How to Utilize Neoprene for High-Stress Applications?

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Evolution and Objectives

Neoprene, a synthetic rubber developed by DuPont in 1930, has undergone significant evolution since its inception. Initially created as an oil-resistant alternative to natural rubber, neoprene has become a versatile material used in various high-stress applications. The journey of neoprene from its discovery to its current state reflects the continuous efforts to enhance its properties and expand its utility.

In its early days, neoprene was primarily used in industrial applications due to its resistance to oil, heat, and weathering. As manufacturing processes improved, the material's properties were refined, leading to its adoption in more diverse fields. The 1950s and 1960s saw neoprene gain popularity in the automotive and aerospace industries, where its durability and resistance to extreme conditions proved invaluable.

The evolution of neoprene has been driven by the growing demand for materials capable of withstanding high-stress environments. Researchers and engineers have focused on improving its tensile strength, elongation properties, and resistance to compression set. These advancements have enabled neoprene to meet the increasingly stringent requirements of modern industrial and consumer applications.

One of the key objectives in neoprene development has been to enhance its performance under extreme temperatures and pressures. This has led to the creation of specialized neoprene compounds tailored for specific high-stress scenarios. For instance, modifications in the polymer structure and the addition of reinforcing agents have resulted in neoprene variants that can maintain their properties in environments ranging from cryogenic temperatures to high-heat applications.

Another important goal in neoprene evolution has been to improve its resistance to chemical degradation. This objective has been particularly crucial for applications in the oil and gas industry, where exposure to corrosive substances is common. The development of chemically resistant neoprene grades has significantly expanded the material's utility in these demanding sectors.

The pursuit of sustainability has also shaped recent objectives in neoprene development. Efforts are underway to create more environmentally friendly production processes and to improve the material's recyclability. These initiatives aim to address growing environmental concerns while maintaining neoprene's high-performance characteristics.

Looking forward, the objectives for neoprene in high-stress applications continue to evolve. Current research focuses on further enhancing its mechanical properties, developing self-healing capabilities, and integrating smart features such as sensors for real-time monitoring. These advancements aim to push the boundaries of neoprene's capabilities, enabling its use in even more challenging and critical applications across various industries.

In its early days, neoprene was primarily used in industrial applications due to its resistance to oil, heat, and weathering. As manufacturing processes improved, the material's properties were refined, leading to its adoption in more diverse fields. The 1950s and 1960s saw neoprene gain popularity in the automotive and aerospace industries, where its durability and resistance to extreme conditions proved invaluable.

The evolution of neoprene has been driven by the growing demand for materials capable of withstanding high-stress environments. Researchers and engineers have focused on improving its tensile strength, elongation properties, and resistance to compression set. These advancements have enabled neoprene to meet the increasingly stringent requirements of modern industrial and consumer applications.

One of the key objectives in neoprene development has been to enhance its performance under extreme temperatures and pressures. This has led to the creation of specialized neoprene compounds tailored for specific high-stress scenarios. For instance, modifications in the polymer structure and the addition of reinforcing agents have resulted in neoprene variants that can maintain their properties in environments ranging from cryogenic temperatures to high-heat applications.

Another important goal in neoprene evolution has been to improve its resistance to chemical degradation. This objective has been particularly crucial for applications in the oil and gas industry, where exposure to corrosive substances is common. The development of chemically resistant neoprene grades has significantly expanded the material's utility in these demanding sectors.

The pursuit of sustainability has also shaped recent objectives in neoprene development. Efforts are underway to create more environmentally friendly production processes and to improve the material's recyclability. These initiatives aim to address growing environmental concerns while maintaining neoprene's high-performance characteristics.

Looking forward, the objectives for neoprene in high-stress applications continue to evolve. Current research focuses on further enhancing its mechanical properties, developing self-healing capabilities, and integrating smart features such as sensors for real-time monitoring. These advancements aim to push the boundaries of neoprene's capabilities, enabling its use in even more challenging and critical applications across various industries.

Market Demand Analysis

The market demand for neoprene in high-stress applications has been steadily increasing across various industries. This versatile synthetic rubber, known for its excellent resistance to oil, heat, weathering, and chemicals, has found widespread use in demanding environments. The automotive sector, in particular, has shown a growing interest in neoprene for components subjected to high stress and extreme conditions, such as engine mounts, hoses, and seals. The material's ability to maintain its properties under severe mechanical stress and temperature fluctuations makes it an ideal choice for these applications.

