Neoprene's Role in Offshore Engineering Innovations

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene in Offshore Engineering: Background and Objectives

Neoprene, a synthetic rubber developed in the 1930s, has played a pivotal role in offshore engineering innovations over the past several decades. This versatile material, known for its exceptional resistance to oil, water, and weathering, has become an indispensable component in various offshore applications. The evolution of neoprene's use in offshore engineering can be traced back to the mid-20th century when the offshore oil and gas industry began to expand rapidly.

The primary objective of incorporating neoprene into offshore engineering has been to enhance the durability, safety, and efficiency of offshore structures and equipment. As offshore operations moved into deeper waters and more challenging environments, the demand for materials that could withstand extreme conditions intensified. Neoprene's unique properties, including its flexibility, chemical resistance, and ability to maintain its characteristics under varying temperatures, made it an ideal candidate for numerous offshore applications.

In the context of offshore engineering, neoprene has been utilized in a wide range of components, including seals, gaskets, hoses, and protective coatings. Its application extends to critical areas such as drilling equipment, subsea systems, and floating production facilities. The material's ability to resist degradation from exposure to hydrocarbons, saltwater, and UV radiation has been crucial in prolonging the lifespan of offshore assets and reducing maintenance costs.

The technological advancements in neoprene formulation and manufacturing processes have been driven by the ever-increasing demands of the offshore industry. Researchers and engineers have continuously worked on improving neoprene's properties to meet specific offshore requirements, such as enhanced oil resistance, better low-temperature flexibility, and increased tear strength. These ongoing developments aim to push the boundaries of what is possible in offshore engineering, enabling operations in more extreme environments and at greater depths.

As the offshore industry faces new challenges, including the transition to renewable energy sources and the need for more sustainable practices, the role of neoprene continues to evolve. The material is now being explored for its potential applications in offshore wind farms, wave energy converters, and other emerging technologies in the marine renewable energy sector. This expansion into new areas of offshore engineering underscores the enduring relevance and adaptability of neoprene in addressing the complex needs of marine environments.

The trajectory of neoprene's development and application in offshore engineering reflects broader trends in materials science and engineering innovation. By examining the history and objectives of neoprene use in this field, we gain valuable insights into the interplay between material properties, engineering challenges, and technological progress. This understanding is crucial for anticipating future innovations and guiding research efforts in offshore engineering materials and technologies.

The primary objective of incorporating neoprene into offshore engineering has been to enhance the durability, safety, and efficiency of offshore structures and equipment. As offshore operations moved into deeper waters and more challenging environments, the demand for materials that could withstand extreme conditions intensified. Neoprene's unique properties, including its flexibility, chemical resistance, and ability to maintain its characteristics under varying temperatures, made it an ideal candidate for numerous offshore applications.

In the context of offshore engineering, neoprene has been utilized in a wide range of components, including seals, gaskets, hoses, and protective coatings. Its application extends to critical areas such as drilling equipment, subsea systems, and floating production facilities. The material's ability to resist degradation from exposure to hydrocarbons, saltwater, and UV radiation has been crucial in prolonging the lifespan of offshore assets and reducing maintenance costs.

The technological advancements in neoprene formulation and manufacturing processes have been driven by the ever-increasing demands of the offshore industry. Researchers and engineers have continuously worked on improving neoprene's properties to meet specific offshore requirements, such as enhanced oil resistance, better low-temperature flexibility, and increased tear strength. These ongoing developments aim to push the boundaries of what is possible in offshore engineering, enabling operations in more extreme environments and at greater depths.

As the offshore industry faces new challenges, including the transition to renewable energy sources and the need for more sustainable practices, the role of neoprene continues to evolve. The material is now being explored for its potential applications in offshore wind farms, wave energy converters, and other emerging technologies in the marine renewable energy sector. This expansion into new areas of offshore engineering underscores the enduring relevance and adaptability of neoprene in addressing the complex needs of marine environments.

