How Polypropylene Enhancements Transform Air Filtration Efficiency

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Filtration Evolution and Objectives

Polypropylene has emerged as a revolutionary material in air filtration technology, transforming the efficiency and effectiveness of air purification systems. The evolution of polypropylene filtration can be traced back to the mid-20th century when synthetic polymers first gained prominence in industrial applications. Initially, polypropylene was primarily used in basic filtration processes due to its low cost and chemical resistance.

As environmental concerns and air quality standards became more stringent, the demand for advanced filtration solutions grew exponentially. This catalyzed intensive research and development efforts to enhance polypropylene's filtration capabilities. The key objectives in this technological evolution have been to improve particle capture efficiency, reduce pressure drop, and enhance the material's durability under various environmental conditions.

One of the most significant milestones in polypropylene filtration was the development of melt-blown technology in the 1970s. This process allowed for the production of microfiber webs with significantly higher surface area and porosity, dramatically improving filtration efficiency. Subsequent advancements focused on optimizing fiber diameter and distribution, leading to the creation of nanofiber polypropylene filters capable of capturing sub-micron particles.

The integration of electrostatic charging techniques marked another pivotal moment in polypropylene filter evolution. By imparting an electrostatic charge to the fibers, manufacturers could enhance the filter's ability to attract and capture fine particles, including those in the PM2.5 range. This innovation significantly broadened the application scope of polypropylene filters, making them suitable for use in high-efficiency particulate air (HEPA) filtration systems.

Recent objectives in polypropylene filtration technology have centered around sustainability and multifunctionality. Researchers are exploring ways to incorporate biodegradable additives into polypropylene filters to address end-of-life environmental concerns. Additionally, there is a growing focus on developing polypropylene filters with antimicrobial properties to combat airborne pathogens, a need highlighted by global health crises.

The current technological trajectory aims to push the boundaries of filtration efficiency while maintaining low energy consumption. This includes the development of gradient density polypropylene filters that optimize particle capture across different layers and the exploration of hybrid materials that combine polypropylene with other advanced filtration media.

As we look to the future, the objectives for polypropylene filtration enhancements are likely to include smart filtration systems with integrated sensors for real-time air quality monitoring, as well as the development of self-cleaning and regenerative filter technologies to extend operational lifespans and reduce maintenance requirements.

As environmental concerns and air quality standards became more stringent, the demand for advanced filtration solutions grew exponentially. This catalyzed intensive research and development efforts to enhance polypropylene's filtration capabilities. The key objectives in this technological evolution have been to improve particle capture efficiency, reduce pressure drop, and enhance the material's durability under various environmental conditions.

One of the most significant milestones in polypropylene filtration was the development of melt-blown technology in the 1970s. This process allowed for the production of microfiber webs with significantly higher surface area and porosity, dramatically improving filtration efficiency. Subsequent advancements focused on optimizing fiber diameter and distribution, leading to the creation of nanofiber polypropylene filters capable of capturing sub-micron particles.

The integration of electrostatic charging techniques marked another pivotal moment in polypropylene filter evolution. By imparting an electrostatic charge to the fibers, manufacturers could enhance the filter's ability to attract and capture fine particles, including those in the PM2.5 range. This innovation significantly broadened the application scope of polypropylene filters, making them suitable for use in high-efficiency particulate air (HEPA) filtration systems.

Recent objectives in polypropylene filtration technology have centered around sustainability and multifunctionality. Researchers are exploring ways to incorporate biodegradable additives into polypropylene filters to address end-of-life environmental concerns. Additionally, there is a growing focus on developing polypropylene filters with antimicrobial properties to combat airborne pathogens, a need highlighted by global health crises.

The current technological trajectory aims to push the boundaries of filtration efficiency while maintaining low energy consumption. This includes the development of gradient density polypropylene filters that optimize particle capture across different layers and the exploration of hybrid materials that combine polypropylene with other advanced filtration media.

