How Neoprene Protects Against Environmental Extremes?

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Protection Background and Objectives

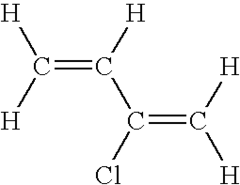

Neoprene, a synthetic rubber developed in the 1930s, has become a cornerstone material in various industries due to its exceptional ability to protect against environmental extremes. This versatile elastomer, also known as polychloroprene, was initially created as an oil-resistant alternative to natural rubber. Over the decades, its unique properties have led to widespread adoption in applications ranging from wetsuits to industrial gaskets.

The primary objective of this technical research report is to explore and analyze how neoprene effectively protects against environmental extremes. We aim to provide a comprehensive understanding of the material's protective capabilities, focusing on its resistance to temperature fluctuations, chemical exposure, and mechanical stress. This investigation will serve as a foundation for potential innovations in protective gear and equipment across various sectors.

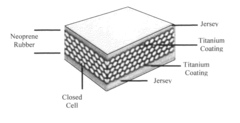

Neoprene's development has been driven by the increasing demand for materials that can withstand harsh conditions while maintaining flexibility and durability. Its closed-cell structure, which consists of tiny gas bubbles trapped within the rubber matrix, plays a crucial role in its insulating properties. This unique composition allows neoprene to provide thermal protection in both hot and cold environments, making it an ideal choice for applications in extreme temperature conditions.

The evolution of neoprene technology has seen significant advancements in recent years. Manufacturers have developed specialized formulations to enhance specific properties, such as improved UV resistance for outdoor applications or increased chemical resistance for industrial use. These developments have expanded the material's potential applications and improved its performance in protecting against environmental extremes.

In the context of this research, we will examine the molecular structure of neoprene and how it contributes to its protective qualities. We will also explore the various manufacturing processes and additives used to tailor neoprene's properties for specific environmental challenges. By understanding these fundamental aspects, we can identify potential areas for improvement and innovation in neoprene-based protective solutions.

Furthermore, this report will investigate the current market trends and emerging technologies that may complement or compete with neoprene in protective applications. By analyzing these factors, we aim to provide insights into the future direction of protective materials and potential opportunities for neoprene's continued development and application in safeguarding against environmental extremes.

The primary objective of this technical research report is to explore and analyze how neoprene effectively protects against environmental extremes. We aim to provide a comprehensive understanding of the material's protective capabilities, focusing on its resistance to temperature fluctuations, chemical exposure, and mechanical stress. This investigation will serve as a foundation for potential innovations in protective gear and equipment across various sectors.

Neoprene's development has been driven by the increasing demand for materials that can withstand harsh conditions while maintaining flexibility and durability. Its closed-cell structure, which consists of tiny gas bubbles trapped within the rubber matrix, plays a crucial role in its insulating properties. This unique composition allows neoprene to provide thermal protection in both hot and cold environments, making it an ideal choice for applications in extreme temperature conditions.

The evolution of neoprene technology has seen significant advancements in recent years. Manufacturers have developed specialized formulations to enhance specific properties, such as improved UV resistance for outdoor applications or increased chemical resistance for industrial use. These developments have expanded the material's potential applications and improved its performance in protecting against environmental extremes.

In the context of this research, we will examine the molecular structure of neoprene and how it contributes to its protective qualities. We will also explore the various manufacturing processes and additives used to tailor neoprene's properties for specific environmental challenges. By understanding these fundamental aspects, we can identify potential areas for improvement and innovation in neoprene-based protective solutions.

Furthermore, this report will investigate the current market trends and emerging technologies that may complement or compete with neoprene in protective applications. By analyzing these factors, we aim to provide insights into the future direction of protective materials and potential opportunities for neoprene's continued development and application in safeguarding against environmental extremes.

Market Analysis for Neoprene-based Products

The neoprene market has experienced significant growth in recent years, driven by the material's unique properties and versatility across various industries. The global neoprene market size was valued at approximately $1.9 billion in 2020 and is projected to reach $2.5 billion by 2027, growing at a CAGR of around 4.5% during the forecast period.

