How Nonwoven Polypropylene Enhances Air Quality in Ventilation Systems

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nonwoven PP in HVAC: Background and Objectives

Nonwoven polypropylene (PP) has emerged as a crucial material in enhancing air quality within ventilation systems, marking a significant advancement in HVAC technology. The evolution of this technology can be traced back to the mid-20th century when synthetic polymers first gained prominence in industrial applications. Over the decades, the unique properties of nonwoven PP, including its high filtration efficiency, durability, and cost-effectiveness, have positioned it as a preferred choice in air filtration systems.

The primary objective of incorporating nonwoven PP in HVAC systems is to improve indoor air quality by effectively capturing airborne particles, allergens, and pollutants. This aligns with the growing global emphasis on creating healthier indoor environments, particularly in light of increasing urbanization and the associated rise in air pollution levels. The technology aims to address the challenges posed by traditional filtration methods, which often struggle to balance high efficiency with low pressure drop and extended filter life.

As environmental concerns and health awareness continue to rise, the demand for advanced air filtration solutions has surged across various sectors, including residential, commercial, and industrial applications. Nonwoven PP filters are designed to meet these evolving needs by offering superior particulate matter removal, including fine particles (PM2.5) and ultrafine particles, which are known to have significant health impacts.

The development trajectory of nonwoven PP in HVAC systems has been characterized by continuous innovation in material science and manufacturing processes. Researchers and engineers have focused on enhancing the fiber structure, optimizing pore size distribution, and improving the electrostatic properties of PP fibers to boost filtration performance. These advancements have led to the creation of multi-layered filter media that can target a wide range of particle sizes and contaminants.

Looking ahead, the technology aims to further refine its capabilities in several key areas. These include developing even more efficient filtration mechanisms, reducing the environmental footprint of filter production and disposal, and integrating smart technologies for real-time air quality monitoring and filter performance optimization. The ultimate goal is to create ventilation systems that not only purify air more effectively but also contribute to overall energy efficiency and sustainability in building operations.

As the field progresses, interdisciplinary collaboration between material scientists, environmental engineers, and HVAC specialists is expected to drive further innovations. This collaborative approach will be crucial in addressing complex challenges such as the filtration of emerging pollutants, adaptation to diverse climatic conditions, and the development of self-cleaning or regenerative filter technologies.

The primary objective of incorporating nonwoven PP in HVAC systems is to improve indoor air quality by effectively capturing airborne particles, allergens, and pollutants. This aligns with the growing global emphasis on creating healthier indoor environments, particularly in light of increasing urbanization and the associated rise in air pollution levels. The technology aims to address the challenges posed by traditional filtration methods, which often struggle to balance high efficiency with low pressure drop and extended filter life.

As environmental concerns and health awareness continue to rise, the demand for advanced air filtration solutions has surged across various sectors, including residential, commercial, and industrial applications. Nonwoven PP filters are designed to meet these evolving needs by offering superior particulate matter removal, including fine particles (PM2.5) and ultrafine particles, which are known to have significant health impacts.

The development trajectory of nonwoven PP in HVAC systems has been characterized by continuous innovation in material science and manufacturing processes. Researchers and engineers have focused on enhancing the fiber structure, optimizing pore size distribution, and improving the electrostatic properties of PP fibers to boost filtration performance. These advancements have led to the creation of multi-layered filter media that can target a wide range of particle sizes and contaminants.

Looking ahead, the technology aims to further refine its capabilities in several key areas. These include developing even more efficient filtration mechanisms, reducing the environmental footprint of filter production and disposal, and integrating smart technologies for real-time air quality monitoring and filter performance optimization. The ultimate goal is to create ventilation systems that not only purify air more effectively but also contribute to overall energy efficiency and sustainability in building operations.

As the field progresses, interdisciplinary collaboration between material scientists, environmental engineers, and HVAC specialists is expected to drive further innovations. This collaborative approach will be crucial in addressing complex challenges such as the filtration of emerging pollutants, adaptation to diverse climatic conditions, and the development of self-cleaning or regenerative filter technologies.

Market Analysis for Air Filtration Solutions

The air filtration market has experienced significant growth in recent years, driven by increasing awareness of indoor air quality and its impact on health. The global air filtration market size was valued at $10.83 billion in 2020 and is projected to reach $16.54 billion by 2028, growing at a CAGR of 7.2% from 2021 to 2028. This growth is primarily attributed to rising concerns over air pollution, stringent environmental regulations, and the ongoing COVID-19 pandemic, which has heightened the importance of clean air in indoor spaces.