As we look to the future, the objectives for polypropylene filtration enhancements are likely to include smart filtration systems with integrated sensors for real-time air quality monitoring, as well as the development of self-cleaning and regenerative filter technologies to extend operational lifespans and reduce maintenance requirements.

Air Purification Market Trends

The air purification market has been experiencing significant growth in recent years, driven by increasing awareness of indoor air quality and its impact on health. This trend has been further accelerated by global events such as the COVID-19 pandemic and rising pollution levels in urban areas. The market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

One of the key factors fueling market growth is the rising prevalence of respiratory diseases and allergies, which has led to a greater demand for effective air purification solutions. Consumers are becoming more conscious of the potential health risks associated with poor indoor air quality, including exposure to particulate matter, volatile organic compounds (VOCs), and airborne pathogens.

The residential sector remains a major contributor to market growth, as homeowners increasingly invest in air purification systems to create healthier living environments. However, the commercial and industrial sectors are also showing substantial growth, with offices, hospitals, schools, and manufacturing facilities recognizing the importance of clean air for employee health and productivity.

Technological advancements are playing a crucial role in shaping market trends. High-efficiency particulate air (HEPA) filters continue to dominate the market, but there is a growing interest in advanced filtration technologies, including activated carbon filters, UV-C light purification, and ionization systems. The integration of smart features and IoT connectivity is also gaining traction, allowing users to monitor and control air quality remotely.

Geographically, Asia-Pacific is emerging as the fastest-growing region in the air purification market, driven by rapid industrialization, urbanization, and increasing air pollution levels in countries like China and India. North America and Europe continue to be significant markets, with stringent air quality regulations and high consumer awareness driving adoption.

The market is characterized by intense competition, with both established players and new entrants vying for market share. Key strategies employed by companies include product innovation, strategic partnerships, and expansion into emerging markets. There is also a growing focus on sustainability, with manufacturers developing eco-friendly filters and energy-efficient purification systems to appeal to environmentally conscious consumers.

As the air purification market evolves, there is an increasing emphasis on developing solutions that can effectively remove a wide range of pollutants, including ultrafine particles and emerging contaminants. This has led to a surge in research and development activities, particularly in the field of advanced filtration materials and technologies.

One of the key factors fueling market growth is the rising prevalence of respiratory diseases and allergies, which has led to a greater demand for effective air purification solutions. Consumers are becoming more conscious of the potential health risks associated with poor indoor air quality, including exposure to particulate matter, volatile organic compounds (VOCs), and airborne pathogens.

The residential sector remains a major contributor to market growth, as homeowners increasingly invest in air purification systems to create healthier living environments. However, the commercial and industrial sectors are also showing substantial growth, with offices, hospitals, schools, and manufacturing facilities recognizing the importance of clean air for employee health and productivity.

Technological advancements are playing a crucial role in shaping market trends. High-efficiency particulate air (HEPA) filters continue to dominate the market, but there is a growing interest in advanced filtration technologies, including activated carbon filters, UV-C light purification, and ionization systems. The integration of smart features and IoT connectivity is also gaining traction, allowing users to monitor and control air quality remotely.

Geographically, Asia-Pacific is emerging as the fastest-growing region in the air purification market, driven by rapid industrialization, urbanization, and increasing air pollution levels in countries like China and India. North America and Europe continue to be significant markets, with stringent air quality regulations and high consumer awareness driving adoption.

The market is characterized by intense competition, with both established players and new entrants vying for market share. Key strategies employed by companies include product innovation, strategic partnerships, and expansion into emerging markets. There is also a growing focus on sustainability, with manufacturers developing eco-friendly filters and energy-efficient purification systems to appeal to environmentally conscious consumers.

As the air purification market evolves, there is an increasing emphasis on developing solutions that can effectively remove a wide range of pollutants, including ultrafine particles and emerging contaminants. This has led to a surge in research and development activities, particularly in the field of advanced filtration materials and technologies.

