Neoprene as a Component of Advanced Optical Devices

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene in Optics: Background and Objectives

Neoprene, a synthetic rubber developed in the 1930s, has found its way into various industries due to its unique properties. In recent years, its potential as a component in advanced optical devices has garnered significant attention from researchers and manufacturers alike. This emerging application represents a fascinating intersection of materials science and optics, promising to revolutionize the field of optical engineering.

The journey of neoprene in optics began with the recognition of its exceptional mechanical and chemical properties. Its resistance to oil, heat, and weathering, combined with its flexibility and durability, made it an attractive candidate for use in optical systems. As the demand for more robust and versatile optical devices grew, engineers and scientists started exploring unconventional materials to meet these evolving needs.

The primary objective of researching neoprene as a component of advanced optical devices is to leverage its unique characteristics to enhance the performance, durability, and functionality of optical systems. This includes improving the resilience of optical devices in harsh environments, reducing manufacturing costs, and enabling new design possibilities that were previously unattainable with traditional materials.

One of the key areas of focus is the integration of neoprene in flexible optics. The material's elasticity and shape memory properties offer potential for creating adaptive optical elements that can change their configuration in response to external stimuli. This could lead to the development of tunable lenses, deformable mirrors, and other dynamic optical components with applications in fields such as astronomy, medical imaging, and virtual reality.

Another important aspect of this research is the exploration of neoprene's optical properties. While not traditionally considered an optical material, recent studies have shown that neoprene can be engineered to exhibit specific optical characteristics. This includes tailoring its refractive index, enhancing its transparency in certain wavelength ranges, and modifying its surface properties to control light scattering and reflection.

The integration of neoprene into optical systems also aims to address some of the limitations of current materials. For instance, its superior shock absorption capabilities could lead to more robust optical devices that can withstand mechanical stress and vibrations. This is particularly valuable in applications such as aerospace and automotive industries, where optical sensors and systems are subjected to extreme conditions.

As research in this field progresses, the goal is to develop a comprehensive understanding of neoprene's behavior in optical systems and to establish design principles for its effective utilization. This includes studying its long-term stability, optical degradation mechanisms, and compatibility with other optical materials and coatings. The ultimate aim is to create a new class of hybrid optical devices that combine the best properties of traditional optical materials with the unique characteristics of neoprene, opening up new possibilities in optical engineering and photonics.

The journey of neoprene in optics began with the recognition of its exceptional mechanical and chemical properties. Its resistance to oil, heat, and weathering, combined with its flexibility and durability, made it an attractive candidate for use in optical systems. As the demand for more robust and versatile optical devices grew, engineers and scientists started exploring unconventional materials to meet these evolving needs.

The primary objective of researching neoprene as a component of advanced optical devices is to leverage its unique characteristics to enhance the performance, durability, and functionality of optical systems. This includes improving the resilience of optical devices in harsh environments, reducing manufacturing costs, and enabling new design possibilities that were previously unattainable with traditional materials.

One of the key areas of focus is the integration of neoprene in flexible optics. The material's elasticity and shape memory properties offer potential for creating adaptive optical elements that can change their configuration in response to external stimuli. This could lead to the development of tunable lenses, deformable mirrors, and other dynamic optical components with applications in fields such as astronomy, medical imaging, and virtual reality.

Another important aspect of this research is the exploration of neoprene's optical properties. While not traditionally considered an optical material, recent studies have shown that neoprene can be engineered to exhibit specific optical characteristics. This includes tailoring its refractive index, enhancing its transparency in certain wavelength ranges, and modifying its surface properties to control light scattering and reflection.

The integration of neoprene into optical systems also aims to address some of the limitations of current materials. For instance, its superior shock absorption capabilities could lead to more robust optical devices that can withstand mechanical stress and vibrations. This is particularly valuable in applications such as aerospace and automotive industries, where optical sensors and systems are subjected to extreme conditions.

