How Renewable Polypropylene Varieties Augment Circular Economies

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Renewable PP Evolution

The evolution of renewable polypropylene (PP) has been a significant development in the pursuit of circular economies and sustainable materials. This journey began in the early 2000s when researchers started exploring bio-based alternatives to traditional petroleum-derived polypropylene. The initial focus was on utilizing plant-based feedstocks, such as corn, sugarcane, and cellulosic biomass, to produce renewable PP monomers.

By the mid-2000s, several breakthrough technologies emerged, enabling the production of bio-based propylene. One notable approach involved the dehydration of bio-ethanol to ethylene, followed by dimerization to produce renewable propylene. This method gained traction due to the increasing availability of bio-ethanol from agricultural sources.

The next major milestone occurred in the early 2010s with the development of more efficient catalytic processes for converting bio-based feedstocks directly into propylene. These advancements significantly improved the economic viability of renewable PP production, making it more competitive with conventional PP.

In parallel, researchers explored alternative pathways, such as the use of methanol derived from captured CO2 or biogas as a feedstock for propylene production. This approach, known as the methanol-to-olefins (MTO) process, gained attention for its potential to create a closed carbon loop in PP production.

By the mid-2010s, the first commercial-scale production of renewable PP became a reality. Several major chemical companies launched pilot plants and began integrating renewable PP into their product portfolios. This period also saw increased collaboration between academia, industry, and government agencies to accelerate the development and adoption of renewable PP technologies.

Recent years have witnessed a shift towards more advanced and sustainable feedstocks. The use of agricultural waste, algae-based biomass, and even plastic waste as raw materials for renewable PP production has gained momentum. These innovations aim to address concerns about land use and food security associated with first-generation bio-based feedstocks.

The latest frontier in renewable PP evolution involves the integration of artificial intelligence and machine learning to optimize production processes and develop new catalyst systems. These technologies are enabling researchers to rapidly screen and identify more efficient and selective catalysts, potentially leading to breakthroughs in renewable PP synthesis.

As we move forward, the focus is increasingly on creating fully circular systems for PP production and use. This includes developing technologies for efficient PP recycling, upcycling, and biodegradation, alongside renewable production methods. The goal is to establish a comprehensive circular economy for PP, where materials can be indefinitely reused or safely returned to the environment.

By the mid-2000s, several breakthrough technologies emerged, enabling the production of bio-based propylene. One notable approach involved the dehydration of bio-ethanol to ethylene, followed by dimerization to produce renewable propylene. This method gained traction due to the increasing availability of bio-ethanol from agricultural sources.

The next major milestone occurred in the early 2010s with the development of more efficient catalytic processes for converting bio-based feedstocks directly into propylene. These advancements significantly improved the economic viability of renewable PP production, making it more competitive with conventional PP.

In parallel, researchers explored alternative pathways, such as the use of methanol derived from captured CO2 or biogas as a feedstock for propylene production. This approach, known as the methanol-to-olefins (MTO) process, gained attention for its potential to create a closed carbon loop in PP production.

By the mid-2010s, the first commercial-scale production of renewable PP became a reality. Several major chemical companies launched pilot plants and began integrating renewable PP into their product portfolios. This period also saw increased collaboration between academia, industry, and government agencies to accelerate the development and adoption of renewable PP technologies.

Recent years have witnessed a shift towards more advanced and sustainable feedstocks. The use of agricultural waste, algae-based biomass, and even plastic waste as raw materials for renewable PP production has gained momentum. These innovations aim to address concerns about land use and food security associated with first-generation bio-based feedstocks.

The latest frontier in renewable PP evolution involves the integration of artificial intelligence and machine learning to optimize production processes and develop new catalyst systems. These technologies are enabling researchers to rapidly screen and identify more efficient and selective catalysts, potentially leading to breakthroughs in renewable PP synthesis.

As we move forward, the focus is increasingly on creating fully circular systems for PP production and use. This includes developing technologies for efficient PP recycling, upcycling, and biodegradation, alongside renewable production methods. The goal is to establish a comprehensive circular economy for PP, where materials can be indefinitely reused or safely returned to the environment.

Circular Economy Demand

The circular economy concept has gained significant traction in recent years, driving demand for sustainable materials and processes across various industries. Renewable polypropylene varieties play a crucial role in meeting this growing demand, as they offer a more environmentally friendly alternative to traditional petroleum-based plastics. The market for circular economy solutions is expanding rapidly, with projections indicating substantial growth in the coming years.

