Neoprene's Integration in Modern Safety Gear Design

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Safety Gear Evolution and Objectives

Neoprene, a synthetic rubber developed in the 1930s, has played a pivotal role in the evolution of modern safety gear design. Initially created as an oil-resistant alternative to natural rubber, neoprene's unique properties quickly found applications in various industries, including personal protective equipment (PPE). The material's journey in safety gear began with its use in diving suits during World War II, showcasing its excellent insulation and water-resistant qualities.

Over the decades, neoprene's integration into safety gear has expanded significantly, driven by advancements in material science and manufacturing techniques. The material's versatility has led to its incorporation in a wide range of safety equipment, from firefighting gear to industrial protective clothing. Its ability to provide thermal insulation, chemical resistance, and flexibility has made it an invaluable component in designing gear that can withstand harsh environments while ensuring user comfort and mobility.

The evolution of neoprene in safety gear design has been marked by continuous improvements in its formulation and processing. Manufacturers have developed specialized blends and layering techniques to enhance specific properties such as fire resistance, impact absorption, and durability. This ongoing refinement has enabled the creation of increasingly sophisticated safety solutions tailored to diverse occupational hazards.

In recent years, the focus of neoprene integration in safety gear has shifted towards sustainability and enhanced performance. Researchers and manufacturers are exploring bio-based alternatives and recycling processes to reduce the environmental impact of neoprene production. Simultaneously, efforts are being made to improve the material's breathability and reduce weight without compromising its protective qualities.

The primary objectives of neoprene's integration in modern safety gear design are multifaceted. These include enhancing user protection against a broader spectrum of hazards, improving comfort and wearability to encourage consistent use, and developing gear that adapts to varying environmental conditions. Additionally, there is a growing emphasis on creating smart safety gear that incorporates sensors and other technologies, with neoprene serving as a flexible and durable substrate for these innovations.

Looking ahead, the integration of neoprene in safety gear design aims to address emerging challenges such as extreme weather conditions due to climate change and new occupational hazards in evolving industries. The material's adaptability positions it as a key component in developing next-generation safety solutions that can meet increasingly stringent safety standards while accommodating the diverse needs of modern workplaces.

Over the decades, neoprene's integration into safety gear has expanded significantly, driven by advancements in material science and manufacturing techniques. The material's versatility has led to its incorporation in a wide range of safety equipment, from firefighting gear to industrial protective clothing. Its ability to provide thermal insulation, chemical resistance, and flexibility has made it an invaluable component in designing gear that can withstand harsh environments while ensuring user comfort and mobility.

The evolution of neoprene in safety gear design has been marked by continuous improvements in its formulation and processing. Manufacturers have developed specialized blends and layering techniques to enhance specific properties such as fire resistance, impact absorption, and durability. This ongoing refinement has enabled the creation of increasingly sophisticated safety solutions tailored to diverse occupational hazards.

In recent years, the focus of neoprene integration in safety gear has shifted towards sustainability and enhanced performance. Researchers and manufacturers are exploring bio-based alternatives and recycling processes to reduce the environmental impact of neoprene production. Simultaneously, efforts are being made to improve the material's breathability and reduce weight without compromising its protective qualities.

The primary objectives of neoprene's integration in modern safety gear design are multifaceted. These include enhancing user protection against a broader spectrum of hazards, improving comfort and wearability to encourage consistent use, and developing gear that adapts to varying environmental conditions. Additionally, there is a growing emphasis on creating smart safety gear that incorporates sensors and other technologies, with neoprene serving as a flexible and durable substrate for these innovations.

Looking ahead, the integration of neoprene in safety gear design aims to address emerging challenges such as extreme weather conditions due to climate change and new occupational hazards in evolving industries. The material's adaptability positions it as a key component in developing next-generation safety solutions that can meet increasingly stringent safety standards while accommodating the diverse needs of modern workplaces.

Market Demand Analysis for Neoprene-based Safety Equipment

The market demand for neoprene-based safety equipment has been experiencing significant growth in recent years, driven by increasing awareness of workplace safety and stringent regulations across various industries. Neoprene, a synthetic rubber known for its excellent chemical resistance, flexibility, and durability, has become a key material in the design and manufacture of modern safety gear.

In the industrial sector, the demand for neoprene-based safety equipment is particularly strong. Industries such as oil and gas, chemical manufacturing, and construction require protective gear that can withstand harsh environments and exposure to hazardous substances. Neoprene gloves, aprons, and boots have become essential in these sectors, offering workers protection against chemicals, acids, and other corrosive materials.

