How Neoprene Contributes to Maritime Safety Innovations?

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene in Maritime Safety: Evolution and Objectives

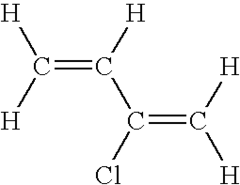

Neoprene, a synthetic rubber developed in the 1930s, has played a pivotal role in maritime safety innovations over the past century. Initially created as an oil-resistant alternative to natural rubber, neoprene's unique properties quickly found applications in various industries, including maritime safety. The evolution of neoprene in this field has been driven by the increasing demands for more effective and reliable safety equipment in marine environments.

The primary objective of neoprene in maritime safety has been to enhance the protection and survival chances of individuals in aquatic settings. This goal has led to continuous improvements in the material's properties and applications. From its early use in wetsuits and life vests to more advanced implementations in modern survival suits and inflatable life rafts, neoprene has consistently demonstrated its value in safeguarding lives at sea.

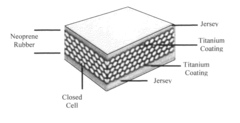

One of the key factors contributing to neoprene's success in maritime safety is its excellent insulation properties. The material's closed-cell structure traps air, providing buoyancy and thermal insulation, which are crucial for survival in cold water environments. This characteristic has been particularly important in the development of immersion suits and other protective gear designed to prevent hypothermia in emergency situations.

Another significant aspect of neoprene's evolution in maritime safety is its durability and resistance to harsh marine conditions. The material's ability to withstand prolonged exposure to saltwater, UV radiation, and extreme temperatures has made it an ideal choice for a wide range of safety equipment. Over time, researchers and manufacturers have worked to enhance these properties, resulting in more robust and long-lasting safety gear.

The ongoing development of neoprene technology aims to address several key objectives in maritime safety. These include improving the material's flexibility and comfort without compromising its protective qualities, enhancing its visibility in water through the incorporation of high-visibility colors or reflective elements, and increasing its resistance to fire and chemical exposure. Additionally, there is a growing focus on developing more environmentally friendly production methods and exploring biodegradable alternatives to traditional neoprene, aligning with the maritime industry's increasing emphasis on sustainability.

As maritime activities continue to expand and diversify, the role of neoprene in safety innovations is expected to evolve further. Future objectives may include the integration of smart technologies into neoprene-based safety equipment, such as embedded sensors for vital sign monitoring or location tracking, further improving the chances of survival and rescue in emergency situations at sea.

The primary objective of neoprene in maritime safety has been to enhance the protection and survival chances of individuals in aquatic settings. This goal has led to continuous improvements in the material's properties and applications. From its early use in wetsuits and life vests to more advanced implementations in modern survival suits and inflatable life rafts, neoprene has consistently demonstrated its value in safeguarding lives at sea.

One of the key factors contributing to neoprene's success in maritime safety is its excellent insulation properties. The material's closed-cell structure traps air, providing buoyancy and thermal insulation, which are crucial for survival in cold water environments. This characteristic has been particularly important in the development of immersion suits and other protective gear designed to prevent hypothermia in emergency situations.

Another significant aspect of neoprene's evolution in maritime safety is its durability and resistance to harsh marine conditions. The material's ability to withstand prolonged exposure to saltwater, UV radiation, and extreme temperatures has made it an ideal choice for a wide range of safety equipment. Over time, researchers and manufacturers have worked to enhance these properties, resulting in more robust and long-lasting safety gear.

The ongoing development of neoprene technology aims to address several key objectives in maritime safety. These include improving the material's flexibility and comfort without compromising its protective qualities, enhancing its visibility in water through the incorporation of high-visibility colors or reflective elements, and increasing its resistance to fire and chemical exposure. Additionally, there is a growing focus on developing more environmentally friendly production methods and exploring biodegradable alternatives to traditional neoprene, aligning with the maritime industry's increasing emphasis on sustainability.

As maritime activities continue to expand and diversify, the role of neoprene in safety innovations is expected to evolve further. Future objectives may include the integration of smart technologies into neoprene-based safety equipment, such as embedded sensors for vital sign monitoring or location tracking, further improving the chances of survival and rescue in emergency situations at sea.

Market Analysis: Maritime Safety Equipment Demand

The maritime safety equipment market has been experiencing significant growth in recent years, driven by increasing awareness of safety measures, stringent regulations, and the expansion of maritime trade. The demand for neoprene-based safety innovations is particularly noteworthy within this sector, as the material's unique properties make it well-suited for various maritime applications.

Global maritime safety equipment market size was valued at approximately $3.2 billion in 2020 and is projected to reach $4.8 billion by 2027, growing at a CAGR of 6.2% during the forecast period. This growth is attributed to the rising number of maritime accidents, increased focus on crew safety, and the implementation of international safety standards by regulatory bodies such as the International Maritime Organization (IMO).