Consumer awareness and preferences are shifting towards sustainable products, creating a strong pull for renewable polypropylene in packaging, automotive, and consumer goods sectors. Companies are increasingly adopting circular economy principles to meet consumer expectations and comply with evolving regulations. This shift is particularly evident in the packaging industry, where renewable polypropylene is being used to create recyclable and compostable packaging solutions.

The automotive sector represents another significant area of demand for renewable polypropylene. As automakers strive to reduce the environmental impact of their vehicles, they are incorporating more sustainable materials into their designs. Renewable polypropylene offers weight reduction benefits while maintaining the necessary performance characteristics, making it an attractive option for automotive components.

In the consumer goods sector, brands are leveraging renewable polypropylene to enhance their sustainability credentials and appeal to environmentally conscious consumers. From household items to personal care products, the demand for eco-friendly alternatives is driving innovation in product design and material selection.

The construction industry is also showing increased interest in renewable polypropylene for applications such as insulation, piping, and structural components. The material's durability, recyclability, and lower carbon footprint compared to traditional options make it an attractive choice for sustainable building practices.

Government policies and regulations supporting circular economy initiatives are further fueling the demand for renewable polypropylene. Many countries have implemented or are considering measures to reduce plastic waste and promote the use of sustainable materials. These policies create a favorable environment for the adoption of renewable polypropylene across various industries.

The textile industry is another sector where renewable polypropylene is gaining traction. As consumers become more aware of the environmental impact of fast fashion, there is a growing demand for sustainable fibers and fabrics. Renewable polypropylene offers potential applications in clothing, upholstery, and industrial textiles, providing a more eco-friendly alternative to conventional synthetic fibers.

As the circular economy concept continues to evolve and mature, the demand for renewable polypropylene is expected to increase further. Companies that invest in developing and implementing renewable polypropylene solutions are likely to gain a competitive advantage in the market, as sustainability becomes an increasingly important factor in consumer and business decision-making processes.

Consumer awareness and preferences are shifting towards sustainable products, creating a strong pull for renewable polypropylene in packaging, automotive, and consumer goods sectors. Companies are increasingly adopting circular economy principles to meet consumer expectations and comply with evolving regulations. This shift is particularly evident in the packaging industry, where renewable polypropylene is being used to create recyclable and compostable packaging solutions.

The automotive sector represents another significant area of demand for renewable polypropylene. As automakers strive to reduce the environmental impact of their vehicles, they are incorporating more sustainable materials into their designs. Renewable polypropylene offers weight reduction benefits while maintaining the necessary performance characteristics, making it an attractive option for automotive components.

In the consumer goods sector, brands are leveraging renewable polypropylene to enhance their sustainability credentials and appeal to environmentally conscious consumers. From household items to personal care products, the demand for eco-friendly alternatives is driving innovation in product design and material selection.

The construction industry is also showing increased interest in renewable polypropylene for applications such as insulation, piping, and structural components. The material's durability, recyclability, and lower carbon footprint compared to traditional options make it an attractive choice for sustainable building practices.

Government policies and regulations supporting circular economy initiatives are further fueling the demand for renewable polypropylene. Many countries have implemented or are considering measures to reduce plastic waste and promote the use of sustainable materials. These policies create a favorable environment for the adoption of renewable polypropylene across various industries.

The textile industry is another sector where renewable polypropylene is gaining traction. As consumers become more aware of the environmental impact of fast fashion, there is a growing demand for sustainable fibers and fabrics. Renewable polypropylene offers potential applications in clothing, upholstery, and industrial textiles, providing a more eco-friendly alternative to conventional synthetic fibers.

As the circular economy concept continues to evolve and mature, the demand for renewable polypropylene is expected to increase further. Companies that invest in developing and implementing renewable polypropylene solutions are likely to gain a competitive advantage in the market, as sustainability becomes an increasingly important factor in consumer and business decision-making processes.

Current Challenges

The development of renewable polypropylene varieties faces several significant challenges in the context of circular economies. One of the primary obstacles is the high production cost compared to conventional petroleum-based polypropylene. The complex processes involved in synthesizing bio-based monomers and the limited availability of renewable feedstocks contribute to this cost disparity, making it difficult for renewable polypropylene to compete in price-sensitive markets.

Another major challenge is the inconsistency in quality and performance of renewable polypropylene compared to its traditional counterpart. Variations in feedstock composition and processing conditions can lead to fluctuations in the final product's properties, such as tensile strength, thermal stability, and durability. This inconsistency poses difficulties for manufacturers in maintaining product specifications and meeting industry standards, potentially limiting the adoption of renewable polypropylene in high-performance applications.