The market for air filtration solutions in ventilation systems is particularly robust, with nonwoven polypropylene filters gaining traction due to their superior performance and cost-effectiveness. The HVAC segment dominates the air filtration market, accounting for over 35% of the total market share. This is largely due to the increasing adoption of HVAC systems in commercial and residential buildings, coupled with growing awareness of the need for regular maintenance and filter replacement.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing disposable income in countries like China and India. The commercial sector, including offices, hospitals, and educational institutions, represents the largest end-user segment for air filtration solutions, followed by the industrial and residential sectors.

Key market trends include the growing demand for high-efficiency particulate air (HEPA) filters, which are capable of removing 99.97% of airborne particles as small as 0.3 microns. Additionally, there is an increasing focus on developing sustainable and eco-friendly filtration solutions, with manufacturers exploring biodegradable materials and energy-efficient designs.

The competitive landscape of the air filtration market is characterized by the presence of several large multinational corporations and numerous small to medium-sized enterprises. Leading players in the market include 3M Company, Daikin Industries, Ltd., Honeywell International Inc., and Parker-Hannifin Corporation. These companies are investing heavily in research and development to innovate and improve their product offerings, with a particular focus on enhancing the performance of nonwoven polypropylene filters in ventilation systems.

The market for air filtration solutions in ventilation systems is particularly robust, with nonwoven polypropylene filters gaining traction due to their superior performance and cost-effectiveness. The HVAC segment dominates the air filtration market, accounting for over 35% of the total market share. This is largely due to the increasing adoption of HVAC systems in commercial and residential buildings, coupled with growing awareness of the need for regular maintenance and filter replacement.

Geographically, North America holds the largest market share, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing disposable income in countries like China and India. The commercial sector, including offices, hospitals, and educational institutions, represents the largest end-user segment for air filtration solutions, followed by the industrial and residential sectors.

Key market trends include the growing demand for high-efficiency particulate air (HEPA) filters, which are capable of removing 99.97% of airborne particles as small as 0.3 microns. Additionally, there is an increasing focus on developing sustainable and eco-friendly filtration solutions, with manufacturers exploring biodegradable materials and energy-efficient designs.

The competitive landscape of the air filtration market is characterized by the presence of several large multinational corporations and numerous small to medium-sized enterprises. Leading players in the market include 3M Company, Daikin Industries, Ltd., Honeywell International Inc., and Parker-Hannifin Corporation. These companies are investing heavily in research and development to innovate and improve their product offerings, with a particular focus on enhancing the performance of nonwoven polypropylene filters in ventilation systems.

Current Challenges in HVAC Air Purification

The HVAC industry faces several significant challenges in air purification, particularly in the context of enhancing air quality through ventilation systems. One of the primary issues is the increasing demand for more efficient and effective filtration methods to combat a wide range of pollutants, including particulate matter, volatile organic compounds (VOCs), and microorganisms. Traditional filtration systems often struggle to capture ultrafine particles and gaseous pollutants, leading to suboptimal indoor air quality.

Another major challenge is the balance between filtration efficiency and energy consumption. High-efficiency filters, while effective at removing contaminants, can significantly increase the pressure drop across the system, resulting in higher energy costs and potentially reduced airflow. This trade-off between air quality and energy efficiency poses a significant dilemma for HVAC designers and building managers.

The growing awareness of airborne pathogens, especially in light of recent global health crises, has intensified the need for advanced air purification technologies in HVAC systems. Conventional filters may not be sufficient to capture or neutralize viruses and bacteria, necessitating the integration of additional purification methods such as UV-C light or photocatalytic oxidation. However, these technologies often come with their own set of challenges, including maintenance requirements, potential by-product formation, and integration complexities.

Sustainability and environmental concerns also present challenges in HVAC air purification. The disposal of used filters, particularly those containing captured pollutants, raises environmental issues. Additionally, the use of certain chemical-based air purification methods may have unintended consequences on indoor air chemistry and occupant health.

The variability of indoor environments and pollutant sources further complicates air purification efforts. Different buildings and spaces have unique air quality needs, influenced by factors such as occupancy patterns, outdoor air quality, and specific indoor activities. Developing flexible and adaptable purification solutions that can effectively address this variability remains a significant challenge.

