How Polypropylene Enhances Acoustic Insulation in Buildings

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Acoustics: Background and Objectives

Polypropylene, a versatile thermoplastic polymer, has emerged as a significant material in the field of acoustic insulation for buildings. The evolution of this technology can be traced back to the mid-20th century when polypropylene was first synthesized. Since then, its application in acoustic insulation has grown exponentially, driven by the increasing demand for noise reduction in urban environments and the need for energy-efficient building materials.

The acoustic properties of polypropylene were initially discovered as a byproduct of its use in other applications. However, as researchers and engineers began to understand its potential, dedicated studies into its sound-absorbing capabilities commenced. This led to the development of specialized polypropylene-based acoustic materials, designed to address the specific challenges of noise control in buildings.

The primary objective of utilizing polypropylene in acoustic insulation is to enhance the overall sound absorption and transmission loss in buildings. This goal aligns with the broader aims of improving indoor environmental quality and occupant comfort. Additionally, the use of polypropylene in this context seeks to provide a cost-effective and sustainable alternative to traditional acoustic insulation materials.

As the construction industry increasingly focuses on sustainable and energy-efficient building practices, polypropylene's role in acoustic insulation has gained further prominence. Its lightweight nature, durability, and recyclability make it an attractive option for architects and builders looking to meet stringent environmental standards without compromising on acoustic performance.

The technological trajectory of polypropylene in acoustic insulation has been marked by continuous innovation. From simple foam structures to complex composite materials, the evolution of polypropylene-based acoustic solutions reflects the industry's commitment to pushing the boundaries of material science. Current research aims to optimize the molecular structure and manufacturing processes of polypropylene to further enhance its sound-absorbing properties.

Looking ahead, the future of polypropylene in acoustic insulation appears promising. Emerging trends indicate a move towards smart, adaptive acoustic materials that can respond to changing noise environments. This vision encompasses the integration of polypropylene with other advanced materials and technologies to create multifunctional acoustic insulation systems that not only dampen sound but also contribute to thermal regulation and air quality improvement in buildings.

The acoustic properties of polypropylene were initially discovered as a byproduct of its use in other applications. However, as researchers and engineers began to understand its potential, dedicated studies into its sound-absorbing capabilities commenced. This led to the development of specialized polypropylene-based acoustic materials, designed to address the specific challenges of noise control in buildings.

The primary objective of utilizing polypropylene in acoustic insulation is to enhance the overall sound absorption and transmission loss in buildings. This goal aligns with the broader aims of improving indoor environmental quality and occupant comfort. Additionally, the use of polypropylene in this context seeks to provide a cost-effective and sustainable alternative to traditional acoustic insulation materials.

As the construction industry increasingly focuses on sustainable and energy-efficient building practices, polypropylene's role in acoustic insulation has gained further prominence. Its lightweight nature, durability, and recyclability make it an attractive option for architects and builders looking to meet stringent environmental standards without compromising on acoustic performance.

The technological trajectory of polypropylene in acoustic insulation has been marked by continuous innovation. From simple foam structures to complex composite materials, the evolution of polypropylene-based acoustic solutions reflects the industry's commitment to pushing the boundaries of material science. Current research aims to optimize the molecular structure and manufacturing processes of polypropylene to further enhance its sound-absorbing properties.

Looking ahead, the future of polypropylene in acoustic insulation appears promising. Emerging trends indicate a move towards smart, adaptive acoustic materials that can respond to changing noise environments. This vision encompasses the integration of polypropylene with other advanced materials and technologies to create multifunctional acoustic insulation systems that not only dampen sound but also contribute to thermal regulation and air quality improvement in buildings.

Market Analysis: Acoustic Insulation Demand

The acoustic insulation market has experienced significant growth in recent years, driven by increasing awareness of noise pollution and its adverse effects on health and well-being. The global acoustic insulation market size was valued at USD 14.1 billion in 2020 and is projected to reach USD 17.6 billion by 2025, growing at a CAGR of 4.5% during the forecast period.

The demand for acoustic insulation in buildings is primarily fueled by stringent noise regulations, growing urbanization, and the rising need for sustainable construction materials. In the residential sector, homeowners are increasingly seeking solutions to reduce noise transmission between rooms and from external sources. This trend is particularly evident in multi-family housing developments and urban areas where noise pollution is more prevalent.

