Neoprene's Role in Personalized Sports Equipment

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Evolution in Sports

Neoprene, a synthetic rubber material, has played a significant role in the evolution of sports equipment since its invention in 1930. Initially used primarily in wetsuits for water sports, neoprene's unique properties have led to its widespread adoption across various sporting disciplines.

In the 1950s and 1960s, neoprene began to gain traction in the surfing community, revolutionizing wetsuit design. The material's excellent insulation properties, flexibility, and water resistance made it ideal for keeping surfers warm in cold waters. This marked the beginning of neoprene's journey in sports equipment.

The 1970s and 1980s saw neoprene expand into other water sports, such as diving, kayaking, and windsurfing. Its ability to provide thermal insulation while maintaining buoyancy made it an essential component in aquatic sports gear. During this period, manufacturers began experimenting with different thicknesses and compositions to optimize performance for specific activities.

In the 1990s, neoprene's application in sports broadened significantly. It found its way into protective gear for contact sports like football and rugby, offering impact absorption and flexibility. The material's ability to conform to body shapes while providing support led to its use in joint braces and compression garments across various sports.

The early 2000s marked a turning point in neoprene's evolution in sports equipment. Advancements in manufacturing techniques allowed for the creation of more specialized neoprene blends. These innovations improved durability, elasticity, and moisture-wicking properties, making neoprene suitable for a wider range of applications in both water and land-based sports.

In recent years, the focus has shifted towards sustainability and personalization. Manufacturers have developed eco-friendly neoprene alternatives, addressing environmental concerns while maintaining performance. Additionally, the integration of neoprene with other advanced materials and technologies has opened up new possibilities for customized sports equipment.

The latest trend in neoprene's evolution is its role in personalized sports equipment. With the advent of 3D printing and advanced molding techniques, neoprene can now be tailored to individual athletes' body shapes and movement patterns. This customization enhances comfort, performance, and injury prevention across various sports, from swimming to athletics.

In the 1950s and 1960s, neoprene began to gain traction in the surfing community, revolutionizing wetsuit design. The material's excellent insulation properties, flexibility, and water resistance made it ideal for keeping surfers warm in cold waters. This marked the beginning of neoprene's journey in sports equipment.

The 1970s and 1980s saw neoprene expand into other water sports, such as diving, kayaking, and windsurfing. Its ability to provide thermal insulation while maintaining buoyancy made it an essential component in aquatic sports gear. During this period, manufacturers began experimenting with different thicknesses and compositions to optimize performance for specific activities.

In the 1990s, neoprene's application in sports broadened significantly. It found its way into protective gear for contact sports like football and rugby, offering impact absorption and flexibility. The material's ability to conform to body shapes while providing support led to its use in joint braces and compression garments across various sports.

The early 2000s marked a turning point in neoprene's evolution in sports equipment. Advancements in manufacturing techniques allowed for the creation of more specialized neoprene blends. These innovations improved durability, elasticity, and moisture-wicking properties, making neoprene suitable for a wider range of applications in both water and land-based sports.

In recent years, the focus has shifted towards sustainability and personalization. Manufacturers have developed eco-friendly neoprene alternatives, addressing environmental concerns while maintaining performance. Additionally, the integration of neoprene with other advanced materials and technologies has opened up new possibilities for customized sports equipment.

The latest trend in neoprene's evolution is its role in personalized sports equipment. With the advent of 3D printing and advanced molding techniques, neoprene can now be tailored to individual athletes' body shapes and movement patterns. This customization enhances comfort, performance, and injury prevention across various sports, from swimming to athletics.

Market Demand Analysis

The market demand for personalized sports equipment incorporating neoprene has been steadily increasing in recent years. This growth is driven by several factors, including the rising awareness of the importance of proper fit and comfort in sports gear, the growing trend of customization in consumer products, and the unique properties of neoprene that make it ideal for various sporting applications.

Neoprene, a synthetic rubber known for its flexibility, durability, and insulation properties, has found widespread use in sports equipment, particularly in water sports and protective gear. The material's ability to provide cushioning, support, and temperature regulation has made it a popular choice for personalized sports equipment.

In the water sports sector, the demand for custom-fit wetsuits, surfing accessories, and swimming gear utilizing neoprene has seen significant growth. Surfers, divers, and swimmers are increasingly seeking personalized equipment that offers better performance and comfort. This trend has led to the development of advanced 3D body scanning technologies and custom manufacturing processes to create tailor-made neoprene products.

