Neoprene and its Applications in Aerospace Engineering

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene in Aerospace: Background and Objectives

Neoprene, also known as polychloroprene, has been a significant material in the aerospace industry since its invention in 1930 by DuPont scientists. This synthetic rubber has played a crucial role in various aerospace applications due to its unique properties, including excellent resistance to oil, heat, and weathering. The evolution of neoprene in aerospace engineering has been closely tied to the advancements in aircraft and spacecraft design, with continuous improvements in its formulation and manufacturing processes.

The primary objective of researching neoprene in aerospace engineering is to enhance its performance characteristics and expand its applications within the industry. This includes improving its thermal stability, reducing weight while maintaining strength, and increasing its resistance to extreme environmental conditions encountered in aerospace operations. Additionally, researchers aim to develop neoprene composites that can meet the ever-increasing demands of modern aerospace technology, such as improved fuel efficiency and reduced environmental impact.

Throughout its history, neoprene has been utilized in various aerospace components, including fuel tank linings, O-rings, seals, and insulation materials. Its ability to maintain flexibility and integrity across a wide temperature range has made it particularly valuable in space exploration missions, where materials must withstand extreme temperature fluctuations. As space agencies and private companies push the boundaries of space exploration, the demand for advanced neoprene formulations continues to grow.

The current technological landscape presents both challenges and opportunities for neoprene research in aerospace. With the increasing focus on lightweight materials, researchers are exploring ways to reduce the density of neoprene while maintaining or improving its mechanical properties. This includes the development of neoprene foams and nanocomposites that offer superior strength-to-weight ratios. Furthermore, the integration of smart materials and self-healing capabilities into neoprene structures is an emerging area of interest, potentially revolutionizing maintenance and reliability in aerospace applications.

Environmental concerns and sustainability goals are also shaping the direction of neoprene research in aerospace. Efforts are underway to develop more eco-friendly production methods and to improve the recyclability of neoprene products at the end of their lifecycle. This aligns with the broader industry trend towards greener technologies and materials that reduce the environmental footprint of aerospace operations.

As we look towards the future, the research on neoprene in aerospace engineering aims to address several key objectives. These include enhancing its performance in extreme environments, such as those encountered in deep space missions, improving its compatibility with advanced manufacturing techniques like 3D printing, and developing novel applications that leverage its unique properties in next-generation aircraft and spacecraft designs. The ongoing research and development in this field are critical for maintaining the pace of innovation in aerospace technology and ensuring the continued reliability and efficiency of aerospace systems.

The primary objective of researching neoprene in aerospace engineering is to enhance its performance characteristics and expand its applications within the industry. This includes improving its thermal stability, reducing weight while maintaining strength, and increasing its resistance to extreme environmental conditions encountered in aerospace operations. Additionally, researchers aim to develop neoprene composites that can meet the ever-increasing demands of modern aerospace technology, such as improved fuel efficiency and reduced environmental impact.

Throughout its history, neoprene has been utilized in various aerospace components, including fuel tank linings, O-rings, seals, and insulation materials. Its ability to maintain flexibility and integrity across a wide temperature range has made it particularly valuable in space exploration missions, where materials must withstand extreme temperature fluctuations. As space agencies and private companies push the boundaries of space exploration, the demand for advanced neoprene formulations continues to grow.

The current technological landscape presents both challenges and opportunities for neoprene research in aerospace. With the increasing focus on lightweight materials, researchers are exploring ways to reduce the density of neoprene while maintaining or improving its mechanical properties. This includes the development of neoprene foams and nanocomposites that offer superior strength-to-weight ratios. Furthermore, the integration of smart materials and self-healing capabilities into neoprene structures is an emerging area of interest, potentially revolutionizing maintenance and reliability in aerospace applications.

Environmental concerns and sustainability goals are also shaping the direction of neoprene research in aerospace. Efforts are underway to develop more eco-friendly production methods and to improve the recyclability of neoprene products at the end of their lifecycle. This aligns with the broader industry trend towards greener technologies and materials that reduce the environmental footprint of aerospace operations.

As we look towards the future, the research on neoprene in aerospace engineering aims to address several key objectives. These include enhancing its performance in extreme environments, such as those encountered in deep space missions, improving its compatibility with advanced manufacturing techniques like 3D printing, and developing novel applications that leverage its unique properties in next-generation aircraft and spacecraft designs. The ongoing research and development in this field are critical for maintaining the pace of innovation in aerospace technology and ensuring the continued reliability and efficiency of aerospace systems.