The automotive industry remains a key driver for neoprene demand, particularly in applications such as hoses, belts, and gaskets. The material's resistance to oil, fuel, and heat makes it ideal for these components. Additionally, the growing electric vehicle market presents new opportunities for neoprene in battery insulation and thermal management systems.

In the construction sector, neoprene-based products are gaining traction due to their weather resistance and durability. Neoprene membranes and sealants are increasingly used in roofing, waterproofing, and insulation applications. The rising focus on energy-efficient buildings further boosts the demand for neoprene-based insulation materials.

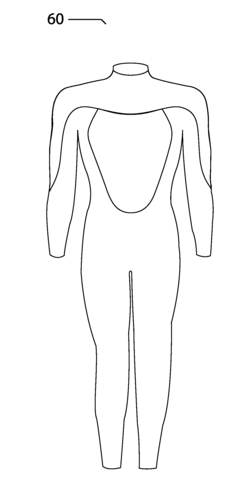

The sports and leisure industry continues to be a significant market for neoprene, especially in the production of wetsuits, athletic supports, and protective gear. The growing popularity of water sports and outdoor activities contributes to the steady demand in this sector.

Emerging applications in the medical and healthcare industries are opening new avenues for neoprene-based products. The material's hypoallergenic properties and resistance to bacteria make it suitable for medical gloves, orthopedic supports, and other healthcare applications.

Geographically, Asia-Pacific dominates the neoprene market, accounting for over 40% of the global share. The region's rapid industrialization, growing automotive production, and increasing construction activities are key factors driving this trend. North America and Europe follow, with steady demand from established industries and ongoing technological advancements.

Environmental concerns and regulations regarding chloroprene production, a key component in neoprene manufacturing, pose challenges to market growth. However, this has also spurred innovation in eco-friendly alternatives and recycling technologies, creating new market segments for sustainable neoprene products.

The competitive landscape of the neoprene market is characterized by the presence of major players such as DuPont, Lanxess, Tosoh Corporation, and Shanxi Synthetic Rubber Group. These companies are focusing on product innovation, strategic partnerships, and geographical expansion to maintain their market positions and capitalize on emerging opportunities in the neoprene-based products market.

The automotive industry remains a key driver for neoprene demand, particularly in applications such as hoses, belts, and gaskets. The material's resistance to oil, fuel, and heat makes it ideal for these components. Additionally, the growing electric vehicle market presents new opportunities for neoprene in battery insulation and thermal management systems.

In the construction sector, neoprene-based products are gaining traction due to their weather resistance and durability. Neoprene membranes and sealants are increasingly used in roofing, waterproofing, and insulation applications. The rising focus on energy-efficient buildings further boosts the demand for neoprene-based insulation materials.

The sports and leisure industry continues to be a significant market for neoprene, especially in the production of wetsuits, athletic supports, and protective gear. The growing popularity of water sports and outdoor activities contributes to the steady demand in this sector.

Emerging applications in the medical and healthcare industries are opening new avenues for neoprene-based products. The material's hypoallergenic properties and resistance to bacteria make it suitable for medical gloves, orthopedic supports, and other healthcare applications.

Geographically, Asia-Pacific dominates the neoprene market, accounting for over 40% of the global share. The region's rapid industrialization, growing automotive production, and increasing construction activities are key factors driving this trend. North America and Europe follow, with steady demand from established industries and ongoing technological advancements.

Environmental concerns and regulations regarding chloroprene production, a key component in neoprene manufacturing, pose challenges to market growth. However, this has also spurred innovation in eco-friendly alternatives and recycling technologies, creating new market segments for sustainable neoprene products.

The competitive landscape of the neoprene market is characterized by the presence of major players such as DuPont, Lanxess, Tosoh Corporation, and Shanxi Synthetic Rubber Group. These companies are focusing on product innovation, strategic partnerships, and geographical expansion to maintain their market positions and capitalize on emerging opportunities in the neoprene-based products market.

Current Challenges in Extreme Environment Protection

The protection of individuals and equipment in extreme environments presents significant challenges that continue to push the boundaries of material science and engineering. As neoprene emerges as a key player in this field, several critical issues persist in ensuring optimal protection against environmental extremes.