The trajectory of neoprene's development and application in offshore engineering reflects broader trends in materials science and engineering innovation. By examining the history and objectives of neoprene use in this field, we gain valuable insights into the interplay between material properties, engineering challenges, and technological progress. This understanding is crucial for anticipating future innovations and guiding research efforts in offshore engineering materials and technologies.

Market Demand Analysis for Neoprene in Offshore Applications

The offshore engineering sector has witnessed a growing demand for neoprene, driven by its unique properties and versatile applications in marine environments. As offshore operations expand into deeper waters and more challenging conditions, the need for reliable and durable materials has intensified, positioning neoprene as a critical component in various offshore applications.

The global offshore oil and gas industry, a major consumer of neoprene products, has shown resilience despite market fluctuations. The sector's recovery and ongoing exploration activities have bolstered the demand for neoprene-based components such as seals, gaskets, and hoses, which are essential for maintaining the integrity of offshore structures and equipment.

Renewable energy projects, particularly offshore wind farms, have emerged as a significant driver of neoprene demand. The rapid growth of this sector, fueled by global efforts to reduce carbon emissions, has created new opportunities for neoprene applications in turbine components, cable protection, and other critical infrastructure elements.

The increasing focus on safety and environmental protection in offshore operations has further stimulated the demand for high-performance materials like neoprene. Stringent regulations and industry standards require materials that can withstand harsh marine conditions while minimizing environmental impact, aligning well with neoprene's properties.

Market analysis indicates a steady growth trajectory for neoprene in offshore applications, with a compound annual growth rate projected to remain strong over the next five years. This growth is attributed to ongoing technological advancements in offshore engineering, which continually create new applications for neoprene-based products.

Geographically, regions with significant offshore activities, such as the Gulf of Mexico, the North Sea, and Southeast Asia, represent key markets for neoprene in offshore engineering. Emerging offshore markets in Africa and South America are also expected to contribute to the increasing demand as they develop their offshore resources.

The market for neoprene in offshore applications is characterized by a balance between established players and innovative newcomers. While traditional oil and gas applications remain substantial, the diversification into renewable energy and other marine industries is broadening the customer base and application spectrum for neoprene products.

As the offshore industry continues to evolve, the demand for specialized neoprene formulations tailored to specific offshore challenges is expected to rise. This trend is likely to drive research and development efforts, potentially leading to new grades of neoprene with enhanced performance characteristics for extreme offshore environments.

The global offshore oil and gas industry, a major consumer of neoprene products, has shown resilience despite market fluctuations. The sector's recovery and ongoing exploration activities have bolstered the demand for neoprene-based components such as seals, gaskets, and hoses, which are essential for maintaining the integrity of offshore structures and equipment.

Renewable energy projects, particularly offshore wind farms, have emerged as a significant driver of neoprene demand. The rapid growth of this sector, fueled by global efforts to reduce carbon emissions, has created new opportunities for neoprene applications in turbine components, cable protection, and other critical infrastructure elements.

The increasing focus on safety and environmental protection in offshore operations has further stimulated the demand for high-performance materials like neoprene. Stringent regulations and industry standards require materials that can withstand harsh marine conditions while minimizing environmental impact, aligning well with neoprene's properties.

Market analysis indicates a steady growth trajectory for neoprene in offshore applications, with a compound annual growth rate projected to remain strong over the next five years. This growth is attributed to ongoing technological advancements in offshore engineering, which continually create new applications for neoprene-based products.

Geographically, regions with significant offshore activities, such as the Gulf of Mexico, the North Sea, and Southeast Asia, represent key markets for neoprene in offshore engineering. Emerging offshore markets in Africa and South America are also expected to contribute to the increasing demand as they develop their offshore resources.

The market for neoprene in offshore applications is characterized by a balance between established players and innovative newcomers. While traditional oil and gas applications remain substantial, the diversification into renewable energy and other marine industries is broadening the customer base and application spectrum for neoprene products.