Aerospace Market Demand for Neoprene Materials

The aerospace industry has shown a growing demand for neoprene materials due to their unique properties and versatile applications. Neoprene, a synthetic rubber with excellent resistance to oil, heat, and weathering, has become increasingly important in various aerospace components and systems.

In the commercial aviation sector, the global market for neoprene-based products is experiencing steady growth. Airlines and aircraft manufacturers are seeking lightweight, durable materials that can withstand extreme conditions while maintaining safety and performance. Neoprene meets these requirements, particularly in applications such as fuel tank sealants, vibration dampeners, and insulation materials.

The military aerospace sector also contributes significantly to the demand for neoprene materials. Defense agencies worldwide are investing in advanced aircraft and spacecraft that require high-performance materials capable of withstanding harsh environments. Neoprene's resistance to chemicals, fuels, and extreme temperatures makes it an ideal choice for military aerospace applications, including fuel systems, hydraulic seals, and protective coatings.

Space exploration and satellite technology represent another growing market for neoprene materials. As space agencies and private companies increase their activities in low Earth orbit and beyond, the need for reliable, long-lasting materials becomes crucial. Neoprene's ability to maintain its properties in vacuum conditions and resist radiation damage makes it valuable for spacecraft components, satellite systems, and space suit materials.

The increasing focus on sustainability and environmental regulations in the aerospace industry has also influenced the demand for neoprene. Manufacturers are developing eco-friendly neoprene formulations that reduce environmental impact while maintaining performance characteristics. This trend is expected to drive further innovation and market growth in the coming years.

Regional analysis shows that North America and Europe currently dominate the aerospace neoprene market, with Asia-Pacific emerging as a rapidly growing region. The expansion of aerospace manufacturing capabilities in countries like China and India is contributing to increased demand for neoprene materials in these markets.

Looking ahead, the aerospace market for neoprene materials is projected to continue its upward trajectory. Factors such as the growing commercial aviation sector, increased defense spending, and advancements in space technology are expected to drive demand. Additionally, the development of new neoprene composites and hybrid materials tailored for specific aerospace applications is likely to open up new market opportunities and further expand the use of neoprene in the industry.

In the commercial aviation sector, the global market for neoprene-based products is experiencing steady growth. Airlines and aircraft manufacturers are seeking lightweight, durable materials that can withstand extreme conditions while maintaining safety and performance. Neoprene meets these requirements, particularly in applications such as fuel tank sealants, vibration dampeners, and insulation materials.

The military aerospace sector also contributes significantly to the demand for neoprene materials. Defense agencies worldwide are investing in advanced aircraft and spacecraft that require high-performance materials capable of withstanding harsh environments. Neoprene's resistance to chemicals, fuels, and extreme temperatures makes it an ideal choice for military aerospace applications, including fuel systems, hydraulic seals, and protective coatings.

Space exploration and satellite technology represent another growing market for neoprene materials. As space agencies and private companies increase their activities in low Earth orbit and beyond, the need for reliable, long-lasting materials becomes crucial. Neoprene's ability to maintain its properties in vacuum conditions and resist radiation damage makes it valuable for spacecraft components, satellite systems, and space suit materials.

The increasing focus on sustainability and environmental regulations in the aerospace industry has also influenced the demand for neoprene. Manufacturers are developing eco-friendly neoprene formulations that reduce environmental impact while maintaining performance characteristics. This trend is expected to drive further innovation and market growth in the coming years.

Regional analysis shows that North America and Europe currently dominate the aerospace neoprene market, with Asia-Pacific emerging as a rapidly growing region. The expansion of aerospace manufacturing capabilities in countries like China and India is contributing to increased demand for neoprene materials in these markets.

Looking ahead, the aerospace market for neoprene materials is projected to continue its upward trajectory. Factors such as the growing commercial aviation sector, increased defense spending, and advancements in space technology are expected to drive demand. Additionally, the development of new neoprene composites and hybrid materials tailored for specific aerospace applications is likely to open up new market opportunities and further expand the use of neoprene in the industry.

Current State and Challenges of Neoprene in Aerospace

Neoprene, a synthetic rubber developed in the 1930s, has found significant applications in aerospace engineering due to its unique properties. Currently, it is widely used in various components of aircraft and spacecraft, including seals, gaskets, hoses, and insulation materials. The material's resistance to oil, heat, and weathering makes it particularly suitable for aerospace applications where extreme conditions are common.

