Neoprene: Enhancing Protective Gear for Extreme Conditions

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Evolution and Research Objectives

Neoprene, a synthetic rubber developed in the 1930s, has undergone significant evolution since its inception. Initially created as an oil-resistant alternative to natural rubber, neoprene quickly found applications in various industries due to its unique properties. The material's journey from a laboratory discovery to a crucial component in protective gear for extreme conditions is marked by continuous research and development.

The early stages of neoprene's evolution focused on improving its basic properties, such as elasticity, durability, and resistance to oils and chemicals. As its potential became apparent, researchers began exploring ways to enhance its performance in specific applications. The 1950s and 1960s saw a surge in neoprene's use in wetsuits, prompting further studies into its insulation properties and water resistance.

In recent decades, the focus has shifted towards optimizing neoprene for extreme conditions. This includes improving its resistance to extreme temperatures, both hot and cold, as well as enhancing its ability to withstand high pressures and corrosive environments. Researchers have also been working on increasing neoprene's flexibility and comfort while maintaining its protective qualities, a crucial factor in its application in protective gear.

The current research objectives for neoprene in the context of protective gear for extreme conditions are multifaceted. One primary goal is to develop neoprene composites that offer superior thermal insulation without compromising flexibility. This is particularly important for gear used in arctic or deep-sea environments. Another objective is to enhance neoprene's resistance to chemical exposure, making it more suitable for hazardous material handling and industrial applications.

Researchers are also exploring ways to improve neoprene's durability and longevity under extreme stress conditions. This includes developing new formulations that resist degradation from UV radiation, ozone, and repeated mechanical stress. Additionally, there is a growing focus on creating neoprene blends that incorporate advanced materials like graphene or carbon nanotubes to enhance specific properties such as strength-to-weight ratio or electrical conductivity.

Sustainability has emerged as a critical research objective in recent years. Scientists are investigating bio-based alternatives to the petroleum-derived compounds traditionally used in neoprene production. The aim is to reduce the environmental impact of neoprene manufacturing while maintaining or improving its performance characteristics.

As we look to the future, the evolution of neoprene and the research objectives surrounding it continue to be driven by the demands of increasingly challenging environments and applications. The goal remains to push the boundaries of what this versatile material can achieve, ensuring that protective gear made from neoprene can meet the ever-growing demands of extreme conditions across various industries and scenarios.

The early stages of neoprene's evolution focused on improving its basic properties, such as elasticity, durability, and resistance to oils and chemicals. As its potential became apparent, researchers began exploring ways to enhance its performance in specific applications. The 1950s and 1960s saw a surge in neoprene's use in wetsuits, prompting further studies into its insulation properties and water resistance.

In recent decades, the focus has shifted towards optimizing neoprene for extreme conditions. This includes improving its resistance to extreme temperatures, both hot and cold, as well as enhancing its ability to withstand high pressures and corrosive environments. Researchers have also been working on increasing neoprene's flexibility and comfort while maintaining its protective qualities, a crucial factor in its application in protective gear.

The current research objectives for neoprene in the context of protective gear for extreme conditions are multifaceted. One primary goal is to develop neoprene composites that offer superior thermal insulation without compromising flexibility. This is particularly important for gear used in arctic or deep-sea environments. Another objective is to enhance neoprene's resistance to chemical exposure, making it more suitable for hazardous material handling and industrial applications.

Researchers are also exploring ways to improve neoprene's durability and longevity under extreme stress conditions. This includes developing new formulations that resist degradation from UV radiation, ozone, and repeated mechanical stress. Additionally, there is a growing focus on creating neoprene blends that incorporate advanced materials like graphene or carbon nanotubes to enhance specific properties such as strength-to-weight ratio or electrical conductivity.

Sustainability has emerged as a critical research objective in recent years. Scientists are investigating bio-based alternatives to the petroleum-derived compounds traditionally used in neoprene production. The aim is to reduce the environmental impact of neoprene manufacturing while maintaining or improving its performance characteristics.

As we look to the future, the evolution of neoprene and the research objectives surrounding it continue to be driven by the demands of increasingly challenging environments and applications. The goal remains to push the boundaries of what this versatile material can achieve, ensuring that protective gear made from neoprene can meet the ever-growing demands of extreme conditions across various industries and scenarios.

