How Polypropylene Enables Next-Gen Acoustic Materials

JUL 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Acoustics: Background and Objectives

Polypropylene, a versatile thermoplastic polymer, has emerged as a key material in the development of next-generation acoustic solutions. The evolution of acoustic materials has been driven by the increasing demand for noise reduction and sound quality enhancement across various industries, including automotive, construction, and consumer electronics.

The journey of polypropylene in acoustics began in the mid-20th century when its unique properties were first recognized. Its low density, high stiffness-to-weight ratio, and excellent vibration damping characteristics made it an attractive option for acoustic applications. Over time, researchers and engineers have continuously explored ways to leverage these properties to create more effective and efficient acoustic materials.

The acoustic industry has witnessed significant technological advancements, from simple sound-absorbing panels to complex, multi-layered structures. Polypropylene has played a crucial role in this progression, enabling the development of lightweight yet highly effective acoustic solutions. Its ability to be easily molded, extruded, or formed into various shapes and structures has opened up new possibilities in acoustic design.

In recent years, the focus has shifted towards developing sustainable and environmentally friendly acoustic materials. Polypropylene, being recyclable and having a relatively low carbon footprint compared to some traditional acoustic materials, aligns well with this trend. This has led to increased research and development efforts to optimize polypropylene-based acoustic solutions.

The primary objective of current research in polypropylene acoustics is to enhance its sound absorption and insulation properties while maintaining its lightweight and cost-effective nature. Scientists and engineers are exploring various approaches, including the development of novel polypropylene composites, the creation of micro and nanostructured polypropylene materials, and the integration of polypropylene with other advanced materials to achieve superior acoustic performance.

Another key goal is to expand the frequency range over which polypropylene-based materials are effective. Traditional polypropylene acoustic solutions have been more effective at higher frequencies, but there is a growing need for materials that can provide broadband noise reduction, especially in low-frequency ranges. This challenge has spurred innovative research into polypropylene foam structures and hybrid materials.

As we look towards the future, the development of smart, adaptive polypropylene acoustic materials is becoming an increasingly important objective. These materials would be capable of dynamically adjusting their properties in response to changing acoustic environments, potentially revolutionizing noise control in various applications.

The journey of polypropylene in acoustics began in the mid-20th century when its unique properties were first recognized. Its low density, high stiffness-to-weight ratio, and excellent vibration damping characteristics made it an attractive option for acoustic applications. Over time, researchers and engineers have continuously explored ways to leverage these properties to create more effective and efficient acoustic materials.

The acoustic industry has witnessed significant technological advancements, from simple sound-absorbing panels to complex, multi-layered structures. Polypropylene has played a crucial role in this progression, enabling the development of lightweight yet highly effective acoustic solutions. Its ability to be easily molded, extruded, or formed into various shapes and structures has opened up new possibilities in acoustic design.

In recent years, the focus has shifted towards developing sustainable and environmentally friendly acoustic materials. Polypropylene, being recyclable and having a relatively low carbon footprint compared to some traditional acoustic materials, aligns well with this trend. This has led to increased research and development efforts to optimize polypropylene-based acoustic solutions.

The primary objective of current research in polypropylene acoustics is to enhance its sound absorption and insulation properties while maintaining its lightweight and cost-effective nature. Scientists and engineers are exploring various approaches, including the development of novel polypropylene composites, the creation of micro and nanostructured polypropylene materials, and the integration of polypropylene with other advanced materials to achieve superior acoustic performance.

Another key goal is to expand the frequency range over which polypropylene-based materials are effective. Traditional polypropylene acoustic solutions have been more effective at higher frequencies, but there is a growing need for materials that can provide broadband noise reduction, especially in low-frequency ranges. This challenge has spurred innovative research into polypropylene foam structures and hybrid materials.

As we look towards the future, the development of smart, adaptive polypropylene acoustic materials is becoming an increasingly important objective. These materials would be capable of dynamically adjusting their properties in response to changing acoustic environments, potentially revolutionizing noise control in various applications.

Market Analysis for Advanced Acoustic Materials

The market for advanced acoustic materials is experiencing significant growth, driven by increasing demand for noise reduction solutions across various industries. Polypropylene, a versatile thermoplastic polymer, is emerging as a key enabler in the development of next-generation acoustic materials. This market analysis explores the current landscape and future prospects of advanced acoustic materials, with a focus on polypropylene-based solutions.