Neoprene, a synthetic rubber with excellent resistance to water, oil, and weathering, has become a crucial component in many maritime safety innovations. The material's flexibility, durability, and insulating properties make it ideal for use in life jackets, survival suits, and other personal protective equipment (PPE) designed for marine environments.

The demand for neoprene-based safety equipment is particularly strong in regions with high maritime activity, such as Asia-Pacific, Europe, and North America. These regions account for over 70% of the global maritime safety equipment market, with Asia-Pacific leading the growth due to its bustling shipping industry and increasing investments in offshore oil and gas exploration.

Key market segments driving the demand for neoprene-based maritime safety innovations include commercial shipping, offshore oil and gas, fishing, and recreational boating. The commercial shipping sector, which includes container ships, tankers, and bulk carriers, represents the largest market segment, accounting for approximately 40% of the total demand for maritime safety equipment.

The offshore oil and gas industry is another significant contributor to the demand for neoprene-based safety innovations. As exploration and production activities move into deeper waters and more challenging environments, the need for advanced safety equipment becomes increasingly critical. This sector is expected to grow at a CAGR of 7.5% through 2027, outpacing the overall market growth.

Technological advancements and product innovations are driving the adoption of neoprene-based safety equipment. Manufacturers are developing new formulations of neoprene that offer enhanced performance characteristics, such as improved buoyancy, thermal insulation, and fire resistance. These innovations are expanding the applications of neoprene in maritime safety and contributing to market growth.

The COVID-19 pandemic has had a mixed impact on the maritime safety equipment market. While it initially disrupted supply chains and slowed down market growth, it has also heightened awareness of safety measures and hygiene protocols in maritime operations. This increased focus on safety is expected to drive long-term demand for advanced safety equipment, including neoprene-based innovations.

Global maritime safety equipment market size was valued at approximately $3.2 billion in 2020 and is projected to reach $4.8 billion by 2027, growing at a CAGR of 6.2% during the forecast period. This growth is attributed to the rising number of maritime accidents, increased focus on crew safety, and the implementation of international safety standards by regulatory bodies such as the International Maritime Organization (IMO).

Neoprene, a synthetic rubber with excellent resistance to water, oil, and weathering, has become a crucial component in many maritime safety innovations. The material's flexibility, durability, and insulating properties make it ideal for use in life jackets, survival suits, and other personal protective equipment (PPE) designed for marine environments.

The demand for neoprene-based safety equipment is particularly strong in regions with high maritime activity, such as Asia-Pacific, Europe, and North America. These regions account for over 70% of the global maritime safety equipment market, with Asia-Pacific leading the growth due to its bustling shipping industry and increasing investments in offshore oil and gas exploration.

Key market segments driving the demand for neoprene-based maritime safety innovations include commercial shipping, offshore oil and gas, fishing, and recreational boating. The commercial shipping sector, which includes container ships, tankers, and bulk carriers, represents the largest market segment, accounting for approximately 40% of the total demand for maritime safety equipment.

The offshore oil and gas industry is another significant contributor to the demand for neoprene-based safety innovations. As exploration and production activities move into deeper waters and more challenging environments, the need for advanced safety equipment becomes increasingly critical. This sector is expected to grow at a CAGR of 7.5% through 2027, outpacing the overall market growth.

Technological advancements and product innovations are driving the adoption of neoprene-based safety equipment. Manufacturers are developing new formulations of neoprene that offer enhanced performance characteristics, such as improved buoyancy, thermal insulation, and fire resistance. These innovations are expanding the applications of neoprene in maritime safety and contributing to market growth.

The COVID-19 pandemic has had a mixed impact on the maritime safety equipment market. While it initially disrupted supply chains and slowed down market growth, it has also heightened awareness of safety measures and hygiene protocols in maritime operations. This increased focus on safety is expected to drive long-term demand for advanced safety equipment, including neoprene-based innovations.

Neoprene Technology: Current State and Challenges

Neoprene, a synthetic rubber developed in the 1930s, has become a cornerstone material in maritime safety innovations. The current state of neoprene technology in maritime applications is characterized by its versatility, durability, and adaptability to harsh marine environments. Its unique properties, including excellent water resistance, thermal insulation, and flexibility, have made it an indispensable component in various safety equipment and protective gear used at sea.

One of the primary challenges facing neoprene technology in maritime safety is the need for continuous improvement in its performance under extreme conditions. As maritime operations extend into more challenging environments, such as deep-sea exploration and Arctic waters, neoprene must evolve to withstand higher pressures, lower temperatures, and prolonged exposure to corrosive elements. Researchers are actively working on enhancing neoprene's molecular structure to improve its resilience and longevity in these demanding scenarios.