The automotive industry has also contributed to the growing demand for neoprene safety equipment. As vehicle production and maintenance processes involve exposure to various chemicals and lubricants, neoprene-based protective gear has become standard in many automotive workshops and manufacturing facilities.

In the healthcare sector, the COVID-19 pandemic has further accelerated the demand for neoprene-based personal protective equipment (PPE). Neoprene face masks and gloves have gained popularity due to their comfort, durability, and ability to provide an effective barrier against pathogens.

The sports and outdoor recreation market has also seen an uptick in demand for neoprene-based safety gear. Wetsuits, life vests, and protective padding made from neoprene are widely used in water sports, skiing, and other high-impact activities, offering both protection and thermal insulation.

Environmental concerns and sustainability initiatives have led to the development of eco-friendly neoprene alternatives, which are gaining traction in the market. These materials aim to maintain the protective properties of traditional neoprene while reducing environmental impact, appealing to environmentally conscious consumers and businesses.

The global market for neoprene-based safety equipment is expected to continue its growth trajectory in the coming years. Factors such as increasing industrialization in developing countries, growing emphasis on workplace safety, and the expansion of extreme sports and outdoor activities are likely to drive demand. Additionally, ongoing research and development efforts to enhance the performance and sustainability of neoprene-based materials are expected to open up new market opportunities and applications in the safety gear industry.

In the industrial sector, the demand for neoprene-based safety equipment is particularly strong. Industries such as oil and gas, chemical manufacturing, and construction require protective gear that can withstand harsh environments and exposure to hazardous substances. Neoprene gloves, aprons, and boots have become essential in these sectors, offering workers protection against chemicals, acids, and other corrosive materials.

The automotive industry has also contributed to the growing demand for neoprene safety equipment. As vehicle production and maintenance processes involve exposure to various chemicals and lubricants, neoprene-based protective gear has become standard in many automotive workshops and manufacturing facilities.

In the healthcare sector, the COVID-19 pandemic has further accelerated the demand for neoprene-based personal protective equipment (PPE). Neoprene face masks and gloves have gained popularity due to their comfort, durability, and ability to provide an effective barrier against pathogens.

The sports and outdoor recreation market has also seen an uptick in demand for neoprene-based safety gear. Wetsuits, life vests, and protective padding made from neoprene are widely used in water sports, skiing, and other high-impact activities, offering both protection and thermal insulation.

Environmental concerns and sustainability initiatives have led to the development of eco-friendly neoprene alternatives, which are gaining traction in the market. These materials aim to maintain the protective properties of traditional neoprene while reducing environmental impact, appealing to environmentally conscious consumers and businesses.

The global market for neoprene-based safety equipment is expected to continue its growth trajectory in the coming years. Factors such as increasing industrialization in developing countries, growing emphasis on workplace safety, and the expansion of extreme sports and outdoor activities are likely to drive demand. Additionally, ongoing research and development efforts to enhance the performance and sustainability of neoprene-based materials are expected to open up new market opportunities and applications in the safety gear industry.

Current Challenges in Neoprene Safety Gear Integration

The integration of neoprene in modern safety gear design faces several significant challenges that require innovative solutions. One of the primary obstacles is achieving optimal balance between flexibility and protection. While neoprene offers excellent shock absorption and insulation properties, it can become rigid and restrictive when used in thicker layers, potentially limiting user mobility and comfort.

Another challenge lies in the material's durability under extreme conditions. Although neoprene is known for its resistance to weathering and chemicals, prolonged exposure to harsh environments can lead to degradation, compromising the gear's protective qualities over time. This necessitates the development of advanced neoprene composites or treatment processes to enhance longevity without sacrificing performance.

Heat management presents a further hurdle in neoprene-based safety gear. The material's insulating properties, while beneficial in cold environments, can lead to overheating and discomfort in warmer conditions or during intense physical activity. Addressing this issue requires innovative design approaches, such as incorporating ventilation systems or developing neoprene variants with improved breathability.

The manufacturing process of neoprene safety gear also poses challenges. Achieving consistent quality across large production runs can be difficult, particularly when creating complex, multi-layered designs. Ensuring uniform thickness, density, and performance characteristics throughout the gear demands precise control over production parameters and advanced quality assurance measures.