In the aerospace industry, neoprene's resistance to ozone and weathering has led to its increased adoption in aircraft seals, gaskets, and vibration dampeners. The material's durability and reliability in high-altitude environments have made it a preferred choice for manufacturers looking to enhance the longevity and performance of aircraft components. Similarly, the marine industry has seen a surge in demand for neoprene-based products, particularly in boat construction, diving suits, and underwater equipment, due to its excellent water resistance and flexibility.

The construction sector has also contributed significantly to the growing market for neoprene in high-stress applications. The material's use in expansion joints, bridge bearings, and seismic isolation systems has increased as builders seek more resilient and long-lasting solutions for infrastructure projects. Neoprene's ability to absorb shock and vibration while maintaining its structural integrity has made it an essential component in modern construction techniques, especially in earthquake-prone regions.

In the industrial machinery and equipment market, neoprene has gained traction for its use in high-performance gaskets, seals, and conveyor belts. The material's resistance to abrasion, tearing, and flexing under high stress has led to its adoption in manufacturing processes that involve extreme temperatures, pressures, or chemical exposure. This trend is expected to continue as industries seek to improve equipment reliability and reduce maintenance costs.

The global neoprene market is projected to experience steady growth in the coming years, driven by these high-stress applications across multiple sectors. Factors such as increasing industrialization, infrastructure development, and the need for more durable materials in extreme environments are expected to fuel this growth. However, the market also faces challenges, including the volatility of raw material prices and the emergence of alternative synthetic rubbers. Despite these challenges, the unique combination of properties offered by neoprene ensures its continued relevance and demand in high-stress applications.

In the aerospace industry, neoprene's resistance to ozone and weathering has led to its increased adoption in aircraft seals, gaskets, and vibration dampeners. The material's durability and reliability in high-altitude environments have made it a preferred choice for manufacturers looking to enhance the longevity and performance of aircraft components. Similarly, the marine industry has seen a surge in demand for neoprene-based products, particularly in boat construction, diving suits, and underwater equipment, due to its excellent water resistance and flexibility.

The construction sector has also contributed significantly to the growing market for neoprene in high-stress applications. The material's use in expansion joints, bridge bearings, and seismic isolation systems has increased as builders seek more resilient and long-lasting solutions for infrastructure projects. Neoprene's ability to absorb shock and vibration while maintaining its structural integrity has made it an essential component in modern construction techniques, especially in earthquake-prone regions.

In the industrial machinery and equipment market, neoprene has gained traction for its use in high-performance gaskets, seals, and conveyor belts. The material's resistance to abrasion, tearing, and flexing under high stress has led to its adoption in manufacturing processes that involve extreme temperatures, pressures, or chemical exposure. This trend is expected to continue as industries seek to improve equipment reliability and reduce maintenance costs.

The global neoprene market is projected to experience steady growth in the coming years, driven by these high-stress applications across multiple sectors. Factors such as increasing industrialization, infrastructure development, and the need for more durable materials in extreme environments are expected to fuel this growth. However, the market also faces challenges, including the volatility of raw material prices and the emergence of alternative synthetic rubbers. Despite these challenges, the unique combination of properties offered by neoprene ensures its continued relevance and demand in high-stress applications.

Current Challenges in High-Stress Applications

The utilization of neoprene in high-stress applications faces several significant challenges that require innovative solutions and advanced engineering approaches. One of the primary obstacles is the material's limited temperature resistance. While neoprene exhibits excellent performance at room temperature, its properties begin to degrade at elevated temperatures, typically above 100°C. This thermal limitation restricts its use in high-temperature environments, such as automotive engine compartments or industrial processing equipment.

Another critical challenge is the material's susceptibility to chemical degradation. Although neoprene demonstrates good resistance to many oils and chemicals, it can be adversely affected by prolonged exposure to certain solvents, strong acids, and oxidizing agents. This vulnerability necessitates careful consideration of the operating environment and potential chemical interactions when designing neoprene components for high-stress applications.

Mechanical fatigue is a significant concern in high-stress scenarios. Neoprene, like many elastomers, can experience stress relaxation and creep under constant load, leading to dimensional changes and potential failure over time. This behavior is particularly problematic in applications requiring long-term stability and precise dimensional tolerances, such as seals and gaskets in pressurized systems.