Commercial and industrial sectors also contribute significantly to the acoustic insulation demand. Office buildings, educational institutions, healthcare facilities, and industrial plants are adopting acoustic insulation solutions to create more productive and comfortable environments. The hospitality industry, including hotels and restaurants, is another key driver of demand as they strive to enhance guest experience through improved sound quality.

The construction industry's shift towards green building practices has further boosted the demand for eco-friendly acoustic insulation materials. Polypropylene, being recyclable and energy-efficient in production, aligns well with this trend. Its ability to enhance acoustic insulation while offering thermal insulation properties makes it an attractive option for builders and architects seeking multifunctional materials.

Geographically, North America and Europe lead the acoustic insulation market, owing to strict building codes and regulations regarding noise levels. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid urbanization, increasing construction activities, and growing awareness about the importance of acoustic comfort.

The COVID-19 pandemic has had a mixed impact on the acoustic insulation market. While it initially caused disruptions in the supply chain and construction activities, the shift towards remote work and increased time spent at home has heightened awareness of the importance of acoustic comfort in living spaces. This is expected to drive long-term demand for acoustic insulation solutions in residential buildings.

As technology advances, there is a growing trend towards the development of smart acoustic insulation materials that can adapt to changing noise levels. This presents new opportunities for innovation in the field of acoustic insulation, potentially revolutionizing how buildings manage sound.

The demand for acoustic insulation in buildings is primarily fueled by stringent noise regulations, growing urbanization, and the rising need for sustainable construction materials. In the residential sector, homeowners are increasingly seeking solutions to reduce noise transmission between rooms and from external sources. This trend is particularly evident in multi-family housing developments and urban areas where noise pollution is more prevalent.

Commercial and industrial sectors also contribute significantly to the acoustic insulation demand. Office buildings, educational institutions, healthcare facilities, and industrial plants are adopting acoustic insulation solutions to create more productive and comfortable environments. The hospitality industry, including hotels and restaurants, is another key driver of demand as they strive to enhance guest experience through improved sound quality.

The construction industry's shift towards green building practices has further boosted the demand for eco-friendly acoustic insulation materials. Polypropylene, being recyclable and energy-efficient in production, aligns well with this trend. Its ability to enhance acoustic insulation while offering thermal insulation properties makes it an attractive option for builders and architects seeking multifunctional materials.

Geographically, North America and Europe lead the acoustic insulation market, owing to strict building codes and regulations regarding noise levels. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid urbanization, increasing construction activities, and growing awareness about the importance of acoustic comfort.

The COVID-19 pandemic has had a mixed impact on the acoustic insulation market. While it initially caused disruptions in the supply chain and construction activities, the shift towards remote work and increased time spent at home has heightened awareness of the importance of acoustic comfort in living spaces. This is expected to drive long-term demand for acoustic insulation solutions in residential buildings.

As technology advances, there is a growing trend towards the development of smart acoustic insulation materials that can adapt to changing noise levels. This presents new opportunities for innovation in the field of acoustic insulation, potentially revolutionizing how buildings manage sound.

Current Challenges in Building Acoustics

Building acoustics faces several significant challenges in the modern construction industry. One of the primary issues is the increasing demand for noise reduction in urban environments, where population density and traffic noise continue to rise. This has led to more stringent building codes and regulations regarding acoustic performance, putting pressure on architects and engineers to develop more effective sound insulation solutions.

Another challenge is the trend towards lightweight construction materials and open-plan designs, which can compromise acoustic insulation. These modern architectural preferences often result in thinner walls and larger open spaces, making it more difficult to control sound transmission between rooms and from external sources. The use of glass facades and large windows in contemporary buildings also presents acoustic challenges, as these materials are inherently less effective at blocking sound compared to traditional solid walls.

The complexity of sound transmission paths in buildings poses another significant hurdle. Sound can travel through various routes, including direct transmission through walls and floors, flanking transmission through connected building elements, and air leaks. This multifaceted nature of sound propagation makes it challenging to develop comprehensive acoustic solutions that address all potential pathways.

Energy efficiency requirements often conflict with acoustic performance goals. For instance, the push for better thermal insulation can sometimes lead to choices that negatively impact sound insulation. Balancing these competing demands requires innovative approaches and materials that can serve multiple functions effectively.

Cost considerations also present a significant challenge in building acoustics. High-performance acoustic materials and systems can be expensive, and there is often a trade-off between acoustic quality and project budget constraints. This economic factor can lead to compromises in acoustic design, particularly in residential and commercial projects where cost is a major consideration.