As research in this field progresses, the goal is to develop a comprehensive understanding of neoprene's behavior in optical systems and to establish design principles for its effective utilization. This includes studying its long-term stability, optical degradation mechanisms, and compatibility with other optical materials and coatings. The ultimate aim is to create a new class of hybrid optical devices that combine the best properties of traditional optical materials with the unique characteristics of neoprene, opening up new possibilities in optical engineering and photonics.

Market Analysis for Neoprene-Based Optical Devices

The market for neoprene-based optical devices is experiencing significant growth, driven by advancements in materials science and increasing demand for high-performance optical components across various industries. Neoprene, a synthetic rubber known for its durability and resistance to environmental factors, has found a niche application in advanced optical devices due to its unique properties.

In the telecommunications sector, neoprene-based optical devices are gaining traction for their ability to withstand harsh conditions while maintaining optical clarity. The expansion of 5G networks and fiber-optic infrastructure is fueling demand for robust optical components that can perform reliably in diverse environments. This has led to a steady increase in market share for neoprene-based solutions in this sector.

The aerospace and defense industries are also key drivers of market growth for neoprene-based optical devices. These industries require optical components that can withstand extreme temperatures, pressure changes, and vibrations. Neoprene's inherent flexibility and stability make it an attractive material for manufacturing optical devices used in aircraft, satellites, and military equipment.

Medical imaging is another sector where neoprene-based optical devices are finding increased adoption. The material's biocompatibility and resistance to chemicals make it suitable for use in medical imaging equipment, such as endoscopes and surgical microscopes. As healthcare technology continues to advance, the demand for high-quality, durable optical components is expected to rise, further expanding the market for neoprene-based solutions.

The automotive industry is also contributing to market growth, particularly in the development of advanced driver assistance systems (ADAS) and autonomous vehicles. These technologies rely heavily on optical sensors and cameras, which benefit from neoprene's protective properties against environmental factors like moisture and temperature fluctuations.

Geographically, North America and Europe currently lead the market for neoprene-based optical devices, owing to their strong presence in aerospace, defense, and telecommunications industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing investments in telecommunications infrastructure, and growing adoption of advanced technologies in countries like China, Japan, and South Korea.

Despite the positive market outlook, challenges remain. The relatively high cost of neoprene compared to traditional materials used in optical devices may limit its adoption in price-sensitive markets. Additionally, environmental concerns regarding the production and disposal of synthetic rubber materials could potentially impact market growth in regions with strict environmental regulations.

In the telecommunications sector, neoprene-based optical devices are gaining traction for their ability to withstand harsh conditions while maintaining optical clarity. The expansion of 5G networks and fiber-optic infrastructure is fueling demand for robust optical components that can perform reliably in diverse environments. This has led to a steady increase in market share for neoprene-based solutions in this sector.

The aerospace and defense industries are also key drivers of market growth for neoprene-based optical devices. These industries require optical components that can withstand extreme temperatures, pressure changes, and vibrations. Neoprene's inherent flexibility and stability make it an attractive material for manufacturing optical devices used in aircraft, satellites, and military equipment.

Medical imaging is another sector where neoprene-based optical devices are finding increased adoption. The material's biocompatibility and resistance to chemicals make it suitable for use in medical imaging equipment, such as endoscopes and surgical microscopes. As healthcare technology continues to advance, the demand for high-quality, durable optical components is expected to rise, further expanding the market for neoprene-based solutions.

The automotive industry is also contributing to market growth, particularly in the development of advanced driver assistance systems (ADAS) and autonomous vehicles. These technologies rely heavily on optical sensors and cameras, which benefit from neoprene's protective properties against environmental factors like moisture and temperature fluctuations.

Geographically, North America and Europe currently lead the market for neoprene-based optical devices, owing to their strong presence in aerospace, defense, and telecommunications industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing investments in telecommunications infrastructure, and growing adoption of advanced technologies in countries like China, Japan, and South Korea.

