Neoprene and its Benefits in Mechanical Applications

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Evolution and Objectives

Neoprene, a synthetic rubber developed by DuPont in 1930, has undergone significant evolution since its inception. Initially created as an oil-resistant alternative to natural rubber, neoprene has become a versatile material with widespread applications in mechanical engineering. The journey of neoprene began with its discovery by Wallace Carothers, who was searching for a synthetic substitute for rubber during World War II when natural rubber supplies were limited.

The evolution of neoprene has been marked by continuous improvements in its properties and manufacturing processes. Early versions of neoprene were primarily focused on oil resistance and durability. However, as research progressed, scientists developed various grades of neoprene with enhanced characteristics such as improved flexibility, weather resistance, and thermal insulation. This evolution has expanded neoprene's utility across diverse industries, from automotive to aerospace.

In the realm of mechanical applications, neoprene's objectives have become increasingly specialized. The material aims to provide superior sealing properties, vibration dampening, and resistance to extreme temperatures and chemicals. These objectives align with the growing demands of modern machinery and equipment, which often operate under harsh conditions and require components that can withstand significant stress and environmental factors.

One of the key goals in neoprene's development has been to enhance its performance in dynamic mechanical systems. This includes improving its fatigue resistance, reducing compression set, and increasing its overall lifespan in applications where repeated stress and strain are common. Engineers and material scientists have focused on optimizing neoprene's molecular structure and additives to achieve these objectives.

Another significant aspect of neoprene's evolution is the pursuit of environmental sustainability. As global awareness of environmental issues has grown, there has been a push to develop more eco-friendly production methods for neoprene and to improve its recyclability. This aligns with the broader industry trend towards sustainable materials and practices in mechanical engineering.

The current objectives for neoprene in mechanical applications include further enhancing its already impressive range of properties. This involves developing neoprene compounds that offer even greater resistance to oils, fuels, and other chemicals while maintaining flexibility across a wider temperature range. Additionally, there is a focus on creating neoprene formulations that provide better electrical insulation properties, making it more suitable for applications in the growing field of electromechanical systems.

The evolution of neoprene has been marked by continuous improvements in its properties and manufacturing processes. Early versions of neoprene were primarily focused on oil resistance and durability. However, as research progressed, scientists developed various grades of neoprene with enhanced characteristics such as improved flexibility, weather resistance, and thermal insulation. This evolution has expanded neoprene's utility across diverse industries, from automotive to aerospace.

In the realm of mechanical applications, neoprene's objectives have become increasingly specialized. The material aims to provide superior sealing properties, vibration dampening, and resistance to extreme temperatures and chemicals. These objectives align with the growing demands of modern machinery and equipment, which often operate under harsh conditions and require components that can withstand significant stress and environmental factors.

One of the key goals in neoprene's development has been to enhance its performance in dynamic mechanical systems. This includes improving its fatigue resistance, reducing compression set, and increasing its overall lifespan in applications where repeated stress and strain are common. Engineers and material scientists have focused on optimizing neoprene's molecular structure and additives to achieve these objectives.

Another significant aspect of neoprene's evolution is the pursuit of environmental sustainability. As global awareness of environmental issues has grown, there has been a push to develop more eco-friendly production methods for neoprene and to improve its recyclability. This aligns with the broader industry trend towards sustainable materials and practices in mechanical engineering.

The current objectives for neoprene in mechanical applications include further enhancing its already impressive range of properties. This involves developing neoprene compounds that offer even greater resistance to oils, fuels, and other chemicals while maintaining flexibility across a wider temperature range. Additionally, there is a focus on creating neoprene formulations that provide better electrical insulation properties, making it more suitable for applications in the growing field of electromechanical systems.

Market Demand Analysis

The market demand for neoprene in mechanical applications has been steadily growing due to its unique properties and versatility. As a synthetic rubber, neoprene offers excellent resistance to oil, grease, water, and weathering, making it highly sought after in various industries. The automotive sector represents a significant portion of the market demand, utilizing neoprene in gaskets, hoses, and seals due to its ability to withstand high temperatures and maintain flexibility.

In the construction industry, neoprene's durability and weather resistance have led to increased adoption in roofing materials, expansion joints, and vibration isolation pads. The material's ability to absorb shock and dampen vibrations has also driven demand in the manufacturing sector, where it is used in machinery mounts and industrial equipment.