Environmental concerns represent another significant challenge in neoprene integration. Traditional neoprene production involves petroleum-based processes and chemicals that can have negative environmental impacts. The industry is under pressure to develop more sustainable manufacturing methods and explore eco-friendly alternatives that maintain the material's protective properties.

Customization and fit present ongoing challenges in safety gear design. Given the diverse body types and specific requirements of different industries, creating neoprene-based gear that offers a universally comfortable and effective fit is complex. This necessitates advancements in 3D modeling, custom fabrication techniques, and adaptive design strategies to ensure optimal protection for all users.

Lastly, the integration of smart technologies with neoprene safety gear introduces new challenges. Incorporating sensors, communication devices, or other electronic components while maintaining the gear's protective integrity and flexibility requires innovative material science and design approaches. Ensuring these technologies function reliably in the often harsh environments where safety gear is used adds another layer of complexity to the integration process.

Another challenge lies in the material's durability under extreme conditions. Although neoprene is known for its resistance to weathering and chemicals, prolonged exposure to harsh environments can lead to degradation, compromising the gear's protective qualities over time. This necessitates the development of advanced neoprene composites or treatment processes to enhance longevity without sacrificing performance.

Heat management presents a further hurdle in neoprene-based safety gear. The material's insulating properties, while beneficial in cold environments, can lead to overheating and discomfort in warmer conditions or during intense physical activity. Addressing this issue requires innovative design approaches, such as incorporating ventilation systems or developing neoprene variants with improved breathability.

The manufacturing process of neoprene safety gear also poses challenges. Achieving consistent quality across large production runs can be difficult, particularly when creating complex, multi-layered designs. Ensuring uniform thickness, density, and performance characteristics throughout the gear demands precise control over production parameters and advanced quality assurance measures.

Environmental concerns represent another significant challenge in neoprene integration. Traditional neoprene production involves petroleum-based processes and chemicals that can have negative environmental impacts. The industry is under pressure to develop more sustainable manufacturing methods and explore eco-friendly alternatives that maintain the material's protective properties.

Customization and fit present ongoing challenges in safety gear design. Given the diverse body types and specific requirements of different industries, creating neoprene-based gear that offers a universally comfortable and effective fit is complex. This necessitates advancements in 3D modeling, custom fabrication techniques, and adaptive design strategies to ensure optimal protection for all users.

Lastly, the integration of smart technologies with neoprene safety gear introduces new challenges. Incorporating sensors, communication devices, or other electronic components while maintaining the gear's protective integrity and flexibility requires innovative material science and design approaches. Ensuring these technologies function reliably in the often harsh environments where safety gear is used adds another layer of complexity to the integration process.

Existing Neoprene Integration Solutions in Safety Gear

01 Composition and synthesis of neoprene

Neoprene is a synthetic rubber produced by polymerization of chloroprene. It has various compositions and methods of synthesis, including emulsion polymerization and solution polymerization techniques. The process often involves the use of catalysts and stabilizers to control the polymer structure and properties.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. It is known for its resistance to oil, heat, and weathering. The manufacturing process involves careful control of reaction conditions and may include various additives to enhance specific properties.

- Applications of neoprene in protective gear: Neoprene is widely used in the production of protective gear such as wetsuits, diving suits, and other water-resistant clothing. Its flexibility, insulation properties, and durability make it ideal for these applications. Neoprene can be combined with other materials to enhance its performance in specific use cases.

- Neoprene foam and cellular structures: Neoprene can be processed into foam or cellular structures, which are useful in various applications requiring cushioning, insulation, or buoyancy. The production of neoprene foam involves the use of blowing agents and specific processing techniques to achieve the desired cellular structure.

- Neoprene in adhesives and sealants: Neoprene-based adhesives and sealants are valued for their strong bonding properties, resistance to chemicals, and durability. These products are used in various industries, including construction, automotive, and aerospace. Formulations may include additional components to enhance specific properties such as tack or curing speed.