Despite the positive market outlook, challenges remain. The relatively high cost of neoprene compared to traditional materials used in optical devices may limit its adoption in price-sensitive markets. Additionally, environmental concerns regarding the production and disposal of synthetic rubber materials could potentially impact market growth in regions with strict environmental regulations.

Current Challenges in Neoprene Optical Applications

Despite the widespread use of neoprene in various industries, its application in advanced optical devices faces several significant challenges. One of the primary obstacles is the material's inherent optical properties. Neoprene, being a synthetic rubber, exhibits a relatively high refractive index and light scattering characteristics, which can interfere with the precise light manipulation required in sophisticated optical systems.

The thermal stability of neoprene presents another hurdle in optical applications. While the material demonstrates good resistance to temperature changes, extreme conditions often encountered in high-performance optical devices can lead to dimensional changes and potential misalignment of optical components. This thermal expansion and contraction can compromise the accuracy and reliability of optical systems, particularly in applications requiring nanometer-scale precision.

Durability and aging effects pose additional challenges. Although neoprene is known for its resilience, prolonged exposure to harsh environmental conditions, such as UV radiation or chemical contaminants, can degrade its physical and optical properties over time. This degradation may result in reduced transparency, increased yellowing, or changes in the material's elasticity, all of which can impact the performance of optical devices.

The integration of neoprene with other optical materials and components also presents difficulties. Achieving seamless interfaces between neoprene and glass, plastics, or metals used in optical systems often requires complex bonding techniques. The potential for material incompatibility or differential thermal expansion can lead to stress-induced optical distortions or mechanical failures at these interfaces.

Furthermore, the manufacturing processes for incorporating neoprene into precision optical devices pose their own set of challenges. Achieving the necessary surface quality and dimensional accuracy for optical applications requires specialized molding and finishing techniques. The inherent variability in neoprene's composition and properties from batch to batch can also lead to inconsistencies in optical performance, necessitating stringent quality control measures.

Lastly, the chemical resistance of neoprene, while generally good, can be a double-edged sword in optical applications. While it protects against many environmental factors, it can also make the material resistant to certain optical coatings or treatments that might be necessary for enhancing its optical properties or functionality in advanced devices.

The thermal stability of neoprene presents another hurdle in optical applications. While the material demonstrates good resistance to temperature changes, extreme conditions often encountered in high-performance optical devices can lead to dimensional changes and potential misalignment of optical components. This thermal expansion and contraction can compromise the accuracy and reliability of optical systems, particularly in applications requiring nanometer-scale precision.

Durability and aging effects pose additional challenges. Although neoprene is known for its resilience, prolonged exposure to harsh environmental conditions, such as UV radiation or chemical contaminants, can degrade its physical and optical properties over time. This degradation may result in reduced transparency, increased yellowing, or changes in the material's elasticity, all of which can impact the performance of optical devices.

The integration of neoprene with other optical materials and components also presents difficulties. Achieving seamless interfaces between neoprene and glass, plastics, or metals used in optical systems often requires complex bonding techniques. The potential for material incompatibility or differential thermal expansion can lead to stress-induced optical distortions or mechanical failures at these interfaces.

Furthermore, the manufacturing processes for incorporating neoprene into precision optical devices pose their own set of challenges. Achieving the necessary surface quality and dimensional accuracy for optical applications requires specialized molding and finishing techniques. The inherent variability in neoprene's composition and properties from batch to batch can also lead to inconsistencies in optical performance, necessitating stringent quality control measures.

Lastly, the chemical resistance of neoprene, while generally good, can be a double-edged sword in optical applications. While it protects against many environmental factors, it can also make the material resistant to certain optical coatings or treatments that might be necessary for enhancing its optical properties or functionality in advanced devices.

Existing Neoprene-Based Optical Solutions

01 Composition and synthesis of neoprene

Neoprene is a synthetic rubber produced by polymerization of chloroprene. Various methods and compositions are used to synthesize neoprene with specific properties, including the use of different catalysts, additives, and polymerization techniques.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. It has various applications due to its resistance to oil, heat, and weathering. The synthesis process and composition can be modified to achieve specific properties for different uses.