The global acoustic materials market is projected to expand rapidly in the coming years, fueled by stringent noise pollution regulations, growing awareness of the health impacts of noise exposure, and the rising need for sound insulation in urban environments. Key sectors driving this growth include automotive, construction, industrial, and consumer electronics. The automotive industry, in particular, is a major consumer of acoustic materials, as manufacturers seek to enhance vehicle comfort and comply with noise emission standards.

Polypropylene-based acoustic materials are gaining traction due to their unique combination of properties. These materials offer excellent sound absorption capabilities, lightweight characteristics, and cost-effectiveness compared to traditional acoustic solutions. The versatility of polypropylene allows for the creation of various acoustic products, including foam panels, fibrous materials, and composite structures, catering to diverse application needs.

The construction sector represents another significant market for advanced acoustic materials. With the trend towards sustainable building practices, polypropylene-based acoustic solutions are becoming increasingly popular due to their recyclability and energy-efficient production processes. These materials are being incorporated into walls, ceilings, and flooring systems to improve indoor acoustics and occupant comfort in residential, commercial, and institutional buildings.

In the industrial sector, the demand for noise control solutions in manufacturing facilities, power plants, and other high-noise environments is driving the adoption of advanced acoustic materials. Polypropylene-based products offer durability and resistance to harsh conditions, making them suitable for industrial applications. The ability to customize these materials for specific frequency ranges and noise levels further enhances their appeal in this sector.

The consumer electronics industry is also contributing to the growth of the acoustic materials market. As devices become smaller and more powerful, the need for effective sound management increases. Polypropylene-based acoustic solutions are being integrated into smartphones, laptops, and other portable devices to improve audio quality and reduce unwanted noise.

Looking ahead, the market for advanced acoustic materials is expected to continue its upward trajectory. Innovations in polypropylene formulations and processing techniques are likely to yield materials with enhanced acoustic properties and broader application potential. The development of hybrid materials combining polypropylene with other advanced materials may open up new opportunities in high-performance acoustic applications.

The global acoustic materials market is projected to expand rapidly in the coming years, fueled by stringent noise pollution regulations, growing awareness of the health impacts of noise exposure, and the rising need for sound insulation in urban environments. Key sectors driving this growth include automotive, construction, industrial, and consumer electronics. The automotive industry, in particular, is a major consumer of acoustic materials, as manufacturers seek to enhance vehicle comfort and comply with noise emission standards.

Polypropylene-based acoustic materials are gaining traction due to their unique combination of properties. These materials offer excellent sound absorption capabilities, lightweight characteristics, and cost-effectiveness compared to traditional acoustic solutions. The versatility of polypropylene allows for the creation of various acoustic products, including foam panels, fibrous materials, and composite structures, catering to diverse application needs.

The construction sector represents another significant market for advanced acoustic materials. With the trend towards sustainable building practices, polypropylene-based acoustic solutions are becoming increasingly popular due to their recyclability and energy-efficient production processes. These materials are being incorporated into walls, ceilings, and flooring systems to improve indoor acoustics and occupant comfort in residential, commercial, and institutional buildings.

In the industrial sector, the demand for noise control solutions in manufacturing facilities, power plants, and other high-noise environments is driving the adoption of advanced acoustic materials. Polypropylene-based products offer durability and resistance to harsh conditions, making them suitable for industrial applications. The ability to customize these materials for specific frequency ranges and noise levels further enhances their appeal in this sector.

The consumer electronics industry is also contributing to the growth of the acoustic materials market. As devices become smaller and more powerful, the need for effective sound management increases. Polypropylene-based acoustic solutions are being integrated into smartphones, laptops, and other portable devices to improve audio quality and reduce unwanted noise.

Looking ahead, the market for advanced acoustic materials is expected to continue its upward trajectory. Innovations in polypropylene formulations and processing techniques are likely to yield materials with enhanced acoustic properties and broader application potential. The development of hybrid materials combining polypropylene with other advanced materials may open up new opportunities in high-performance acoustic applications.