Lastly, the cost-effectiveness of advanced air purification technologies poses a challenge for widespread adoption. While there is a growing recognition of the importance of indoor air quality, the initial investment and ongoing operational costs of sophisticated air purification systems can be prohibitive for many building owners and operators. Striking a balance between performance, cost, and long-term benefits continues to be a key challenge in the industry.

Another major challenge is the balance between filtration efficiency and energy consumption. High-efficiency filters, while effective at removing contaminants, can significantly increase the pressure drop across the system, resulting in higher energy costs and potentially reduced airflow. This trade-off between air quality and energy efficiency poses a significant dilemma for HVAC designers and building managers.

The growing awareness of airborne pathogens, especially in light of recent global health crises, has intensified the need for advanced air purification technologies in HVAC systems. Conventional filters may not be sufficient to capture or neutralize viruses and bacteria, necessitating the integration of additional purification methods such as UV-C light or photocatalytic oxidation. However, these technologies often come with their own set of challenges, including maintenance requirements, potential by-product formation, and integration complexities.

Sustainability and environmental concerns also present challenges in HVAC air purification. The disposal of used filters, particularly those containing captured pollutants, raises environmental issues. Additionally, the use of certain chemical-based air purification methods may have unintended consequences on indoor air chemistry and occupant health.

The variability of indoor environments and pollutant sources further complicates air purification efforts. Different buildings and spaces have unique air quality needs, influenced by factors such as occupancy patterns, outdoor air quality, and specific indoor activities. Developing flexible and adaptable purification solutions that can effectively address this variability remains a significant challenge.

Lastly, the cost-effectiveness of advanced air purification technologies poses a challenge for widespread adoption. While there is a growing recognition of the importance of indoor air quality, the initial investment and ongoing operational costs of sophisticated air purification systems can be prohibitive for many building owners and operators. Striking a balance between performance, cost, and long-term benefits continues to be a key challenge in the industry.

Existing Nonwoven PP Filtration Technologies

01 Nonwoven polypropylene filter materials for air purification

Nonwoven polypropylene materials are used in air filtration systems to improve air quality. These materials are effective in capturing particles and contaminants from the air, making them suitable for use in various air purification applications, including HVAC systems, face masks, and industrial air filters.- Nonwoven polypropylene filter materials for air quality improvement: Nonwoven polypropylene materials are used in air filtration systems to improve air quality. These materials are effective in capturing particulate matter, dust, and other airborne contaminants. The nonwoven structure provides a high surface area and porosity, enhancing filtration efficiency while maintaining good air permeability.

- Electret treatment of nonwoven polypropylene for enhanced filtration: Electret treatment is applied to nonwoven polypropylene filters to enhance their air filtration capabilities. This process imparts an electrostatic charge to the fibers, increasing their ability to attract and capture small particles from the air. The electret treatment significantly improves the filter's efficiency in removing fine particulates and maintaining air quality.

- Multi-layer nonwoven polypropylene filters for improved air purification: Multi-layer nonwoven polypropylene filters are designed to provide enhanced air purification. These filters combine different layers of nonwoven materials, each optimized for specific particle sizes or contaminants. The multi-layer structure allows for more comprehensive filtration, addressing a wider range of air quality issues while maintaining good airflow.

- Meltblown nonwoven polypropylene for high-efficiency air filtration: Meltblown nonwoven polypropylene is utilized in high-efficiency air filtration applications. This manufacturing process creates extremely fine fibers with high surface area and low pore size, resulting in excellent filtration efficiency for submicron particles. Meltblown polypropylene filters are particularly effective in removing fine dust, bacteria, and other small airborne contaminants.

- Additives and treatments for enhanced nonwoven polypropylene air filters: Various additives and treatments are incorporated into nonwoven polypropylene air filters to enhance their performance. These may include antimicrobial agents, activated carbon, or other functional additives that provide additional air purification benefits. Such enhancements can improve the filter's ability to remove odors, volatile organic compounds, and biological contaminants, contributing to better overall air quality.