Lastly, the retrofitting of existing buildings for improved acoustic performance presents unique challenges. Older structures may have inherent acoustic weaknesses that are difficult to address without significant structural modifications. The integration of modern acoustic solutions into historical or protected buildings must also be done sensitively, balancing preservation requirements with acoustic improvements.

Another challenge is the trend towards lightweight construction materials and open-plan designs, which can compromise acoustic insulation. These modern architectural preferences often result in thinner walls and larger open spaces, making it more difficult to control sound transmission between rooms and from external sources. The use of glass facades and large windows in contemporary buildings also presents acoustic challenges, as these materials are inherently less effective at blocking sound compared to traditional solid walls.

The complexity of sound transmission paths in buildings poses another significant hurdle. Sound can travel through various routes, including direct transmission through walls and floors, flanking transmission through connected building elements, and air leaks. This multifaceted nature of sound propagation makes it challenging to develop comprehensive acoustic solutions that address all potential pathways.

Energy efficiency requirements often conflict with acoustic performance goals. For instance, the push for better thermal insulation can sometimes lead to choices that negatively impact sound insulation. Balancing these competing demands requires innovative approaches and materials that can serve multiple functions effectively.

Cost considerations also present a significant challenge in building acoustics. High-performance acoustic materials and systems can be expensive, and there is often a trade-off between acoustic quality and project budget constraints. This economic factor can lead to compromises in acoustic design, particularly in residential and commercial projects where cost is a major consideration.

Lastly, the retrofitting of existing buildings for improved acoustic performance presents unique challenges. Older structures may have inherent acoustic weaknesses that are difficult to address without significant structural modifications. The integration of modern acoustic solutions into historical or protected buildings must also be done sensitively, balancing preservation requirements with acoustic improvements.

Polypropylene-based Acoustic Solutions

01 Polypropylene-based acoustic insulation materials

Acoustic insulation materials made from polypropylene fibers or composites offer effective sound absorption and noise reduction properties. These materials can be used in various applications, including automotive, construction, and industrial settings. The lightweight and durable nature of polypropylene makes it an ideal choice for acoustic insulation.- Polypropylene-based acoustic insulation materials: Acoustic insulation materials incorporating polypropylene as a primary component. These materials can be in the form of fibers, foams, or composites, offering effective sound absorption and noise reduction properties while being lightweight and durable.

- Multilayer acoustic insulation structures: Acoustic insulation systems comprising multiple layers of materials, including polypropylene, to enhance sound absorption across different frequency ranges. These structures may include combinations of dense and porous layers to improve overall acoustic performance.

- Recycled polypropylene in acoustic insulation: Utilization of recycled polypropylene in acoustic insulation products, promoting sustainability and reducing environmental impact. These materials can be processed into various forms such as fibers or panels for use in construction and automotive applications.

- Polypropylene acoustic insulation for vehicles: Specialized acoustic insulation solutions using polypropylene for automotive applications. These materials are designed to reduce cabin noise, improve passenger comfort, and meet specific requirements for weight reduction and fire resistance in vehicles.

- Manufacturing processes for polypropylene acoustic insulation: Innovative manufacturing techniques for producing polypropylene-based acoustic insulation materials. These processes may include extrusion, thermoforming, or nonwoven technologies to create materials with optimal acoustic properties and structural integrity.

02 Multilayer acoustic insulation structures

Multilayer structures incorporating polypropylene layers can enhance acoustic insulation performance. These structures may include combinations of polypropylene with other materials such as foam, fabric, or air gaps to optimize sound absorption across different frequency ranges. The layered approach allows for customization of acoustic properties for specific applications.Expand Specific Solutions03 Recycled polypropylene in acoustic insulation

Utilizing recycled polypropylene in acoustic insulation products promotes sustainability and reduces environmental impact. Recycled polypropylene can be processed into fibers or composites that maintain effective sound-absorbing properties while contributing to circular economy initiatives. This approach addresses both acoustic performance and environmental concerns.Expand Specific Solutions04 Polypropylene acoustic insulation in vehicles

Polypropylene-based acoustic insulation is widely used in the automotive industry to reduce cabin noise and improve passenger comfort. These materials can be molded or shaped to fit complex vehicle geometries and can be integrated into various components such as door panels, headliners, and floor mats. The lightweight nature of polypropylene also contributes to overall vehicle efficiency.Expand Specific Solutions05 Manufacturing processes for polypropylene acoustic insulation