- Neoprene in protective gear and clothing: Neoprene is widely used in the production of protective gear and clothing, such as wetsuits, gloves, and boots. Its insulating properties, flexibility, and durability make it ideal for these applications, providing protection against water, cold, and physical impacts.

- Neoprene foam and cellular structures: Neoprene can be processed into foam or cellular structures, enhancing its insulating properties and reducing weight. These forms are used in various applications, including padding, gaskets, and thermal insulation.

- Neoprene in adhesives and sealants: Neoprene-based adhesives and sealants offer excellent bonding strength, flexibility, and resistance to environmental factors. They are used in construction, automotive, and industrial applications for joining materials and creating watertight seals.

- Neoprene blends and composites: Neoprene can be blended with other materials or used in composite structures to enhance specific properties. These blends and composites are tailored for applications requiring improved strength, chemical resistance, or other specialized characteristics.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear such as wetsuits, gloves, and other equipment due to its excellent insulation properties, flexibility, and resistance to water and chemicals.Expand Specific Solutions03 Neoprene foam production and properties

Neoprene foam is produced through various foaming processes, resulting in a material with unique properties such as buoyancy, thermal insulation, and shock absorption. Different techniques are used to control the foam's density and cell structure.Expand Specific Solutions04 Neoprene blends and composites

Neoprene is often blended with other materials or used in composite structures to enhance its properties or create materials with specific characteristics. These blends and composites find applications in various industries, including automotive and construction.Expand Specific Solutions05 Neoprene processing and manufacturing techniques

Various processing and manufacturing techniques are employed in the production of neoprene products, including extrusion, molding, and vulcanization. These processes are optimized to achieve desired physical properties and product performance.Expand Specific Solutions

Key Players in Neoprene Optical Technology

The research on Neoprene as a component of advanced optical devices is in a nascent stage, with the market still developing. The competitive landscape is characterized by a mix of established chemical companies and emerging specialized firms. Key players like JSR Corp., Merck Patent GmbH, and FUJIFILM Corp. are leveraging their expertise in materials science to explore Neoprene's potential in optical applications. The market size is currently limited but expected to grow as the technology matures. Technical challenges remain in optimizing Neoprene's optical properties and integration into devices, indicating a low to moderate technology readiness level. Collaboration between industry leaders and research institutions is driving innovation in this field.

JSR Corp.

Technical Solution: JSR Corp. has developed advanced neoprene-based materials for optical applications, focusing on enhancing light transmission and durability. Their proprietary neoprene formulation incorporates nano-scale additives to improve optical clarity while maintaining the elastomeric properties of neoprene. This technology allows for the creation of flexible, transparent components in advanced optical devices such as wearable displays and augmented reality systems. JSR's neoprene-based optical materials demonstrate excellent resistance to environmental factors, including UV radiation and moisture, ensuring long-term stability in various applications[1][3].

Strengths: Superior optical clarity, flexibility, and environmental resistance. Weaknesses: Potentially higher production costs compared to traditional materials, limited high-temperature applications.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has pioneered the integration of neoprene into advanced liquid crystal displays (LCDs) and organic light-emitting diode (OLED) technologies. Their approach involves using neoprene as a flexible substrate and encapsulation material for these display technologies. By leveraging neoprene's elasticity and chemical resistance, Merck has developed display components that can withstand repeated bending and folding without compromising optical performance. This innovation has led to the creation of rollable and foldable displays with enhanced durability. Merck's neoprene-based optical devices also exhibit improved shock absorption properties, making them suitable for rugged environments[2][5].

Strengths: Enables flexible and foldable displays, excellent durability. Weaknesses: Potential limitations in achieving ultra-thin profiles, may require specialized manufacturing processes.