Current State and Challenges in Acoustic Material Development

The development of acoustic materials has seen significant advancements in recent years, with polypropylene emerging as a key enabler for next-generation solutions. Currently, the acoustic material industry is experiencing a shift towards more sustainable, lightweight, and high-performance materials. Polypropylene, with its unique properties, is at the forefront of this transformation.

Traditional acoustic materials, such as fiberglass and mineral wool, have long been the standard in sound insulation and absorption. However, these materials often come with drawbacks such as potential health risks, moisture sensitivity, and limited recyclability. The current state of acoustic material development is focused on overcoming these limitations while enhancing performance characteristics.

Polypropylene-based acoustic materials are gaining traction due to their excellent sound absorption properties, low density, and recyclability. These materials can be engineered to have specific pore structures and surface treatments, allowing for tailored acoustic performance across different frequency ranges. The versatility of polypropylene enables its use in various forms, including fibers, foams, and composites, each offering unique acoustic properties.

One of the main challenges in acoustic material development is achieving a balance between sound absorption efficiency and material thickness. Polypropylene-based solutions are addressing this by utilizing advanced manufacturing techniques such as melt-blown processes and 3D printing to create complex, multi-layered structures that maximize acoustic performance while minimizing material usage.

Another significant challenge is the need for materials that can perform well in diverse environmental conditions. Polypropylene's inherent resistance to moisture, chemicals, and temperature fluctuations makes it an ideal candidate for acoustic applications in challenging environments, from automotive interiors to outdoor noise barriers.

The integration of polypropylene with other materials to create hybrid acoustic solutions is an area of active research. These composites aim to combine the benefits of different materials, such as the lightweight nature of polypropylene with the high-temperature resistance of ceramics, to create acoustic materials suitable for extreme conditions.

Sustainability is a driving force in current acoustic material development. The recyclability of polypropylene aligns well with circular economy principles, addressing the growing demand for environmentally friendly building materials. However, challenges remain in developing efficient recycling processes for composite acoustic materials that incorporate polypropylene.

As the acoustic material industry evolves, there is an increasing focus on smart materials that can adapt to changing noise environments. Research is underway to develop polypropylene-based acoustic materials with embedded sensors and actuators, capable of dynamically adjusting their properties in response to different sound frequencies and intensities.

The current state of acoustic material development is characterized by a push towards multifunctionality. Researchers are exploring ways to imbue polypropylene-based acoustic materials with additional properties such as fire resistance, thermal insulation, and even energy harvesting capabilities, to create more value-added solutions for various applications.

Traditional acoustic materials, such as fiberglass and mineral wool, have long been the standard in sound insulation and absorption. However, these materials often come with drawbacks such as potential health risks, moisture sensitivity, and limited recyclability. The current state of acoustic material development is focused on overcoming these limitations while enhancing performance characteristics.

Polypropylene-based acoustic materials are gaining traction due to their excellent sound absorption properties, low density, and recyclability. These materials can be engineered to have specific pore structures and surface treatments, allowing for tailored acoustic performance across different frequency ranges. The versatility of polypropylene enables its use in various forms, including fibers, foams, and composites, each offering unique acoustic properties.

One of the main challenges in acoustic material development is achieving a balance between sound absorption efficiency and material thickness. Polypropylene-based solutions are addressing this by utilizing advanced manufacturing techniques such as melt-blown processes and 3D printing to create complex, multi-layered structures that maximize acoustic performance while minimizing material usage.

Another significant challenge is the need for materials that can perform well in diverse environmental conditions. Polypropylene's inherent resistance to moisture, chemicals, and temperature fluctuations makes it an ideal candidate for acoustic applications in challenging environments, from automotive interiors to outdoor noise barriers.

The integration of polypropylene with other materials to create hybrid acoustic solutions is an area of active research. These composites aim to combine the benefits of different materials, such as the lightweight nature of polypropylene with the high-temperature resistance of ceramics, to create acoustic materials suitable for extreme conditions.

Sustainability is a driving force in current acoustic material development. The recyclability of polypropylene aligns well with circular economy principles, addressing the growing demand for environmentally friendly building materials. However, challenges remain in developing efficient recycling processes for composite acoustic materials that incorporate polypropylene.