One of the primary challenges is maintaining flexibility and durability across a wide temperature range. While neoprene exhibits excellent performance in moderate conditions, its effectiveness can be compromised in extreme heat or cold. At very low temperatures, neoprene may become stiff and brittle, potentially reducing its protective capabilities. Conversely, in high-temperature environments, the material may soften excessively, leading to decreased structural integrity and potential degradation.

Chemical resistance poses another significant hurdle. Although neoprene demonstrates good resistance to many chemicals, it can still be vulnerable to certain solvents and oils. This limitation becomes particularly problematic in industrial settings or hazardous environments where exposure to a diverse range of chemicals is common. Enhancing neoprene's chemical resistance without compromising its other beneficial properties remains a complex challenge for material scientists.

The issue of long-term durability under constant exposure to harsh conditions is also a concern. Prolonged exposure to UV radiation, ozone, and other environmental factors can lead to degradation of neoprene over time. This degradation may manifest as cracking, loss of elasticity, or reduced protective properties, potentially compromising the safety of users or the integrity of protected equipment.

Balancing protection with comfort and breathability presents another significant challenge. While neoprene offers excellent insulation and protection, it can also lead to heat buildup and moisture accumulation, especially in high-exertion scenarios. This can result in discomfort for wearers and potentially create conditions conducive to heat stress or other health risks.

The need for specialized formulations to address specific environmental threats adds another layer of complexity. Different extreme environments may require tailored neoprene compositions to provide optimal protection. For instance, the requirements for deep-sea diving equipment differ significantly from those for firefighting gear or arctic exploration suits. Developing versatile yet specialized neoprene formulations that can adapt to various extreme conditions remains an ongoing challenge.

Lastly, the environmental impact of neoprene production and disposal is becoming an increasingly important consideration. As sustainability concerns grow, finding ways to manufacture neoprene more eco-friendly and improve its end-of-life recyclability or biodegradability presents a significant challenge for the industry.

One of the primary challenges is maintaining flexibility and durability across a wide temperature range. While neoprene exhibits excellent performance in moderate conditions, its effectiveness can be compromised in extreme heat or cold. At very low temperatures, neoprene may become stiff and brittle, potentially reducing its protective capabilities. Conversely, in high-temperature environments, the material may soften excessively, leading to decreased structural integrity and potential degradation.

Chemical resistance poses another significant hurdle. Although neoprene demonstrates good resistance to many chemicals, it can still be vulnerable to certain solvents and oils. This limitation becomes particularly problematic in industrial settings or hazardous environments where exposure to a diverse range of chemicals is common. Enhancing neoprene's chemical resistance without compromising its other beneficial properties remains a complex challenge for material scientists.

The issue of long-term durability under constant exposure to harsh conditions is also a concern. Prolonged exposure to UV radiation, ozone, and other environmental factors can lead to degradation of neoprene over time. This degradation may manifest as cracking, loss of elasticity, or reduced protective properties, potentially compromising the safety of users or the integrity of protected equipment.

Balancing protection with comfort and breathability presents another significant challenge. While neoprene offers excellent insulation and protection, it can also lead to heat buildup and moisture accumulation, especially in high-exertion scenarios. This can result in discomfort for wearers and potentially create conditions conducive to heat stress or other health risks.

The need for specialized formulations to address specific environmental threats adds another layer of complexity. Different extreme environments may require tailored neoprene compositions to provide optimal protection. For instance, the requirements for deep-sea diving equipment differ significantly from those for firefighting gear or arctic exploration suits. Developing versatile yet specialized neoprene formulations that can adapt to various extreme conditions remains an ongoing challenge.

Lastly, the environmental impact of neoprene production and disposal is becoming an increasingly important consideration. As sustainability concerns grow, finding ways to manufacture neoprene more eco-friendly and improve its end-of-life recyclability or biodegradability presents a significant challenge for the industry.

Existing Neoprene Protection Solutions

01 Neoprene composition and manufacturing

Various methods and compositions for manufacturing neoprene with improved properties are described. These include specific formulations, polymerization techniques, and additives to enhance the material's performance and durability.- Neoprene composition and manufacturing: Various methods and compositions for manufacturing neoprene with improved properties are described. These include specific formulations, polymerization techniques, and additives to enhance the protective qualities of neoprene materials.