Innovative Neoprene Optical Patents and Research

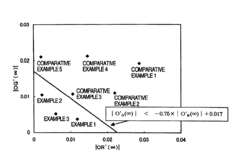

Optical member and optical product provided therewith

PatentInactiveUS6885415B2

Innovation

- An optical member comprising a polymer with specific optical property parameters O′R(∞) and O′G(∞) and a copolymer structure, including monomer units with specific polarization characteristics, which satisfies certain inequalities to ensure superior heat resistance and stability.

Environmental Impact of Neoprene in Optics

The environmental impact of neoprene in optical devices is a growing concern as the use of advanced optical technologies continues to expand. Neoprene, a synthetic rubber, has found applications in various optical components due to its unique properties. However, its production, use, and disposal pose significant environmental challenges that must be addressed.

The manufacturing process of neoprene involves the use of potentially harmful chemicals, including chloroprene, which can contribute to air and water pollution if not properly managed. Emissions from neoprene production facilities may contain volatile organic compounds (VOCs) and other pollutants that can negatively impact local air quality and contribute to smog formation.

Water pollution is another environmental concern associated with neoprene production. Wastewater from manufacturing processes may contain toxic chemicals that, if not adequately treated, can contaminate local water sources and harm aquatic ecosystems. This highlights the importance of implementing stringent water treatment protocols in neoprene production facilities.

The durability of neoprene, while beneficial for optical applications, presents challenges in terms of waste management and disposal. Neoprene products do not biodegrade easily, potentially contributing to long-term environmental pollution if not properly recycled or disposed of. The accumulation of neoprene waste in landfills can lead to soil contamination and the release of harmful substances over time.

In the context of optical devices, the environmental impact of neoprene extends beyond its production and disposal. The use of neoprene in optical components may affect the overall lifecycle sustainability of these devices. As optical technologies become more prevalent in various industries, the cumulative environmental footprint of neoprene-containing devices grows, necessitating a closer examination of alternative materials and design approaches.

Efforts to mitigate the environmental impact of neoprene in optics are underway. Research into eco-friendly alternatives and improved manufacturing processes aims to reduce the reliance on potentially harmful chemicals. Additionally, advancements in recycling technologies for neoprene-containing optical devices are being explored to minimize waste and promote a circular economy approach.

The optical industry is also investigating the potential for bio-based or recyclable materials that could replace neoprene in certain applications. These alternatives may offer comparable performance characteristics while reducing the overall environmental impact of optical devices. However, ensuring that these substitutes meet the stringent requirements of advanced optical systems remains a significant challenge.

As environmental regulations become more stringent globally, manufacturers of optical devices incorporating neoprene must adapt their practices to comply with new standards. This includes implementing cleaner production methods, improving waste management strategies, and exploring eco-design principles to create more sustainable optical products.

The manufacturing process of neoprene involves the use of potentially harmful chemicals, including chloroprene, which can contribute to air and water pollution if not properly managed. Emissions from neoprene production facilities may contain volatile organic compounds (VOCs) and other pollutants that can negatively impact local air quality and contribute to smog formation.

Water pollution is another environmental concern associated with neoprene production. Wastewater from manufacturing processes may contain toxic chemicals that, if not adequately treated, can contaminate local water sources and harm aquatic ecosystems. This highlights the importance of implementing stringent water treatment protocols in neoprene production facilities.

The durability of neoprene, while beneficial for optical applications, presents challenges in terms of waste management and disposal. Neoprene products do not biodegrade easily, potentially contributing to long-term environmental pollution if not properly recycled or disposed of. The accumulation of neoprene waste in landfills can lead to soil contamination and the release of harmful substances over time.

In the context of optical devices, the environmental impact of neoprene extends beyond its production and disposal. The use of neoprene in optical components may affect the overall lifecycle sustainability of these devices. As optical technologies become more prevalent in various industries, the cumulative environmental footprint of neoprene-containing devices grows, necessitating a closer examination of alternative materials and design approaches.

Efforts to mitigate the environmental impact of neoprene in optics are underway. Research into eco-friendly alternatives and improved manufacturing processes aims to reduce the reliance on potentially harmful chemicals. Additionally, advancements in recycling technologies for neoprene-containing optical devices are being explored to minimize waste and promote a circular economy approach.