Another significant challenge is the balance between neoprene's protective qualities and user comfort. While neoprene offers excellent insulation and buoyancy, prolonged use in maritime safety gear can lead to heat stress and reduced mobility. Innovations are focused on developing neoprene variants that provide optimal protection while minimizing these drawbacks, such as incorporating breathable layers or utilizing advanced manufacturing techniques to create more ergonomic designs.

Environmental concerns also pose a challenge to neoprene technology. As the maritime industry increasingly emphasizes sustainability, there is growing pressure to develop eco-friendly alternatives or improve the recyclability of neoprene products. This has led to research into bio-based neoprene substitutes and more efficient recycling processes for end-of-life neoprene equipment.

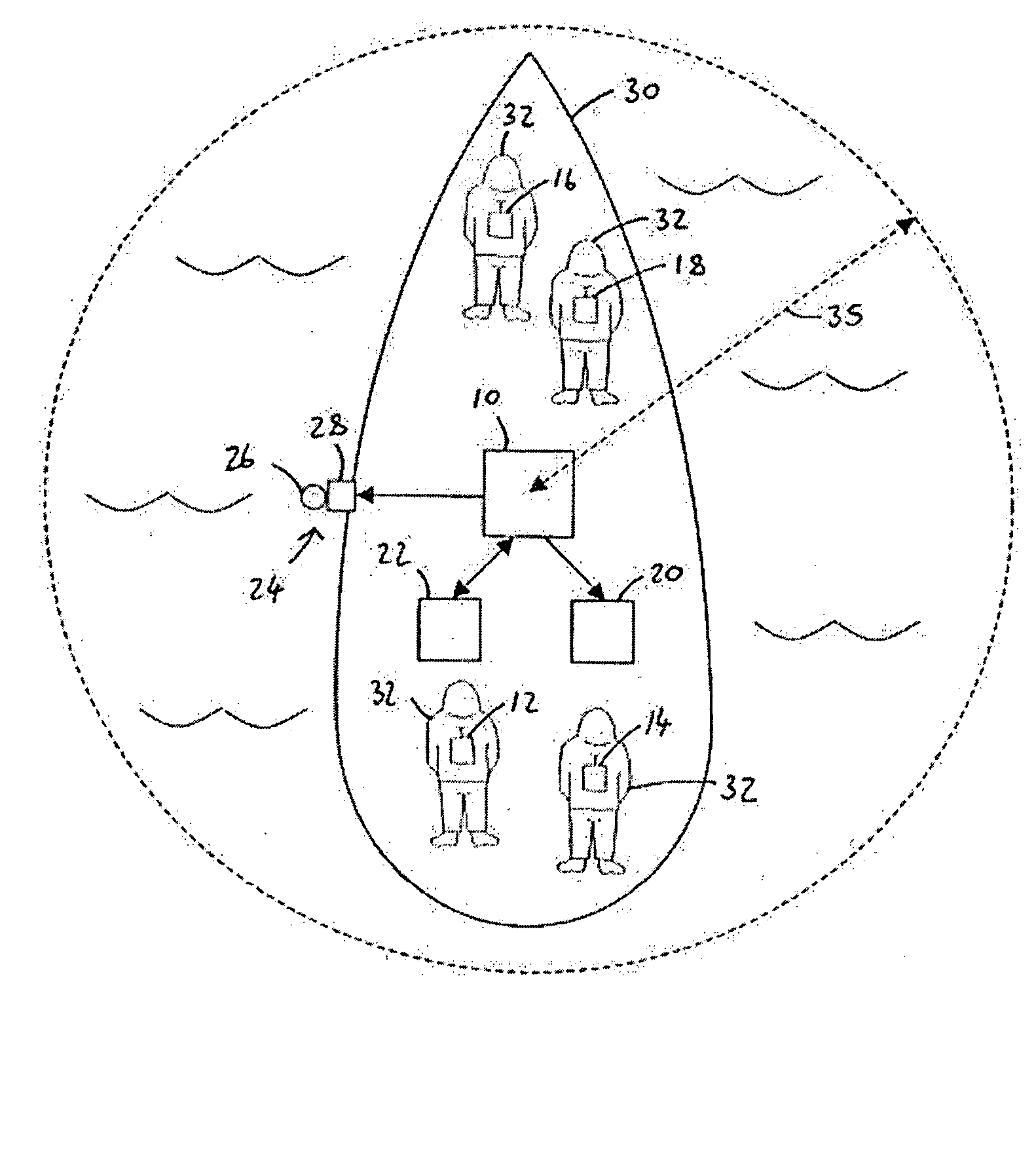

The integration of smart technologies with neoprene is an emerging trend in maritime safety innovations. Researchers are exploring ways to incorporate sensors, communication devices, and other electronic components into neoprene-based safety gear. This integration aims to enhance real-time monitoring of environmental conditions and the wearer's physiological state, thereby improving overall safety and response capabilities in maritime operations.