02 Melt-blown polypropylene fibers for enhanced filtration

Melt-blown polypropylene fibers are utilized to create high-efficiency filter media. The fine fibers produced through this process offer improved filtration performance, capturing smaller particles and enhancing overall air quality. These materials are particularly useful in applications requiring high filtration efficiency.Expand Specific Solutions03 Electret treatment of polypropylene nonwovens

Electret treatment is applied to polypropylene nonwoven materials to enhance their filtration capabilities. This process imparts an electrical charge to the fibers, increasing their ability to attract and capture airborne particles, thus improving air quality in various applications.Expand Specific Solutions04 Multi-layer nonwoven polypropylene structures

Multi-layer nonwoven polypropylene structures are developed to enhance filtration performance and air quality. These structures combine different fiber sizes, densities, or treatments to create a more effective filtration system, capable of capturing a wide range of particle sizes and improving overall air purification.Expand Specific Solutions05 Additives and treatments for improved polypropylene filter performance

Various additives and treatments are incorporated into nonwoven polypropylene materials to enhance their air filtration properties. These may include antimicrobial agents, nanoparticles, or surface modifications that improve particle capture efficiency, reduce microbial growth, or extend filter lifespan, ultimately contributing to better air quality.Expand Specific Solutions

Key Players in Nonwoven PP and HVAC Industries

The market for nonwoven polypropylene in ventilation systems is in a growth phase, driven by increasing awareness of air quality and the need for efficient filtration. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Toray Industries, Berry Global, and 3M Innovative Properties leading innovation. These firms are developing enhanced materials and processes to improve filtration efficiency and durability. Emerging players such as Fitesa Germany and Norafin Industries are also contributing to technological advancements, focusing on specialized applications and sustainable solutions. The competitive landscape is characterized by a mix of established multinational corporations and innovative smaller companies, all striving to meet the growing demand for high-performance air filtration solutions.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed advanced nonwoven polypropylene filters for ventilation systems that significantly enhance air quality. Their proprietary meltblown technology creates ultra-fine fibers with diameters as small as 0.3 microns[1], allowing for high filtration efficiency of particulate matter and airborne contaminants. The company's filters incorporate electrostatic charging to improve capture of sub-micron particles, achieving up to 99.9% filtration efficiency for particles as small as 0.1 microns[2]. Toray has also implemented a multi-layer design, combining different fiber densities and pore sizes to optimize both filtration performance and air permeability[3]. This approach ensures effective removal of pollutants while maintaining good airflow, crucial for energy-efficient ventilation systems.

Strengths: High filtration efficiency, advanced meltblown technology, and multi-layer design for optimized performance. Weaknesses: Potentially higher cost due to advanced manufacturing processes, and possible need for more frequent replacement compared to less efficient filters.

Carl Freudenberg KG

Technical Solution: Carl Freudenberg KG has innovated in nonwoven polypropylene technology for ventilation systems with their Viledon brand. Their filters utilize a gradient density structure, where fiber density increases towards the air exit side, allowing for depth filtration and extended filter life[4]. The company has developed a unique thermal bonding process that eliminates the need for chemical binders, resulting in low outgassing and making the filters suitable for sensitive environments[5]. Freudenberg's filters also incorporate nanofiber layers, which significantly increase the filtration surface area and improve the capture of fine particles without compromising airflow[6]. The company has implemented a hydrophobic treatment to their polypropylene fibers, enhancing the filter's resistance to moisture and microbial growth, thus maintaining air quality even in high-humidity conditions[7].

Strengths: Gradient density structure for depth filtration, chemical-free thermal bonding, and nanofiber technology for improved performance. Weaknesses: Potentially higher initial costs and may require specialized maintenance procedures.

Innovations in Nonwoven PP for Air Purification

Non-woven with improved filtration performance and manufacturing method of thereof

PatentPendingKR1020230101133A

Innovation

- A nonwoven fabric composed of a mixed fiber yarn with a hollow first filament and a non-hollow second filament, having specific ratios and properties, is produced through a spinning and embossing process to enhance surface area and thickness while maintaining mechanical stability.

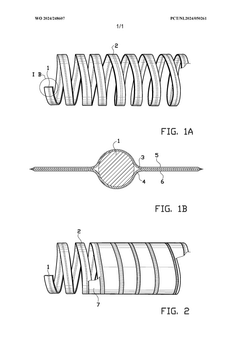

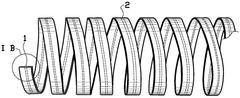

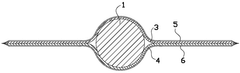

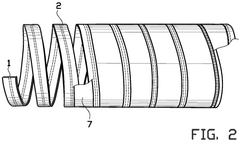

Duct and uses thereof

PatentWO2024248607A1

Innovation

- A duct comprising a cylindrical body with a polypropylene nonwoven fabric reinforced with integrated helical elements and an airtight liner layer of monoaxially or biaxially oriented polypropylene on both sides, enhancing acoustic properties by improving insertion and transmission loss, particularly in lower frequency regions, while maintaining flexibility and resistance to chemicals and water.