- Modifications and blends of neoprene: Neoprene can be modified or blended with other polymers to enhance its properties or create materials with specific characteristics. This includes chemical modifications, physical blending, or the creation of composite materials. Such modifications can improve properties like flame resistance, electrical insulation, or compatibility with other materials.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear due to its excellent insulation and flexibility properties. It is commonly used in wetsuits, diving suits, and other water-resistant clothing. Neoprene-based materials are also used in safety equipment and protective padding for various sports and industrial applications.Expand Specific Solutions03 Neoprene foam production and properties

Neoprene foam is a versatile material with closed-cell structure, providing excellent insulation and buoyancy. The production process involves the use of blowing agents and specific curing conditions to create the foam structure. Neoprene foam finds applications in various industries, including automotive, construction, and marine sectors.Expand Specific Solutions04 Neoprene adhesives and sealants

Neoprene-based adhesives and sealants offer strong bonding capabilities and resistance to various environmental factors. These products are formulated with specific additives to enhance their adhesion, flexibility, and durability. They are widely used in construction, automotive, and industrial applications for bonding and sealing purposes.Expand Specific Solutions05 Modifications and blends of neoprene

Neoprene can be modified or blended with other polymers to enhance its properties or create specialized materials. These modifications can improve characteristics such as heat resistance, chemical resistance, or mechanical properties. Blending neoprene with other elastomers or incorporating additives allows for the development of materials tailored for specific applications.Expand Specific Solutions

Key Players in Neoprene Safety Gear Industry

The integration of neoprene in modern safety gear design is at a mature stage, with a well-established market and diverse applications. The global neoprene market size is projected to reach significant growth in the coming years, driven by increasing demand in various industries. Companies like DuPont de Nemours, Inc. and Tianjin Pengling Group Co. Ltd. are leading players in this field, leveraging their extensive research and development capabilities to innovate and improve neoprene-based safety gear. The technology has evolved to offer enhanced protection, flexibility, and durability, making it a preferred material in personal protective equipment. Emerging players such as Zhuzhou Times New Materials Technology Co., Ltd. and Global Graphene Group, Inc. are exploring advanced applications, potentially revolutionizing the safety gear landscape with novel neoprene composites and nanotechnology integrations.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced neoprene formulations for modern safety gear, focusing on improved flexibility and durability. Their Neoprene XP technology offers enhanced resistance to oils, fuels, and chemicals, making it ideal for protective gloves and clothing in industrial settings[1]. DuPont's neoprene compounds also feature improved tear strength and abrasion resistance, crucial for high-performance safety equipment. The company has integrated neoprene with other materials like Kevlar to create hybrid fabrics that combine the chemical resistance of neoprene with the cut-resistance of aramid fibers[2]. This synergy has resulted in safety gear that offers multi-hazard protection, addressing the complex needs of modern workplaces.

Strengths: Extensive R&D capabilities, wide range of neoprene formulations for specific applications, strong brand recognition in safety materials. Weaknesses: Higher cost compared to some competitors, potential environmental concerns related to neoprene production.

Denka Corp.

Technical Solution: Denka Corporation has made significant strides in neoprene technology for safety applications, particularly in the development of high-performance chloroprene rubber (CR) materials. Their Denka Chloroprene series offers a range of neoprene compounds tailored for specific safety gear requirements, including excellent oil and weather resistance[7]. Denka's research has focused on improving the heat resistance and flame-retardant properties of neoprene, making it suitable for firefighting gear and other high-risk environments. The company has also developed neoprene formulations with enhanced dynamic properties, crucial for safety equipment that requires flexibility and durability under stress, such as protective suits and gloves for industrial use[8].

Strengths: Extensive experience in chloroprene rubber production, diverse range of neoprene compounds for various applications, strong presence in Asian markets. Weaknesses: Less brand recognition in Western markets compared to some competitors, potential challenges in global distribution.

Innovative Neoprene Applications in Safety Equipment

Safety gear

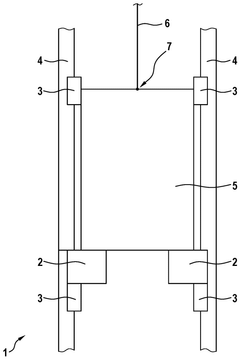

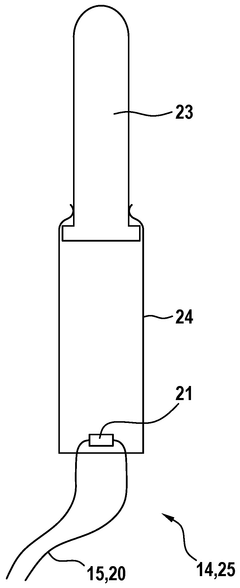

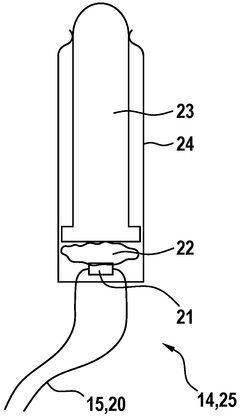

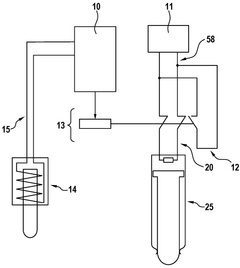

PatentWO2025119764A1

Innovation

- A braking system with a pyrotechnic second actuator and an emergency release mechanism that allows safe triggering of the safety gear during power failures, and automatically resets without service intervention after power restoration.