Current Polypropylene Filter Technology Challenges

Polypropylene filters have become a cornerstone in air filtration technology, offering a balance of efficiency and cost-effectiveness. However, as air quality concerns intensify globally, these filters face several significant challenges that limit their performance and applicability in advanced filtration systems.

One of the primary challenges is the trade-off between filtration efficiency and pressure drop. While increasing the density of polypropylene fibers can enhance particle capture, it simultaneously raises air resistance, leading to higher energy consumption in HVAC systems. This balance becomes particularly critical in high-performance applications where both air quality and energy efficiency are paramount.

Another persistent issue is the limited electrostatic charge retention of polypropylene filters. Although electret filters, which rely on electrostatic attraction to capture particles, are highly effective initially, their performance degrades over time as the charge dissipates. This degradation is accelerated in humid environments or when exposed to certain chemical contaminants, reducing the filter's long-term efficacy.

The mechanical strength of polypropylene filters also presents challenges, especially in high-flow or variable pressure environments. The relatively low tensile strength of polypropylene fibers can lead to filter deformation or breakdown under stress, compromising filtration integrity and potentially releasing captured particles back into the airstream.

Furthermore, the hydrophobic nature of polypropylene, while beneficial for moisture resistance, limits its effectiveness in capturing water-soluble contaminants and bioaerosols. This characteristic restricts the filter's versatility in environments where a broad spectrum of pollutants, including airborne microorganisms, needs to be addressed.

The environmental impact of polypropylene filters is an increasing concern. As single-use products, they contribute to plastic waste, and their non-biodegradable nature poses long-term ecological challenges. The industry faces pressure to develop more sustainable alternatives or improve the recyclability of existing filter materials.

Lastly, the performance of polypropylene filters in capturing ultrafine particles, particularly those below 0.3 microns, remains a significant challenge. As awareness of the health impacts of these minute particles grows, there is a pressing need for filter technologies that can effectively remove them without compromising on other performance aspects.

Addressing these challenges requires innovative approaches to material science, filter design, and manufacturing processes. The future of polypropylene filter technology lies in overcoming these limitations to create more efficient, durable, and environmentally friendly air filtration solutions.

One of the primary challenges is the trade-off between filtration efficiency and pressure drop. While increasing the density of polypropylene fibers can enhance particle capture, it simultaneously raises air resistance, leading to higher energy consumption in HVAC systems. This balance becomes particularly critical in high-performance applications where both air quality and energy efficiency are paramount.

Another persistent issue is the limited electrostatic charge retention of polypropylene filters. Although electret filters, which rely on electrostatic attraction to capture particles, are highly effective initially, their performance degrades over time as the charge dissipates. This degradation is accelerated in humid environments or when exposed to certain chemical contaminants, reducing the filter's long-term efficacy.

The mechanical strength of polypropylene filters also presents challenges, especially in high-flow or variable pressure environments. The relatively low tensile strength of polypropylene fibers can lead to filter deformation or breakdown under stress, compromising filtration integrity and potentially releasing captured particles back into the airstream.

Furthermore, the hydrophobic nature of polypropylene, while beneficial for moisture resistance, limits its effectiveness in capturing water-soluble contaminants and bioaerosols. This characteristic restricts the filter's versatility in environments where a broad spectrum of pollutants, including airborne microorganisms, needs to be addressed.

The environmental impact of polypropylene filters is an increasing concern. As single-use products, they contribute to plastic waste, and their non-biodegradable nature poses long-term ecological challenges. The industry faces pressure to develop more sustainable alternatives or improve the recyclability of existing filter materials.

Lastly, the performance of polypropylene filters in capturing ultrafine particles, particularly those below 0.3 microns, remains a significant challenge. As awareness of the health impacts of these minute particles grows, there is a pressing need for filter technologies that can effectively remove them without compromising on other performance aspects.