The marine industry has shown a growing interest in neoprene for its corrosion resistance and ability to withstand harsh saltwater environments. This has led to increased use in boat components, dock bumpers, and underwater cable insulation. Additionally, the aerospace industry has been incorporating neoprene into various applications due to its flame-retardant properties and ability to maintain performance under extreme conditions.

The global neoprene market has been experiencing steady growth, with projections indicating continued expansion in the coming years. This growth is driven by the increasing demand for durable and versatile materials in mechanical applications across various industries. The Asia-Pacific region, particularly China and India, has emerged as a significant market for neoprene due to rapid industrialization and infrastructure development.

Environmental concerns and regulations have also influenced market demand, with manufacturers focusing on developing eco-friendly neoprene alternatives. This trend has led to innovations in production processes and the exploration of bio-based materials that offer similar mechanical properties to traditional neoprene.

The COVID-19 pandemic initially caused disruptions in the supply chain and temporary slowdowns in certain industries. However, the increased focus on personal protective equipment (PPE) has created new opportunities for neoprene in medical applications, such as gloves and face masks, further diversifying its market demand.

As industries continue to seek materials that offer durability, flexibility, and resistance to various environmental factors, the demand for neoprene in mechanical applications is expected to remain strong. Manufacturers are likely to focus on developing specialized neoprene formulations to meet specific industry requirements, further driving market growth and innovation in this sector.

In the construction industry, neoprene's durability and weather resistance have led to increased adoption in roofing materials, expansion joints, and vibration isolation pads. The material's ability to absorb shock and dampen vibrations has also driven demand in the manufacturing sector, where it is used in machinery mounts and industrial equipment.

The marine industry has shown a growing interest in neoprene for its corrosion resistance and ability to withstand harsh saltwater environments. This has led to increased use in boat components, dock bumpers, and underwater cable insulation. Additionally, the aerospace industry has been incorporating neoprene into various applications due to its flame-retardant properties and ability to maintain performance under extreme conditions.

The global neoprene market has been experiencing steady growth, with projections indicating continued expansion in the coming years. This growth is driven by the increasing demand for durable and versatile materials in mechanical applications across various industries. The Asia-Pacific region, particularly China and India, has emerged as a significant market for neoprene due to rapid industrialization and infrastructure development.

Environmental concerns and regulations have also influenced market demand, with manufacturers focusing on developing eco-friendly neoprene alternatives. This trend has led to innovations in production processes and the exploration of bio-based materials that offer similar mechanical properties to traditional neoprene.

The COVID-19 pandemic initially caused disruptions in the supply chain and temporary slowdowns in certain industries. However, the increased focus on personal protective equipment (PPE) has created new opportunities for neoprene in medical applications, such as gloves and face masks, further diversifying its market demand.

As industries continue to seek materials that offer durability, flexibility, and resistance to various environmental factors, the demand for neoprene in mechanical applications is expected to remain strong. Manufacturers are likely to focus on developing specialized neoprene formulations to meet specific industry requirements, further driving market growth and innovation in this sector.

Technical Challenges

Despite its widespread use and numerous advantages, neoprene faces several technical challenges in mechanical applications. One of the primary issues is its limited temperature range. While neoprene performs well in moderate temperatures, it can degrade or lose its properties when exposed to extreme heat or cold. This limitation restricts its use in certain high-temperature industrial environments or extremely cold conditions.

Another significant challenge is neoprene's susceptibility to oil and petroleum-based products. Although it offers good resistance to many chemicals, prolonged exposure to oils can cause swelling, degradation, and a reduction in mechanical properties. This vulnerability necessitates careful consideration when selecting neoprene for applications involving frequent contact with lubricants or fuels.

Aging and weathering pose additional challenges for neoprene in long-term mechanical applications. Over time, exposure to UV radiation, ozone, and atmospheric pollutants can lead to surface cracking, discoloration, and a decrease in elasticity. This degradation can compromise the material's sealing properties and overall performance, particularly in outdoor or harsh environmental conditions.

The manufacturing process of neoprene also presents technical hurdles. Achieving consistent quality across large production batches can be challenging, as variations in raw materials and processing conditions can affect the final properties of the material. This inconsistency may lead to performance variations in mechanical applications, potentially impacting product reliability and longevity.