The fitness and training equipment market has also witnessed a surge in demand for personalized neoprene-based products. Items such as customized weightlifting belts, knee sleeves, and compression gear have gained popularity among fitness enthusiasts and professional athletes alike. The ability to provide targeted support and compression while allowing for a full range of motion has made neoprene a preferred material in this segment.

In team sports, there is a growing market for personalized protective gear incorporating neoprene. Custom-fit shoulder pads, shin guards, and impact-absorbing accessories are being developed to cater to individual athletes' needs, enhancing both safety and performance. This trend is particularly evident in high-contact sports such as football, hockey, and lacrosse.

The global sports equipment market, which includes personalized gear, has been expanding at a steady rate. The increasing focus on health and fitness, coupled with rising disposable incomes in many regions, has contributed to this growth. The personalized sports equipment segment, including neoprene-based products, is expected to outpace the overall market growth rate in the coming years.

However, challenges remain in scaling up the production of personalized neoprene sports equipment. The cost of customization and the need for specialized manufacturing processes can result in higher prices for consumers. Additionally, the environmental impact of neoprene production and disposal has raised concerns, leading to research into more sustainable alternatives and recycling methods.

Despite these challenges, the market demand for personalized sports equipment incorporating neoprene continues to show strong potential. As technology advances and manufacturing processes become more efficient, the accessibility and affordability of custom neoprene-based sports gear are likely to improve, further driving market growth in this sector.

Neoprene, a synthetic rubber known for its flexibility, durability, and insulation properties, has found widespread use in sports equipment, particularly in water sports and protective gear. The material's ability to provide cushioning, support, and temperature regulation has made it a popular choice for personalized sports equipment.

In the water sports sector, the demand for custom-fit wetsuits, surfing accessories, and swimming gear utilizing neoprene has seen significant growth. Surfers, divers, and swimmers are increasingly seeking personalized equipment that offers better performance and comfort. This trend has led to the development of advanced 3D body scanning technologies and custom manufacturing processes to create tailor-made neoprene products.

The fitness and training equipment market has also witnessed a surge in demand for personalized neoprene-based products. Items such as customized weightlifting belts, knee sleeves, and compression gear have gained popularity among fitness enthusiasts and professional athletes alike. The ability to provide targeted support and compression while allowing for a full range of motion has made neoprene a preferred material in this segment.

In team sports, there is a growing market for personalized protective gear incorporating neoprene. Custom-fit shoulder pads, shin guards, and impact-absorbing accessories are being developed to cater to individual athletes' needs, enhancing both safety and performance. This trend is particularly evident in high-contact sports such as football, hockey, and lacrosse.

The global sports equipment market, which includes personalized gear, has been expanding at a steady rate. The increasing focus on health and fitness, coupled with rising disposable incomes in many regions, has contributed to this growth. The personalized sports equipment segment, including neoprene-based products, is expected to outpace the overall market growth rate in the coming years.

However, challenges remain in scaling up the production of personalized neoprene sports equipment. The cost of customization and the need for specialized manufacturing processes can result in higher prices for consumers. Additionally, the environmental impact of neoprene production and disposal has raised concerns, leading to research into more sustainable alternatives and recycling methods.

Despite these challenges, the market demand for personalized sports equipment incorporating neoprene continues to show strong potential. As technology advances and manufacturing processes become more efficient, the accessibility and affordability of custom neoprene-based sports gear are likely to improve, further driving market growth in this sector.

Technical Challenges

The integration of neoprene into personalized sports equipment presents several technical challenges that researchers and manufacturers must address. One of the primary obstacles is achieving optimal balance between flexibility and support. Neoprene's inherent elasticity makes it ideal for conforming to an athlete's body, but ensuring it provides adequate support for specific sports activities requires careful engineering and material composition adjustments.

Another significant challenge lies in the durability of neoprene-based personalized equipment. While neoprene is known for its resilience, repeated stress from intense athletic movements can lead to premature wear and tear. Developing neoprene composites that maintain flexibility while enhancing longevity is a key area of focus for materials scientists in this field.

Thermal management poses a unique challenge in neoprene-based sports equipment. Neoprene's insulating properties, while beneficial in some contexts, can lead to overheating during intense physical activity. Innovators are exploring ways to incorporate breathable elements or moisture-wicking technologies into neoprene structures without compromising its protective qualities.

The customization process itself presents technical hurdles. Creating truly personalized equipment requires precise measurements and sophisticated manufacturing techniques. Developing cost-effective methods for mass customization, such as 3D scanning and printing technologies compatible with neoprene materials, is an ongoing challenge for the industry.