As the offshore industry continues to evolve, the demand for specialized neoprene formulations tailored to specific offshore challenges is expected to rise. This trend is likely to drive research and development efforts, potentially leading to new grades of neoprene with enhanced performance characteristics for extreme offshore environments.

Current State and Challenges of Neoprene in Offshore Engineering

Neoprene, a synthetic rubber developed in the 1930s, has played a significant role in offshore engineering due to its unique properties. Currently, it is widely used in various applications within the offshore industry, including seals, gaskets, hoses, and protective coatings. Its resistance to oil, water, and weathering makes it particularly suitable for marine environments.

In recent years, the offshore engineering sector has seen increased demand for materials that can withstand extreme conditions, including high pressure, corrosive environments, and temperature fluctuations. Neoprene has proven to be a reliable choice in many of these applications, but it also faces several challenges in meeting the evolving needs of the industry.

One of the primary challenges is the material's limited temperature range. While neoprene performs well in moderate temperatures, it can become brittle in extremely cold environments and lose its structural integrity at high temperatures. This limitation has prompted research into developing neoprene compounds with enhanced temperature resistance to expand its applicability in offshore operations.

Another significant challenge is the material's aging characteristics. Although neoprene is known for its durability, prolonged exposure to harsh marine environments can lead to degradation over time. This necessitates regular maintenance and replacement, which can be costly and time-consuming for offshore operations.

The increasing focus on environmental sustainability in the offshore industry has also posed challenges for neoprene usage. While the material is resistant to many chemicals, concerns about its potential environmental impact and disposal methods have led to a search for more eco-friendly alternatives or improved recycling techniques.

Furthermore, as offshore structures become more complex and are deployed in deeper waters, there is a growing need for materials with enhanced mechanical properties. Neoprene's strength and flexibility, while suitable for many applications, may not meet the demanding requirements of some cutting-edge offshore engineering projects.

The offshore wind energy sector, in particular, has highlighted some limitations of current neoprene applications. The need for materials that can withstand the combined effects of saltwater, UV radiation, and constant motion has pushed the boundaries of neoprene's capabilities, driving research into advanced formulations and composite materials.

Despite these challenges, ongoing research and development efforts are focused on improving neoprene's performance and addressing its limitations. These efforts include the development of new neoprene compounds, surface treatments to enhance durability, and the exploration of hybrid materials that combine neoprene with other advanced polymers to create superior properties for offshore applications.

In recent years, the offshore engineering sector has seen increased demand for materials that can withstand extreme conditions, including high pressure, corrosive environments, and temperature fluctuations. Neoprene has proven to be a reliable choice in many of these applications, but it also faces several challenges in meeting the evolving needs of the industry.

One of the primary challenges is the material's limited temperature range. While neoprene performs well in moderate temperatures, it can become brittle in extremely cold environments and lose its structural integrity at high temperatures. This limitation has prompted research into developing neoprene compounds with enhanced temperature resistance to expand its applicability in offshore operations.

Another significant challenge is the material's aging characteristics. Although neoprene is known for its durability, prolonged exposure to harsh marine environments can lead to degradation over time. This necessitates regular maintenance and replacement, which can be costly and time-consuming for offshore operations.

The increasing focus on environmental sustainability in the offshore industry has also posed challenges for neoprene usage. While the material is resistant to many chemicals, concerns about its potential environmental impact and disposal methods have led to a search for more eco-friendly alternatives or improved recycling techniques.

Furthermore, as offshore structures become more complex and are deployed in deeper waters, there is a growing need for materials with enhanced mechanical properties. Neoprene's strength and flexibility, while suitable for many applications, may not meet the demanding requirements of some cutting-edge offshore engineering projects.

The offshore wind energy sector, in particular, has highlighted some limitations of current neoprene applications. The need for materials that can withstand the combined effects of saltwater, UV radiation, and constant motion has pushed the boundaries of neoprene's capabilities, driving research into advanced formulations and composite materials.