The material's relatively low tear strength compared to some other elastomers poses challenges in applications involving sharp edges or high shear forces. This limitation can lead to premature failure in components subjected to repeated flexing or abrasion, necessitating careful design considerations and potential reinforcement strategies.

Neoprene's electrical properties present both advantages and challenges. While it offers good electrical insulation, its dielectric strength may not be sufficient for certain high-voltage applications. Additionally, the material's electrical properties can change with temperature and environmental conditions, requiring careful characterization and design allowances.

The manufacturing and processing of neoprene for high-stress applications also present challenges. Achieving consistent material properties across large production batches can be difficult, potentially leading to variability in performance. Moreover, the bonding of neoprene to other materials, such as metals or composites, often requires specialized surface treatments and adhesives to ensure durable connections under high-stress conditions.

Environmental concerns and regulatory pressures pose additional challenges. The production of neoprene involves chloroprene, which has raised environmental and health concerns. As a result, there is growing pressure to develop more sustainable alternatives or improve the eco-friendliness of neoprene production processes, which may impact its availability and cost-effectiveness for high-stress applications in the future.

Another critical challenge is the material's susceptibility to chemical degradation. Although neoprene demonstrates good resistance to many oils and chemicals, it can be adversely affected by prolonged exposure to certain solvents, strong acids, and oxidizing agents. This vulnerability necessitates careful consideration of the operating environment and potential chemical interactions when designing neoprene components for high-stress applications.

Mechanical fatigue is a significant concern in high-stress scenarios. Neoprene, like many elastomers, can experience stress relaxation and creep under constant load, leading to dimensional changes and potential failure over time. This behavior is particularly problematic in applications requiring long-term stability and precise dimensional tolerances, such as seals and gaskets in pressurized systems.

The material's relatively low tear strength compared to some other elastomers poses challenges in applications involving sharp edges or high shear forces. This limitation can lead to premature failure in components subjected to repeated flexing or abrasion, necessitating careful design considerations and potential reinforcement strategies.

Neoprene's electrical properties present both advantages and challenges. While it offers good electrical insulation, its dielectric strength may not be sufficient for certain high-voltage applications. Additionally, the material's electrical properties can change with temperature and environmental conditions, requiring careful characterization and design allowances.

The manufacturing and processing of neoprene for high-stress applications also present challenges. Achieving consistent material properties across large production batches can be difficult, potentially leading to variability in performance. Moreover, the bonding of neoprene to other materials, such as metals or composites, often requires specialized surface treatments and adhesives to ensure durable connections under high-stress conditions.

Environmental concerns and regulatory pressures pose additional challenges. The production of neoprene involves chloroprene, which has raised environmental and health concerns. As a result, there is growing pressure to develop more sustainable alternatives or improve the eco-friendliness of neoprene production processes, which may impact its availability and cost-effectiveness for high-stress applications in the future.

Existing High-Stress Neoprene Solutions

01 Composition and synthesis of neoprene

Neoprene is a synthetic rubber produced by polymerization of chloroprene. It is known for its resistance to oil, heat, and weathering. The manufacturing process involves careful control of reaction conditions and may include various additives to enhance specific properties.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. It is known for its resistance to oil, heat, and weathering. The manufacturing process involves careful control of reaction conditions and may include various additives to enhance specific properties.

- Applications of neoprene in protective gear: Neoprene is widely used in the production of protective gear such as wetsuits, diving suits, and other water-resistant clothing. Its flexibility, insulation properties, and durability make it ideal for these applications. Neoprene-based protective gear can be designed with varying thicknesses and compositions to suit different environmental conditions.

- Neoprene foam and cellular structures: Neoprene can be processed into foam or cellular structures, which enhance its insulation properties and reduce weight. These structures are created through various foaming techniques and can be tailored for specific applications such as thermal insulation, cushioning, or buoyancy aids.

- Neoprene blends and composites: Neoprene can be blended with other materials or used in composite structures to enhance its properties or create specialized materials. These blends and composites may incorporate other elastomers, fibers, or fillers to achieve desired characteristics such as improved strength, flame resistance, or electrical properties.