Environmental concerns also factor into the technical challenges. Traditional neoprene production involves petroleum-based processes, which are not environmentally sustainable. Researchers are working on developing eco-friendly alternatives or recycling methods for neoprene to address these sustainability issues without sacrificing performance.

Lastly, the integration of smart technologies into neoprene-based equipment presents a new frontier of technical challenges. Incorporating sensors, data transmission capabilities, and other electronic components into flexible neoprene structures while maintaining comfort and functionality requires innovative approaches to materials science and electronic design.

Addressing these technical challenges is crucial for advancing the role of neoprene in personalized sports equipment. Overcoming these hurdles will not only enhance athletic performance and comfort but also open new possibilities for data-driven training and injury prevention in sports.

Another significant challenge lies in the durability of neoprene-based personalized equipment. While neoprene is known for its resilience, repeated stress from intense athletic movements can lead to premature wear and tear. Developing neoprene composites that maintain flexibility while enhancing longevity is a key area of focus for materials scientists in this field.

Thermal management poses a unique challenge in neoprene-based sports equipment. Neoprene's insulating properties, while beneficial in some contexts, can lead to overheating during intense physical activity. Innovators are exploring ways to incorporate breathable elements or moisture-wicking technologies into neoprene structures without compromising its protective qualities.

The customization process itself presents technical hurdles. Creating truly personalized equipment requires precise measurements and sophisticated manufacturing techniques. Developing cost-effective methods for mass customization, such as 3D scanning and printing technologies compatible with neoprene materials, is an ongoing challenge for the industry.

Environmental concerns also factor into the technical challenges. Traditional neoprene production involves petroleum-based processes, which are not environmentally sustainable. Researchers are working on developing eco-friendly alternatives or recycling methods for neoprene to address these sustainability issues without sacrificing performance.

Lastly, the integration of smart technologies into neoprene-based equipment presents a new frontier of technical challenges. Incorporating sensors, data transmission capabilities, and other electronic components into flexible neoprene structures while maintaining comfort and functionality requires innovative approaches to materials science and electronic design.

Addressing these technical challenges is crucial for advancing the role of neoprene in personalized sports equipment. Overcoming these hurdles will not only enhance athletic performance and comfort but also open new possibilities for data-driven training and injury prevention in sports.

Current Neoprene Solutions

01 Composition and synthesis of neoprene

Neoprene is a synthetic rubber produced by polymerization of chloroprene. It is known for its resistance to oil, heat, and weathering. The manufacturing process involves careful control of reaction conditions and may include various additives to enhance specific properties.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. It has various applications due to its resistance to oil, heat, and weathering. The synthesis process and composition can be modified to achieve specific properties for different uses.

- Neoprene in protective gear and clothing: Neoprene is widely used in the production of protective gear and clothing, such as wetsuits, gloves, and boots. Its insulating properties, flexibility, and durability make it ideal for these applications. Various manufacturing techniques are employed to enhance its performance in different environments.

- Neoprene foam and cellular structures: Neoprene can be processed into foam or cellular structures, which are useful in applications requiring cushioning, insulation, or buoyancy. The production methods and additives used can influence the foam's properties, such as density, cell structure, and compression resistance.

- Neoprene in adhesives and sealants: Neoprene-based adhesives and sealants are valued for their strong bonding capabilities and resistance to various environmental factors. These products are used in construction, automotive, and industrial applications. The formulation can be adjusted to optimize properties like viscosity, curing time, and bond strength.

- Neoprene blends and composites: Neoprene can be blended with other materials or used in composites to enhance its properties or create specialized products. These blends and composites may offer improved strength, chemical resistance, or other characteristics suited for specific applications in industries such as automotive, aerospace, and electronics.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear such as wetsuits, gloves, and boots. Its flexibility, insulation properties, and resistance to water make it ideal for these applications. The material can be engineered to provide varying levels of thickness and protection based on specific needs.Expand Specific Solutions03 Neoprene foam production and properties

Neoprene foam is a versatile material created by introducing gas bubbles into the neoprene during the manufacturing process. This results in a lightweight, flexible, and insulating material with closed-cell structure. The foam can be produced with varying densities and cell sizes to suit different applications.Expand Specific Solutions04 Neoprene in automotive and industrial applications

Neoprene is used in various automotive and industrial applications due to its resistance to oil, chemicals, and extreme temperatures. It is commonly used in gaskets, seals, hoses, and belts. The material can be formulated to meet specific requirements for hardness, tensile strength, and elongation.Expand Specific Solutions05 Neoprene blends and composites