Market Analysis for Advanced Protective Gear

The market for advanced protective gear, particularly those utilizing neoprene for extreme conditions, has shown significant growth in recent years. This trend is driven by increasing awareness of safety requirements across various industries and the rising demand for high-performance protective equipment in challenging environments.

The global market for protective gear is experiencing robust expansion, with a particular focus on materials that can withstand extreme conditions. Neoprene, known for its excellent insulation properties and resistance to oil, water, and weathering, has emerged as a key material in this sector. Its versatility allows for applications in diverse fields, including marine, industrial, and outdoor recreational activities.

In the marine industry, there is a growing demand for neoprene-based protective gear such as wetsuits, gloves, and boots. This is fueled by the expansion of water sports and recreational diving activities worldwide. The increasing popularity of extreme water sports like surfing in cold waters has further boosted the need for high-performance neoprene gear.

The industrial sector presents another significant market for neoprene-enhanced protective equipment. Industries dealing with hazardous materials, extreme temperatures, or harsh chemical environments are increasingly seeking advanced protective solutions. Neoprene's resistance to many chemicals and its ability to maintain flexibility across a wide temperature range make it an ideal choice for protective clothing, gloves, and footwear in these settings.

The outdoor recreation market also contributes substantially to the demand for neoprene-based protective gear. Activities such as mountaineering, winter sports, and extreme adventure tourism require equipment that can withstand severe weather conditions while providing comfort and mobility. Neoprene's thermal insulation properties make it particularly valuable in this segment.

Geographically, North America and Europe currently lead the market for advanced protective gear, owing to stringent safety regulations and a high adoption rate of advanced materials. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing safety awareness, and growing disposable incomes.

The market is characterized by continuous innovation, with manufacturers focusing on enhancing the properties of neoprene to meet specific industry needs. This includes developing neoprene composites with improved durability, flexibility, and resistance to extreme temperatures. The integration of smart technologies into neoprene-based protective gear is an emerging trend, offering features like temperature regulation and biometric monitoring.

The global market for protective gear is experiencing robust expansion, with a particular focus on materials that can withstand extreme conditions. Neoprene, known for its excellent insulation properties and resistance to oil, water, and weathering, has emerged as a key material in this sector. Its versatility allows for applications in diverse fields, including marine, industrial, and outdoor recreational activities.

In the marine industry, there is a growing demand for neoprene-based protective gear such as wetsuits, gloves, and boots. This is fueled by the expansion of water sports and recreational diving activities worldwide. The increasing popularity of extreme water sports like surfing in cold waters has further boosted the need for high-performance neoprene gear.

The industrial sector presents another significant market for neoprene-enhanced protective equipment. Industries dealing with hazardous materials, extreme temperatures, or harsh chemical environments are increasingly seeking advanced protective solutions. Neoprene's resistance to many chemicals and its ability to maintain flexibility across a wide temperature range make it an ideal choice for protective clothing, gloves, and footwear in these settings.

The outdoor recreation market also contributes substantially to the demand for neoprene-based protective gear. Activities such as mountaineering, winter sports, and extreme adventure tourism require equipment that can withstand severe weather conditions while providing comfort and mobility. Neoprene's thermal insulation properties make it particularly valuable in this segment.

Geographically, North America and Europe currently lead the market for advanced protective gear, owing to stringent safety regulations and a high adoption rate of advanced materials. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing safety awareness, and growing disposable incomes.

The market is characterized by continuous innovation, with manufacturers focusing on enhancing the properties of neoprene to meet specific industry needs. This includes developing neoprene composites with improved durability, flexibility, and resistance to extreme temperatures. The integration of smart technologies into neoprene-based protective gear is an emerging trend, offering features like temperature regulation and biometric monitoring.

Current Neoprene Limitations in Extreme Conditions

Neoprene, a synthetic rubber widely used in protective gear for extreme conditions, faces several limitations that hinder its performance in challenging environments. One of the primary constraints is its thermal stability range. While neoprene exhibits excellent insulation properties, it tends to degrade when exposed to extreme temperatures, particularly in high-heat scenarios. This degradation can lead to reduced flexibility and compromised protective capabilities, potentially endangering users in critical situations.