Despite these challenges, ongoing research and development efforts are focused on improving neoprene's performance and addressing its limitations. These efforts include the development of new neoprene compounds, surface treatments to enhance durability, and the exploration of hybrid materials that combine neoprene with other advanced polymers to create superior properties for offshore applications.

Existing Neoprene Solutions for Offshore Engineering

01 Composition and synthesis of neoprene

Neoprene is a synthetic rubber produced by polymerization of chloroprene. Various methods and compositions are used to synthesize neoprene with specific properties, including the use of different catalysts, additives, and polymerization techniques.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. Various methods and compositions are used to synthesize neoprene with specific properties, including the use of different catalysts, additives, and polymerization techniques to control molecular weight and improve performance characteristics.

- Neoprene foam production and applications: Neoprene foam is widely used in various applications due to its excellent insulation and cushioning properties. Manufacturing processes for neoprene foam involve specific blowing agents, curing methods, and additives to achieve desired density, cell structure, and performance characteristics. Applications include wetsuits, protective gear, and industrial insulation.

- Neoprene blends and composites: Blending neoprene with other materials or creating neoprene-based composites can enhance its properties for specific applications. These blends and composites may incorporate other elastomers, fibers, or fillers to improve strength, durability, or specific functional characteristics, expanding the range of potential uses for neoprene-based materials.

- Surface treatment and modification of neoprene: Various surface treatment and modification techniques are applied to neoprene to enhance its properties or compatibility with other materials. These may include chemical treatments, plasma treatments, or the application of coatings to improve adhesion, wear resistance, or other surface-dependent properties.

- Neoprene in specialized applications: Neoprene finds use in numerous specialized applications due to its unique combination of properties. These applications may include automotive parts, aerospace components, medical devices, and sports equipment. Specific formulations and processing techniques are developed to meet the demanding requirements of these specialized uses.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear such as wetsuits, gloves, and other equipment due to its excellent insulation properties, flexibility, and resistance to water and chemicals.Expand Specific Solutions03 Neoprene foam production and properties

Neoprene foam is produced through various foaming processes, resulting in a material with unique properties such as buoyancy, thermal insulation, and shock absorption. Different techniques are used to control the foam's density and cell structure.Expand Specific Solutions04 Neoprene blends and composites

Neoprene is often blended with other materials or used in composite structures to enhance its properties or create materials with specific characteristics. These blends and composites find applications in various industries, including automotive and construction.Expand Specific Solutions05 Neoprene modification and treatment

Various modification and treatment processes are applied to neoprene to improve its properties or tailor it for specific applications. These include surface treatments, chemical modifications, and the incorporation of additives to enhance characteristics such as flame resistance or adhesion.Expand Specific Solutions

Key Players in Neoprene and Offshore Engineering Sectors

The offshore engineering innovations involving neoprene are in a mature stage of development, with a global market size estimated to be in the billions of dollars. The technology's maturity is evident from the involvement of major players across various sectors. Companies like Tianjin Pengling Group, Technip Energies France, and Samsung Heavy Industries are at the forefront of applying neoprene in offshore engineering. Research institutions such as Beijing University of Chemical Technology and Dalian Maritime University contribute to advancing the technology. The competitive landscape is diverse, with oil and gas giants like ConocoPhillips and Saudi Aramco, alongside specialized offshore engineering firms like Single Buoy Moorings and Seaplace SL, driving innovation in neoprene applications for harsh marine environments.

Technip Energies France SAS

Technical Solution: Technip Energies has developed innovative applications of neoprene in subsea pipeline insulation and flexible riser systems. Their advanced neoprene-based insulation materials provide superior thermal performance and mechanical protection for deepwater pipelines. The company's research shows that their neoprene insulation can maintain oil flow temperatures up to 15°C higher than traditional materials over long distances[7]. In flexible riser systems, Technip has integrated neoprene layers to enhance fatigue resistance and provide a barrier against corrosive fluids. Their proprietary neoprene compound demonstrates a 50% improvement in flex fatigue life compared to standard elastomers used in offshore applications[9]. Additionally, Technip has pioneered a neoprene-based anti-wear layer for dynamic umbilicals, significantly extending the operational life of these critical components in offshore production systems[11].