As the acoustic material industry evolves, there is an increasing focus on smart materials that can adapt to changing noise environments. Research is underway to develop polypropylene-based acoustic materials with embedded sensors and actuators, capable of dynamically adjusting their properties in response to different sound frequencies and intensities.

The current state of acoustic material development is characterized by a push towards multifunctionality. Researchers are exploring ways to imbue polypropylene-based acoustic materials with additional properties such as fire resistance, thermal insulation, and even energy harvesting capabilities, to create more value-added solutions for various applications.

Existing Polypropylene-based Acoustic Solutions

01 Acoustic properties of polypropylene composites

Polypropylene composites can be engineered to enhance acoustic properties. By incorporating various fillers or additives, the sound absorption and transmission loss characteristics of polypropylene can be improved. These composites find applications in automotive interiors, building materials, and industrial noise control solutions.- Acoustic properties of polypropylene composites: Polypropylene composites can be engineered to enhance acoustic properties. By incorporating various fillers or additives, the sound absorption and transmission loss characteristics of polypropylene can be improved. These composites find applications in automotive interiors, building materials, and industrial noise control solutions.

- Polypropylene foam for acoustic insulation: Polypropylene foam exhibits excellent acoustic insulation properties due to its cellular structure. The foam can be tailored to absorb specific frequency ranges by controlling cell size and distribution. This makes it suitable for use in automotive, construction, and appliance industries where noise reduction is crucial.

- Acoustic measurement techniques for polypropylene materials: Various techniques and devices have been developed to measure the acoustic properties of polypropylene materials accurately. These include impedance tube methods, reverberation chamber tests, and advanced signal processing algorithms. Such measurements are essential for characterizing and optimizing the acoustic performance of polypropylene products.

- Polypropylene in acoustic transducer components: Polypropylene is used in the manufacturing of acoustic transducer components due to its favorable mechanical and acoustic properties. It can be found in speaker cones, diaphragms, and housings. The material's low density and high stiffness contribute to improved sound quality and efficiency in audio devices.

- Acoustic metamaterials using polypropylene: Researchers are exploring the use of polypropylene in acoustic metamaterials, which are engineered structures designed to manipulate sound waves in unconventional ways. These materials can exhibit properties such as negative refraction or acoustic cloaking. Polypropylene's versatility and ease of processing make it a promising candidate for creating complex acoustic metamaterial structures.

02 Polypropylene foam for acoustic insulation

Polypropylene foam exhibits excellent acoustic insulation properties due to its cellular structure. The foam can be tailored to absorb specific frequency ranges by controlling cell size and distribution. This makes it suitable for use in automotive, construction, and appliance industries where noise reduction is crucial.Expand Specific Solutions03 Acoustic measurement techniques for polypropylene materials

Various techniques and devices have been developed to accurately measure the acoustic properties of polypropylene materials. These include impedance tube methods, reverberation chamber tests, and advanced signal processing algorithms. Such measurements are essential for characterizing and optimizing the acoustic performance of polypropylene products.Expand Specific Solutions04 Polypropylene acoustic panels and barriers

Polypropylene can be used to create effective acoustic panels and barriers. These products are designed to absorb or reflect sound waves, reducing noise transmission in various environments. The lightweight nature of polypropylene makes it an attractive option for portable or modular acoustic solutions.Expand Specific Solutions05 Acoustic properties of polypropylene in marine applications

Polypropylene's acoustic properties make it suitable for marine applications. Its ability to absorb and dampen underwater sound waves is utilized in sonar systems, marine vessel components, and underwater acoustic devices. The material's resistance to water and chemicals further enhances its suitability for marine environments.Expand Specific Solutions

Key Players in Polypropylene Acoustic Materials Industry

The development of next-generation acoustic materials using polypropylene is in a growth phase, with increasing market size driven by demand for improved sound insulation in various industries. The technology is maturing rapidly, with several key players advancing innovations. Companies like Koninklijke Philips NV, Goertek Inc., and Sony Group Corp. are leveraging their expertise in consumer electronics to develop advanced acoustic solutions. Materials specialists such as Kingfa Sci. & Tech. Co., Ltd. and Borealis AG are focusing on enhancing polypropylene properties for acoustic applications. Automotive giants like Hyundai Motor Co., Ltd. and Ford Global Technologies LLC are also investing in this technology to improve vehicle acoustics. The competitive landscape is diverse, with collaborations between industry and academia, such as Jilin University, driving further advancements in this field.