Addressing these challenges requires innovative approaches to material science, filter design, and manufacturing processes. The future of polypropylene filter technology lies in overcoming these limitations to create more efficient, durable, and environmentally friendly air filtration solutions.

Cutting-edge Polypropylene Enhancement Techniques

01 Melt-blown polypropylene fiber filtration

Melt-blown polypropylene fibers are widely used in filtration applications due to their high efficiency and low pressure drop. The process involves extruding molten polypropylene through fine nozzles to create a web of fibers with varying diameters. These fibers can be engineered to capture particles of different sizes, making them suitable for various filtration needs.- Melt-blown polypropylene fiber filtration: Melt-blown polypropylene fibers are widely used in filtration applications due to their high efficiency and low cost. The process involves extruding molten polypropylene through fine nozzles to create a web of fibers with small diameters, resulting in a high surface area for particle capture. These filters are effective for various applications, including air and liquid filtration.

- Electret treatment for enhanced filtration: Electret treatment of polypropylene filters involves imparting an electric charge to the fibers, which enhances their ability to attract and capture particles. This treatment significantly improves filtration efficiency, especially for submicron particles, without increasing airflow resistance. The electret effect can be achieved through various methods, including corona charging or triboelectric charging.

- Multilayer polypropylene filter structures: Multilayer filter structures incorporating polypropylene layers can offer improved filtration efficiency and durability. These structures often combine layers with different fiber diameters, densities, or treatments to optimize particle capture across a range of sizes. Some designs include support layers for mechanical strength or pre-filtration layers to extend the life of the main filter.

- Surface modification of polypropylene filters: Surface modification techniques can enhance the filtration efficiency of polypropylene filters. These methods include chemical treatments, plasma treatments, or grafting of functional groups onto the fiber surface. Such modifications can improve particle adhesion, hydrophilicity, or introduce specific chemical affinities for target contaminants, thereby increasing overall filtration performance.

- Testing and characterization of polypropylene filter efficiency: Accurate testing and characterization of polypropylene filter efficiency are crucial for quality control and performance validation. Methods include particle penetration tests, pressure drop measurements, and accelerated aging studies. Advanced techniques such as scanning electron microscopy and computational fluid dynamics simulations are also used to analyze filter structure and predict performance under various conditions.

02 Electret treatment for enhanced filtration

Electret treatment of polypropylene filters involves imparting an electric charge to the fibers, which significantly improves their filtration efficiency. This process enhances the ability of the filter to attract and capture particles, including submicron particles and aerosols. Electret-treated polypropylene filters maintain high efficiency while allowing for better airflow.Expand Specific Solutions03 Multi-layer polypropylene filter structures

Multi-layer polypropylene filter structures combine different densities and fiber diameters to optimize filtration efficiency and dust-holding capacity. These structures typically include a coarse pre-filter layer, a main filtration layer, and sometimes a support layer. This design allows for the capture of a wide range of particle sizes while maintaining good air permeability.Expand Specific Solutions04 Nanofiber-enhanced polypropylene filters

Incorporating nanofibers into polypropylene filter media significantly increases filtration efficiency without substantially increasing pressure drop. Nanofibers, often electrospun onto a polypropylene substrate, create an additional fine filtration layer that can capture submicron particles more effectively than traditional melt-blown fibers alone.Expand Specific Solutions05 Surface modification of polypropylene filters

Surface modification techniques, such as plasma treatment or chemical grafting, can enhance the filtration efficiency of polypropylene filters. These treatments can alter the surface properties of the fibers, improving their ability to capture specific contaminants or enhancing their hydrophobic or hydrophilic characteristics for specialized filtration applications.Expand Specific Solutions