Lastly, the standardization and regulatory compliance of neoprene-based safety equipment present ongoing challenges. As maritime safety standards evolve, manufacturers must continuously adapt their neoprene products to meet new requirements while maintaining cost-effectiveness. This necessitates a delicate balance between innovation, compliance, and economic viability in the development and production of neoprene-based maritime safety solutions.

One of the primary challenges facing neoprene technology in maritime safety is the need for continuous improvement in its performance under extreme conditions. As maritime operations extend into more challenging environments, such as deep-sea exploration and Arctic waters, neoprene must evolve to withstand higher pressures, lower temperatures, and prolonged exposure to corrosive elements. Researchers are actively working on enhancing neoprene's molecular structure to improve its resilience and longevity in these demanding scenarios.

Another significant challenge is the balance between neoprene's protective qualities and user comfort. While neoprene offers excellent insulation and buoyancy, prolonged use in maritime safety gear can lead to heat stress and reduced mobility. Innovations are focused on developing neoprene variants that provide optimal protection while minimizing these drawbacks, such as incorporating breathable layers or utilizing advanced manufacturing techniques to create more ergonomic designs.

Environmental concerns also pose a challenge to neoprene technology. As the maritime industry increasingly emphasizes sustainability, there is growing pressure to develop eco-friendly alternatives or improve the recyclability of neoprene products. This has led to research into bio-based neoprene substitutes and more efficient recycling processes for end-of-life neoprene equipment.

The integration of smart technologies with neoprene is an emerging trend in maritime safety innovations. Researchers are exploring ways to incorporate sensors, communication devices, and other electronic components into neoprene-based safety gear. This integration aims to enhance real-time monitoring of environmental conditions and the wearer's physiological state, thereby improving overall safety and response capabilities in maritime operations.

Lastly, the standardization and regulatory compliance of neoprene-based safety equipment present ongoing challenges. As maritime safety standards evolve, manufacturers must continuously adapt their neoprene products to meet new requirements while maintaining cost-effectiveness. This necessitates a delicate balance between innovation, compliance, and economic viability in the development and production of neoprene-based maritime safety solutions.

Current Neoprene Applications in Maritime Safety

01 Composition and synthesis of neoprene

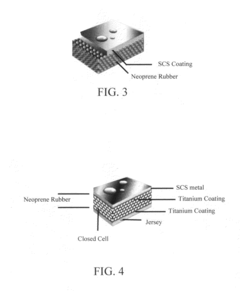

Neoprene is a synthetic rubber produced by polymerization of chloroprene. Various methods and compositions are used to synthesize neoprene with specific properties, including the use of different catalysts, additives, and polymerization techniques.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. It has various compositions and methods of synthesis, including emulsion polymerization and solution polymerization techniques. Different additives and catalysts can be used to modify its properties and improve its performance for specific applications.

- Applications of neoprene in protective gear: Neoprene is widely used in the production of protective gear due to its excellent insulation and flexibility properties. It is commonly used in wetsuits, diving suits, and other water-resistant clothing. Neoprene-based materials are also utilized in safety equipment, gloves, and protective padding for various industries and sports.

- Neoprene foam and cellular structures: Neoprene can be processed into foam or cellular structures, which enhance its insulation and cushioning properties. These foams are used in various applications, including thermal insulation, shock absorption, and sound dampening. Different techniques are employed to create neoprene foams with specific densities and cell structures for targeted uses.

- Neoprene blends and composites: Neoprene can be blended with other materials or used in composite structures to enhance its properties or create specialized materials. These blends and composites may incorporate other elastomers, fibers, or fillers to improve strength, durability, or specific performance characteristics for various industrial and consumer applications.

- Neoprene in adhesives and sealants: Neoprene is used in the formulation of adhesives and sealants due to its excellent bonding properties and resistance to weathering, oils, and chemicals. These neoprene-based adhesives and sealants find applications in construction, automotive, and marine industries, providing strong and durable bonds in various environmental conditions.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear due to its durability, flexibility, and water-resistant properties. It is commonly used in wetsuits, gloves, and other protective equipment for various industries and sports activities.Expand Specific Solutions03 Neoprene foam production and properties

Neoprene foam is produced through various foaming processes, resulting in a closed-cell structure with excellent insulation and cushioning properties. Different techniques are employed to control the foam density, cell size, and overall performance characteristics.Expand Specific Solutions04 Neoprene blends and composites