Neoprene's relatively high compression set compared to some other elastomers is another technical limitation. This characteristic means that neoprene may not fully recover its original shape after prolonged compression, which can be problematic in applications requiring long-term sealing or cushioning properties.

The material's electrical insulation properties, while generally good, may not be sufficient for all electrical applications. In high-voltage or sensitive electronic environments, neoprene's electrical resistance might not meet the stringent requirements, necessitating the use of alternative materials or additional insulation measures.

Lastly, the environmental impact of neoprene production and disposal presents a growing challenge. The manufacturing process involves the use of potentially harmful chemicals, and the material is not biodegradable. As sustainability becomes increasingly important in industrial applications, finding more environmentally friendly alternatives or developing recycling methods for neoprene remains a significant technical and ecological challenge.

Another significant challenge is neoprene's susceptibility to oil and petroleum-based products. Although it offers good resistance to many chemicals, prolonged exposure to oils can cause swelling, degradation, and a reduction in mechanical properties. This vulnerability necessitates careful consideration when selecting neoprene for applications involving frequent contact with lubricants or fuels.

Aging and weathering pose additional challenges for neoprene in long-term mechanical applications. Over time, exposure to UV radiation, ozone, and atmospheric pollutants can lead to surface cracking, discoloration, and a decrease in elasticity. This degradation can compromise the material's sealing properties and overall performance, particularly in outdoor or harsh environmental conditions.

The manufacturing process of neoprene also presents technical hurdles. Achieving consistent quality across large production batches can be challenging, as variations in raw materials and processing conditions can affect the final properties of the material. This inconsistency may lead to performance variations in mechanical applications, potentially impacting product reliability and longevity.

Neoprene's relatively high compression set compared to some other elastomers is another technical limitation. This characteristic means that neoprene may not fully recover its original shape after prolonged compression, which can be problematic in applications requiring long-term sealing or cushioning properties.

The material's electrical insulation properties, while generally good, may not be sufficient for all electrical applications. In high-voltage or sensitive electronic environments, neoprene's electrical resistance might not meet the stringent requirements, necessitating the use of alternative materials or additional insulation measures.

Lastly, the environmental impact of neoprene production and disposal presents a growing challenge. The manufacturing process involves the use of potentially harmful chemicals, and the material is not biodegradable. As sustainability becomes increasingly important in industrial applications, finding more environmentally friendly alternatives or developing recycling methods for neoprene remains a significant technical and ecological challenge.

Current Neoprene Solutions

01 Composition and synthesis of neoprene

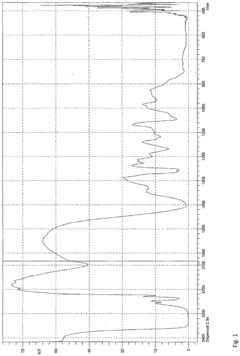

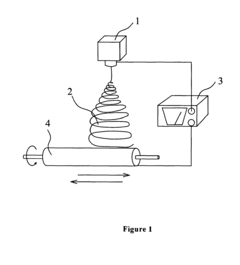

Neoprene is a synthetic rubber produced by polymerization of chloroprene. It has various compositions and methods of synthesis, including emulsion polymerization and solution polymerization techniques. The process often involves the use of specific catalysts and additives to control the properties of the final product.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. It has various compositions and synthesis methods, including emulsion polymerization and solution polymerization. Different additives and catalysts can be used to modify its properties and improve its performance for specific applications.

- Applications of neoprene in protective gear: Neoprene is widely used in the production of protective gear due to its excellent insulation, flexibility, and durability. It is commonly used in wetsuits, diving suits, and other water-resistant clothing. Neoprene-based materials are also used in safety equipment for various industries, providing protection against heat, chemicals, and impacts.

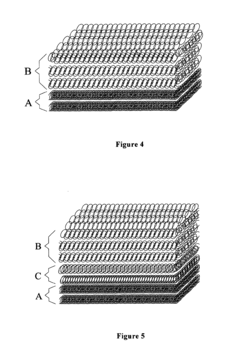

- Neoprene foams and cellular structures: Neoprene can be processed into foam or cellular structures, which enhance its insulation properties and reduce weight. These foams are used in various applications, including thermal insulation, cushioning, and buoyancy devices. Different manufacturing techniques and additives can be used to control the cell structure and density of neoprene foams.