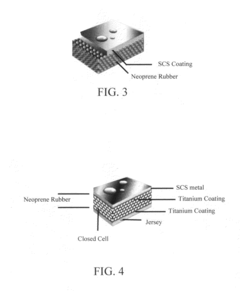

- Protective gear and clothing made from neoprene: Neoprene is used in the production of protective gear and clothing, such as wetsuits, gloves, and specialized apparel. These items offer insulation, flexibility, and protection against various environmental factors.

- Neoprene coatings and surface treatments: Surface treatments and coatings are applied to neoprene to enhance its protective properties. These treatments can improve resistance to chemicals, abrasion, and weathering, extending the material's durability and protective capabilities.

- Neoprene in automotive and industrial applications: Neoprene is utilized in various automotive and industrial applications for its protective properties. This includes gaskets, seals, hoses, and other components that require resistance to heat, oil, and environmental factors.

- Neoprene foam and insulation products: Neoprene foam and insulation products are developed for thermal and acoustic protection. These materials offer excellent insulation properties and are used in construction, marine, and other industries where protection from temperature extremes and sound is required.

02 Protective gear and clothing made from neoprene

Neoprene is used in the production of protective gear and clothing, such as wetsuits, gloves, and other specialized apparel. These items offer insulation, flexibility, and protection against various environmental factors.Expand Specific Solutions03 Neoprene in automotive and industrial applications

Neoprene finds applications in automotive and industrial sectors, including gaskets, seals, and protective coatings. Its resistance to oil, heat, and weathering makes it suitable for various mechanical and structural uses.Expand Specific Solutions04 Neoprene foam and insulation products

Neoprene foam and insulation products are developed for thermal and acoustic insulation in various applications. These materials offer excellent insulation properties while maintaining flexibility and durability.Expand Specific Solutions05 Environmental and safety considerations in neoprene production

Advancements in neoprene production focus on improving environmental sustainability and safety. This includes developing eco-friendly manufacturing processes, reducing harmful emissions, and enhancing worker safety during production.Expand Specific Solutions

Key Players in Neoprene Manufacturing

The competition landscape for neoprene's environmental protection capabilities is characterized by a mature market with established players and ongoing innovation. The global neoprene market size is estimated to be over $1.5 billion, with steady growth projected. Technologically, neoprene is well-developed, but companies continue to refine its properties for extreme conditions. Key players like W. L. Gore & Associates and NIKE, Inc. are investing in R&D to enhance neoprene's performance in harsh environments. Smaller specialized firms such as TecNiq, Inc. and Fatzer AG are also contributing innovations. Government agencies like NASA and academic institutions are researching advanced applications, indicating the technology's ongoing relevance and potential for further development.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced neoprene-based materials that offer superior protection against environmental extremes. Their technology incorporates a unique microporous structure that enhances thermal insulation while maintaining flexibility[1]. The company's neoprene products feature a proprietary cross-linking process that improves durability and resistance to chemical degradation[2]. Gore's neoprene solutions also integrate moisture-wicking properties, allowing for better temperature regulation in extreme conditions[3]. The company has further enhanced their neoprene's performance by incorporating nano-scale additives, which significantly improve its resistance to UV radiation and ozone[4].

Strengths: Superior thermal insulation, enhanced durability, and improved chemical resistance. Weaknesses: Potentially higher cost due to advanced manufacturing processes and proprietary technology.

BLÜCHER GmbH

Technical Solution: BLÜCHER GmbH has developed specialized neoprene-based materials for protection against chemical, biological, and environmental hazards. Their technology incorporates a unique layered structure that combines neoprene with activated carbon for enhanced protection[9]. BLÜCHER's neoprene solutions feature a proprietary surface treatment that improves resistance to chemical permeation and degradation[10]. The company has also developed a neoprene composite that offers improved flame resistance and thermal stability, crucial for extreme environmental conditions[11]. BLÜCHER's neoprene products integrate advanced vapor management systems, allowing for extended use in high-risk environments[12].

Strengths: Superior chemical and biological protection, enhanced flame resistance, and advanced vapor management. Weaknesses: Potentially higher cost and weight compared to standard neoprene products.