Another significant limitation of neoprene is its susceptibility to chemical degradation. When exposed to certain solvents, oils, and aggressive chemicals, neoprene can experience swelling, softening, or even dissolution. This vulnerability restricts its application in environments where chemical exposure is a concern, such as in certain industrial or hazardous material handling scenarios.

Durability under prolonged stress is another area where neoprene shows limitations. In applications requiring continuous flexing or stretching, such as in joint areas of protective suits, neoprene may exhibit fatigue and develop cracks over time. This wear and tear can compromise the integrity of the protective gear, reducing its effectiveness and lifespan.

Neoprene's performance in extreme pressure conditions also presents challenges. While it offers good compression resistance, it may not provide sufficient protection in high-pressure environments, limiting its use in deep-sea diving suits or certain aerospace applications without additional reinforcement.

The material's breathability is another limitation, particularly in hot and humid conditions. Neoprene's closed-cell structure, while excellent for insulation, can lead to heat and moisture buildup inside protective gear. This can cause discomfort and potentially dangerous overheating for the wearer during prolonged use or intense physical activity.

Electromagnetic shielding is an area where standard neoprene falls short. In environments with high electromagnetic interference or radiation, neoprene alone does not provide adequate protection, necessitating additional layers or treatments to enhance its shielding capabilities.

Lastly, the environmental impact of neoprene production and disposal is a growing concern. The manufacturing process involves potentially harmful chemicals, and the material's slow degradation rate poses challenges for sustainable disposal. This limitation is becoming increasingly significant as industries strive for more environmentally friendly solutions in protective gear.

Addressing these limitations is crucial for expanding neoprene's applicability in extreme conditions and improving the safety and comfort of users relying on neoprene-based protective gear. Future research and development efforts must focus on enhancing these aspects to unlock the full potential of neoprene in challenging environments.

Another significant limitation of neoprene is its susceptibility to chemical degradation. When exposed to certain solvents, oils, and aggressive chemicals, neoprene can experience swelling, softening, or even dissolution. This vulnerability restricts its application in environments where chemical exposure is a concern, such as in certain industrial or hazardous material handling scenarios.

Durability under prolonged stress is another area where neoprene shows limitations. In applications requiring continuous flexing or stretching, such as in joint areas of protective suits, neoprene may exhibit fatigue and develop cracks over time. This wear and tear can compromise the integrity of the protective gear, reducing its effectiveness and lifespan.

Neoprene's performance in extreme pressure conditions also presents challenges. While it offers good compression resistance, it may not provide sufficient protection in high-pressure environments, limiting its use in deep-sea diving suits or certain aerospace applications without additional reinforcement.

The material's breathability is another limitation, particularly in hot and humid conditions. Neoprene's closed-cell structure, while excellent for insulation, can lead to heat and moisture buildup inside protective gear. This can cause discomfort and potentially dangerous overheating for the wearer during prolonged use or intense physical activity.

Electromagnetic shielding is an area where standard neoprene falls short. In environments with high electromagnetic interference or radiation, neoprene alone does not provide adequate protection, necessitating additional layers or treatments to enhance its shielding capabilities.

Lastly, the environmental impact of neoprene production and disposal is a growing concern. The manufacturing process involves potentially harmful chemicals, and the material's slow degradation rate poses challenges for sustainable disposal. This limitation is becoming increasingly significant as industries strive for more environmentally friendly solutions in protective gear.

Addressing these limitations is crucial for expanding neoprene's applicability in extreme conditions and improving the safety and comfort of users relying on neoprene-based protective gear. Future research and development efforts must focus on enhancing these aspects to unlock the full potential of neoprene in challenging environments.

Existing Neoprene Enhancement Techniques

01 Neoprene composition and manufacturing

Various methods and compositions for producing neoprene with improved properties are described. These include specific polymerization techniques, additives, and processing methods to enhance the material's durability, flexibility, and resistance to environmental factors.- Neoprene composition and manufacturing: Various methods and compositions for manufacturing neoprene with improved properties are described. These include specific formulations, curing processes, and additives to enhance the material's performance and durability for protective applications.

- Protective gear made from neoprene: Neoprene is used in the production of various protective gear items, including wetsuits, gloves, and other specialized equipment. The material's flexibility, insulation properties, and water resistance make it ideal for these applications.