- Neoprene blends and composites: Neoprene can be blended with other polymers or materials to create composites with enhanced properties. These blends and composites can improve characteristics such as chemical resistance, flame retardancy, or mechanical strength. The combination of neoprene with other materials allows for tailored solutions in various industrial and consumer applications.

- Environmental considerations and alternatives: As environmental concerns grow, there is increasing focus on developing more sustainable alternatives to traditional neoprene. This includes research into bio-based materials, recycling methods for neoprene products, and the development of neoprene formulations with reduced environmental impact. Efforts are also being made to improve the production processes to minimize waste and energy consumption.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear due to its excellent insulation and flexibility properties. It is commonly used in wetsuits, diving suits, and other water-resistant clothing. The material's ability to provide thermal insulation while maintaining flexibility makes it ideal for various protective applications.Expand Specific Solutions03 Neoprene foam production and properties

Neoprene foam is a versatile material with unique properties such as excellent insulation, buoyancy, and shock absorption. The production process involves the introduction of gas bubbles into the neoprene compound during polymerization or through post-polymerization foaming techniques. The resulting foam can be tailored for specific applications by adjusting cell size and density.Expand Specific Solutions04 Neoprene in adhesive and sealant applications

Neoprene-based adhesives and sealants are known for their strong bonding properties, resistance to weathering, and flexibility. These products are used in various industries, including construction, automotive, and marine applications. The formulation often includes additional components to enhance specific properties such as tack, cure rate, and chemical resistance.Expand Specific Solutions05 Modifications and blends of neoprene

To enhance its properties or create specialized materials, neoprene is often modified or blended with other polymers or additives. These modifications can improve characteristics such as heat resistance, oil resistance, or flame retardancy. Blending neoprene with other elastomers or incorporating specific fillers can result in materials with unique combinations of properties suited for specialized applications.Expand Specific Solutions

Key Industry Players

The market for neoprene in mechanical applications is in a mature growth stage, with a steady global demand driven by its versatile properties. The market size is estimated to be in the billions of dollars, with consistent growth projected due to expanding industrial and automotive sectors. Technologically, neoprene is well-established, but innovation continues in specialized formulations and applications. Key players like Denka Corp., ExxonMobil Chemical Patents, Inc., and Mitsui Chemicals, Inc. are investing in R&D to enhance neoprene's performance characteristics and explore new uses. Smaller companies such as Hyalex Orthopaedics, Inc. are focusing on niche applications, developing novel neoprene-based materials for specific industries like orthopedics.

Denka Corp.

Technical Solution: Denka Corp. has developed advanced neoprene formulations with improved mechanical properties. Their neoprene compounds feature enhanced oil and heat resistance, making them suitable for demanding industrial applications[1]. The company utilizes a proprietary vulcanization process that results in neoprene with superior tensile strength and elongation characteristics[2]. Denka's neoprene products also incorporate special additives to improve flame retardancy and chemical resistance, expanding their use in safety-critical environments[3].

Strengths: Superior oil and heat resistance, high tensile strength, improved flame retardancy. Weaknesses: Potentially higher cost due to specialized formulations, may require specific processing conditions.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed a novel neoprene compound with enhanced low-temperature flexibility and improved compression set resistance[4]. Their patented technology involves the incorporation of specific plasticizers and cross-linking agents, resulting in neoprene that maintains its mechanical properties across a wider temperature range[5]. The company has also introduced a neoprene blend that combines the material's inherent chemical resistance with improved abrasion resistance, making it ideal for sealing applications in harsh environments[6].

Strengths: Excellent low-temperature performance, improved compression set resistance, enhanced abrasion resistance. Weaknesses: May have limited high-temperature capabilities compared to standard neoprene, potentially higher production costs.

Core Neoprene Innovations

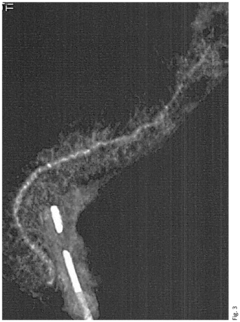

Neoprene medical device

PatentInactiveEP3159016A1

Innovation

- A neoprene-based occlusive material is developed, comprising a sterile aqueous dispersion of poly(2-chloro-1,3-butadiene) stabilized at pH 13-13.5, which is injected into the pancreatic duct after surgical removal of the pancreas head, polymerizing to block pancreatic juice discharge, thereby inducing chemical pancreatectomy and preventing fistula formation.