Core Innovations in Neoprene Composition

Anti-microbial compounds used in garments for water based activities

PatentInactiveUS20100205709A1

Innovation

- Incorporating colloidal or nanosized metals such as silver, platinum, palladium, and other metals into the insulation materials to create an antimicrobial barrier that inhibits bacterial and fungal growth, combined with polymers like polychloroprene, Hypalon, and polyurethanes, which are effective in reducing infection risk.

Bio based material and wetsuit

PatentInactiveUS20140283273A1

Innovation

- A sugar cane-derived closed-cell foam material is developed, which is free of polychloroprene, toxic agents, and heavy metals, and has a lower carbon footprint, offering insulation, flexibility, and ease of decomposition, formed by polymerizing sugar cane with foaming agents and additives to create a low-density, flexible, and chemically inert material.

Environmental Impact of Neoprene Production

The production of neoprene, a synthetic rubber widely used for its protective properties against environmental extremes, has significant environmental implications. The manufacturing process involves several stages that contribute to various forms of pollution and resource depletion.

One of the primary environmental concerns is the emission of chloroprene, a key ingredient in neoprene production. Chloroprene is classified as a probable human carcinogen and can have detrimental effects on air quality. The release of this compound during manufacturing processes poses risks to both workers and surrounding communities.

Water pollution is another critical issue associated with neoprene production. The manufacturing process generates wastewater containing various chemicals, including solvents and unreacted monomers. If not properly treated, these effluents can contaminate local water sources, affecting aquatic ecosystems and potentially entering the human water supply.

Energy consumption in neoprene production is substantial, contributing to greenhouse gas emissions and climate change. The high-temperature polymerization process and subsequent processing steps require significant amounts of energy, often derived from fossil fuels. This energy-intensive nature of production adds to the carbon footprint of neoprene products.

The raw materials used in neoprene production, primarily petroleum-based chemicals, also raise sustainability concerns. The extraction and processing of these non-renewable resources contribute to environmental degradation and resource depletion. Additionally, the transportation of raw materials and finished products adds to the overall environmental impact through increased carbon emissions.

Waste generation is another environmental challenge in neoprene production. Off-spec materials, trimmings, and end-of-life products often end up in landfills, as neoprene is not easily biodegradable. This contributes to the growing problem of plastic pollution and waste management.

Despite these environmental challenges, efforts are being made to mitigate the impact of neoprene production. Some manufacturers are implementing closed-loop systems to reduce emissions and improve resource efficiency. Research is also ongoing to develop more sustainable alternatives and improve recycling technologies for neoprene products.

In conclusion, while neoprene offers valuable protective properties against environmental extremes, its production process presents significant environmental challenges. Balancing the benefits of neoprene with its environmental impact remains a crucial consideration for manufacturers and consumers alike.

One of the primary environmental concerns is the emission of chloroprene, a key ingredient in neoprene production. Chloroprene is classified as a probable human carcinogen and can have detrimental effects on air quality. The release of this compound during manufacturing processes poses risks to both workers and surrounding communities.

Water pollution is another critical issue associated with neoprene production. The manufacturing process generates wastewater containing various chemicals, including solvents and unreacted monomers. If not properly treated, these effluents can contaminate local water sources, affecting aquatic ecosystems and potentially entering the human water supply.

Energy consumption in neoprene production is substantial, contributing to greenhouse gas emissions and climate change. The high-temperature polymerization process and subsequent processing steps require significant amounts of energy, often derived from fossil fuels. This energy-intensive nature of production adds to the carbon footprint of neoprene products.

The raw materials used in neoprene production, primarily petroleum-based chemicals, also raise sustainability concerns. The extraction and processing of these non-renewable resources contribute to environmental degradation and resource depletion. Additionally, the transportation of raw materials and finished products adds to the overall environmental impact through increased carbon emissions.

Waste generation is another environmental challenge in neoprene production. Off-spec materials, trimmings, and end-of-life products often end up in landfills, as neoprene is not easily biodegradable. This contributes to the growing problem of plastic pollution and waste management.

Despite these environmental challenges, efforts are being made to mitigate the impact of neoprene production. Some manufacturers are implementing closed-loop systems to reduce emissions and improve resource efficiency. Research is also ongoing to develop more sustainable alternatives and improve recycling technologies for neoprene products.