Key Players in Advanced Filtration Materials

The air filtration efficiency enhancement through polypropylene advancements is in a growth phase, with increasing market size driven by rising air quality concerns. The technology's maturity is progressing, with major players like DuPont, ExxonMobil, and LG Chem leading innovation. These companies are leveraging their expertise in polymer science to develop high-performance polypropylene materials for air filtration applications. Emerging players such as Kingfa Sci. & Tech. and R-Zero Systems are also contributing to the competitive landscape, focusing on specialized solutions and smart building technologies. The market is characterized by ongoing research and development efforts to improve filtration efficiency, durability, and sustainability of polypropylene-based air filtration systems.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced polypropylene fibers for air filtration, utilizing their proprietary spinning technology to create ultra-fine fibers with enhanced surface area. Their Hybrid Membrane Technology (HMT) combines electrospun nanofibers with traditional meltblown fibers, resulting in a composite material with superior filtration efficiency[1]. This technology allows for the creation of filters with high particle capture rates (>99.9% for particles as small as 0.3 microns) while maintaining low pressure drop. DuPont's polypropylene-based filters also incorporate antimicrobial additives to prevent microbial growth, extending filter life and improving indoor air quality[2]. The company has further enhanced their filters' performance through electrostatic charging, which significantly improves the capture of sub-micron particles without increasing airflow resistance[3].

Strengths: Superior filtration efficiency, low pressure drop, antimicrobial properties, and extended filter life. Weaknesses: Potentially higher production costs due to advanced technology, and possible limitations in extreme temperature environments.

LG Chem Ltd.

Technical Solution: LG Chem has innovated in polypropylene air filtration technology by developing a multi-layer filter structure that combines different grades of polypropylene fibers. Their approach utilizes a gradient density design, where coarser fibers are used in the outer layers for pre-filtration, while finer fibers in the inner layers capture smaller particles[4]. LG Chem's filters incorporate nanofiber technology, producing fibers with diameters as small as 100 nanometers, which significantly increases the filter's surface area and particle capture efficiency. The company has also implemented a unique fiber charging process that enhances electrostatic attraction, improving the filter's ability to capture sub-micron particles and volatile organic compounds (VOCs)[5]. Additionally, LG Chem has developed polypropylene filters with self-cleaning properties, utilizing photocatalytic materials that break down captured pollutants when exposed to light, extending the filter's lifespan and maintaining high efficiency over time[6].

Strengths: High filtration efficiency for a wide range of particle sizes, including VOCs; self-cleaning properties for extended lifespan. Weaknesses: Potential higher initial costs; may require specific conditions (e.g., light exposure) for optimal self-cleaning functionality.

Breakthrough Innovations in Filter Media Design

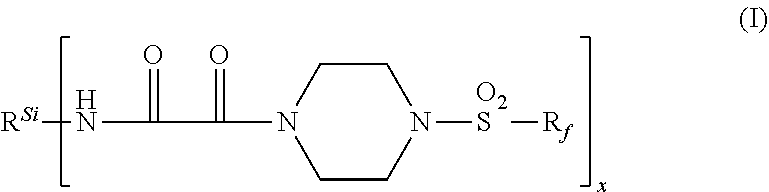

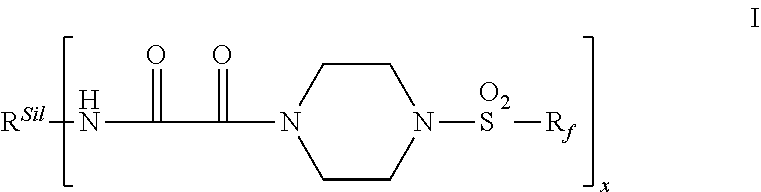

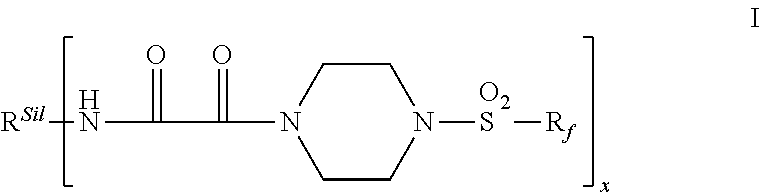

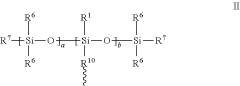

Flurochemical piperazine carboxamides

PatentActiveUS20200308349A1

Innovation

- Development of partially fluorinated piperazine carboxamide compounds with polysiloxane chains and shorter perfluoroalkyl groups (C3-C5) that are less bioaccumulative, combined with thermoplastic or thermoset polymers to create repellent polymer compositions for improved oil and water repellency, and electret filter media with enhanced filtration efficiency.