Various manufacturing processes are employed to produce polypropylene acoustic insulation materials, including melt-blown, spunbond, and needle-punching techniques. These processes allow for the creation of fibrous or porous structures that enhance sound absorption. Additives or treatments may be incorporated during manufacturing to further improve acoustic performance or add flame-retardant properties.Expand Specific Solutions

Key Players in Acoustic Insulation Industry

The acoustic insulation market for polypropylene in buildings is in a growth phase, driven by increasing demand for energy-efficient construction and noise reduction solutions. The market size is expanding as more countries implement stricter building codes for sound insulation. Technologically, polypropylene-based acoustic insulation is maturing, with companies like Kingfa Sci. & Tech. and Wanhua Chemical leading innovation in advanced materials. Established players such as Henkel and LANXESS are also contributing to the development of high-performance acoustic solutions. The competitive landscape is diverse, with both specialized manufacturers and large chemical conglomerates vying for market share in this growing sector.

Certainteed Gypsum, Inc.

Technical Solution: Certainteed Gypsum has developed a polypropylene-enhanced gypsum board system for superior acoustic insulation in buildings. Their technology incorporates polypropylene fibers into the gypsum core, creating a composite material that significantly improves sound attenuation. The polypropylene fibers form a complex network within the gypsum matrix, increasing the material's density and providing additional pathways for sound energy dissipation. This results in a Sound Transmission Class (STC) rating improvement of up to 5-7 points compared to standard gypsum boards[1]. The company has also implemented a proprietary manufacturing process that ensures uniform distribution of polypropylene fibers throughout the board, enhancing overall performance consistency[3].

Strengths: Improved STC ratings, consistent performance, and integration with existing construction methods. Weaknesses: Potentially higher cost compared to standard gypsum boards and limited recyclability due to the composite nature of the material.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed a cutting-edge polypropylene-based acoustic insulation material utilizing nanotechnology. Their approach involves incorporating nano-sized particles into the polypropylene matrix, creating a material with enhanced sound-damping properties. The nanoparticles increase the material's density and create numerous interfaces that effectively scatter and absorb sound waves. Kingfa's research has shown that their nano-enhanced polypropylene insulation can achieve a Sound Transmission Loss (STL) of up to 35 dB in the mid-frequency range (500-1000 Hz), which is crucial for speech privacy in buildings[9]. The company has also developed a proprietary compounding process that ensures uniform distribution of nanoparticles, maintaining consistent acoustic performance across large surface areas[10].

Strengths: High sound transmission loss, consistent performance, and potential for multifunctional properties (e.g., thermal insulation). Weaknesses: Complex manufacturing process may lead to higher costs, and potential environmental concerns regarding nanoparticle use.

Innovations in Polypropylene Acoustic Technology

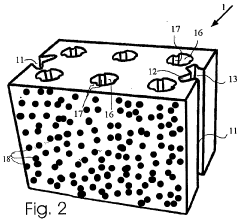

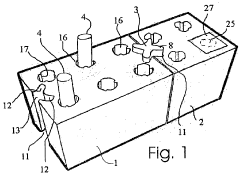

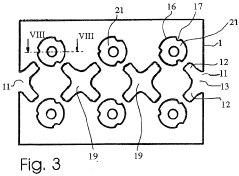

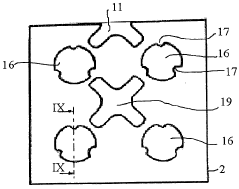

Set of building elements with elements of polypropylene

PatentWO2008138377A1

Innovation

- The use of expanded polypropylene (EPP) with a molding density of 40-70 kg/m³ for building components, combined with a ribbed surface design for enhanced sound absorption, and the integration of connecting elements with dovetail-like engagement structures for easy assembly and disassembly, along with the option to include electrical and water ducts for installation of lines.