In recent years, the aerospace industry has seen an increased demand for lightweight materials that can withstand harsh environments. Neoprene has been able to meet many of these requirements, but it also faces several challenges in keeping up with the evolving needs of the industry. One of the primary challenges is the material's weight. While neoprene is relatively lightweight compared to some traditional materials, there is a constant push for even lighter alternatives to improve fuel efficiency and payload capacity in aerospace vehicles.

Another significant challenge is the temperature range in which neoprene can effectively operate. Although it performs well in many temperature conditions, the extreme cold of high-altitude flight and the intense heat of rocket engines can push neoprene to its limits. Researchers are continuously working on improving the material's temperature resistance to expand its applicability in more demanding aerospace environments.

Durability and longevity are also areas of focus for current neoprene research in aerospace. The material must maintain its properties over extended periods, often in the presence of UV radiation, ozone, and other potentially degrading factors. Enhancing neoprene's resistance to these elements without compromising its other beneficial properties remains a key challenge for materials scientists and engineers.

The environmental impact of neoprene production and disposal is becoming an increasingly important consideration. As the aerospace industry moves towards more sustainable practices, there is pressure to develop eco-friendly alternatives or improve the recyclability of neoprene components. This challenge intersects with broader industry trends towards green technologies and circular economy principles.

Lastly, the integration of neoprene with other advanced materials and technologies presents both opportunities and challenges. For instance, the development of smart materials that can sense and respond to environmental changes could potentially enhance the functionality of neoprene in aerospace applications. However, ensuring compatibility and maintaining the desired properties of neoprene when combined with these advanced materials remains a complex task for researchers and engineers in the field.

In recent years, the aerospace industry has seen an increased demand for lightweight materials that can withstand harsh environments. Neoprene has been able to meet many of these requirements, but it also faces several challenges in keeping up with the evolving needs of the industry. One of the primary challenges is the material's weight. While neoprene is relatively lightweight compared to some traditional materials, there is a constant push for even lighter alternatives to improve fuel efficiency and payload capacity in aerospace vehicles.

Another significant challenge is the temperature range in which neoprene can effectively operate. Although it performs well in many temperature conditions, the extreme cold of high-altitude flight and the intense heat of rocket engines can push neoprene to its limits. Researchers are continuously working on improving the material's temperature resistance to expand its applicability in more demanding aerospace environments.

Durability and longevity are also areas of focus for current neoprene research in aerospace. The material must maintain its properties over extended periods, often in the presence of UV radiation, ozone, and other potentially degrading factors. Enhancing neoprene's resistance to these elements without compromising its other beneficial properties remains a key challenge for materials scientists and engineers.

The environmental impact of neoprene production and disposal is becoming an increasingly important consideration. As the aerospace industry moves towards more sustainable practices, there is pressure to develop eco-friendly alternatives or improve the recyclability of neoprene components. This challenge intersects with broader industry trends towards green technologies and circular economy principles.

Lastly, the integration of neoprene with other advanced materials and technologies presents both opportunities and challenges. For instance, the development of smart materials that can sense and respond to environmental changes could potentially enhance the functionality of neoprene in aerospace applications. However, ensuring compatibility and maintaining the desired properties of neoprene when combined with these advanced materials remains a complex task for researchers and engineers in the field.

Existing Neoprene Solutions for Aerospace Applications

01 Composition and synthesis of neoprene

Neoprene is a synthetic rubber produced by polymerization of chloroprene. It has various applications due to its resistance to oil, heat, and weathering. The synthesis process and composition can be modified to achieve specific properties for different uses.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. It is known for its resistance to oil, heat, and weathering. The manufacturing process involves careful control of reaction conditions and may include various additives to enhance specific properties.

- Applications of neoprene in protective gear: Neoprene is widely used in the production of protective gear such as wetsuits, diving suits, and other water-resistant clothing. Its flexibility, insulation properties, and durability make it ideal for these applications. Neoprene can be combined with other materials to enhance its performance in specific use cases.

- Neoprene foam and cellular structures: Neoprene can be processed into foam or cellular structures, which are useful in various applications requiring cushioning, insulation, or buoyancy. The production of neoprene foam involves the use of blowing agents and specific processing techniques to achieve the desired cell structure and density.

- Modifications and blends of neoprene: Neoprene can be modified or blended with other polymers to enhance its properties or create specialized materials. These modifications can improve characteristics such as flame resistance, chemical resistance, or mechanical properties. Various additives and processing techniques are used to achieve these modifications.