Air filter comprising polycarbonate nanofiber, and manufacturing method therefor

PatentWO2021177690A1

Innovation

- An air filter comprising a polyethylene terephthalate substrate with electrospun polycarbonate nanofibers and electrostatically treated polypropylene melt blown nonwoven fabric, stacked sequentially, which enhances filtration efficiency while minimizing pressure loss by optimizing fiber diameter and basis weight.

Environmental Impact of Enhanced Filters

The enhanced polypropylene filters in air filtration systems have significant environmental implications, both positive and negative. On the positive side, these advanced filters contribute to improved indoor air quality, which has far-reaching health benefits for occupants. By effectively removing particulate matter, allergens, and other pollutants from the air, these filters reduce the risk of respiratory illnesses and other health issues associated with poor air quality. This, in turn, can lead to decreased healthcare costs and improved productivity in workplaces and educational settings.

Furthermore, the increased efficiency of polypropylene-enhanced filters can result in energy savings for HVAC systems. As these filters capture more particles with less airflow resistance, the overall system requires less energy to maintain optimal air quality. This reduction in energy consumption translates to lower greenhouse gas emissions from power plants, contributing to broader environmental sustainability goals.

However, the environmental impact of these enhanced filters is not without challenges. The production of polypropylene, a petroleum-based plastic, involves the consumption of non-renewable resources and generates greenhouse gas emissions during manufacturing processes. While polypropylene is recyclable, the complex nature of filter materials often makes recycling difficult in practice. This can lead to increased waste in landfills, as many used filters end up being discarded rather than recycled.

The disposal of used filters also presents environmental concerns. As these filters capture more pollutants and particulates, they potentially become hazardous waste when disposed of improperly. This necessitates careful handling and specialized disposal methods to prevent the release of captured contaminants back into the environment.

Another consideration is the potential for microplastic shedding from polypropylene fibers during the filter's lifecycle. While the extent of this issue in air filtration systems is not fully understood, it is a growing concern in environmental science and may require further research and mitigation strategies.

Despite these challenges, the net environmental impact of enhanced polypropylene filters is generally positive when considering their role in improving air quality and reducing energy consumption. To maximize the environmental benefits and minimize drawbacks, ongoing research and development efforts are focusing on sustainable production methods, improved recyclability, and the exploration of bio-based alternatives to traditional polypropylene. These advancements aim to create more environmentally friendly filtration solutions without compromising on performance and efficiency.

Furthermore, the increased efficiency of polypropylene-enhanced filters can result in energy savings for HVAC systems. As these filters capture more particles with less airflow resistance, the overall system requires less energy to maintain optimal air quality. This reduction in energy consumption translates to lower greenhouse gas emissions from power plants, contributing to broader environmental sustainability goals.

However, the environmental impact of these enhanced filters is not without challenges. The production of polypropylene, a petroleum-based plastic, involves the consumption of non-renewable resources and generates greenhouse gas emissions during manufacturing processes. While polypropylene is recyclable, the complex nature of filter materials often makes recycling difficult in practice. This can lead to increased waste in landfills, as many used filters end up being discarded rather than recycled.

The disposal of used filters also presents environmental concerns. As these filters capture more pollutants and particulates, they potentially become hazardous waste when disposed of improperly. This necessitates careful handling and specialized disposal methods to prevent the release of captured contaminants back into the environment.

Another consideration is the potential for microplastic shedding from polypropylene fibers during the filter's lifecycle. While the extent of this issue in air filtration systems is not fully understood, it is a growing concern in environmental science and may require further research and mitigation strategies.