The scalability of production remains a significant hurdle for the widespread implementation of renewable polypropylene. Current production capacities are limited, and scaling up to meet global demand requires substantial investments in infrastructure and technology. The lack of established supply chains for renewable feedstocks further complicates the scaling process, creating uncertainties in raw material availability and pricing.

Technological limitations in the conversion of biomass to polypropylene precursors present another challenge. The efficiency of catalytic processes for converting renewable feedstocks into propylene monomers needs improvement to enhance yield and reduce energy consumption. Additionally, the development of more effective purification methods is crucial to remove impurities that can affect the quality of the final polymer.

The integration of renewable polypropylene into existing recycling streams poses a significant challenge for circular economies. While chemically identical to conventional polypropylene, the presence of additives or slight variations in molecular structure can complicate recycling processes. Developing sorting and recycling technologies that can effectively handle mixed streams of conventional and renewable polypropylene is essential for maintaining the circularity of these materials.

Regulatory hurdles and the lack of standardized certification processes for bio-based and renewable plastics create uncertainty in the market. The absence of clear guidelines for labeling and verifying the renewable content of polypropylene products can lead to confusion among consumers and hinder market acceptance. Establishing comprehensive standards and certification schemes is crucial for building trust and promoting the adoption of renewable polypropylene varieties.

Lastly, the environmental impact of renewable polypropylene production requires careful assessment. While derived from renewable sources, the cultivation and processing of feedstocks can have significant land use implications and potentially compete with food production. Addressing these sustainability concerns and developing life cycle assessment methodologies that accurately reflect the environmental benefits of renewable polypropylene are essential for its long-term viability in circular economies.

Another major challenge is the inconsistency in quality and performance of renewable polypropylene compared to its traditional counterpart. Variations in feedstock composition and processing conditions can lead to fluctuations in the final product's properties, such as tensile strength, thermal stability, and durability. This inconsistency poses difficulties for manufacturers in maintaining product specifications and meeting industry standards, potentially limiting the adoption of renewable polypropylene in high-performance applications.

The scalability of production remains a significant hurdle for the widespread implementation of renewable polypropylene. Current production capacities are limited, and scaling up to meet global demand requires substantial investments in infrastructure and technology. The lack of established supply chains for renewable feedstocks further complicates the scaling process, creating uncertainties in raw material availability and pricing.

Technological limitations in the conversion of biomass to polypropylene precursors present another challenge. The efficiency of catalytic processes for converting renewable feedstocks into propylene monomers needs improvement to enhance yield and reduce energy consumption. Additionally, the development of more effective purification methods is crucial to remove impurities that can affect the quality of the final polymer.

The integration of renewable polypropylene into existing recycling streams poses a significant challenge for circular economies. While chemically identical to conventional polypropylene, the presence of additives or slight variations in molecular structure can complicate recycling processes. Developing sorting and recycling technologies that can effectively handle mixed streams of conventional and renewable polypropylene is essential for maintaining the circularity of these materials.

Regulatory hurdles and the lack of standardized certification processes for bio-based and renewable plastics create uncertainty in the market. The absence of clear guidelines for labeling and verifying the renewable content of polypropylene products can lead to confusion among consumers and hinder market acceptance. Establishing comprehensive standards and certification schemes is crucial for building trust and promoting the adoption of renewable polypropylene varieties.

Lastly, the environmental impact of renewable polypropylene production requires careful assessment. While derived from renewable sources, the cultivation and processing of feedstocks can have significant land use implications and potentially compete with food production. Addressing these sustainability concerns and developing life cycle assessment methodologies that accurately reflect the environmental benefits of renewable polypropylene are essential for its long-term viability in circular economies.

Renewable PP Solutions

01 Renewable polypropylene production methods

Various methods for producing renewable polypropylene from sustainable sources are explored. These techniques aim to reduce reliance on fossil fuels and decrease the carbon footprint of polypropylene production. Processes may include using bio-based feedstocks, catalytic conversion of renewable resources, or innovative polymerization techniques to create polypropylene from renewable monomers.- Renewable polypropylene production methods: Various methods for producing renewable polypropylene from sustainable sources are explored. These techniques aim to reduce reliance on fossil fuels and create more environmentally friendly plastics. Processes may include using bio-based feedstocks, catalytic conversion of renewable resources, or innovative polymerization techniques to create polypropylene with properties similar to conventional materials.