- Neoprene in industrial applications: Neoprene finds extensive use in various industrial applications due to its chemical resistance and durability. It is used in the production of gaskets, seals, hoses, and conveyor belts. Neoprene-based products can withstand harsh environments and are often employed in automotive, aerospace, and marine industries.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear such as wetsuits, diving suits, and other water-resistant clothing. Its flexibility, insulation properties, and durability make it ideal for these applications. Neoprene can be combined with other materials to enhance its performance in specific use cases.Expand Specific Solutions03 Neoprene foam production and properties

Neoprene foam is a versatile material with applications in various industries. The production process involves introducing gas bubbles into the neoprene compound during vulcanization. The resulting foam exhibits excellent insulation properties, buoyancy, and shock absorption characteristics.Expand Specific Solutions04 Modifications and improvements to neoprene

Ongoing research focuses on enhancing neoprene's properties through various modifications. These include the incorporation of nanomaterials, blending with other polymers, and surface treatments. Such modifications aim to improve characteristics like tensile strength, thermal stability, and chemical resistance.Expand Specific Solutions05 Environmental considerations and alternatives

As environmental concerns grow, efforts are being made to develop more sustainable alternatives to traditional neoprene. This includes exploring bio-based materials, improving recycling processes for neoprene products, and developing neoprene formulations with reduced environmental impact during production and disposal.Expand Specific Solutions

Key Industry Players

The market for neoprene in high-stress applications is in a mature growth phase, with a global market size estimated to exceed $2 billion by 2025. The technology's maturity is evident in its widespread use across industries, but ongoing research focuses on enhancing performance in extreme conditions. Key players like DuPont de Nemours, Dow Global Technologies, and Denka Corp. are at the forefront of innovation, developing advanced neoprene formulations for aerospace, automotive, and industrial applications. These companies are investing in R&D to improve neoprene's resistance to heat, chemicals, and mechanical stress, driving the material's evolution for next-generation high-stress applications.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced neoprene formulations for high-stress applications, focusing on improving the material's resistance to heat, oil, and ozone. Their proprietary compounding techniques enhance neoprene's durability and flexibility, making it suitable for extreme environments. Dow's neoprene compounds incorporate specialized additives that improve its resistance to compression set and tear strength, crucial for applications involving repeated stress cycles[1]. The company has also introduced neoprene grades with improved low-temperature flexibility, extending its use in cold environments while maintaining its characteristic resilience[3].

Strengths: Superior chemical resistance, excellent weatherability, and enhanced durability in extreme conditions. Weaknesses: Higher cost compared to some alternative elastomers, limited high-temperature performance compared to some specialized rubbers.

DuPont de Nemours, Inc.

Technical Solution: DuPont, the original inventor of neoprene, continues to innovate in high-stress applications. Their latest neoprene compounds feature improved cross-linking technology, resulting in enhanced tensile strength and elongation properties. DuPont's research has led to the development of neoprene grades with superior flex crack resistance, crucial for applications involving repeated bending or flexing under high stress[2]. The company has also focused on improving the material's compression set resistance, allowing for better performance in sealing and gasket applications where constant pressure is applied[4]. DuPont's neoprene formulations now offer improved resistance to dynamic fatigue, making them ideal for vibration isolation in industrial machinery.

Strengths: Excellent balance of physical properties, superior aging resistance, and versatility across various high-stress applications. Weaknesses: Relatively high density compared to some other elastomers, which may limit its use in weight-sensitive applications.

Core Neoprene Innovations

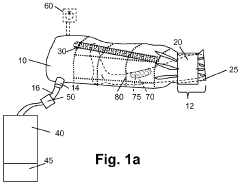

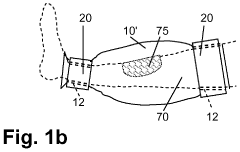

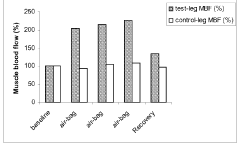

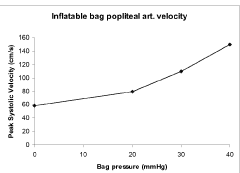

Method and apparatus for increasing blood flow in a body part

PatentWO2007137207A2

Innovation

- A device that applies external air pressure around the body part using a substantially airtight enclosure with a pump and pressure gauge, avoiding direct contact, to provide uniform compression and increase microvascular flow, allowing for easy access and inspection.