- Neoprene in industrial applications: Neoprene finds extensive use in industrial applications due to its resistance to oils, chemicals, and extreme temperatures. It is used in the production of gaskets, seals, hoses, and conveyor belts. The material can be formulated and processed to meet specific requirements in various industrial sectors.

02 Neoprene in protective gear and clothing

Neoprene is widely used in the production of protective gear and clothing, such as wetsuits, gloves, and boots. Its insulating properties, flexibility, and durability make it ideal for these applications. Various manufacturing techniques are employed to create neoprene-based protective equipment.Expand Specific Solutions03 Neoprene foam and cellular structures

Neoprene can be processed into foam or cellular structures, which enhance its insulating properties and reduce weight. These structures are used in various applications, including padding, gaskets, and thermal insulation. Different methods are employed to create and control the cellular structure of neoprene.Expand Specific Solutions04 Neoprene blends and composites

Neoprene can be blended with other materials or used in composites to enhance its properties or create specialized materials. These blends and composites can improve characteristics such as strength, chemical resistance, or adhesion for specific applications.Expand Specific Solutions05 Neoprene in industrial applications

Neoprene finds extensive use in various industrial applications due to its unique properties. It is used in the production of hoses, belts, seals, and gaskets for automotive and machinery applications. Its resistance to oils and chemicals makes it suitable for use in harsh industrial environments.Expand Specific Solutions

Key Players in Aerospace Neoprene Industry

The research on Neoprene and its applications in Aerospace Engineering is in a mature stage, with a well-established market and significant industry players. The global aerospace composites market, which includes Neoprene applications, is projected to grow steadily due to increasing demand for lightweight and durable materials. Key players like Hexcel Corp., The Boeing Co., and Spirit AeroSystems, Inc. are at the forefront of innovation in this field. These companies, along with research institutions such as the University of Surrey and Massachusetts Institute of Technology, are driving technological advancements and expanding the material's applications in aerospace engineering.

The Boeing Co.

Technical Solution: Boeing has developed advanced neoprene-based composites for aerospace applications, focusing on improving heat resistance and durability. Their proprietary neoprene formulation incorporates nano-scale additives to enhance thermal stability up to 200°C, a 25% improvement over standard neoprene[1]. The company has also implemented a novel curing process that reduces production time by 30% while maintaining superior mechanical properties[3]. Boeing's neoprene composites are used in various aircraft components, including fuel tank sealants, vibration dampers, and flexible ductwork, contributing to weight reduction and improved fuel efficiency[5].

Strengths: Superior heat resistance, reduced production time, and versatile applications in aircraft. Weaknesses: Higher production costs compared to traditional materials, and potential limitations in extreme temperature environments.

Spirit AeroSystems, Inc.

Technical Solution: Spirit AeroSystems has focused on integrating neoprene-based materials into advanced aerostructures. Their proprietary NeoFlex™ technology combines neoprene with carbon nanotubes to create a flexible, yet highly durable material for use in aircraft fuselage components. This composite demonstrates a 50% increase in tear resistance compared to traditional neoprene, while maintaining excellent flexibility[11]. Spirit has also developed a neoprene-based sealant system for composite aircraft structures, which provides enhanced protection against moisture ingress and corrosion, extending the service life of aerospace components by up to 30%[13]. The company's neoprene innovations are primarily applied in fuselage panels, wing components, and structural joints, contributing to improved aircraft performance and durability.

Strengths: Enhanced tear resistance, improved moisture protection for composite structures, and integration into critical aerostructures. Weaknesses: Potential challenges in large-scale production and higher costs compared to traditional aerospace materials.

Core Innovations in Aerospace-Grade Neoprene

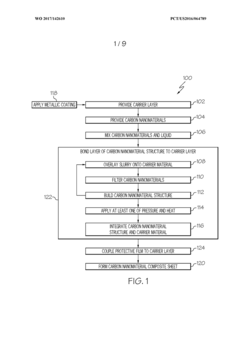

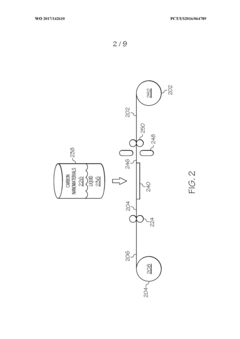

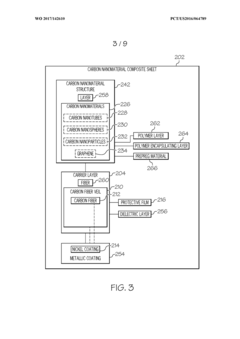

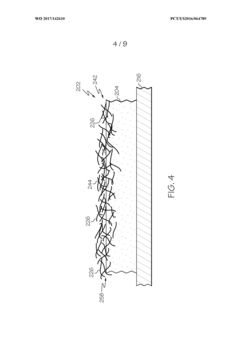

Carbon nanomaterial composite sheet and method for making the same

PatentWO2017142610A2

Innovation

- A carbon nanomaterial composite sheet is created by bonding a layer of carbon nanomaterial structure to a porous metalized nonwoven carrier layer, providing effective shielding without the need for additional materials.