- Neoprene coatings and laminates: Techniques for applying neoprene coatings or creating laminates with other materials are explored to enhance protection. These methods can improve the material's resistance to chemicals, abrasion, or environmental factors.

- Neoprene foam and insulation: Development of neoprene foam and insulation materials for protective applications. These innovations focus on improving thermal insulation, shock absorption, and overall protective qualities of neoprene-based products.

- Neoprene modifications for specific protective purposes: Modifications to neoprene's structure or composition to enhance its protective properties for specific applications. This includes improvements in chemical resistance, fire retardancy, or electrical insulation capabilities.

02 Protective gear and clothing made from neoprene

Neoprene is utilized in the production of protective gear and clothing, such as wetsuits, gloves, and specialized apparel. These applications take advantage of neoprene's insulating properties, flexibility, and resistance to water and chemicals.Expand Specific Solutions03 Neoprene coatings and surface treatments

Various coating techniques and surface treatments are applied to neoprene to enhance its protective properties. These methods can improve resistance to abrasion, chemicals, and UV radiation, extending the material's lifespan and performance in demanding environments.Expand Specific Solutions04 Neoprene in automotive and industrial applications

Neoprene finds extensive use in automotive and industrial settings for its protective qualities. Applications include gaskets, seals, hoses, and vibration dampening components, where the material's resistance to oil, heat, and weathering is crucial.Expand Specific Solutions05 Neoprene foam and insulation technologies

Advancements in neoprene foam production and insulation technologies are described. These innovations focus on improving thermal insulation properties, sound dampening capabilities, and overall protective performance in various applications.Expand Specific Solutions

Key Manufacturers and Industry Landscape

The research on neoprene for enhancing protective gear in extreme conditions is in a mature stage, with a competitive landscape shaped by established players and innovative newcomers. The market size is substantial, driven by growing demand across various sectors including sports, industrial, and military applications. Companies like Dainese SpA, NIKE Innovate CV, and Alpinestars Research SpA are leading the charge in sports protective gear, while Airboss Engineered Products and Tosoh Corp. focus on industrial applications. The technology's maturity is evident in the diverse range of products offered by these companies, from advanced motorcycle suits to specialized rubber compounds for extreme environments.

Dainese SpA

Technical Solution: Dainese SpA has developed advanced neoprene-based protective gear for extreme conditions, focusing on impact absorption and flexibility. Their D-Air technology incorporates neoprene with intelligent sensors and airbag systems, providing superior protection for motorcyclists and winter sports enthusiasts[1]. The company has also introduced a new neoprene compound that offers enhanced thermal insulation while maintaining elasticity, crucial for deep-sea diving suits[2]. Dainese's research has led to the creation of multi-layer neoprene structures that combine different densities to optimize protection and comfort in varying environmental conditions[3].

Strengths: Innovative integration of electronics with neoprene, superior impact protection, and adaptability to various extreme sports. Weaknesses: Potentially higher cost due to advanced technology integration, and complexity in manufacturing processes.

NIKE Innovate CV

Technical Solution: NIKE Innovate CV has made significant strides in neoprene research for protective gear, particularly in the realm of athletic performance and safety. Their approach involves the development of a proprietary neoprene blend that incorporates nano-scale carbon fibers, enhancing both durability and flexibility[4]. This advanced material is used in their latest line of compression gear and protective equipment for high-impact sports. Nike has also pioneered a thermoregulating neoprene that actively manages moisture and heat, crucial for maintaining optimal body temperature in extreme conditions[5]. Additionally, they have developed a neoprene-based foam with variable density zones, providing targeted support and protection for different body areas[6].

Strengths: Superior moisture management, targeted protection for specific body areas, and integration with performance-enhancing technologies. Weaknesses: Potentially higher production costs and limited applicability outside of sports and athletic contexts.

Innovative Neoprene Formulations and Patents

Friction and wear resistant articles

PatentWO2015059216A1

Innovation

- A composition comprising 35-98% polymeric material, including 25-85% PEI and 15-75% PAEK, combined with 2-65% filler, specifically 5-95% fibrous and 5-95% mineral non-fibrous fillers, which synergistically enhances mechanical performance over a broad temperature range up to 330°C.