Environmental Impact of Neoprene in Safety Equipment

The environmental impact of neoprene in safety equipment is a critical consideration in modern gear design. Neoprene, a synthetic rubber, has been widely used in various safety applications due to its durability, flexibility, and resistance to water and chemicals. However, its production and disposal processes raise significant environmental concerns.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and energy consumption. The production process releases chloroprene, a potentially harmful compound, into the atmosphere. This not only affects air quality but also poses risks to workers and nearby communities.

Water pollution is another environmental issue associated with neoprene production. The manufacturing process generates wastewater containing toxic chemicals, which, if not properly treated, can contaminate local water sources. This pollution can have far-reaching effects on aquatic ecosystems and human health.

The disposal of neoprene-based safety equipment presents additional environmental challenges. Neoprene is not biodegradable, meaning it persists in landfills for extended periods. When incinerated, it releases harmful chemicals, including hydrogen chloride, which can contribute to acid rain and air pollution.

Recycling neoprene is possible but often complex and energy-intensive. The material needs to be separated from other components in safety gear, which can be a labor-intensive process. Additionally, the quality of recycled neoprene may not always meet the high standards required for safety equipment.

The long-term environmental impact of neoprene in marine environments is particularly concerning. As safety gear deteriorates, microparticles of neoprene can enter water systems, potentially harming marine life and entering the food chain. This issue is especially relevant for water-based safety equipment.

In response to these environmental concerns, there is a growing trend towards developing more sustainable alternatives to neoprene in safety gear design. Bio-based materials and recycled fabrics are being explored as potential substitutes. These alternatives aim to maintain the protective properties of neoprene while reducing the environmental footprint.

Manufacturers are also focusing on improving the production processes of neoprene to minimize environmental impact. This includes implementing more efficient waste management systems, reducing energy consumption, and exploring cleaner production technologies. Some companies are adopting closed-loop manufacturing systems to recycle and reuse materials, thereby reducing waste and resource consumption.

The integration of lifecycle assessment (LCA) in safety gear design is becoming increasingly important. LCA helps in evaluating the environmental impact of neoprene-based products from production to disposal, enabling manufacturers to make more informed decisions about material selection and design processes.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which contribute to greenhouse gas emissions and energy consumption. The production process releases chloroprene, a potentially harmful compound, into the atmosphere. This not only affects air quality but also poses risks to workers and nearby communities.

Water pollution is another environmental issue associated with neoprene production. The manufacturing process generates wastewater containing toxic chemicals, which, if not properly treated, can contaminate local water sources. This pollution can have far-reaching effects on aquatic ecosystems and human health.

The disposal of neoprene-based safety equipment presents additional environmental challenges. Neoprene is not biodegradable, meaning it persists in landfills for extended periods. When incinerated, it releases harmful chemicals, including hydrogen chloride, which can contribute to acid rain and air pollution.

Recycling neoprene is possible but often complex and energy-intensive. The material needs to be separated from other components in safety gear, which can be a labor-intensive process. Additionally, the quality of recycled neoprene may not always meet the high standards required for safety equipment.

The long-term environmental impact of neoprene in marine environments is particularly concerning. As safety gear deteriorates, microparticles of neoprene can enter water systems, potentially harming marine life and entering the food chain. This issue is especially relevant for water-based safety equipment.

In response to these environmental concerns, there is a growing trend towards developing more sustainable alternatives to neoprene in safety gear design. Bio-based materials and recycled fabrics are being explored as potential substitutes. These alternatives aim to maintain the protective properties of neoprene while reducing the environmental footprint.

Manufacturers are also focusing on improving the production processes of neoprene to minimize environmental impact. This includes implementing more efficient waste management systems, reducing energy consumption, and exploring cleaner production technologies. Some companies are adopting closed-loop manufacturing systems to recycle and reuse materials, thereby reducing waste and resource consumption.