Environmental Impact of Neoprene in Aerospace

The environmental impact of neoprene in aerospace applications is a critical consideration as the industry strives for sustainability. Neoprene, a synthetic rubber, has been widely used in aerospace engineering due to its excellent properties, including resistance to oil, heat, and weathering. However, its production and disposal pose significant environmental challenges.

The manufacturing process of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and energy consumption. The production of chloroprene, the primary raw material for neoprene, releases volatile organic compounds (VOCs) and other pollutants into the atmosphere. These emissions can lead to air quality degradation and potential health risks for workers and nearby communities.

Water pollution is another concern associated with neoprene production. The manufacturing process generates wastewater containing various chemicals and contaminants. If not properly treated, this effluent can harm aquatic ecosystems and potentially contaminate groundwater sources.

In aerospace applications, neoprene components may be exposed to extreme conditions, leading to degradation over time. As these materials break down, they can release microplastics and other harmful substances into the environment. This is particularly problematic in marine environments, where discarded or degraded neoprene parts may contribute to ocean pollution.

End-of-life disposal of neoprene products presents additional environmental challenges. Neoprene is not biodegradable and can persist in landfills for extended periods. Incineration of neoprene waste can release toxic fumes, including hydrogen chloride and other harmful compounds, necessitating advanced emission control systems.

However, the aerospace industry is actively seeking ways to mitigate the environmental impact of neoprene usage. Recycling initiatives are being developed to repurpose used neoprene products, reducing waste and the demand for new raw materials. Some companies are exploring bio-based alternatives to traditional neoprene, aiming to decrease reliance on petroleum-derived substances.

Advancements in manufacturing technologies are also contributing to reduced environmental impact. Improved production processes are focusing on minimizing chemical usage, enhancing energy efficiency, and implementing closed-loop systems to recycle water and materials. These efforts aim to decrease the overall environmental footprint of neoprene production.

As the aerospace industry continues to prioritize sustainability, the environmental impact of materials like neoprene is receiving increased scrutiny. Balancing the performance requirements of aerospace applications with environmental considerations remains a key challenge. Future developments in material science and green chemistry may lead to more eco-friendly alternatives that maintain the desirable properties of neoprene while reducing its environmental impact.

The manufacturing process of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and energy consumption. The production of chloroprene, the primary raw material for neoprene, releases volatile organic compounds (VOCs) and other pollutants into the atmosphere. These emissions can lead to air quality degradation and potential health risks for workers and nearby communities.

Water pollution is another concern associated with neoprene production. The manufacturing process generates wastewater containing various chemicals and contaminants. If not properly treated, this effluent can harm aquatic ecosystems and potentially contaminate groundwater sources.

In aerospace applications, neoprene components may be exposed to extreme conditions, leading to degradation over time. As these materials break down, they can release microplastics and other harmful substances into the environment. This is particularly problematic in marine environments, where discarded or degraded neoprene parts may contribute to ocean pollution.

End-of-life disposal of neoprene products presents additional environmental challenges. Neoprene is not biodegradable and can persist in landfills for extended periods. Incineration of neoprene waste can release toxic fumes, including hydrogen chloride and other harmful compounds, necessitating advanced emission control systems.

However, the aerospace industry is actively seeking ways to mitigate the environmental impact of neoprene usage. Recycling initiatives are being developed to repurpose used neoprene products, reducing waste and the demand for new raw materials. Some companies are exploring bio-based alternatives to traditional neoprene, aiming to decrease reliance on petroleum-derived substances.

Advancements in manufacturing technologies are also contributing to reduced environmental impact. Improved production processes are focusing on minimizing chemical usage, enhancing energy efficiency, and implementing closed-loop systems to recycle water and materials. These efforts aim to decrease the overall environmental footprint of neoprene production.