Despite these challenges, the net environmental impact of enhanced polypropylene filters is generally positive when considering their role in improving air quality and reducing energy consumption. To maximize the environmental benefits and minimize drawbacks, ongoing research and development efforts are focusing on sustainable production methods, improved recyclability, and the exploration of bio-based alternatives to traditional polypropylene. These advancements aim to create more environmentally friendly filtration solutions without compromising on performance and efficiency.

Regulatory Standards for Air Filtration Systems

Air filtration systems play a crucial role in maintaining indoor air quality and protecting public health. As such, they are subject to a comprehensive set of regulatory standards that govern their design, performance, and testing procedures. These standards are established and enforced by various national and international organizations to ensure consistent quality and effectiveness across the industry.

In the United States, the primary regulatory body for air filtration systems is the Environmental Protection Agency (EPA). The EPA sets National Ambient Air Quality Standards (NAAQS) that indirectly influence air filtration requirements. Additionally, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides widely adopted standards, such as ASHRAE Standard 52.2, which outlines testing methods for evaluating the performance of air-cleaning devices.

The European Union has its own set of standards, including EN 779 and EN 1822, which classify air filters based on their efficiency in removing particles of different sizes. These standards are gradually being replaced by the newer ISO 16890 global standard, which aims to harmonize air filter testing and classification worldwide.

For specific applications, such as healthcare facilities, more stringent standards apply. In the US, the Centers for Disease Control and Prevention (CDC) and the Healthcare Infection Control Practices Advisory Committee (HICPAC) provide guidelines for air filtration in hospitals and other medical settings. These guidelines often recommend the use of high-efficiency particulate air (HEPA) filters in critical areas.

Regulatory standards also address the environmental impact of air filtration systems. Energy efficiency requirements, such as those outlined in the US Department of Energy's appliance standards, push manufacturers to develop filters that maintain high performance while minimizing energy consumption. Furthermore, regulations on the disposal of used filters and the materials used in their construction are becoming increasingly important as sustainability concerns grow.

As polypropylene enhancements continue to improve air filtration efficiency, regulatory bodies are likely to update their standards to reflect these technological advancements. This may include revising testing methodologies to better evaluate the performance of filters incorporating enhanced polypropylene materials, as well as potentially raising minimum efficiency requirements for various applications.

In the United States, the primary regulatory body for air filtration systems is the Environmental Protection Agency (EPA). The EPA sets National Ambient Air Quality Standards (NAAQS) that indirectly influence air filtration requirements. Additionally, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides widely adopted standards, such as ASHRAE Standard 52.2, which outlines testing methods for evaluating the performance of air-cleaning devices.

The European Union has its own set of standards, including EN 779 and EN 1822, which classify air filters based on their efficiency in removing particles of different sizes. These standards are gradually being replaced by the newer ISO 16890 global standard, which aims to harmonize air filter testing and classification worldwide.

For specific applications, such as healthcare facilities, more stringent standards apply. In the US, the Centers for Disease Control and Prevention (CDC) and the Healthcare Infection Control Practices Advisory Committee (HICPAC) provide guidelines for air filtration in hospitals and other medical settings. These guidelines often recommend the use of high-efficiency particulate air (HEPA) filters in critical areas.

Regulatory standards also address the environmental impact of air filtration systems. Energy efficiency requirements, such as those outlined in the US Department of Energy's appliance standards, push manufacturers to develop filters that maintain high performance while minimizing energy consumption. Furthermore, regulations on the disposal of used filters and the materials used in their construction are becoming increasingly important as sustainability concerns grow.

As polypropylene enhancements continue to improve air filtration efficiency, regulatory bodies are likely to update their standards to reflect these technological advancements. This may include revising testing methodologies to better evaluate the performance of filters incorporating enhanced polypropylene materials, as well as potentially raising minimum efficiency requirements for various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!