The integration of lifecycle assessment (LCA) in safety gear design is becoming increasingly important. LCA helps in evaluating the environmental impact of neoprene-based products from production to disposal, enabling manufacturers to make more informed decisions about material selection and design processes.

Regulatory Standards for Neoprene-based Safety Gear

The regulatory landscape for neoprene-based safety gear is complex and multifaceted, reflecting the diverse applications of this versatile material in personal protective equipment (PPE). Regulatory bodies across different regions have established stringent standards to ensure the safety and efficacy of neoprene-integrated gear.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth guidelines for neoprene-based safety equipment in various industries. These standards encompass chemical resistance, durability, and performance under different environmental conditions. The National Institute for Occupational Safety and Health (NIOSH) also plays a crucial role in testing and certifying neoprene-based respirators and other protective gear.

The European Union has implemented the Personal Protective Equipment Regulation (EU) 2016/425, which outlines specific requirements for neoprene-based safety gear. This regulation categorizes PPE into three risk levels, with neoprene products often falling into Category II or III, requiring rigorous testing and conformity assessment procedures.

In the maritime sector, the International Maritime Organization (IMO) has established the International Convention for the Safety of Life at Sea (SOLAS), which includes provisions for neoprene-based immersion suits and other safety equipment. These standards focus on thermal protection, buoyancy, and durability in harsh marine environments.

The automotive industry adheres to standards set by organizations such as the Society of Automotive Engineers (SAE) for neoprene-based components in vehicle safety systems. These standards address issues like flame resistance, chemical compatibility, and performance under extreme temperatures.

For firefighting and emergency response applications, the National Fire Protection Association (NFPA) in the United States has developed specific standards for neoprene-based protective gear. These include NFPA 1971 for structural firefighting protective ensembles and NFPA 1992 for liquid splash-protective ensembles.

In the sports and recreation sector, organizations like the American Society for Testing and Materials (ASTM) have established standards for neoprene-based protective gear such as wetsuits and impact-resistant padding. These standards focus on factors like thermal insulation, flexibility, and impact absorption.

Globally, the International Organization for Standardization (ISO) has developed several standards relevant to neoprene-based safety gear, including ISO 16602 for protective clothing against chemicals and ISO 12402 for personal flotation devices. These standards provide a framework for consistent quality and performance across international markets.

As technology and manufacturing processes evolve, regulatory bodies continually update their standards to address new applications and potential risks associated with neoprene-based safety gear. This ongoing process ensures that safety equipment remains effective and reliable in protecting users across various industries and environments.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth guidelines for neoprene-based safety equipment in various industries. These standards encompass chemical resistance, durability, and performance under different environmental conditions. The National Institute for Occupational Safety and Health (NIOSH) also plays a crucial role in testing and certifying neoprene-based respirators and other protective gear.

The European Union has implemented the Personal Protective Equipment Regulation (EU) 2016/425, which outlines specific requirements for neoprene-based safety gear. This regulation categorizes PPE into three risk levels, with neoprene products often falling into Category II or III, requiring rigorous testing and conformity assessment procedures.

In the maritime sector, the International Maritime Organization (IMO) has established the International Convention for the Safety of Life at Sea (SOLAS), which includes provisions for neoprene-based immersion suits and other safety equipment. These standards focus on thermal protection, buoyancy, and durability in harsh marine environments.

The automotive industry adheres to standards set by organizations such as the Society of Automotive Engineers (SAE) for neoprene-based components in vehicle safety systems. These standards address issues like flame resistance, chemical compatibility, and performance under extreme temperatures.

For firefighting and emergency response applications, the National Fire Protection Association (NFPA) in the United States has developed specific standards for neoprene-based protective gear. These include NFPA 1971 for structural firefighting protective ensembles and NFPA 1992 for liquid splash-protective ensembles.

In the sports and recreation sector, organizations like the American Society for Testing and Materials (ASTM) have established standards for neoprene-based protective gear such as wetsuits and impact-resistant padding. These standards focus on factors like thermal insulation, flexibility, and impact absorption.

Globally, the International Organization for Standardization (ISO) has developed several standards relevant to neoprene-based safety gear, including ISO 16602 for protective clothing against chemicals and ISO 12402 for personal flotation devices. These standards provide a framework for consistent quality and performance across international markets.

As technology and manufacturing processes evolve, regulatory bodies continually update their standards to address new applications and potential risks associated with neoprene-based safety gear. This ongoing process ensures that safety equipment remains effective and reliable in protecting users across various industries and environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!