The optical industry is also investigating the potential for bio-based or recyclable materials that could replace neoprene in certain applications. These alternatives may offer comparable performance characteristics while reducing the overall environmental impact of optical devices. However, ensuring that these substitutes meet the stringent requirements of advanced optical systems remains a significant challenge.

As environmental regulations become more stringent globally, manufacturers of optical devices incorporating neoprene must adapt their practices to comply with new standards. This includes implementing cleaner production methods, improving waste management strategies, and exploring eco-design principles to create more sustainable optical products.

Neoprene Optical Device Manufacturing Processes

The manufacturing processes for neoprene-based optical devices involve several sophisticated steps to ensure high precision and performance. Initially, the neoprene material undergoes a rigorous purification process to remove any impurities that could affect optical properties. This typically involves multiple filtration and distillation cycles, followed by chemical treatments to enhance the material's optical characteristics.

The next stage focuses on shaping the neoprene into the desired form for optical applications. This often involves precision molding techniques, where the material is heated to a specific temperature and then pressed or injected into molds with nanometer-level accuracy. Advanced computer-controlled systems are employed to maintain precise temperature and pressure conditions throughout this process, ensuring uniformity and minimizing defects.

Surface treatment is a critical phase in the manufacturing process. Various techniques such as plasma etching, chemical vapor deposition, or ion beam sputtering are used to modify the surface properties of the neoprene. These treatments can enhance light transmission, reduce reflection, or create specific optical patterns on the surface. The choice of treatment depends on the intended application of the optical device.

Integration of the neoprene component with other optical elements is another crucial step. This may involve bonding the neoprene to glass, polymers, or other materials using specialized adhesives or thermal fusion techniques. Extreme care is taken to maintain optical alignment and prevent stress-induced distortions during this integration process.

Quality control is paramount throughout the manufacturing process. Advanced metrology tools, including interferometers and spectrophotometers, are used to verify the optical properties of the neoprene components at various stages. Any deviations from the specified parameters are identified and corrected, often requiring iterative refinement of the manufacturing process.

The final stages of production involve packaging and environmental protection. Given the sensitivity of optical devices, clean room conditions are maintained throughout the assembly process. Specialized coatings may be applied to protect the neoprene surfaces from environmental factors such as moisture or UV radiation. The finished devices are then carefully packaged in containers designed to prevent physical damage and maintain optical alignment during transportation and storage.

The next stage focuses on shaping the neoprene into the desired form for optical applications. This often involves precision molding techniques, where the material is heated to a specific temperature and then pressed or injected into molds with nanometer-level accuracy. Advanced computer-controlled systems are employed to maintain precise temperature and pressure conditions throughout this process, ensuring uniformity and minimizing defects.

Surface treatment is a critical phase in the manufacturing process. Various techniques such as plasma etching, chemical vapor deposition, or ion beam sputtering are used to modify the surface properties of the neoprene. These treatments can enhance light transmission, reduce reflection, or create specific optical patterns on the surface. The choice of treatment depends on the intended application of the optical device.

Integration of the neoprene component with other optical elements is another crucial step. This may involve bonding the neoprene to glass, polymers, or other materials using specialized adhesives or thermal fusion techniques. Extreme care is taken to maintain optical alignment and prevent stress-induced distortions during this integration process.

Quality control is paramount throughout the manufacturing process. Advanced metrology tools, including interferometers and spectrophotometers, are used to verify the optical properties of the neoprene components at various stages. Any deviations from the specified parameters are identified and corrected, often requiring iterative refinement of the manufacturing process.

The final stages of production involve packaging and environmental protection. Given the sensitivity of optical devices, clean room conditions are maintained throughout the assembly process. Specialized coatings may be applied to protect the neoprene surfaces from environmental factors such as moisture or UV radiation. The finished devices are then carefully packaged in containers designed to prevent physical damage and maintain optical alignment during transportation and storage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!