Artificial dura mater and manufacturing method thereof

PatentActiveEP2340785A1

Innovation

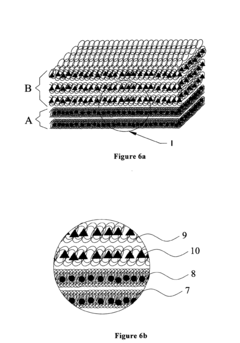

- An artificial dura mater made of electrospun layers with hydrophobic and hydrophilic polymers, where the hydrophobic layer prevents adhesion and the hydrophilic layer promotes cell migration and drug release, combined with a transition layer for improved compatibility, and the ability to incorporate cytokines and medicines for controlled release.

Environmental Impact

The environmental impact of neoprene in mechanical applications is a complex issue that requires careful consideration. Neoprene, a synthetic rubber, offers numerous benefits in terms of durability, flexibility, and resistance to various environmental factors. However, its production and disposal processes raise significant environmental concerns.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and the depletion of non-renewable resources. The production process also generates volatile organic compounds (VOCs) and other pollutants that can harm air quality and contribute to smog formation. Additionally, the energy-intensive nature of neoprene production further increases its carbon footprint.

Water pollution is another environmental concern associated with neoprene production. The manufacturing process can release harmful chemicals into water systems, potentially affecting aquatic ecosystems and human health. Proper wastewater treatment and management are crucial to mitigate these risks.

On the positive side, neoprene's durability and long lifespan in mechanical applications can contribute to reduced waste generation. Its resistance to wear and tear means that neoprene components often need less frequent replacement, potentially lowering the overall environmental impact of mechanical systems over time.

End-of-life disposal of neoprene products presents additional environmental challenges. Neoprene is not biodegradable and can persist in the environment for extended periods. While recycling technologies for neoprene exist, they are not widely implemented, leading to a significant portion of neoprene waste ending up in landfills or being incinerated, both of which have negative environmental consequences.

Recent advancements in green chemistry and sustainable manufacturing practices are beginning to address some of these environmental concerns. Researchers are exploring bio-based alternatives to traditional neoprene, aiming to reduce reliance on petroleum-derived materials. Additionally, improved production techniques are being developed to minimize emissions and waste generation during the manufacturing process.

The mechanical industry is increasingly focusing on lifecycle assessments of materials, including neoprene, to better understand and mitigate their environmental impacts. This holistic approach considers the environmental effects from raw material extraction through production, use, and disposal, enabling more informed decision-making in material selection for mechanical applications.

In conclusion, while neoprene offers significant benefits in mechanical applications, its environmental impact remains a concern. Balancing these benefits against environmental considerations is crucial for sustainable development in the mechanical engineering sector. Ongoing research and innovation in greener production methods and alternative materials will be key to addressing these environmental challenges in the future.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and the depletion of non-renewable resources. The production process also generates volatile organic compounds (VOCs) and other pollutants that can harm air quality and contribute to smog formation. Additionally, the energy-intensive nature of neoprene production further increases its carbon footprint.

Water pollution is another environmental concern associated with neoprene production. The manufacturing process can release harmful chemicals into water systems, potentially affecting aquatic ecosystems and human health. Proper wastewater treatment and management are crucial to mitigate these risks.

On the positive side, neoprene's durability and long lifespan in mechanical applications can contribute to reduced waste generation. Its resistance to wear and tear means that neoprene components often need less frequent replacement, potentially lowering the overall environmental impact of mechanical systems over time.

End-of-life disposal of neoprene products presents additional environmental challenges. Neoprene is not biodegradable and can persist in the environment for extended periods. While recycling technologies for neoprene exist, they are not widely implemented, leading to a significant portion of neoprene waste ending up in landfills or being incinerated, both of which have negative environmental consequences.

Recent advancements in green chemistry and sustainable manufacturing practices are beginning to address some of these environmental concerns. Researchers are exploring bio-based alternatives to traditional neoprene, aiming to reduce reliance on petroleum-derived materials. Additionally, improved production techniques are being developed to minimize emissions and waste generation during the manufacturing process.