Neoprene can be blended with other materials or used in composites to enhance its properties or create specialized materials. These blends and composites may offer improved strength, durability, or specific functional characteristics. The combination of neoprene with other polymers or reinforcing materials allows for tailored solutions in various industries.Expand Specific Solutions

Key Industry Players

The competitive landscape for neoprene's role in personalized sports equipment is evolving rapidly, with the industry in a growth phase. The market size is expanding due to increasing demand for customized sports gear and advancements in material technology. Major players like Nike, Adidas, and Puma are leveraging their R&D capabilities to innovate in this space. Smaller specialized companies such as Salomon and Alpinestars are also making significant contributions. The technology's maturity is progressing, with companies like Tianjin Pengling Group and Li-Bond Resin focusing on improving neoprene's properties for sports applications. Academic institutions like The Hong Kong Polytechnic University are contributing to research, potentially accelerating technological advancements in this field.

Denka Corp.

Technical Solution: Denka Corporation, a leading chemical manufacturer, has developed advanced neoprene formulations specifically tailored for sports equipment applications. Their "Denka Chloroprene" line includes specialized grades of neoprene that offer enhanced durability, flexibility, and resistance to environmental factors. These materials are used by various sports equipment manufacturers to create personalized gear. Denka's neoprene formulations feature improved tear strength and abrasion resistance, making them ideal for high-stress applications in sports equipment[10]. The company has also developed neoprene compounds with varying shore hardness levels, allowing manufacturers to create zones of different flexibility and support within a single piece of equipment, enhancing personalization options[11].

Strengths: High-quality raw material production, customizable material properties. Weaknesses: Reliant on partnerships with equipment manufacturers for end-product development.

Salomon SAS

Technical Solution: Salomon has innovated in the use of neoprene for personalized sports equipment, particularly in their trail running and outdoor footwear lines. They have developed a technology called "Sensifit," which uses neoprene-based materials to create a customized fit that wraps around the foot. This system adapts to different foot shapes and sizes, providing enhanced comfort and performance. Salomon has also incorporated neoprene into their "Quicklace" system, which allows for rapid, personalized adjustment of shoe tightness[2]. In their winter sports equipment, Salomon uses neoprene in boot liners for improved insulation and comfort, with the material's properties allowing for a more personalized fit as it molds to the user's foot shape over time[4].

Strengths: Customized fit technology, versatile application across product lines. Weaknesses: May be less suitable for extreme temperature conditions.