GoerTek Inc.

Technical Solution: GoerTek Inc. has developed advanced polypropylene-based acoustic materials for their audio products, particularly in earphones and headphones. Their proprietary technology involves creating micro-perforated polypropylene membranes that offer superior sound quality and noise cancellation. These membranes are engineered with precise pore sizes and distributions to optimize acoustic performance across different frequency ranges[3]. GoerTek has also implemented a multi-layer polypropylene structure in their acoustic designs, which allows for fine-tuning of sound transmission and absorption characteristics. This technology has enabled the company to produce lightweight, durable, and high-performance audio devices with enhanced acoustic properties[4].

Strengths: Expertise in audio applications, innovative micro-perforation techniques, customizable acoustic properties. Weaknesses: Primarily focused on personal audio devices, may have limited applications in other industries.

Sony Group Corp.

Technical Solution: Sony Group Corp. has leveraged polypropylene in developing next-generation acoustic materials for their high-end audio products. Their research has focused on creating hybrid polypropylene composites that combine the lightweight and moldable properties of polypropylene with other materials to enhance acoustic performance. One notable innovation is their use of polypropylene-carbon nanotube composites in speaker diaphragms, which offers improved rigidity and damping characteristics[5]. Sony has also developed a proprietary polypropylene foam technology that provides excellent sound absorption across a wide frequency range. This material is used in their professional-grade acoustic panels and studio equipment, offering superior noise reduction and sound shaping capabilities[6].

Strengths: Strong research and development capabilities, integration of advanced materials with polypropylene, wide range of audio applications. Weaknesses: High-end focus may limit accessibility to mass-market products, potential for higher costs.

Innovations in Polypropylene Acoustic Technology

Polypropylene composition comprising reduced graphite oxide worm-like structures and having improved mechanical properties

PatentWO2019115544A1

Innovation

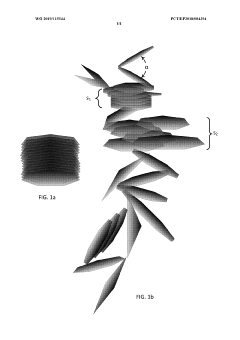

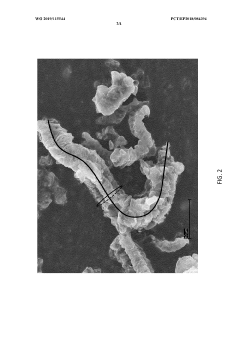

- A polypropylene composition incorporating reduced graphite oxide worm-like structures with high BET surface area and low density, which are intimately mixed with the propylene polymer base resin to enhance mechanical properties and thermal conductivity.

Recyclable acoustic absorbent and manufacturing method thereof

PatentInactiveIN3702DEL2012A

Innovation

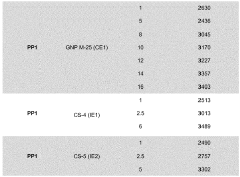

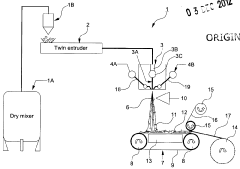

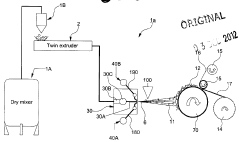

- A recyclable acoustic absorbent is developed using a combination of melt-blown fibers and polypropylene staple fibers, where the melt-blown fibers are made from a resin composition comprising 90-99 wt% homo polypropylene and 1-10 wt% polypropylene-based elastomer, enhancing elasticity and acoustic absorption, and the entire material is 100% recyclable.

Environmental Impact of Polypropylene Acoustic Materials

The environmental impact of polypropylene acoustic materials is a critical consideration in the development and adoption of next-generation acoustic solutions. Polypropylene, a versatile thermoplastic polymer, offers several environmental advantages over traditional acoustic materials, but also presents certain challenges that must be addressed.