Wear resistant high molecular weight polyacetal-ultrahigh molecular weight polyethylene compositions and articles formed therefrom

PatentInactiveUS20070015869A1

Innovation

- A melt-mixed blend of high molecular weight polyacetal and UHMWPE, with weight percentages ranging from 55 to 95% polyacetal and 5 to 45% UHMWPE, which is melt-processable and exhibits improved wear resistance, impact resistance, and suitable for forming articles through extrusion processes.

Environmental Impact Assessment

The environmental impact of utilizing neoprene in high-stress applications is a critical consideration that requires thorough assessment. Neoprene, a synthetic rubber produced through polymerization of chloroprene, has both positive and negative environmental implications throughout its lifecycle.

Production of neoprene involves energy-intensive processes and the use of potentially harmful chemicals. The manufacturing process releases volatile organic compounds (VOCs) and other pollutants, contributing to air and water pollution if not properly managed. However, advancements in production technologies have led to more efficient and cleaner manufacturing methods, reducing the overall environmental footprint.

Neoprene's durability and resistance to degradation, while beneficial for high-stress applications, pose challenges for end-of-life disposal. The material does not biodegrade easily, potentially contributing to long-term environmental pollution if not properly recycled or disposed of. However, recent developments in recycling technologies have improved the ability to recover and reuse neoprene, mitigating some of these concerns.

In high-stress applications, neoprene's longevity can be seen as an environmental advantage. Its ability to withstand harsh conditions and maintain performance over extended periods reduces the need for frequent replacements, thereby conserving resources and energy associated with manufacturing and transportation of replacement materials.

Water pollution is another concern, particularly in marine applications. While neoprene is generally inert, prolonged exposure to saltwater and UV radiation can cause degradation, potentially releasing microplastics and chemical additives into aquatic ecosystems. This highlights the importance of proper maintenance and timely replacement in marine environments.

On the positive side, neoprene's excellent insulation properties can contribute to energy efficiency in certain applications, such as in building materials or industrial equipment. This indirect environmental benefit should be considered when evaluating its overall impact.

The carbon footprint of neoprene production and transportation is significant, given its petroleum-based origins. However, ongoing research into bio-based alternatives and more sustainable production methods shows promise in reducing the material's overall environmental impact.

In conclusion, while neoprene offers valuable properties for high-stress applications, its environmental impact is complex and multifaceted. Balancing its performance benefits against environmental concerns requires careful consideration and ongoing efforts to improve production processes, enhance recyclability, and develop more sustainable alternatives.

Production of neoprene involves energy-intensive processes and the use of potentially harmful chemicals. The manufacturing process releases volatile organic compounds (VOCs) and other pollutants, contributing to air and water pollution if not properly managed. However, advancements in production technologies have led to more efficient and cleaner manufacturing methods, reducing the overall environmental footprint.

Neoprene's durability and resistance to degradation, while beneficial for high-stress applications, pose challenges for end-of-life disposal. The material does not biodegrade easily, potentially contributing to long-term environmental pollution if not properly recycled or disposed of. However, recent developments in recycling technologies have improved the ability to recover and reuse neoprene, mitigating some of these concerns.

In high-stress applications, neoprene's longevity can be seen as an environmental advantage. Its ability to withstand harsh conditions and maintain performance over extended periods reduces the need for frequent replacements, thereby conserving resources and energy associated with manufacturing and transportation of replacement materials.

Water pollution is another concern, particularly in marine applications. While neoprene is generally inert, prolonged exposure to saltwater and UV radiation can cause degradation, potentially releasing microplastics and chemical additives into aquatic ecosystems. This highlights the importance of proper maintenance and timely replacement in marine environments.

On the positive side, neoprene's excellent insulation properties can contribute to energy efficiency in certain applications, such as in building materials or industrial equipment. This indirect environmental benefit should be considered when evaluating its overall impact.

The carbon footprint of neoprene production and transportation is significant, given its petroleum-based origins. However, ongoing research into bio-based alternatives and more sustainable production methods shows promise in reducing the material's overall environmental impact.

In conclusion, while neoprene offers valuable properties for high-stress applications, its environmental impact is complex and multifaceted. Balancing its performance benefits against environmental concerns requires careful consideration and ongoing efforts to improve production processes, enhance recyclability, and develop more sustainable alternatives.