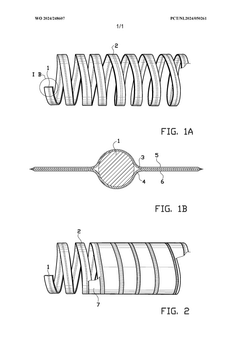

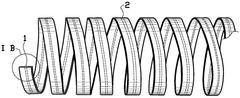

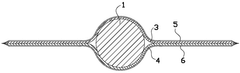

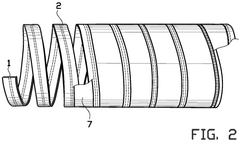

Duct and uses thereof

PatentWO2024248607A1

Innovation

- A duct comprising a cylindrical body with a polypropylene nonwoven fabric reinforced with integrated helical elements and an airtight liner layer of monoaxially or biaxially oriented polypropylene on both sides, enhancing acoustic properties by improving insertion and transmission loss, particularly in lower frequency regions, while maintaining flexibility and resistance to chemicals and water.

Environmental Impact of Polypropylene Insulation

The environmental impact of polypropylene insulation in buildings is a complex issue that requires careful consideration. Polypropylene, a thermoplastic polymer, offers excellent acoustic insulation properties but also raises concerns about its ecological footprint.

One of the primary environmental advantages of polypropylene insulation is its energy-saving potential. By effectively reducing heat transfer and sound transmission, it can significantly decrease the energy consumption required for heating and cooling in buildings. This, in turn, leads to lower greenhouse gas emissions associated with energy production and consumption over the lifespan of the building.

However, the production of polypropylene insulation does have environmental drawbacks. The manufacturing process relies heavily on fossil fuels, as polypropylene is derived from petroleum or natural gas. This dependency contributes to the depletion of non-renewable resources and generates greenhouse gas emissions during extraction and processing stages.

The durability of polypropylene insulation is a double-edged sword from an environmental perspective. On one hand, its long lifespan reduces the need for frequent replacements, minimizing waste generation and resource consumption. On the other hand, polypropylene is not biodegradable, which means it persists in the environment for extended periods when disposed of improperly.

Recycling potential is another crucial aspect to consider. While polypropylene is theoretically recyclable, the recycling process for insulation materials can be challenging due to contamination and the presence of additives. Improving recycling technologies and establishing effective collection systems are essential steps to mitigate the end-of-life environmental impact of polypropylene insulation.

The production of polypropylene insulation also raises concerns about air and water pollution. Volatile organic compounds (VOCs) may be released during manufacturing and installation, potentially affecting indoor air quality and contributing to atmospheric pollution. Additionally, the risk of microplastic pollution from polypropylene particles entering water systems during production or disposal cannot be overlooked.

When comparing polypropylene insulation to alternative materials, its environmental performance is mixed. While it may outperform some traditional insulation materials in terms of energy efficiency and durability, natural and recycled insulation options often have a lower overall environmental impact.

To address these environmental concerns, the industry is exploring various strategies. These include developing bio-based polypropylene alternatives, improving manufacturing processes to reduce emissions and energy consumption, and enhancing recycling capabilities. Additionally, the implementation of life cycle assessments and eco-design principles in product development can help minimize the overall environmental footprint of polypropylene insulation.

One of the primary environmental advantages of polypropylene insulation is its energy-saving potential. By effectively reducing heat transfer and sound transmission, it can significantly decrease the energy consumption required for heating and cooling in buildings. This, in turn, leads to lower greenhouse gas emissions associated with energy production and consumption over the lifespan of the building.

However, the production of polypropylene insulation does have environmental drawbacks. The manufacturing process relies heavily on fossil fuels, as polypropylene is derived from petroleum or natural gas. This dependency contributes to the depletion of non-renewable resources and generates greenhouse gas emissions during extraction and processing stages.

The durability of polypropylene insulation is a double-edged sword from an environmental perspective. On one hand, its long lifespan reduces the need for frequent replacements, minimizing waste generation and resource consumption. On the other hand, polypropylene is not biodegradable, which means it persists in the environment for extended periods when disposed of improperly.

Recycling potential is another crucial aspect to consider. While polypropylene is theoretically recyclable, the recycling process for insulation materials can be challenging due to contamination and the presence of additives. Improving recycling technologies and establishing effective collection systems are essential steps to mitigate the end-of-life environmental impact of polypropylene insulation.

The production of polypropylene insulation also raises concerns about air and water pollution. Volatile organic compounds (VOCs) may be released during manufacturing and installation, potentially affecting indoor air quality and contributing to atmospheric pollution. Additionally, the risk of microplastic pollution from polypropylene particles entering water systems during production or disposal cannot be overlooked.