Protective Gear for Body

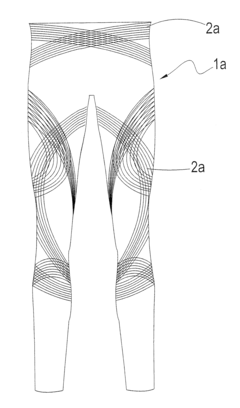

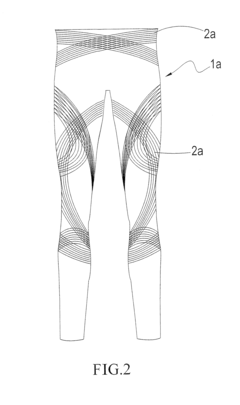

PatentInactiveUS20140075656A1

Innovation

- An improved protective gear design featuring an elastic base layer interlaced with a constraining layer on one side, equipped with elastic securing portions that provide a four-way elastic constraining force, ensuring secure fit and support to joints and cartilages, while allowing for comfortable movement and preventing injuries.

Environmental Impact of Neoprene Production

The production of neoprene, a synthetic rubber widely used in protective gear for extreme conditions, has significant environmental implications. The manufacturing process involves the use of chloroprene, a chemical compound derived from petroleum or acetylene. This reliance on fossil fuels contributes to carbon emissions and resource depletion, raising concerns about the material's long-term sustainability.

One of the primary environmental issues associated with neoprene production is the release of volatile organic compounds (VOCs) into the atmosphere. These emissions can lead to air pollution and contribute to the formation of ground-level ozone, a key component of smog. Additionally, the production process generates wastewater containing various chemicals, which, if not properly treated, can contaminate local water sources and harm aquatic ecosystems.

The energy-intensive nature of neoprene manufacturing further exacerbates its environmental footprint. The high temperatures required for polymerization and vulcanization processes consume substantial amounts of electricity, often sourced from non-renewable energy sources. This energy consumption contributes to greenhouse gas emissions and climate change.

Another environmental concern is the disposal of neoprene products at the end of their lifecycle. Neoprene is not biodegradable and can persist in landfills for extended periods. While recycling technologies for neoprene exist, they are not widely implemented, leading to a significant waste management challenge.

The production of neoprene also involves the use of potentially hazardous chemicals, such as chloroprene and other additives. Proper handling and disposal of these substances are crucial to prevent soil and water contamination. Accidental spills or improper management can have severe consequences for local ecosystems and human health.

To address these environmental concerns, researchers and manufacturers are exploring more sustainable alternatives and production methods. These include developing bio-based neoprene substitutes, improving energy efficiency in manufacturing processes, and implementing closed-loop systems to reduce waste and emissions. Some companies are also investing in advanced wastewater treatment technologies and exploring ways to increase the recyclability of neoprene products.

As the demand for protective gear in extreme conditions continues to grow, balancing the performance benefits of neoprene with its environmental impact remains a critical challenge. Future research and development efforts in this field will likely focus on finding innovative solutions that maintain the material's protective properties while minimizing its ecological footprint.

One of the primary environmental issues associated with neoprene production is the release of volatile organic compounds (VOCs) into the atmosphere. These emissions can lead to air pollution and contribute to the formation of ground-level ozone, a key component of smog. Additionally, the production process generates wastewater containing various chemicals, which, if not properly treated, can contaminate local water sources and harm aquatic ecosystems.

The energy-intensive nature of neoprene manufacturing further exacerbates its environmental footprint. The high temperatures required for polymerization and vulcanization processes consume substantial amounts of electricity, often sourced from non-renewable energy sources. This energy consumption contributes to greenhouse gas emissions and climate change.

Another environmental concern is the disposal of neoprene products at the end of their lifecycle. Neoprene is not biodegradable and can persist in landfills for extended periods. While recycling technologies for neoprene exist, they are not widely implemented, leading to a significant waste management challenge.

The production of neoprene also involves the use of potentially hazardous chemicals, such as chloroprene and other additives. Proper handling and disposal of these substances are crucial to prevent soil and water contamination. Accidental spills or improper management can have severe consequences for local ecosystems and human health.