- Circular economy strategies for polypropylene: Implementing circular economy principles in polypropylene production and use involves developing efficient recycling processes, designing products for easier disassembly and reuse, and creating closed-loop systems. These strategies aim to minimize waste, extend product lifecycles, and maximize resource efficiency in the polypropylene value chain.

- Advanced recycling technologies for polypropylene: Innovative recycling technologies are being developed to improve the quality and efficiency of polypropylene recycling. These may include chemical recycling methods, advanced sorting techniques, and purification processes to remove contaminants. The goal is to produce high-quality recycled polypropylene that can be used in a wider range of applications.

- Bio-based additives and reinforcements for polypropylene: Incorporating bio-based additives and reinforcements into polypropylene can enhance its properties while increasing its renewable content. This approach may involve using natural fibers, bio-derived plasticizers, or other sustainable materials to improve the performance and environmental profile of polypropylene products.

- Supply chain optimization for circular polypropylene economy: Optimizing the supply chain for a circular polypropylene economy involves developing efficient collection systems, implementing track-and-trace technologies, and creating collaborative networks among stakeholders. These efforts aim to improve the flow of materials, increase transparency, and enhance the overall sustainability of the polypropylene lifecycle.

02 Circular economy strategies for polypropylene

Implementation of circular economy principles in polypropylene production and use. This includes developing efficient recycling processes, designing products for easier recyclability, and creating closed-loop systems for polypropylene. Strategies may involve chemical recycling, mechanical recycling improvements, and the integration of recycled content into new polypropylene products.Expand Specific Solutions03 Enhancing polypropylene properties for circular use

Techniques to improve the properties of polypropylene to make it more suitable for circular economy applications. This may include enhancing durability, improving recyclability, or developing additives that facilitate multiple recycling cycles without significant property degradation. The focus is on maintaining or improving material performance throughout multiple use cycles.Expand Specific Solutions04 Supply chain optimization for circular polypropylene

Strategies for optimizing the supply chain to support a circular economy for polypropylene. This includes developing efficient collection systems, implementing tracking technologies for material flows, and creating collaborative networks between producers, consumers, and recyclers. The aim is to ensure a steady supply of recyclable polypropylene and efficient redistribution of recycled materials.Expand Specific Solutions05 Economic models for renewable polypropylene circularity

Development of economic models and business strategies to support the transition to renewable polypropylene and circular economy practices. This includes creating incentives for recycling, developing new market mechanisms for recycled materials, and assessing the economic viability of various circular economy initiatives in the polypropylene industry.Expand Specific Solutions

Key Industry Players

The renewable polypropylene market is in its early growth stage, characterized by increasing demand for sustainable plastics and circular economy initiatives. The global market size is expanding, driven by environmental regulations and consumer preferences for eco-friendly products. Technologically, the field is evolving rapidly, with companies like Borealis AG, SABIC, and Chevron U.S.A. leading innovation in bio-based and chemically recycled polypropylene. Academic institutions such as the University of Florida and Sichuan University are contributing to research advancements. While the technology is progressing, it's not yet fully mature, with challenges in scalability and cost-effectiveness. Companies like Kingfa Sci. & Tech. and Resinate Materials Group are working on improving material properties and production processes to enhance commercial viability.

Chevron U.S.A., Inc.

Technical Solution: Chevron, through its subsidiary Chevron Phillips Chemical, has made significant strides in renewable polypropylene production. The company has successfully produced circular polyethylene from recycled mixed waste plastics and is extending this technology to polypropylene. Their advanced recycling process converts plastic waste into a liquid feedstock, which can then be used to create new plastics, including PP[10]. Chevron is also exploring bio-based feedstocks for PP production, aiming to reduce the carbon footprint of their polymer products. The company has set a target to produce 1 million metric tons of recycled and renewable polymers annually by 2030[11]. Additionally, Chevron is investing in chemical recycling technologies that can process a wider range of plastic waste, potentially increasing the availability of feedstock for renewable PP production[12].

Strengths: Leverages existing petrochemical infrastructure for renewable PP production. Ambitious targets for recycled and renewable polymer production. Weaknesses: Still in early stages of renewable PP development compared to some competitors. Heavy reliance on chemical recycling technologies, which are still scaling up.