Advanced Neoprene Tech

Personalized Sports Equipment

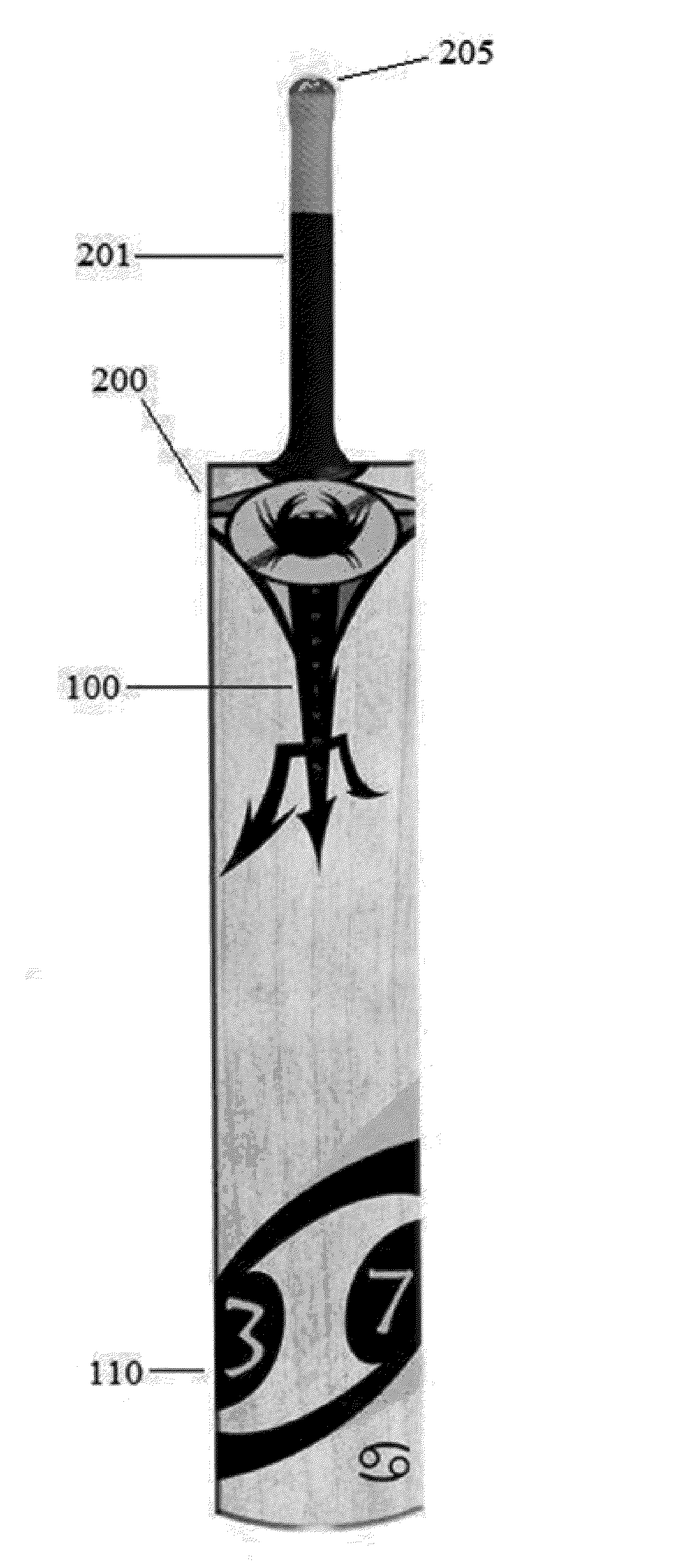

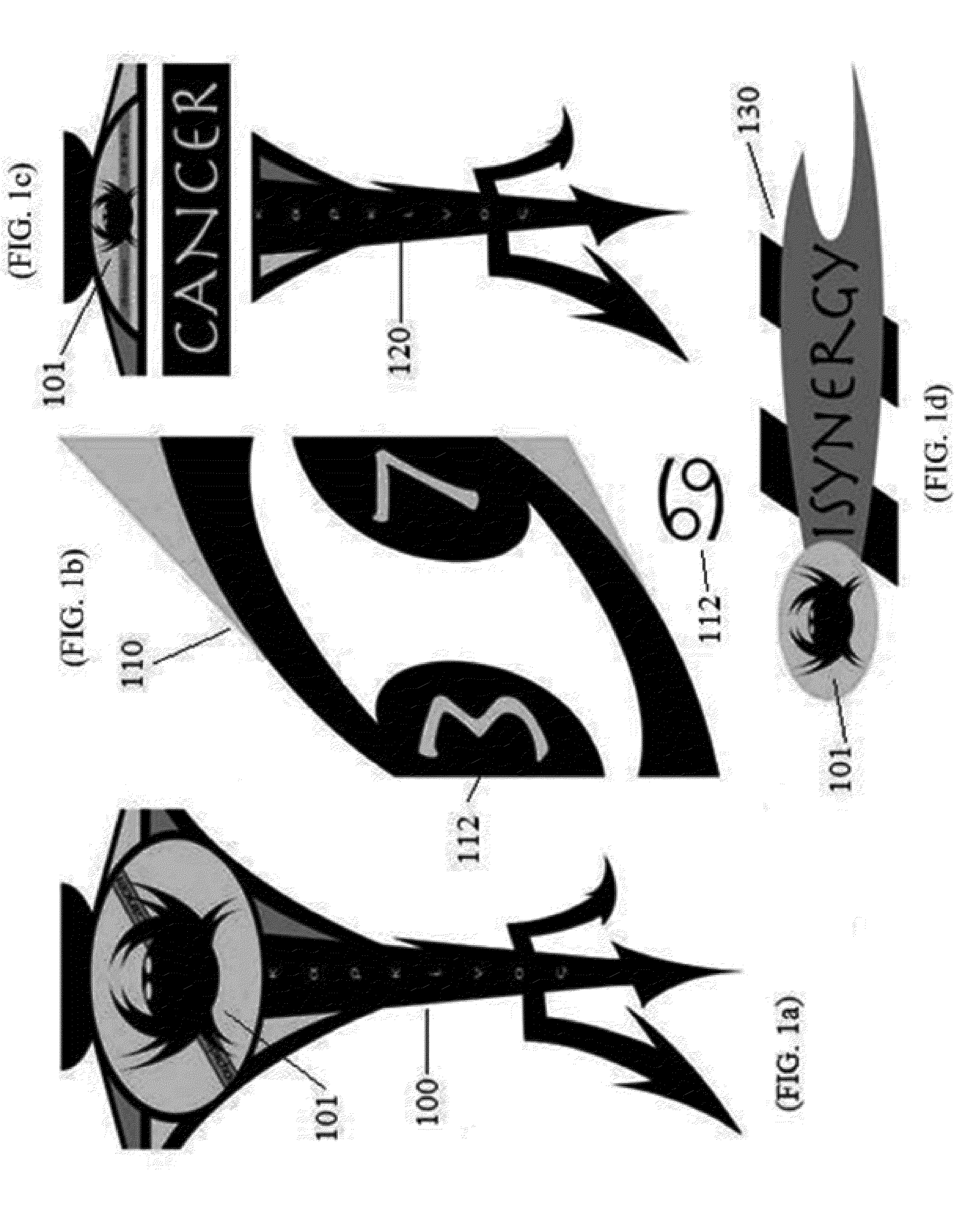

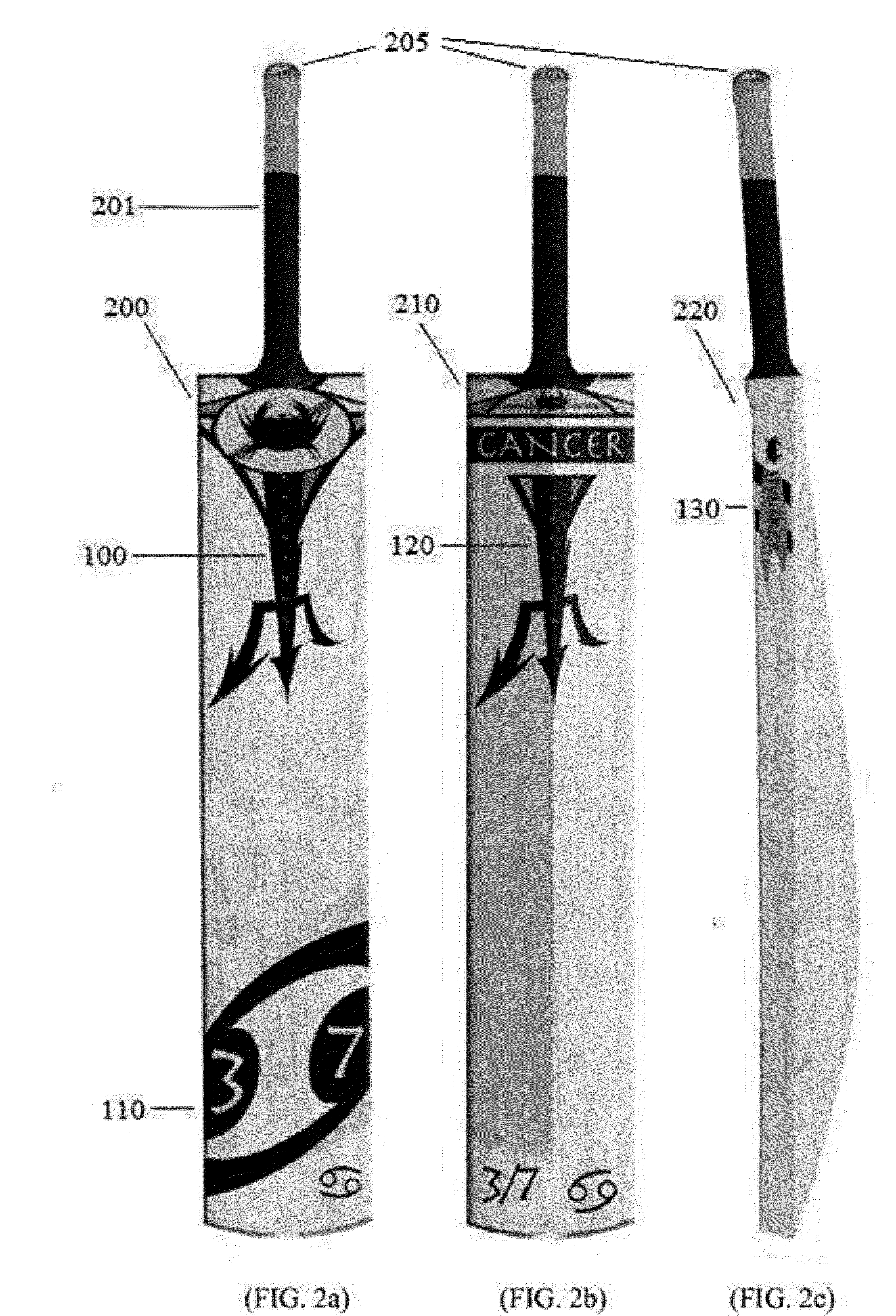

PatentInactiveUS20130005519A1

Innovation

- Personalized sports equipment featuring zodiac-based design elements, including symbols, birth stones, and lucky numbers, are integrated into the equipment's surface to create a customized and motivating aesthetic appearance.