Neoprene is often blended with other materials or used in composite structures to enhance its properties or create specialized materials. These blends and composites can improve characteristics such as strength, chemical resistance, or thermal stability for specific applications.Expand Specific Solutions05 Testing and quality control of neoprene products

Various testing methods and quality control procedures are employed to ensure the performance and consistency of neoprene products. These include physical property tests, chemical analysis, and durability assessments to meet industry standards and specific application requirements.Expand Specific Solutions

Key Players in Neoprene-based Maritime Safety Solutions

The maritime safety innovations utilizing neoprene are in a growth phase, with an expanding market driven by increasing focus on safety at sea. The global market for maritime safety products is projected to reach significant size in the coming years. Technologically, neoprene applications are advancing, with companies like Tianjin Pengling Group Co. Ltd. and ExxonMobil Chemical Patents, Inc. leading research and development efforts. These firms are exploring new formulations and manufacturing processes to enhance neoprene's performance in maritime environments. Academic institutions such as Beijing University of Chemical Technology and Dalian Maritime University are also contributing to the field through collaborative research projects, further accelerating innovation in this sector.

Denka Corp.

Technical Solution: Denka Corp. has developed advanced neoprene formulations specifically for maritime safety applications. Their neoprene compounds feature enhanced UV resistance and improved flexibility in cold temperatures, crucial for maritime environments[1]. The company has also introduced a new manufacturing process that reduces the environmental impact of neoprene production while maintaining its high-performance characteristics[2]. Denka's neoprene products are used in various maritime safety innovations, including advanced life jackets, survival suits, and inflatable life rafts, providing superior insulation and buoyancy in harsh sea conditions[3].

Strengths: Superior UV and cold temperature resistance, environmentally friendly production process, versatile applications in maritime safety gear. Weaknesses: Potentially higher cost compared to standard neoprene, limited availability in some regions.

Zhik Pty Ltd.

Technical Solution: Zhik Pty Ltd. has pioneered the use of neoprene in high-performance sailing gear, contributing significantly to maritime safety innovations. Their patented Hydromerino neoprene technology combines the insulating properties of neoprene with the moisture-wicking capabilities of merino wool, providing superior comfort and protection in wet conditions[4]. Zhik has also developed a unique neoprene foam structure that enhances buoyancy while maintaining flexibility, crucial for safety gear like life vests and impact protection equipment[5]. The company's neoprene products feature advanced seam-sealing techniques that improve waterproofing and durability in harsh marine environments[6].

Strengths: Innovative neoprene-wool hybrid material, enhanced buoyancy foam structure, advanced seam-sealing techniques. Weaknesses: Primarily focused on high-end sailing gear, potentially limiting broader maritime safety applications.

Innovative Neoprene Technologies for Maritime Use

Anti-microbial compounds used in garments for water based activities

PatentInactiveUS20100205709A1

Innovation

- Incorporating colloidal or nanosized metals such as silver, platinum, palladium, and other metals into the insulation materials to create an antimicrobial barrier that inhibits bacterial and fungal growth, combined with polymers like polychloroprene, Hypalon, and polyurethanes, which are effective in reducing infection risk.