One of the primary environmental benefits of polypropylene acoustic materials is their potential for recyclability. Unlike many conventional acoustic materials that are difficult to recycle due to their composite nature, polypropylene can be more easily recycled and repurposed. This characteristic aligns with circular economy principles and helps reduce waste in the long term.

Furthermore, polypropylene acoustic materials often have a lower carbon footprint compared to traditional alternatives. The production process for polypropylene is generally less energy-intensive than that of some other acoustic materials, such as fiberglass or mineral wool. This reduced energy consumption during manufacturing contributes to lower greenhouse gas emissions throughout the product lifecycle.

Durability is another key factor in the environmental impact assessment of polypropylene acoustic materials. These materials typically have a longer lifespan than many traditional options, reducing the need for frequent replacements. This longevity translates to less material consumption and waste generation over time, further minimizing environmental impact.

However, it is important to note that polypropylene is derived from fossil fuels, which raises concerns about resource depletion and the material's overall sustainability. The petrochemical origin of polypropylene contributes to its carbon footprint and ties its production to the oil and gas industry. This association has led to increased interest in developing bio-based alternatives that could offer similar acoustic properties with a reduced environmental impact.

Water pollution is another environmental concern associated with polypropylene acoustic materials. Microplastic shedding during the use and disposal of these materials can contribute to water contamination, potentially harming aquatic ecosystems. Research is ongoing to develop methods to mitigate this issue, such as improving the material's stability or incorporating biodegradable additives.

End-of-life management for polypropylene acoustic materials presents both opportunities and challenges. While recyclability is a significant advantage, the actual recycling rates for these materials can be low due to various factors, including contamination and lack of proper recycling infrastructure. Improving collection and recycling systems is crucial to fully realizing the environmental benefits of polypropylene acoustic materials.

In conclusion, the environmental impact of polypropylene acoustic materials is multifaceted. While offering advantages in recyclability, energy efficiency, and durability, challenges remain in terms of fossil fuel dependence and potential microplastic pollution. As the industry continues to innovate, addressing these environmental concerns will be crucial in establishing polypropylene as a truly sustainable option for next-generation acoustic materials.

One of the primary environmental benefits of polypropylene acoustic materials is their potential for recyclability. Unlike many conventional acoustic materials that are difficult to recycle due to their composite nature, polypropylene can be more easily recycled and repurposed. This characteristic aligns with circular economy principles and helps reduce waste in the long term.

Furthermore, polypropylene acoustic materials often have a lower carbon footprint compared to traditional alternatives. The production process for polypropylene is generally less energy-intensive than that of some other acoustic materials, such as fiberglass or mineral wool. This reduced energy consumption during manufacturing contributes to lower greenhouse gas emissions throughout the product lifecycle.

Durability is another key factor in the environmental impact assessment of polypropylene acoustic materials. These materials typically have a longer lifespan than many traditional options, reducing the need for frequent replacements. This longevity translates to less material consumption and waste generation over time, further minimizing environmental impact.

However, it is important to note that polypropylene is derived from fossil fuels, which raises concerns about resource depletion and the material's overall sustainability. The petrochemical origin of polypropylene contributes to its carbon footprint and ties its production to the oil and gas industry. This association has led to increased interest in developing bio-based alternatives that could offer similar acoustic properties with a reduced environmental impact.

Water pollution is another environmental concern associated with polypropylene acoustic materials. Microplastic shedding during the use and disposal of these materials can contribute to water contamination, potentially harming aquatic ecosystems. Research is ongoing to develop methods to mitigate this issue, such as improving the material's stability or incorporating biodegradable additives.

End-of-life management for polypropylene acoustic materials presents both opportunities and challenges. While recyclability is a significant advantage, the actual recycling rates for these materials can be low due to various factors, including contamination and lack of proper recycling infrastructure. Improving collection and recycling systems is crucial to fully realizing the environmental benefits of polypropylene acoustic materials.

In conclusion, the environmental impact of polypropylene acoustic materials is multifaceted. While offering advantages in recyclability, energy efficiency, and durability, challenges remain in terms of fossil fuel dependence and potential microplastic pollution. As the industry continues to innovate, addressing these environmental concerns will be crucial in establishing polypropylene as a truly sustainable option for next-generation acoustic materials.