In conclusion, while neoprene offers valuable protective properties against environmental extremes, its production process presents significant environmental challenges. Balancing the benefits of neoprene with its environmental impact remains a crucial consideration for manufacturers and consumers alike.

Neoprene Recycling and Sustainability

Neoprene, a synthetic rubber known for its versatility and durability, has been widely used in various industries for decades. However, as environmental concerns grow, the focus on recycling and sustainability of neoprene products has intensified. The recycling process for neoprene presents unique challenges due to its complex composition and the presence of additives used to enhance its properties.

Several innovative approaches have emerged to address the recycling of neoprene. One method involves mechanical recycling, where neoprene products are shredded and ground into small particles. These particles can then be used as filler material in new rubber products or as a component in construction materials. This process helps reduce waste but does not fully recover the original neoprene properties.

Chemical recycling offers a more promising solution for neoprene sustainability. This method involves breaking down the polymer chains of neoprene into their constituent monomers or other valuable chemical compounds. These recovered materials can then be used to produce new neoprene or other polymers, creating a more circular economy for the material.

Advancements in thermal decomposition techniques have also shown potential for neoprene recycling. By carefully controlling temperature and pressure, it is possible to convert neoprene waste into useful products such as oils and gases, which can be used as fuel or chemical feedstock.

The sustainability of neoprene extends beyond recycling efforts. Manufacturers are increasingly focusing on developing bio-based alternatives to traditional petroleum-derived neoprene. These bio-neoprenes, made from renewable resources such as plant-based oils, offer a more environmentally friendly option while maintaining similar performance characteristics.

Efforts to improve the sustainability of neoprene also include optimizing production processes to reduce energy consumption and minimize waste. This involves implementing more efficient manufacturing techniques, using cleaner energy sources, and developing closed-loop systems that recapture and reuse materials throughout the production cycle.

The adoption of sustainable practices in neoprene production and recycling is driven not only by environmental concerns but also by economic factors. As regulations on waste disposal and carbon emissions become more stringent, companies are finding that investing in recycling and sustainability initiatives can lead to long-term cost savings and improved brand reputation.

While progress has been made in neoprene recycling and sustainability, challenges remain. The diversity of neoprene products and the presence of contaminants can complicate recycling efforts. Additionally, the cost of implementing advanced recycling technologies can be a barrier for some manufacturers. However, ongoing research and development in this field continue to yield promising solutions, paving the way for a more sustainable future for neoprene.

Several innovative approaches have emerged to address the recycling of neoprene. One method involves mechanical recycling, where neoprene products are shredded and ground into small particles. These particles can then be used as filler material in new rubber products or as a component in construction materials. This process helps reduce waste but does not fully recover the original neoprene properties.

Chemical recycling offers a more promising solution for neoprene sustainability. This method involves breaking down the polymer chains of neoprene into their constituent monomers or other valuable chemical compounds. These recovered materials can then be used to produce new neoprene or other polymers, creating a more circular economy for the material.

Advancements in thermal decomposition techniques have also shown potential for neoprene recycling. By carefully controlling temperature and pressure, it is possible to convert neoprene waste into useful products such as oils and gases, which can be used as fuel or chemical feedstock.

The sustainability of neoprene extends beyond recycling efforts. Manufacturers are increasingly focusing on developing bio-based alternatives to traditional petroleum-derived neoprene. These bio-neoprenes, made from renewable resources such as plant-based oils, offer a more environmentally friendly option while maintaining similar performance characteristics.

Efforts to improve the sustainability of neoprene also include optimizing production processes to reduce energy consumption and minimize waste. This involves implementing more efficient manufacturing techniques, using cleaner energy sources, and developing closed-loop systems that recapture and reuse materials throughout the production cycle.

The adoption of sustainable practices in neoprene production and recycling is driven not only by environmental concerns but also by economic factors. As regulations on waste disposal and carbon emissions become more stringent, companies are finding that investing in recycling and sustainability initiatives can lead to long-term cost savings and improved brand reputation.

While progress has been made in neoprene recycling and sustainability, challenges remain. The diversity of neoprene products and the presence of contaminants can complicate recycling efforts. Additionally, the cost of implementing advanced recycling technologies can be a barrier for some manufacturers. However, ongoing research and development in this field continue to yield promising solutions, paving the way for a more sustainable future for neoprene.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!