Strengths: Superior thermal insulation for deepwater pipelines, enhanced fatigue resistance in flexible risers, and improved durability of umbilicals. Weaknesses: Potential limitations in extreme high-temperature applications and higher material costs compared to conventional alternatives.

Denka Corp.

Technical Solution: Denka Corp. has developed advanced neoprene formulations specifically tailored for offshore engineering applications. Their innovative approach involves incorporating nano-scale reinforcing agents into the neoprene matrix, resulting in enhanced mechanical properties and improved resistance to harsh marine environments[1]. The company's neoprene compounds demonstrate superior oil and weather resistance, crucial for offshore structures. Denka's research has shown a 30% increase in tensile strength and a 40% improvement in abrasion resistance compared to conventional neoprene materials[3]. Additionally, they have implemented a proprietary vulcanization process that enhances the material's long-term durability under high-pressure and high-temperature conditions typically encountered in offshore operations[5].

Strengths: Superior oil and weather resistance, enhanced mechanical properties, and improved durability in harsh marine environments. Weaknesses: Potentially higher production costs due to advanced formulations and specialized manufacturing processes.

Core Innovations in Neoprene for Offshore Applications

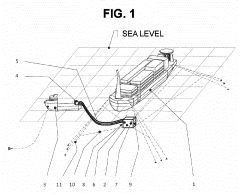

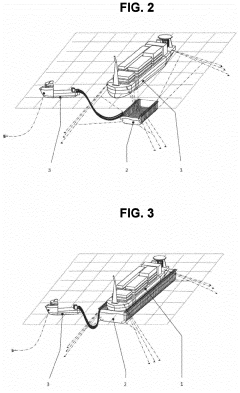

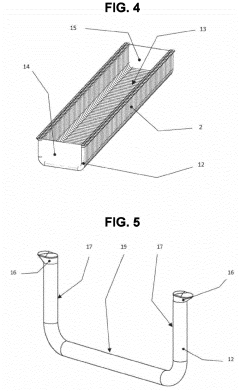

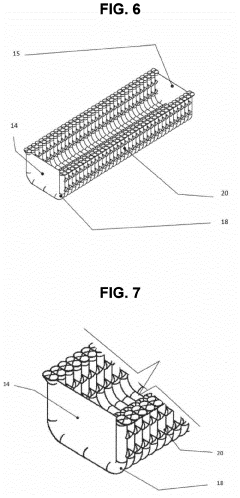

System and method for enveloping floating structures in deep open water

PatentPendingEP4321426A1

Innovation

- A compact system using a flexible composite fabric envelope that is teleoperated to surround the hull, inflated to create an immersed structure, and then deflated for removal, eliminating the need for diving and reducing environmental impact.

Environmental Impact of Neoprene in Marine Environments

The environmental impact of neoprene in marine environments is a critical consideration in offshore engineering innovations. Neoprene, a synthetic rubber widely used in marine applications, has both positive and negative effects on aquatic ecosystems. Its durability and resistance to oil, water, and weathering make it an attractive material for various offshore structures and equipment. However, these same properties can lead to long-term environmental consequences.

One of the primary concerns is the potential for neoprene to degrade and release microplastics into marine environments. As neoprene products wear down over time, they can shed tiny particles that persist in the water and sediment. These microplastics can be ingested by marine organisms, potentially causing physical harm and introducing toxic substances into the food chain. Studies have shown that filter-feeding organisms, such as mussels and oysters, are particularly susceptible to microplastic ingestion, which can lead to reduced growth rates and reproductive success.