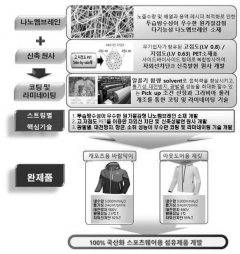

Materials for sportswear with excellent multi-functional properties such as light heat performance using nanomembrane and manufacturing method thereof

PatentInactiveKR1020210022865A

Innovation

- A nanomembrane material with high-low viscosity PET side-by-side yarn is used, laminated with PU resin and MEK solvent, incorporating additives for antistatic, antibacterial, and light heating functions, to create a fabric with enhanced elasticity and UV protection.

Sustainability Aspects

Sustainability has become a crucial aspect in the development and production of personalized sports equipment, particularly when considering the use of neoprene. As the demand for customized gear continues to grow, manufacturers are increasingly focusing on environmentally friendly practices to mitigate the ecological impact of their products.

Neoprene, a synthetic rubber widely used in sports equipment for its flexibility and insulating properties, has traditionally been associated with environmental concerns due to its petroleum-based production process. However, recent advancements in material science have led to the development of more sustainable alternatives, such as limestone-based neoprene and plant-based neoprene substitutes.

These eco-friendly materials offer similar performance characteristics to traditional neoprene while significantly reducing the carbon footprint of production. For instance, limestone-based neoprene utilizes calcium carbonate from limestone quarries, which requires less energy to process compared to petroleum-based alternatives. Plant-based substitutes, derived from sources like eucalyptus and sugarcane, further reduce reliance on non-renewable resources.

In the context of personalized sports equipment, sustainability efforts extend beyond material selection. Manufacturers are implementing advanced production techniques, such as 3D printing and computer-aided design, to minimize waste and optimize resource utilization. These technologies allow for precise customization of equipment, reducing excess material usage and improving overall product efficiency.

Additionally, the durability and longevity of personalized neoprene-based sports equipment contribute to sustainability by reducing the frequency of replacements. Customized fit and design not only enhance performance but also extend the product's lifespan, ultimately decreasing the environmental impact associated with frequent manufacturing and disposal.

Recycling initiatives have also gained traction in the neoprene-based sports equipment industry. Some manufacturers have implemented take-back programs, allowing customers to return used products for recycling or repurposing. This circular economy approach helps minimize waste and promotes the reuse of valuable materials.

As consumer awareness of environmental issues grows, the demand for sustainable personalized sports equipment is expected to increase. This trend is driving innovation in material science and manufacturing processes, pushing the industry towards more eco-friendly practices. The integration of sustainability aspects in neoprene-based personalized sports equipment not only addresses environmental concerns but also offers a competitive advantage in an increasingly conscious market.

Neoprene, a synthetic rubber widely used in sports equipment for its flexibility and insulating properties, has traditionally been associated with environmental concerns due to its petroleum-based production process. However, recent advancements in material science have led to the development of more sustainable alternatives, such as limestone-based neoprene and plant-based neoprene substitutes.

These eco-friendly materials offer similar performance characteristics to traditional neoprene while significantly reducing the carbon footprint of production. For instance, limestone-based neoprene utilizes calcium carbonate from limestone quarries, which requires less energy to process compared to petroleum-based alternatives. Plant-based substitutes, derived from sources like eucalyptus and sugarcane, further reduce reliance on non-renewable resources.

In the context of personalized sports equipment, sustainability efforts extend beyond material selection. Manufacturers are implementing advanced production techniques, such as 3D printing and computer-aided design, to minimize waste and optimize resource utilization. These technologies allow for precise customization of equipment, reducing excess material usage and improving overall product efficiency.

Additionally, the durability and longevity of personalized neoprene-based sports equipment contribute to sustainability by reducing the frequency of replacements. Customized fit and design not only enhance performance but also extend the product's lifespan, ultimately decreasing the environmental impact associated with frequent manufacturing and disposal.

Recycling initiatives have also gained traction in the neoprene-based sports equipment industry. Some manufacturers have implemented take-back programs, allowing customers to return used products for recycling or repurposing. This circular economy approach helps minimize waste and promotes the reuse of valuable materials.