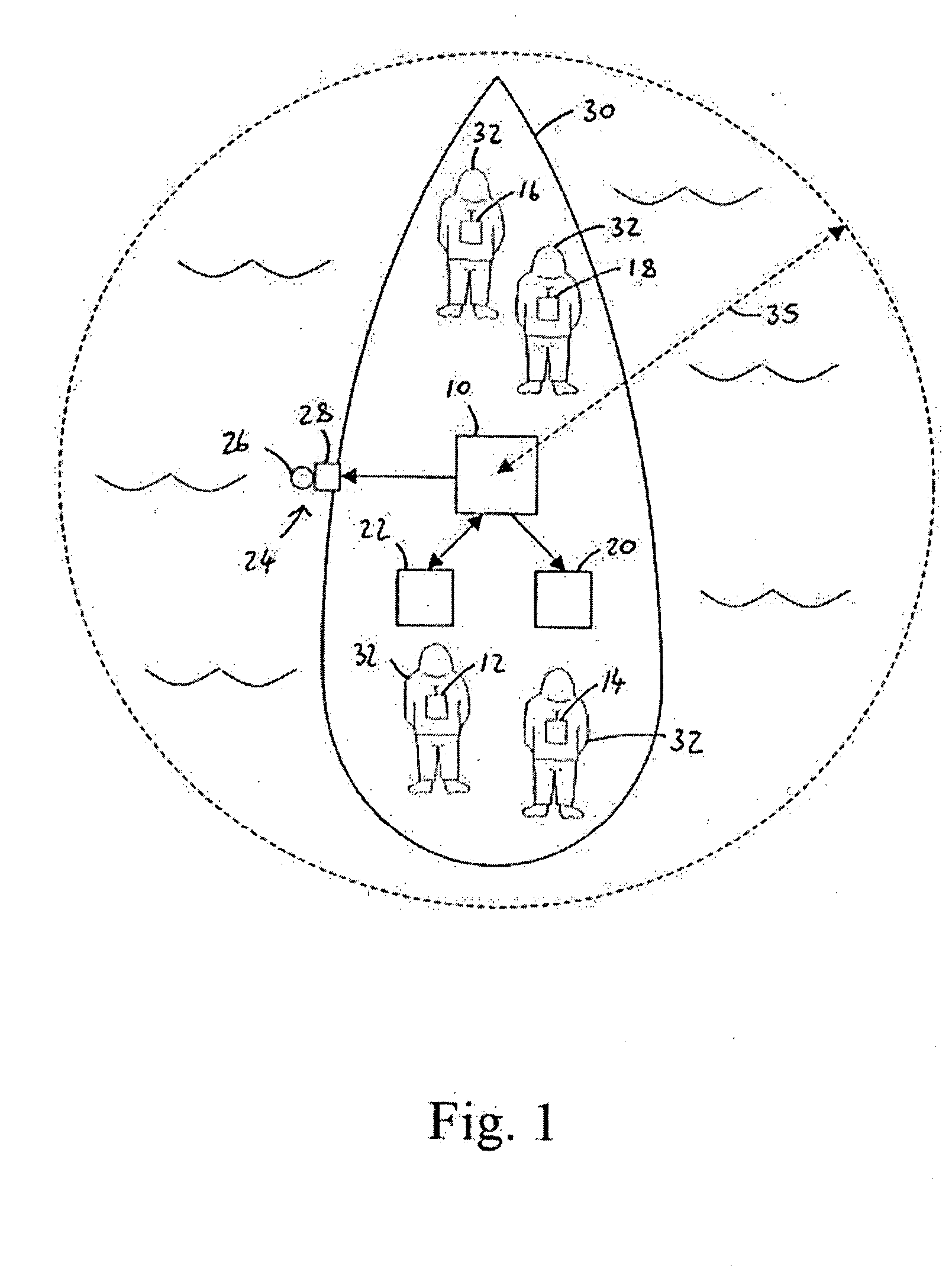

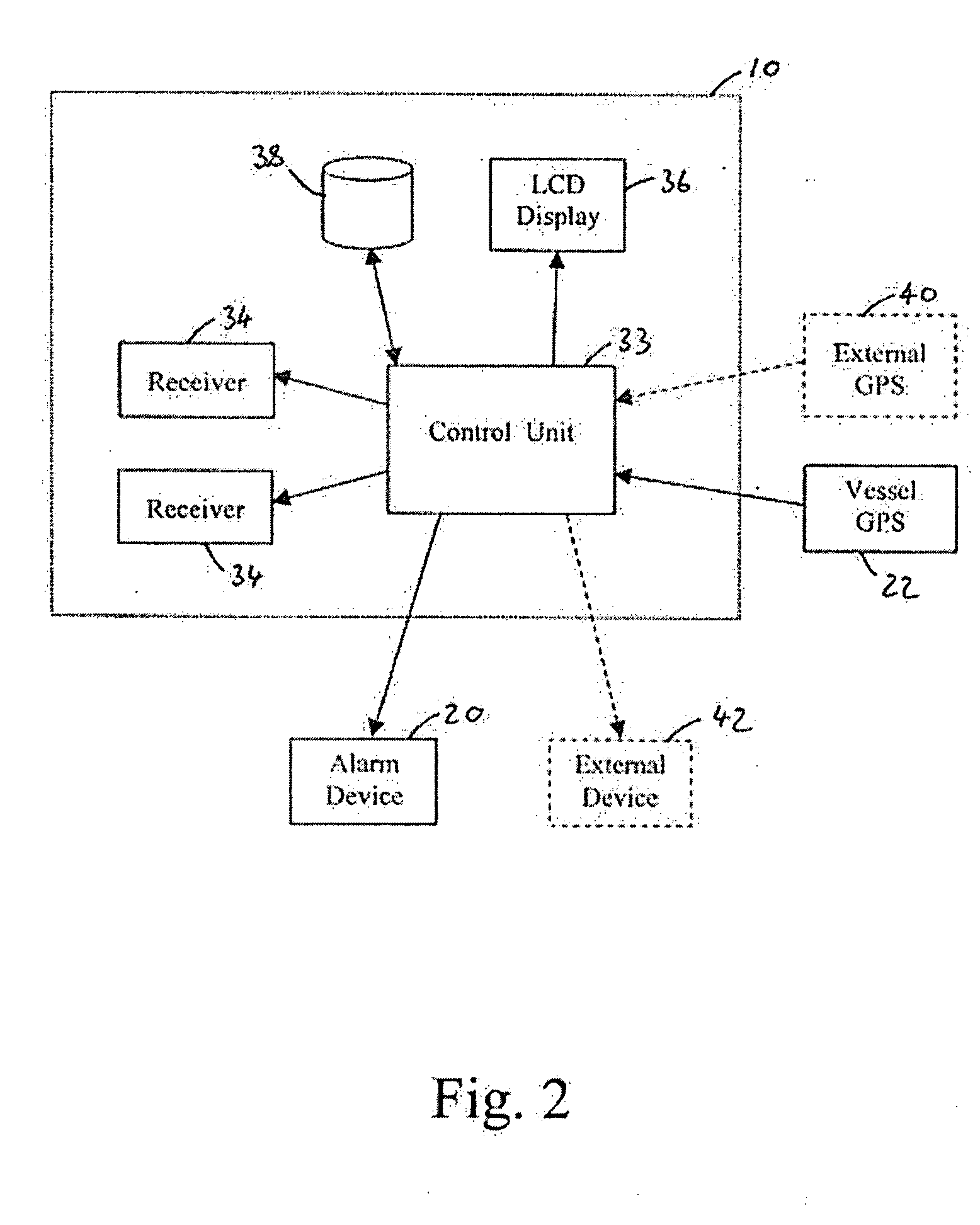

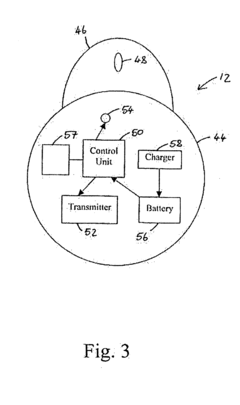

Maritime safety system

PatentInactiveUS20050118905A1

Innovation

- A maritime safety system comprising transmitter units that send pseudo-random wireless signals, a base station to detect these signals, and an alarm device that generates alerts when signals are not received, ensuring prompt notification of potential overboard situations, with features like unique codes, frequency differentiation, and integration with GPS and EPIRB for location and emergency response.

Environmental Impact of Neoprene in Maritime Applications

The environmental impact of neoprene in maritime applications is a critical consideration as the material's widespread use intersects with growing concerns about marine ecosystem health. Neoprene, a synthetic rubber, has become ubiquitous in maritime safety equipment due to its excellent insulation properties and durability. However, its production and disposal processes raise significant environmental questions.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which can contribute to carbon emissions and potential chemical runoff. The production process also requires substantial energy inputs, further increasing its carbon footprint. These factors have led to scrutiny of neoprene's overall environmental sustainability in maritime contexts.

In marine environments, neoprene products such as wetsuits, life jackets, and other safety gear can shed microplastics over time. These tiny particles can enter marine food chains, potentially affecting various aquatic species and ultimately human health. The long-term effects of neoprene-derived microplastics in marine ecosystems are still being studied, but initial research suggests cause for concern.