Borealis AG

Technical Solution: Borealis AG has developed a groundbreaking renewable polypropylene (PP) technology called Bornewables™. This portfolio of circular polyolefins is produced using renewable feedstocks derived from waste and residue streams, such as used cooking oil. The company utilizes mass balance approach to trace the renewable content through the production process[1]. Borealis has also introduced Borcycle™ M, a portfolio of recycled polyolefin compounds containing up to 80% recycled content, demonstrating their commitment to circular economy principles[2]. Their technology allows for the production of renewable PP with properties identical to fossil-based PP, ensuring seamless integration into existing manufacturing processes[3].

Strengths: Utilizes waste streams as feedstock, reducing reliance on fossil resources. Produces renewable PP with identical properties to conventional PP. Weaknesses: May face challenges in scaling up production to meet growing demand. Dependent on availability and quality of waste feedstocks.

Innovative PP Patents

Process to produce polypropylene-based composition from post-consumer resins and articles made of said compositions

PatentWO2019224129A1

Innovation

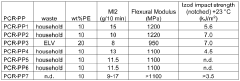

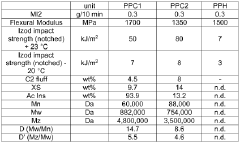

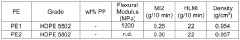

- A process involving a combination of polypropylene post-consumer resin (PCR) and virgin impact propylene copolymer, along with polyethylene resin, is used to enhance the stiffness and impact properties of the polypropylene-based composition, achieving a balance suitable for applications requiring low MI2 values and good impact resistance at low temperatures.

Environmental Impact

The environmental impact of renewable polypropylene varieties in circular economies is multifaceted and significant. These innovative materials offer substantial benefits in reducing the carbon footprint associated with traditional polypropylene production and usage.

Renewable polypropylene, derived from bio-based sources such as sugarcane or corn, presents a more sustainable alternative to fossil fuel-based plastics. The production process of these materials typically requires less energy and generates fewer greenhouse gas emissions compared to conventional polypropylene manufacturing. This reduction in carbon intensity aligns with global efforts to mitigate climate change and transition towards a low-carbon economy.

In the context of circular economies, renewable polypropylene varieties contribute to resource conservation by decreasing reliance on finite petroleum resources. By utilizing renewable feedstocks, these materials help preserve natural resources and reduce the environmental pressures associated with fossil fuel extraction. This shift towards bio-based inputs also promotes the development of sustainable agricultural practices and supports rural economies.

The end-of-life management of renewable polypropylene products plays a crucial role in their environmental impact. Many of these materials are designed to be recyclable, allowing them to be reprocessed and reused multiple times. This recyclability helps to extend the lifespan of the material, reducing waste and minimizing the need for virgin resource extraction. Additionally, some renewable polypropylene varieties are biodegradable under specific conditions, offering an alternative end-of-life pathway that can reduce plastic pollution in natural environments.

Water conservation is another environmental benefit associated with renewable polypropylene. The production of these materials often requires less water compared to traditional polypropylene manufacturing processes. This reduction in water consumption is particularly important in regions facing water scarcity and helps to preserve this vital resource for other essential uses.

However, it is important to consider potential trade-offs and challenges. The cultivation of crops for bio-based feedstocks may lead to land-use changes and compete with food production. Careful management and sustainable farming practices are necessary to mitigate these concerns and ensure that the production of renewable polypropylene does not negatively impact food security or biodiversity.

In conclusion, renewable polypropylene varieties offer significant environmental benefits within circular economies. Their potential to reduce greenhouse gas emissions, conserve resources, and minimize waste aligns well with sustainability goals. As technology advances and production scales up, these materials are poised to play an increasingly important role in creating more environmentally friendly and circular plastic value chains.

Renewable polypropylene, derived from bio-based sources such as sugarcane or corn, presents a more sustainable alternative to fossil fuel-based plastics. The production process of these materials typically requires less energy and generates fewer greenhouse gas emissions compared to conventional polypropylene manufacturing. This reduction in carbon intensity aligns with global efforts to mitigate climate change and transition towards a low-carbon economy.

In the context of circular economies, renewable polypropylene varieties contribute to resource conservation by decreasing reliance on finite petroleum resources. By utilizing renewable feedstocks, these materials help preserve natural resources and reduce the environmental pressures associated with fossil fuel extraction. This shift towards bio-based inputs also promotes the development of sustainable agricultural practices and supports rural economies.

The end-of-life management of renewable polypropylene products plays a crucial role in their environmental impact. Many of these materials are designed to be recyclable, allowing them to be reprocessed and reused multiple times. This recyclability helps to extend the lifespan of the material, reducing waste and minimizing the need for virgin resource extraction. Additionally, some renewable polypropylene varieties are biodegradable under specific conditions, offering an alternative end-of-life pathway that can reduce plastic pollution in natural environments.