As consumer awareness of environmental issues grows, the demand for sustainable personalized sports equipment is expected to increase. This trend is driving innovation in material science and manufacturing processes, pushing the industry towards more eco-friendly practices. The integration of sustainability aspects in neoprene-based personalized sports equipment not only addresses environmental concerns but also offers a competitive advantage in an increasingly conscious market.

Performance Metrics

Neoprene's impact on personalized sports equipment can be quantified through various performance metrics. These metrics provide valuable insights into the material's effectiveness and its contribution to enhancing athletic performance.

Durability is a key performance indicator for neoprene-based sports equipment. Manufacturers typically measure the material's resistance to wear and tear through abrasion tests, which simulate repeated use and environmental exposure. The number of cycles a neoprene product can withstand before showing signs of degradation is a crucial metric for assessing its longevity and value to athletes.

Flexibility and range of motion are essential for many sports applications. Neoprene's elasticity is often measured using stretch and recovery tests, quantifying the material's ability to return to its original shape after being stretched. This is particularly important for compression gear and form-fitting equipment, where maintaining consistent pressure and support is critical.

Thermal insulation properties are another vital metric, especially for water sports and cold-weather activities. The thermal conductivity of neoprene is typically measured in watts per meter-kelvin (W/m·K), with lower values indicating better insulation. Additionally, the material's ability to maintain insulation when wet is assessed through water absorption tests and thermal imaging under various conditions.

Comfort and fit are subjective but crucial aspects of personalized sports equipment. Manufacturers often use pressure mapping technology to measure the distribution of force across the body when wearing neoprene gear. This data helps in optimizing designs for maximum comfort and support. User feedback scores and wear-test results also contribute to quantifying the perceived comfort and fit of neoprene products.

Impact protection is a critical metric for contact sports and high-impact activities. Neoprene's shock absorption capabilities are typically measured using drop tests and force plate analysis. The peak force reduction and energy dissipation provided by neoprene padding are key indicators of its protective qualities.

Weight and buoyancy are important considerations, particularly for aquatic sports. The specific gravity of neoprene and its buoyancy force in water are measured to ensure optimal performance. For dryland applications, the weight-to-protection ratio is a crucial metric in evaluating the efficiency of neoprene-based equipment.

Breathability and moisture management are assessed through metrics such as water vapor transmission rate (WVTR) and moisture wicking capability. These factors are crucial for maintaining comfort during intense physical activity and preventing overheating or excessive sweating.

By analyzing these performance metrics, manufacturers and athletes can make informed decisions about the suitability of neoprene for specific sports applications and tailor equipment designs to meet individual needs and preferences.

Durability is a key performance indicator for neoprene-based sports equipment. Manufacturers typically measure the material's resistance to wear and tear through abrasion tests, which simulate repeated use and environmental exposure. The number of cycles a neoprene product can withstand before showing signs of degradation is a crucial metric for assessing its longevity and value to athletes.

Flexibility and range of motion are essential for many sports applications. Neoprene's elasticity is often measured using stretch and recovery tests, quantifying the material's ability to return to its original shape after being stretched. This is particularly important for compression gear and form-fitting equipment, where maintaining consistent pressure and support is critical.

Thermal insulation properties are another vital metric, especially for water sports and cold-weather activities. The thermal conductivity of neoprene is typically measured in watts per meter-kelvin (W/m·K), with lower values indicating better insulation. Additionally, the material's ability to maintain insulation when wet is assessed through water absorption tests and thermal imaging under various conditions.

Comfort and fit are subjective but crucial aspects of personalized sports equipment. Manufacturers often use pressure mapping technology to measure the distribution of force across the body when wearing neoprene gear. This data helps in optimizing designs for maximum comfort and support. User feedback scores and wear-test results also contribute to quantifying the perceived comfort and fit of neoprene products.

Impact protection is a critical metric for contact sports and high-impact activities. Neoprene's shock absorption capabilities are typically measured using drop tests and force plate analysis. The peak force reduction and energy dissipation provided by neoprene padding are key indicators of its protective qualities.

Weight and buoyancy are important considerations, particularly for aquatic sports. The specific gravity of neoprene and its buoyancy force in water are measured to ensure optimal performance. For dryland applications, the weight-to-protection ratio is a crucial metric in evaluating the efficiency of neoprene-based equipment.

Breathability and moisture management are assessed through metrics such as water vapor transmission rate (WVTR) and moisture wicking capability. These factors are crucial for maintaining comfort during intense physical activity and preventing overheating or excessive sweating.

By analyzing these performance metrics, manufacturers and athletes can make informed decisions about the suitability of neoprene for specific sports applications and tailor equipment designs to meet individual needs and preferences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!