The chemical composition of neoprene also raises environmental concerns. Neoprene contains chlorine, which can contribute to the formation of persistent organic pollutants (POPs) when the material breaks down. These POPs can accumulate in marine organisms and biomagnify through the food web, potentially affecting the health of entire ecosystems. Additionally, the manufacturing process of neoprene involves the use of petroleum-based products and energy-intensive procedures, contributing to carbon emissions and climate change impacts that indirectly affect marine environments.

Despite these challenges, neoprene's use in offshore engineering has some positive environmental aspects. Its durability and resistance to corrosion can extend the lifespan of marine structures, reducing the frequency of replacements and associated environmental disturbances. Neoprene coatings and seals also help prevent oil spills and leaks from offshore equipment, protecting marine ecosystems from potentially catastrophic pollution events.

To mitigate the negative environmental impacts of neoprene, researchers and engineers are exploring more sustainable alternatives and improved recycling methods. Bio-based neoprene substitutes derived from renewable resources are being developed, offering similar performance characteristics with reduced environmental footprints. Additionally, advanced recycling technologies are being implemented to recover and reprocess used neoprene products, minimizing waste and the release of harmful substances into marine environments.

In conclusion, while neoprene plays a crucial role in offshore engineering innovations, its environmental impact in marine environments requires careful consideration and ongoing research. Balancing the material's beneficial properties with its potential ecological risks is essential for sustainable offshore development. As the industry continues to evolve, finding eco-friendly alternatives and improving end-of-life management for neoprene products will be key to minimizing long-term environmental consequences in marine ecosystems.

One of the primary concerns is the potential for neoprene to degrade and release microplastics into marine environments. As neoprene products wear down over time, they can shed tiny particles that persist in the water and sediment. These microplastics can be ingested by marine organisms, potentially causing physical harm and introducing toxic substances into the food chain. Studies have shown that filter-feeding organisms, such as mussels and oysters, are particularly susceptible to microplastic ingestion, which can lead to reduced growth rates and reproductive success.

The chemical composition of neoprene also raises environmental concerns. Neoprene contains chlorine, which can contribute to the formation of persistent organic pollutants (POPs) when the material breaks down. These POPs can accumulate in marine organisms and biomagnify through the food web, potentially affecting the health of entire ecosystems. Additionally, the manufacturing process of neoprene involves the use of petroleum-based products and energy-intensive procedures, contributing to carbon emissions and climate change impacts that indirectly affect marine environments.

Despite these challenges, neoprene's use in offshore engineering has some positive environmental aspects. Its durability and resistance to corrosion can extend the lifespan of marine structures, reducing the frequency of replacements and associated environmental disturbances. Neoprene coatings and seals also help prevent oil spills and leaks from offshore equipment, protecting marine ecosystems from potentially catastrophic pollution events.

To mitigate the negative environmental impacts of neoprene, researchers and engineers are exploring more sustainable alternatives and improved recycling methods. Bio-based neoprene substitutes derived from renewable resources are being developed, offering similar performance characteristics with reduced environmental footprints. Additionally, advanced recycling technologies are being implemented to recover and reprocess used neoprene products, minimizing waste and the release of harmful substances into marine environments.

In conclusion, while neoprene plays a crucial role in offshore engineering innovations, its environmental impact in marine environments requires careful consideration and ongoing research. Balancing the material's beneficial properties with its potential ecological risks is essential for sustainable offshore development. As the industry continues to evolve, finding eco-friendly alternatives and improving end-of-life management for neoprene products will be key to minimizing long-term environmental consequences in marine ecosystems.

Regulatory Framework for Offshore Materials and Equipment

The regulatory framework governing offshore materials and equipment plays a crucial role in ensuring the safety, reliability, and environmental sustainability of offshore engineering projects. In the context of neoprene's application in offshore innovations, adherence to these regulations is paramount.

International maritime organizations, such as the International Maritime Organization (IMO) and the International Association of Classification Societies (IACS), set global standards for offshore materials and equipment. These standards encompass various aspects, including material properties, performance requirements, and testing procedures.