The disposal of neoprene products at the end of their lifecycle presents another environmental challenge. Neoprene is not biodegradable and can persist in landfills for extended periods. Incineration of neoprene waste can release harmful chemicals into the atmosphere, contributing to air pollution and potentially affecting both marine and terrestrial ecosystems.

Despite these environmental concerns, neoprene continues to play a crucial role in maritime safety innovations. The material's unique properties make it difficult to replace entirely with more environmentally friendly alternatives. This has led to increased research into sustainable production methods and recycling technologies for neoprene.

Some manufacturers are exploring bio-based alternatives to traditional neoprene, using plant-derived materials to reduce reliance on petroleum products. Others are developing advanced recycling techniques to break down used neoprene products and repurpose the materials, creating a more circular economy for maritime safety equipment.

The maritime industry is also adopting strategies to mitigate the environmental impact of neoprene use. These include extending the lifespan of neoprene products through improved design and maintenance, implementing proper disposal and recycling programs, and educating users about the environmental implications of their gear.

As awareness of environmental issues grows, balancing the safety benefits of neoprene with its ecological impact remains a key challenge for the maritime industry. Future innovations in maritime safety will likely focus on developing materials and technologies that maintain or exceed neoprene's performance while significantly reducing environmental footprint.

The manufacturing of neoprene involves the use of petroleum-based chemicals, which can contribute to carbon emissions and potential chemical runoff. The production process also requires substantial energy inputs, further increasing its carbon footprint. These factors have led to scrutiny of neoprene's overall environmental sustainability in maritime contexts.