Environmental Impact of Nonwoven PP Filters

The environmental impact of nonwoven polypropylene (PP) filters in ventilation systems is a critical consideration in the broader context of air quality management and sustainable building practices. These filters play a significant role in improving indoor air quality, but their production, use, and disposal also have environmental implications that must be carefully evaluated.

Nonwoven PP filters are highly effective in capturing airborne particles, including dust, pollen, and other pollutants. This efficiency contributes to improved indoor air quality, which can lead to better health outcomes for building occupants and reduced energy consumption in HVAC systems. By effectively removing particulate matter, these filters help maintain cleaner air circulation, potentially reducing the need for frequent air exchanges and thus lowering overall energy usage.

However, the production of nonwoven PP filters involves the use of petroleum-based materials, which raises concerns about resource depletion and carbon emissions. The manufacturing process requires energy and may involve the use of chemical additives, potentially contributing to industrial pollution if not properly managed. Despite these concerns, advancements in production technologies have led to more efficient manufacturing processes, reducing the overall environmental footprint of filter production.

The lifespan of nonwoven PP filters is another important factor in assessing their environmental impact. While these filters are designed for single use, their durability allows for extended periods of effective filtration before replacement is necessary. This longevity helps offset the environmental costs associated with frequent filter changes and disposal.

End-of-life considerations for nonwoven PP filters present both challenges and opportunities. These filters are not biodegradable and can contribute to landfill waste if not properly managed. However, recycling technologies for polypropylene are advancing, offering potential avenues for reducing the environmental impact of filter disposal. Some manufacturers are exploring take-back programs and recycling initiatives to address this issue.

When comparing nonwoven PP filters to alternative filtration materials, their lightweight nature and efficient production processes often result in lower transportation-related emissions. Additionally, their effectiveness in air filtration can lead to reduced energy consumption in buildings, potentially offsetting some of the environmental costs associated with their production and disposal.

In conclusion, while nonwoven PP filters offer significant benefits in terms of air quality improvement, their environmental impact is complex and multifaceted. Ongoing research and development efforts are focused on improving the sustainability of these filters, from production to disposal, aiming to enhance their positive contributions to indoor air quality while minimizing their environmental footprint.

Nonwoven PP filters are highly effective in capturing airborne particles, including dust, pollen, and other pollutants. This efficiency contributes to improved indoor air quality, which can lead to better health outcomes for building occupants and reduced energy consumption in HVAC systems. By effectively removing particulate matter, these filters help maintain cleaner air circulation, potentially reducing the need for frequent air exchanges and thus lowering overall energy usage.

However, the production of nonwoven PP filters involves the use of petroleum-based materials, which raises concerns about resource depletion and carbon emissions. The manufacturing process requires energy and may involve the use of chemical additives, potentially contributing to industrial pollution if not properly managed. Despite these concerns, advancements in production technologies have led to more efficient manufacturing processes, reducing the overall environmental footprint of filter production.

The lifespan of nonwoven PP filters is another important factor in assessing their environmental impact. While these filters are designed for single use, their durability allows for extended periods of effective filtration before replacement is necessary. This longevity helps offset the environmental costs associated with frequent filter changes and disposal.

End-of-life considerations for nonwoven PP filters present both challenges and opportunities. These filters are not biodegradable and can contribute to landfill waste if not properly managed. However, recycling technologies for polypropylene are advancing, offering potential avenues for reducing the environmental impact of filter disposal. Some manufacturers are exploring take-back programs and recycling initiatives to address this issue.

When comparing nonwoven PP filters to alternative filtration materials, their lightweight nature and efficient production processes often result in lower transportation-related emissions. Additionally, their effectiveness in air filtration can lead to reduced energy consumption in buildings, potentially offsetting some of the environmental costs associated with their production and disposal.