When comparing polypropylene insulation to alternative materials, its environmental performance is mixed. While it may outperform some traditional insulation materials in terms of energy efficiency and durability, natural and recycled insulation options often have a lower overall environmental impact.

To address these environmental concerns, the industry is exploring various strategies. These include developing bio-based polypropylene alternatives, improving manufacturing processes to reduce emissions and energy consumption, and enhancing recycling capabilities. Additionally, the implementation of life cycle assessments and eco-design principles in product development can help minimize the overall environmental footprint of polypropylene insulation.

Cost-Benefit Analysis of Polypropylene Acoustics

The cost-benefit analysis of polypropylene acoustics in building insulation reveals a compelling case for its adoption. Initial investment in polypropylene-based acoustic solutions may be higher compared to traditional materials, but the long-term benefits often outweigh the upfront costs.

Polypropylene offers superior sound absorption properties, effectively reducing noise transmission between rooms and from external sources. This enhanced acoustic performance leads to improved occupant comfort and productivity, particularly in residential and commercial settings. The material's lightweight nature also contributes to easier installation and reduced structural load, potentially lowering overall construction costs.

Durability is a key factor in the cost-benefit equation. Polypropylene-based acoustic materials typically have a longer lifespan compared to conventional alternatives, reducing the frequency of replacements and associated labor costs. This longevity translates to lower maintenance expenses over the building's lifetime.

Energy efficiency is another significant benefit. Polypropylene's thermal insulation properties can contribute to reduced heating and cooling costs, providing additional savings on energy bills. This dual functionality of acoustic and thermal insulation offers a more cost-effective solution compared to separate systems for each purpose.

From an environmental perspective, polypropylene is recyclable and can be produced from recycled materials, aligning with sustainable building practices. This aspect can lead to potential cost savings through green building certifications and associated tax incentives.

However, it's important to consider potential drawbacks. The higher initial cost may be a barrier for some projects with tight budgets. Additionally, while polypropylene is fire-resistant, it may require additional treatments to meet stringent fire safety regulations, potentially increasing costs.

When evaluating the return on investment, factors such as building type, location, and specific acoustic requirements must be considered. For high-end residential properties or commercial spaces where acoustic quality is paramount, the benefits of polypropylene acoustics are likely to justify the investment more readily.

In conclusion, while the upfront costs of polypropylene acoustic solutions may be higher, the long-term benefits in terms of performance, durability, energy efficiency, and sustainability often result in a favorable cost-benefit ratio. As the technology continues to evolve and production scales up, it's anticipated that the cost-effectiveness of polypropylene acoustics will further improve, making it an increasingly attractive option for a wide range of building projects.

Polypropylene offers superior sound absorption properties, effectively reducing noise transmission between rooms and from external sources. This enhanced acoustic performance leads to improved occupant comfort and productivity, particularly in residential and commercial settings. The material's lightweight nature also contributes to easier installation and reduced structural load, potentially lowering overall construction costs.

Durability is a key factor in the cost-benefit equation. Polypropylene-based acoustic materials typically have a longer lifespan compared to conventional alternatives, reducing the frequency of replacements and associated labor costs. This longevity translates to lower maintenance expenses over the building's lifetime.

Energy efficiency is another significant benefit. Polypropylene's thermal insulation properties can contribute to reduced heating and cooling costs, providing additional savings on energy bills. This dual functionality of acoustic and thermal insulation offers a more cost-effective solution compared to separate systems for each purpose.

From an environmental perspective, polypropylene is recyclable and can be produced from recycled materials, aligning with sustainable building practices. This aspect can lead to potential cost savings through green building certifications and associated tax incentives.

However, it's important to consider potential drawbacks. The higher initial cost may be a barrier for some projects with tight budgets. Additionally, while polypropylene is fire-resistant, it may require additional treatments to meet stringent fire safety regulations, potentially increasing costs.

When evaluating the return on investment, factors such as building type, location, and specific acoustic requirements must be considered. For high-end residential properties or commercial spaces where acoustic quality is paramount, the benefits of polypropylene acoustics are likely to justify the investment more readily.

In conclusion, while the upfront costs of polypropylene acoustic solutions may be higher, the long-term benefits in terms of performance, durability, energy efficiency, and sustainability often result in a favorable cost-benefit ratio. As the technology continues to evolve and production scales up, it's anticipated that the cost-effectiveness of polypropylene acoustics will further improve, making it an increasingly attractive option for a wide range of building projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!