The mechanical industry is increasingly focusing on lifecycle assessments of materials, including neoprene, to better understand and mitigate their environmental impacts. This holistic approach considers the environmental effects from raw material extraction through production, use, and disposal, enabling more informed decision-making in material selection for mechanical applications.

In conclusion, while neoprene offers significant benefits in mechanical applications, its environmental impact remains a concern. Balancing these benefits against environmental considerations is crucial for sustainable development in the mechanical engineering sector. Ongoing research and innovation in greener production methods and alternative materials will be key to addressing these environmental challenges in the future.

Regulatory Compliance

Regulatory compliance is a critical aspect of neoprene's application in mechanical systems. The use of neoprene in various industries is subject to a complex web of regulations and standards, which manufacturers and end-users must navigate to ensure legal and safe usage of the material.

In the United States, the Environmental Protection Agency (EPA) regulates neoprene under the Toxic Substances Control Act (TSCA). This act requires manufacturers to report new chemical substances and maintain records of health and safety studies. The Occupational Safety and Health Administration (OSHA) also sets standards for neoprene's use in workplace environments, particularly concerning exposure limits and protective equipment requirements.

Internationally, the European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts neoprene production and use. REACH aims to protect human health and the environment from risks posed by chemicals. Manufacturers and importers must register substances with the European Chemicals Agency (ECHA) and provide safety information.

In the automotive industry, neoprene components must comply with various standards set by organizations such as the Society of Automotive Engineers (SAE). These standards ensure that neoprene parts meet performance and safety requirements for vehicle applications.

For marine applications, neoprene products often need to meet standards set by classification societies like Lloyd's Register or the American Bureau of Shipping. These standards cover aspects such as fire resistance, durability, and chemical compatibility in marine environments.

In the construction sector, neoprene-based products must adhere to building codes and standards. For instance, the International Building Code (IBC) specifies requirements for neoprene-based sealants and gaskets used in construction.

Manufacturers must also consider food safety regulations when producing neoprene components for food processing equipment. In the United States, the Food and Drug Administration (FDA) regulates materials that come into contact with food, including certain neoprene formulations.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers typically need to provide Material Safety Data Sheets (MSDS) detailing the composition, hazards, and safe handling procedures for neoprene products. They may also need to obtain certifications from recognized testing laboratories to demonstrate compliance with specific standards.

As environmental concerns grow, regulations are evolving to address the lifecycle of neoprene products. This includes considerations for recycling and disposal, as well as potential restrictions on certain chemical additives used in neoprene production.

In the United States, the Environmental Protection Agency (EPA) regulates neoprene under the Toxic Substances Control Act (TSCA). This act requires manufacturers to report new chemical substances and maintain records of health and safety studies. The Occupational Safety and Health Administration (OSHA) also sets standards for neoprene's use in workplace environments, particularly concerning exposure limits and protective equipment requirements.

Internationally, the European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts neoprene production and use. REACH aims to protect human health and the environment from risks posed by chemicals. Manufacturers and importers must register substances with the European Chemicals Agency (ECHA) and provide safety information.

In the automotive industry, neoprene components must comply with various standards set by organizations such as the Society of Automotive Engineers (SAE). These standards ensure that neoprene parts meet performance and safety requirements for vehicle applications.

For marine applications, neoprene products often need to meet standards set by classification societies like Lloyd's Register or the American Bureau of Shipping. These standards cover aspects such as fire resistance, durability, and chemical compatibility in marine environments.

In the construction sector, neoprene-based products must adhere to building codes and standards. For instance, the International Building Code (IBC) specifies requirements for neoprene-based sealants and gaskets used in construction.

Manufacturers must also consider food safety regulations when producing neoprene components for food processing equipment. In the United States, the Food and Drug Administration (FDA) regulates materials that come into contact with food, including certain neoprene formulations.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers typically need to provide Material Safety Data Sheets (MSDS) detailing the composition, hazards, and safe handling procedures for neoprene products. They may also need to obtain certifications from recognized testing laboratories to demonstrate compliance with specific standards.

As environmental concerns grow, regulations are evolving to address the lifecycle of neoprene products. This includes considerations for recycling and disposal, as well as potential restrictions on certain chemical additives used in neoprene production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!