Standardization and Testing of Acoustic Performance

Standardization and testing of acoustic performance are crucial aspects in the development and application of polypropylene-based acoustic materials. As these materials gain prominence in various industries, establishing consistent methods for evaluating their acoustic properties becomes increasingly important.

The International Organization for Standardization (ISO) has developed several standards specifically for acoustic testing, including ISO 10534 for impedance tube measurements and ISO 354 for reverberation room testing. These standards provide guidelines for measuring sound absorption coefficients, transmission loss, and other acoustic parameters. However, the unique properties of polypropylene-based materials may require adaptations or new standards to accurately assess their performance.

One key challenge in standardizing acoustic testing for polypropylene materials is accounting for their viscoelastic behavior. Unlike traditional rigid materials, polypropylene-based acoustic solutions can exhibit frequency-dependent properties, necessitating more comprehensive testing procedures across a wide range of frequencies and environmental conditions.

To address these challenges, researchers and industry experts are collaborating to develop new testing methodologies. For instance, the use of advanced computational models, such as finite element analysis (FEA) and boundary element method (BEM), is becoming increasingly common to predict and validate the acoustic performance of polypropylene materials. These simulation tools allow for rapid prototyping and optimization of acoustic designs before physical testing.

In addition to laboratory testing, in-situ measurements are gaining importance in evaluating the real-world performance of polypropylene acoustic materials. Field testing methods, such as those outlined in ISO 16283 for field measurements of sound insulation, are being adapted to assess the effectiveness of these materials in various applications, from automotive interiors to building acoustics.

The development of standardized aging tests is another critical area of focus. As polypropylene-based acoustic materials are exposed to various environmental factors over time, understanding their long-term performance is essential. Accelerated aging tests that simulate exposure to UV radiation, temperature fluctuations, and humidity are being refined to provide more accurate predictions of material durability and acoustic stability.

As the field of polypropylene-based acoustic materials continues to evolve, ongoing efforts are being made to harmonize testing procedures across different regions and industries. This includes the development of round-robin testing programs, where multiple laboratories perform tests on identical samples to ensure consistency and reproducibility of results. Such initiatives are crucial for establishing trust in the performance claims of new acoustic materials and facilitating their adoption in diverse applications.

The International Organization for Standardization (ISO) has developed several standards specifically for acoustic testing, including ISO 10534 for impedance tube measurements and ISO 354 for reverberation room testing. These standards provide guidelines for measuring sound absorption coefficients, transmission loss, and other acoustic parameters. However, the unique properties of polypropylene-based materials may require adaptations or new standards to accurately assess their performance.

One key challenge in standardizing acoustic testing for polypropylene materials is accounting for their viscoelastic behavior. Unlike traditional rigid materials, polypropylene-based acoustic solutions can exhibit frequency-dependent properties, necessitating more comprehensive testing procedures across a wide range of frequencies and environmental conditions.

To address these challenges, researchers and industry experts are collaborating to develop new testing methodologies. For instance, the use of advanced computational models, such as finite element analysis (FEA) and boundary element method (BEM), is becoming increasingly common to predict and validate the acoustic performance of polypropylene materials. These simulation tools allow for rapid prototyping and optimization of acoustic designs before physical testing.

In addition to laboratory testing, in-situ measurements are gaining importance in evaluating the real-world performance of polypropylene acoustic materials. Field testing methods, such as those outlined in ISO 16283 for field measurements of sound insulation, are being adapted to assess the effectiveness of these materials in various applications, from automotive interiors to building acoustics.

The development of standardized aging tests is another critical area of focus. As polypropylene-based acoustic materials are exposed to various environmental factors over time, understanding their long-term performance is essential. Accelerated aging tests that simulate exposure to UV radiation, temperature fluctuations, and humidity are being refined to provide more accurate predictions of material durability and acoustic stability.

As the field of polypropylene-based acoustic materials continues to evolve, ongoing efforts are being made to harmonize testing procedures across different regions and industries. This includes the development of round-robin testing programs, where multiple laboratories perform tests on identical samples to ensure consistency and reproducibility of results. Such initiatives are crucial for establishing trust in the performance claims of new acoustic materials and facilitating their adoption in diverse applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!