Water conservation is another environmental benefit associated with renewable polypropylene. The production of these materials often requires less water compared to traditional polypropylene manufacturing processes. This reduction in water consumption is particularly important in regions facing water scarcity and helps to preserve this vital resource for other essential uses.

However, it is important to consider potential trade-offs and challenges. The cultivation of crops for bio-based feedstocks may lead to land-use changes and compete with food production. Careful management and sustainable farming practices are necessary to mitigate these concerns and ensure that the production of renewable polypropylene does not negatively impact food security or biodiversity.

In conclusion, renewable polypropylene varieties offer significant environmental benefits within circular economies. Their potential to reduce greenhouse gas emissions, conserve resources, and minimize waste aligns well with sustainability goals. As technology advances and production scales up, these materials are poised to play an increasingly important role in creating more environmentally friendly and circular plastic value chains.

Policy Implications

The adoption of renewable polypropylene varieties in circular economies has significant policy implications that require careful consideration and strategic planning. Governments and regulatory bodies play a crucial role in shaping the landscape for these sustainable materials and their integration into circular economic models.

One of the primary policy considerations is the development of incentive structures to promote the use of renewable polypropylene. This may include tax breaks, subsidies, or grants for companies that invest in research, development, and production of these materials. Such incentives can help offset the initially higher costs associated with renewable alternatives and accelerate their market adoption.

Standardization and certification processes are another critical area for policy intervention. Establishing clear guidelines and standards for renewable polypropylene can ensure consistency in quality and performance across different manufacturers. This standardization can also facilitate easier integration into existing recycling streams and circular economy frameworks.

Waste management policies need to be updated to accommodate the unique properties of renewable polypropylene varieties. This may involve revising recycling protocols, investing in new sorting technologies, and developing specialized collection systems to maximize the recovery and reuse of these materials.

Extended Producer Responsibility (EPR) programs can be expanded or modified to specifically address renewable polypropylene products. These policies can encourage manufacturers to design products with end-of-life considerations in mind, promoting easier disassembly, recycling, or biodegradation.

Education and awareness campaigns, supported by government initiatives, are essential to inform consumers and businesses about the benefits and proper handling of renewable polypropylene products. This can drive demand and ensure proper disposal practices, further supporting circular economy goals.

International trade policies may need adjustment to facilitate the global exchange of renewable polypropylene materials and technologies. This could involve reducing trade barriers for sustainable materials or establishing international cooperation frameworks for research and development in this field.

Lastly, policies should be designed to support the entire value chain of renewable polypropylene, from feedstock production to end-of-life management. This holistic approach can ensure a robust and sustainable ecosystem for these materials within circular economies, maximizing their environmental and economic benefits.

One of the primary policy considerations is the development of incentive structures to promote the use of renewable polypropylene. This may include tax breaks, subsidies, or grants for companies that invest in research, development, and production of these materials. Such incentives can help offset the initially higher costs associated with renewable alternatives and accelerate their market adoption.

Standardization and certification processes are another critical area for policy intervention. Establishing clear guidelines and standards for renewable polypropylene can ensure consistency in quality and performance across different manufacturers. This standardization can also facilitate easier integration into existing recycling streams and circular economy frameworks.

Waste management policies need to be updated to accommodate the unique properties of renewable polypropylene varieties. This may involve revising recycling protocols, investing in new sorting technologies, and developing specialized collection systems to maximize the recovery and reuse of these materials.

Extended Producer Responsibility (EPR) programs can be expanded or modified to specifically address renewable polypropylene products. These policies can encourage manufacturers to design products with end-of-life considerations in mind, promoting easier disassembly, recycling, or biodegradation.

Education and awareness campaigns, supported by government initiatives, are essential to inform consumers and businesses about the benefits and proper handling of renewable polypropylene products. This can drive demand and ensure proper disposal practices, further supporting circular economy goals.

International trade policies may need adjustment to facilitate the global exchange of renewable polypropylene materials and technologies. This could involve reducing trade barriers for sustainable materials or establishing international cooperation frameworks for research and development in this field.

Lastly, policies should be designed to support the entire value chain of renewable polypropylene, from feedstock production to end-of-life management. This holistic approach can ensure a robust and sustainable ecosystem for these materials within circular economies, maximizing their environmental and economic benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!