In marine environments, neoprene products such as wetsuits, life jackets, and other safety gear can shed microplastics over time. These tiny particles can enter marine food chains, potentially affecting various aquatic species and ultimately human health. The long-term effects of neoprene-derived microplastics in marine ecosystems are still being studied, but initial research suggests cause for concern.

The disposal of neoprene products at the end of their lifecycle presents another environmental challenge. Neoprene is not biodegradable and can persist in landfills for extended periods. Incineration of neoprene waste can release harmful chemicals into the atmosphere, contributing to air pollution and potentially affecting both marine and terrestrial ecosystems.

Despite these environmental concerns, neoprene continues to play a crucial role in maritime safety innovations. The material's unique properties make it difficult to replace entirely with more environmentally friendly alternatives. This has led to increased research into sustainable production methods and recycling technologies for neoprene.

Some manufacturers are exploring bio-based alternatives to traditional neoprene, using plant-derived materials to reduce reliance on petroleum products. Others are developing advanced recycling techniques to break down used neoprene products and repurpose the materials, creating a more circular economy for maritime safety equipment.

The maritime industry is also adopting strategies to mitigate the environmental impact of neoprene use. These include extending the lifespan of neoprene products through improved design and maintenance, implementing proper disposal and recycling programs, and educating users about the environmental implications of their gear.

As awareness of environmental issues grows, balancing the safety benefits of neoprene with its ecological impact remains a key challenge for the maritime industry. Future innovations in maritime safety will likely focus on developing materials and technologies that maintain or exceed neoprene's performance while significantly reducing environmental footprint.

Regulatory Framework for Maritime Safety Materials

The regulatory framework for maritime safety materials plays a crucial role in ensuring the safety and reliability of equipment used in marine environments. Neoprene, as a versatile synthetic rubber, is subject to various regulations and standards that govern its use in maritime safety applications.

International maritime organizations, such as the International Maritime Organization (IMO), have established comprehensive guidelines for the use of materials in marine safety equipment. These regulations often specify the required properties of materials, including their resistance to water, UV radiation, and chemical exposure. Neoprene, with its excellent resistance to these factors, often meets or exceeds these requirements.

In the United States, the Coast Guard is responsible for enforcing maritime safety regulations. They have specific standards for personal flotation devices (PFDs) and other safety equipment that incorporate neoprene. These standards outline performance requirements, such as buoyancy retention and durability under various conditions, which neoprene-based products must meet to be approved for use.

The European Union has its own set of regulations, including the Marine Equipment Directive (MED), which sets standards for materials used in maritime safety applications. Neoprene products intended for use in EU waters must comply with these regulations and bear the appropriate certification marks.

Many countries have adopted the International Convention for the Safety of Life at Sea (SOLAS), which includes provisions for life-saving appliances. Neoprene-based products used in these applications must adhere to SOLAS requirements, ensuring their effectiveness in emergency situations.

Regulatory bodies also focus on the environmental impact of materials used in maritime applications. Neoprene manufacturers must comply with regulations regarding the production and disposal of their products to minimize environmental harm. This includes adherence to guidelines on chemical usage and waste management.

As maritime safety technology evolves, regulatory frameworks are continuously updated to incorporate new materials and innovations. Manufacturers working with neoprene must stay informed about these changes and adapt their products accordingly to maintain compliance and ensure the highest levels of safety in maritime environments.

International maritime organizations, such as the International Maritime Organization (IMO), have established comprehensive guidelines for the use of materials in marine safety equipment. These regulations often specify the required properties of materials, including their resistance to water, UV radiation, and chemical exposure. Neoprene, with its excellent resistance to these factors, often meets or exceeds these requirements.

In the United States, the Coast Guard is responsible for enforcing maritime safety regulations. They have specific standards for personal flotation devices (PFDs) and other safety equipment that incorporate neoprene. These standards outline performance requirements, such as buoyancy retention and durability under various conditions, which neoprene-based products must meet to be approved for use.

The European Union has its own set of regulations, including the Marine Equipment Directive (MED), which sets standards for materials used in maritime safety applications. Neoprene products intended for use in EU waters must comply with these regulations and bear the appropriate certification marks.

Many countries have adopted the International Convention for the Safety of Life at Sea (SOLAS), which includes provisions for life-saving appliances. Neoprene-based products used in these applications must adhere to SOLAS requirements, ensuring their effectiveness in emergency situations.

Regulatory bodies also focus on the environmental impact of materials used in maritime applications. Neoprene manufacturers must comply with regulations regarding the production and disposal of their products to minimize environmental harm. This includes adherence to guidelines on chemical usage and waste management.

As maritime safety technology evolves, regulatory frameworks are continuously updated to incorporate new materials and innovations. Manufacturers working with neoprene must stay informed about these changes and adapt their products accordingly to maintain compliance and ensure the highest levels of safety in maritime environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!