As the aerospace industry continues to prioritize sustainability, the environmental impact of materials like neoprene is receiving increased scrutiny. Balancing the performance requirements of aerospace applications with environmental considerations remains a key challenge. Future developments in material science and green chemistry may lead to more eco-friendly alternatives that maintain the desirable properties of neoprene while reducing its environmental impact.

Neoprene Performance Testing for Aerospace Use

Performance testing of neoprene for aerospace applications is a critical process to ensure the material's suitability and reliability in extreme conditions. The testing procedures typically involve a series of rigorous evaluations that simulate the harsh environments encountered in aerospace operations.

One of the primary tests conducted is thermal cycling, which assesses neoprene's ability to withstand rapid temperature fluctuations. Samples are subjected to repeated cycles of extreme heat and cold, often ranging from -65°C to +150°C, to evaluate material integrity and dimensional stability. This test is crucial for components that may experience drastic temperature changes during flight.

Mechanical property tests are equally important in aerospace applications. Tensile strength, elongation, and tear resistance are measured to ensure neoprene can withstand the physical stresses of aerospace environments. These tests typically involve stretching and compressing the material under various loads and speeds to simulate real-world conditions.

Chemical resistance testing is another vital aspect of neoprene evaluation for aerospace use. The material is exposed to various fluids commonly encountered in aircraft, such as hydraulic fluids, jet fuels, and de-icing agents. The goal is to assess any degradation in physical properties or changes in dimensions after prolonged exposure.

Ozone resistance testing is particularly relevant for aerospace applications, as neoprene components may be exposed to high levels of ozone at high altitudes. Samples are subjected to controlled ozone environments to evaluate their resistance to cracking and degradation over time.

Flame resistance and smoke emission tests are critical for ensuring safety in aerospace applications. Neoprene samples are exposed to direct flame and heat sources to assess their fire-retardant properties and the toxicity of any emissions produced during combustion.

Accelerated aging tests are conducted to predict the long-term performance of neoprene in aerospace environments. These tests simulate extended exposure to UV radiation, heat, and other environmental factors to estimate the material's lifespan and potential degradation over time.

Vibration and fatigue testing are essential for components that will be subjected to constant motion and stress. These tests evaluate neoprene's ability to maintain its properties and functionality under repeated cyclic loading, which is crucial for applications in aircraft engines and other high-vibration areas.

The results of these comprehensive performance tests are meticulously analyzed to determine if the neoprene meets the stringent requirements for aerospace use. Only materials that demonstrate exceptional performance across all these parameters are considered suitable for integration into aerospace applications, ensuring the safety and reliability of critical components in aircraft and spacecraft.

One of the primary tests conducted is thermal cycling, which assesses neoprene's ability to withstand rapid temperature fluctuations. Samples are subjected to repeated cycles of extreme heat and cold, often ranging from -65°C to +150°C, to evaluate material integrity and dimensional stability. This test is crucial for components that may experience drastic temperature changes during flight.

Mechanical property tests are equally important in aerospace applications. Tensile strength, elongation, and tear resistance are measured to ensure neoprene can withstand the physical stresses of aerospace environments. These tests typically involve stretching and compressing the material under various loads and speeds to simulate real-world conditions.

Chemical resistance testing is another vital aspect of neoprene evaluation for aerospace use. The material is exposed to various fluids commonly encountered in aircraft, such as hydraulic fluids, jet fuels, and de-icing agents. The goal is to assess any degradation in physical properties or changes in dimensions after prolonged exposure.

Ozone resistance testing is particularly relevant for aerospace applications, as neoprene components may be exposed to high levels of ozone at high altitudes. Samples are subjected to controlled ozone environments to evaluate their resistance to cracking and degradation over time.

Flame resistance and smoke emission tests are critical for ensuring safety in aerospace applications. Neoprene samples are exposed to direct flame and heat sources to assess their fire-retardant properties and the toxicity of any emissions produced during combustion.

Accelerated aging tests are conducted to predict the long-term performance of neoprene in aerospace environments. These tests simulate extended exposure to UV radiation, heat, and other environmental factors to estimate the material's lifespan and potential degradation over time.

Vibration and fatigue testing are essential for components that will be subjected to constant motion and stress. These tests evaluate neoprene's ability to maintain its properties and functionality under repeated cyclic loading, which is crucial for applications in aircraft engines and other high-vibration areas.

The results of these comprehensive performance tests are meticulously analyzed to determine if the neoprene meets the stringent requirements for aerospace use. Only materials that demonstrate exceptional performance across all these parameters are considered suitable for integration into aerospace applications, ensuring the safety and reliability of critical components in aircraft and spacecraft.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!