Regulatory Compliance for Neoprene Use

Regulatory compliance for neoprene use in high-stress applications is a critical consideration for manufacturers and end-users alike. The use of neoprene in demanding environments necessitates adherence to a complex web of regulations and standards that vary across industries and geographical regions.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth guidelines for the safe use of neoprene in industrial settings. These regulations cover aspects such as personal protective equipment (PPE), exposure limits, and proper handling procedures. Manufacturers must ensure that their neoprene products meet OSHA's requirements for chemical resistance and durability when used in high-stress applications.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of neoprene in high-stress applications within EU member states. REACH requires manufacturers to register chemicals used in their products and provide safety data sheets detailing potential hazards and safe handling practices. Compliance with REACH is essential for companies looking to market neoprene products in Europe.

International standards organizations, such as ISO and ASTM, provide guidelines for testing and certifying neoprene products used in high-stress applications. These standards ensure consistency in product quality and performance across different manufacturers and applications. Adherence to these standards is often a prerequisite for regulatory compliance in many jurisdictions.

In the automotive industry, neoprene components used in high-stress applications must comply with specific regulations such as FMVSS (Federal Motor Vehicle Safety Standards) in the United States or UN/ECE regulations in Europe. These standards cover aspects like flammability, durability, and chemical resistance of neoprene parts used in vehicles.

For marine applications, neoprene products must often meet Coast Guard regulations and international maritime standards. These regulations focus on factors such as fire resistance, oil resistance, and overall durability in harsh marine environments. Compliance with these standards is crucial for ensuring the safety and reliability of neoprene components used in ships and offshore structures.

The aerospace industry has particularly stringent regulatory requirements for materials used in high-stress applications. Neoprene products used in aircraft must comply with FAA (Federal Aviation Administration) regulations in the United States or EASA (European Union Aviation Safety Agency) standards in Europe. These regulations cover aspects such as fire resistance, outgassing properties, and resistance to extreme temperatures and pressures.

As environmental concerns grow, regulations surrounding the disposal and recycling of neoprene products are becoming increasingly important. Manufacturers must consider end-of-life regulations when designing neoprene products for high-stress applications, ensuring that their products can be safely disposed of or recycled in compliance with local and international environmental standards.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth guidelines for the safe use of neoprene in industrial settings. These regulations cover aspects such as personal protective equipment (PPE), exposure limits, and proper handling procedures. Manufacturers must ensure that their neoprene products meet OSHA's requirements for chemical resistance and durability when used in high-stress applications.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of neoprene in high-stress applications within EU member states. REACH requires manufacturers to register chemicals used in their products and provide safety data sheets detailing potential hazards and safe handling practices. Compliance with REACH is essential for companies looking to market neoprene products in Europe.

International standards organizations, such as ISO and ASTM, provide guidelines for testing and certifying neoprene products used in high-stress applications. These standards ensure consistency in product quality and performance across different manufacturers and applications. Adherence to these standards is often a prerequisite for regulatory compliance in many jurisdictions.

In the automotive industry, neoprene components used in high-stress applications must comply with specific regulations such as FMVSS (Federal Motor Vehicle Safety Standards) in the United States or UN/ECE regulations in Europe. These standards cover aspects like flammability, durability, and chemical resistance of neoprene parts used in vehicles.

For marine applications, neoprene products must often meet Coast Guard regulations and international maritime standards. These regulations focus on factors such as fire resistance, oil resistance, and overall durability in harsh marine environments. Compliance with these standards is crucial for ensuring the safety and reliability of neoprene components used in ships and offshore structures.

The aerospace industry has particularly stringent regulatory requirements for materials used in high-stress applications. Neoprene products used in aircraft must comply with FAA (Federal Aviation Administration) regulations in the United States or EASA (European Union Aviation Safety Agency) standards in Europe. These regulations cover aspects such as fire resistance, outgassing properties, and resistance to extreme temperatures and pressures.

As environmental concerns grow, regulations surrounding the disposal and recycling of neoprene products are becoming increasingly important. Manufacturers must consider end-of-life regulations when designing neoprene products for high-stress applications, ensuring that their products can be safely disposed of or recycled in compliance with local and international environmental standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!