National regulatory bodies, like the Bureau of Safety and Environmental Enforcement (BSEE) in the United States and the Health and Safety Executive (HSE) in the United Kingdom, enforce specific regulations for offshore operations within their jurisdictions. These regulations often incorporate international standards while addressing unique regional concerns.

For neoprene and other synthetic rubbers used in offshore applications, compliance with standards such as ASTM D2000 and ISO 1629 is essential. These standards define the physical and chemical properties required for materials used in harsh marine environments, ensuring their durability and performance under extreme conditions.

Certification processes for offshore materials and equipment involve rigorous testing and documentation. Third-party certification bodies, such as DNV GL and ABS, conduct independent assessments to verify compliance with relevant standards and regulations. This certification is critical for neoprene-based products used in offshore engineering innovations.

Environmental regulations also significantly impact the use of materials in offshore engineering. The MARPOL Convention, for instance, sets guidelines for preventing pollution from ships and offshore structures. Neoprene and other materials used in offshore applications must meet these environmental standards to minimize their ecological impact.

Safety regulations, such as those outlined in the Safety of Life at Sea (SOLAS) Convention, dictate requirements for fire resistance and structural integrity. Neoprene's inherent flame-retardant properties make it a suitable material for meeting these safety standards in offshore applications.

As offshore engineering continues to evolve, regulatory frameworks are adapting to address emerging technologies and challenges. This includes the development of new standards for innovative materials and equipment, as well as updates to existing regulations to reflect advancements in offshore engineering practices.

Compliance with these regulatory frameworks is not only a legal requirement but also a key factor in ensuring the long-term success and sustainability of offshore engineering projects. As neoprene finds new applications in offshore innovations, its development and implementation must align with these evolving regulatory standards to maintain safety, reliability, and environmental responsibility in offshore operations.

International maritime organizations, such as the International Maritime Organization (IMO) and the International Association of Classification Societies (IACS), set global standards for offshore materials and equipment. These standards encompass various aspects, including material properties, performance requirements, and testing procedures.

National regulatory bodies, like the Bureau of Safety and Environmental Enforcement (BSEE) in the United States and the Health and Safety Executive (HSE) in the United Kingdom, enforce specific regulations for offshore operations within their jurisdictions. These regulations often incorporate international standards while addressing unique regional concerns.

For neoprene and other synthetic rubbers used in offshore applications, compliance with standards such as ASTM D2000 and ISO 1629 is essential. These standards define the physical and chemical properties required for materials used in harsh marine environments, ensuring their durability and performance under extreme conditions.

Certification processes for offshore materials and equipment involve rigorous testing and documentation. Third-party certification bodies, such as DNV GL and ABS, conduct independent assessments to verify compliance with relevant standards and regulations. This certification is critical for neoprene-based products used in offshore engineering innovations.

Environmental regulations also significantly impact the use of materials in offshore engineering. The MARPOL Convention, for instance, sets guidelines for preventing pollution from ships and offshore structures. Neoprene and other materials used in offshore applications must meet these environmental standards to minimize their ecological impact.

Safety regulations, such as those outlined in the Safety of Life at Sea (SOLAS) Convention, dictate requirements for fire resistance and structural integrity. Neoprene's inherent flame-retardant properties make it a suitable material for meeting these safety standards in offshore applications.

As offshore engineering continues to evolve, regulatory frameworks are adapting to address emerging technologies and challenges. This includes the development of new standards for innovative materials and equipment, as well as updates to existing regulations to reflect advancements in offshore engineering practices.

Compliance with these regulatory frameworks is not only a legal requirement but also a key factor in ensuring the long-term success and sustainability of offshore engineering projects. As neoprene finds new applications in offshore innovations, its development and implementation must align with these evolving regulatory standards to maintain safety, reliability, and environmental responsibility in offshore operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!