To address these environmental concerns, researchers and manufacturers are exploring more sustainable alternatives and production methods. These include developing bio-based neoprene substitutes, improving energy efficiency in manufacturing processes, and implementing closed-loop systems to reduce waste and emissions. Some companies are also investing in advanced wastewater treatment technologies and exploring ways to increase the recyclability of neoprene products.

As the demand for protective gear in extreme conditions continues to grow, balancing the performance benefits of neoprene with its environmental impact remains a critical challenge. Future research and development efforts in this field will likely focus on finding innovative solutions that maintain the material's protective properties while minimizing its ecological footprint.

Safety Standards for Extreme Condition Gear

Safety standards for protective gear in extreme conditions are crucial to ensure the well-being of individuals operating in hazardous environments. These standards are developed and enforced by various international and national organizations, such as the International Organization for Standardization (ISO), the European Committee for Standardization (CEN), and the Occupational Safety and Health Administration (OSHA) in the United States.

For neoprene-based protective gear designed for extreme conditions, safety standards typically cover several key aspects. These include material properties, performance requirements, testing methods, and labeling guidelines. The standards often specify minimum requirements for physical properties such as tensile strength, tear resistance, and abrasion resistance. They also address chemical resistance, thermal insulation, and flame retardancy, which are particularly important for gear used in extreme environments.

Performance requirements outlined in safety standards may include factors such as water tightness, buoyancy, and visibility. For instance, protective suits used in cold water environments must meet specific thermal insulation criteria to prevent hypothermia. Standards may also dictate the minimum buoyancy levels required for flotation devices incorporated into the gear.

Testing methods prescribed by safety standards ensure that protective gear meets the specified requirements. These may include accelerated aging tests to simulate long-term use, impact resistance tests, and tests for resistance to specific chemicals or environmental conditions. For neoprene-based gear, standards often include protocols for evaluating the material's performance after exposure to UV radiation, saltwater, and extreme temperatures.

Labeling and user information requirements are another critical component of safety standards. These ensure that users are provided with essential information about the gear's capabilities, limitations, and proper use. Labels typically include details such as the applicable standards met, size information, care instructions, and any specific warnings or precautions.

Compliance with these safety standards is often mandatory for manufacturers and suppliers of protective gear. Many countries require certification or approval from recognized bodies before such equipment can be sold or used in professional settings. This certification process typically involves rigorous testing and quality control measures to ensure that the gear consistently meets the required standards.

As research on neoprene and other materials for protective gear advances, safety standards are regularly reviewed and updated to incorporate new findings and technologies. This ongoing process helps to ensure that safety standards remain relevant and effective in protecting users in increasingly challenging and diverse extreme conditions.

For neoprene-based protective gear designed for extreme conditions, safety standards typically cover several key aspects. These include material properties, performance requirements, testing methods, and labeling guidelines. The standards often specify minimum requirements for physical properties such as tensile strength, tear resistance, and abrasion resistance. They also address chemical resistance, thermal insulation, and flame retardancy, which are particularly important for gear used in extreme environments.

Performance requirements outlined in safety standards may include factors such as water tightness, buoyancy, and visibility. For instance, protective suits used in cold water environments must meet specific thermal insulation criteria to prevent hypothermia. Standards may also dictate the minimum buoyancy levels required for flotation devices incorporated into the gear.

Testing methods prescribed by safety standards ensure that protective gear meets the specified requirements. These may include accelerated aging tests to simulate long-term use, impact resistance tests, and tests for resistance to specific chemicals or environmental conditions. For neoprene-based gear, standards often include protocols for evaluating the material's performance after exposure to UV radiation, saltwater, and extreme temperatures.

Labeling and user information requirements are another critical component of safety standards. These ensure that users are provided with essential information about the gear's capabilities, limitations, and proper use. Labels typically include details such as the applicable standards met, size information, care instructions, and any specific warnings or precautions.

Compliance with these safety standards is often mandatory for manufacturers and suppliers of protective gear. Many countries require certification or approval from recognized bodies before such equipment can be sold or used in professional settings. This certification process typically involves rigorous testing and quality control measures to ensure that the gear consistently meets the required standards.

As research on neoprene and other materials for protective gear advances, safety standards are regularly reviewed and updated to incorporate new findings and technologies. This ongoing process helps to ensure that safety standards remain relevant and effective in protecting users in increasingly challenging and diverse extreme conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!