In conclusion, while nonwoven PP filters offer significant benefits in terms of air quality improvement, their environmental impact is complex and multifaceted. Ongoing research and development efforts are focused on improving the sustainability of these filters, from production to disposal, aiming to enhance their positive contributions to indoor air quality while minimizing their environmental footprint.

Regulatory Standards for Indoor Air Quality

Regulatory standards for indoor air quality play a crucial role in ensuring the effectiveness of nonwoven polypropylene in ventilation systems. These standards are established by various governmental and non-governmental organizations to protect public health and maintain optimal indoor environments. In the United States, the Environmental Protection Agency (EPA) sets guidelines for indoor air quality, while the Occupational Safety and Health Administration (OSHA) regulates workplace air quality.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides widely recognized standards for ventilation and indoor air quality. ASHRAE Standard 62.1, "Ventilation for Acceptable Indoor Air Quality," outlines minimum ventilation rates and other measures to maintain acceptable indoor air quality in various building types. This standard is often referenced in building codes and regulations across North America.

In Europe, the European Committee for Standardization (CEN) has developed EN 13779, which specifies performance requirements for ventilation and room-conditioning systems. This standard categorizes indoor air quality into four levels, from IDA 1 (high) to IDA 4 (low), and provides corresponding ventilation rates. The World Health Organization (WHO) also offers guidelines for indoor air quality, addressing specific pollutants and their health impacts.

Many countries have adopted these international standards or developed their own regulations. For instance, Singapore's Building and Construction Authority (BCA) has implemented the Green Mark Scheme, which includes indoor air quality criteria for buildings. In China, the Ministry of Environmental Protection has established national standards for indoor air quality, including GB/T 18883-2002 for residential buildings and GB/T 17093-2008 for office buildings.

These regulatory standards typically focus on key air quality parameters such as particulate matter (PM2.5 and PM10), volatile organic compounds (VOCs), carbon dioxide (CO2), and other pollutants. They often specify maximum allowable concentrations for these contaminants and minimum ventilation rates to maintain healthy indoor environments. The standards also address factors like temperature, humidity, and air movement, which can affect the performance of nonwoven polypropylene filters in ventilation systems.

Compliance with these standards is essential for manufacturers and users of nonwoven polypropylene filters in ventilation systems. The filters must demonstrate their ability to effectively remove pollutants and maintain air quality within the specified limits. This often requires rigorous testing and certification processes to ensure that the filters meet or exceed the regulatory requirements. As air quality standards continue to evolve and become more stringent, the development of nonwoven polypropylene filters must keep pace to meet these challenges and provide effective solutions for improving indoor air quality.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides widely recognized standards for ventilation and indoor air quality. ASHRAE Standard 62.1, "Ventilation for Acceptable Indoor Air Quality," outlines minimum ventilation rates and other measures to maintain acceptable indoor air quality in various building types. This standard is often referenced in building codes and regulations across North America.

In Europe, the European Committee for Standardization (CEN) has developed EN 13779, which specifies performance requirements for ventilation and room-conditioning systems. This standard categorizes indoor air quality into four levels, from IDA 1 (high) to IDA 4 (low), and provides corresponding ventilation rates. The World Health Organization (WHO) also offers guidelines for indoor air quality, addressing specific pollutants and their health impacts.

Many countries have adopted these international standards or developed their own regulations. For instance, Singapore's Building and Construction Authority (BCA) has implemented the Green Mark Scheme, which includes indoor air quality criteria for buildings. In China, the Ministry of Environmental Protection has established national standards for indoor air quality, including GB/T 18883-2002 for residential buildings and GB/T 17093-2008 for office buildings.

These regulatory standards typically focus on key air quality parameters such as particulate matter (PM2.5 and PM10), volatile organic compounds (VOCs), carbon dioxide (CO2), and other pollutants. They often specify maximum allowable concentrations for these contaminants and minimum ventilation rates to maintain healthy indoor environments. The standards also address factors like temperature, humidity, and air movement, which can affect the performance of nonwoven polypropylene filters in ventilation systems.

Compliance with these standards is essential for manufacturers and users of nonwoven polypropylene filters in ventilation systems. The filters must demonstrate their ability to effectively remove pollutants and maintain air quality within the specified limits. This often requires rigorous testing and certification processes to ensure that the filters meet or exceed the regulatory requirements. As air quality standards continue to evolve and become more stringent, the development of nonwoven polypropylene filters must keep pace to meet these challenges and provide effective solutions for improving indoor air quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!