exposure to various chemicals or petroleum-based products is a concern.

PVC (Polyvinyl Chloride) is often used in weatherproofing due to its low cost and ease of production. However, neoprene outperforms PVC in terms of flexibility at low temperatures and overall durability. Neoprene remains pliable in cold conditions, ensuring consistent performance across a wide range of temperatures.

Natural rubber, while eco-friendly, cannot match neoprene's resistance to degradation from sunlight, ozone, and oxidation. This makes neoprene a more reliable choice for outdoor applications where UV exposure is a significant factor.

When considering advanced weatherproofing solutions, the balance between cost and performance is crucial. While neoprene may have a higher initial cost compared to some alternatives, its longevity and superior performance in diverse environmental conditions often result in lower long-term costs and reduced maintenance requirements.

In terms of environmental impact, neoprene has faced criticism due to its chloroprene-based production process. However, advancements in manufacturing techniques and the development of eco-friendly alternatives, such as limestone-based neoprene, are addressing these concerns. This evolution positions neoprene as a more sustainable option compared to some petroleum-based alternatives.

In conclusion, while each material has its strengths, neoprene's unique combination of durability, flexibility, and resistance to various environmental factors makes it a standout choice for advanced weatherproofing solutions. Its ability to maintain performance across a wide range of conditions, coupled with ongoing improvements in sustainability, reinforces its position as a leading material in the field of weatherproofing.

One of the primary competitors to neoprene is silicone rubber. While silicone offers excellent temperature resistance and flexibility, it falls short in terms of durability and tear resistance compared to neoprene. Neoprene maintains its structural integrity under harsh weather conditions for extended periods, making it a preferred choice for long-term weatherproofing solutions.

Another alternative is EPDM (Ethylene Propylene Diene Monomer) rubber. EPDM is known for its resistance to ozone and weathering, but it lacks the oil and chemical resistance that neoprene provides. This makes neoprene a superior option for applications where exposure to various chemicals or petroleum-based products is a concern.

PVC (Polyvinyl Chloride) is often used in weatherproofing due to its low cost and ease of production. However, neoprene outperforms PVC in terms of flexibility at low temperatures and overall durability. Neoprene remains pliable in cold conditions, ensuring consistent performance across a wide range of temperatures.

Natural rubber, while eco-friendly, cannot match neoprene's resistance to degradation from sunlight, ozone, and oxidation. This makes neoprene a more reliable choice for outdoor applications where UV exposure is a significant factor.

When considering advanced weatherproofing solutions, the balance between cost and performance is crucial. While neoprene may have a higher initial cost compared to some alternatives, its longevity and superior performance in diverse environmental conditions often result in lower long-term costs and reduced maintenance requirements.

In terms of environmental impact, neoprene has faced criticism due to its chloroprene-based production process. However, advancements in manufacturing techniques and the development of eco-friendly alternatives, such as limestone-based neoprene, are addressing these concerns. This evolution positions neoprene as a more sustainable option compared to some petroleum-based alternatives.

In conclusion, while each material has its strengths, neoprene's unique combination of durability, flexibility, and resistance to various environmental factors makes it a standout choice for advanced weatherproofing solutions. Its ability to maintain performance across a wide range of conditions, coupled with ongoing improvements in sustainability, reinforces its position as a leading material in the field of weatherproofing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!