How To Achieve LS7 Powertrain Integration In Custom Builds

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS7 Powertrain Integration Background and Objectives

The LS7 engine represents a pinnacle achievement in General Motors' small-block V8 development, first introduced in the 2006 Corvette Z06. This naturally aspirated 7.0-liter (427 cubic inch) powerplant was designed as a high-performance variant in the LS engine family, featuring advanced technologies such as dry-sump lubrication, titanium connecting rods, and CNC-ported cylinder heads. The evolution of this powertrain reflects GM's commitment to pushing the boundaries of naturally aspirated performance while maintaining the fundamental architecture that has made LS engines popular among enthusiasts.

The technical trajectory of LS7 integration has evolved significantly since its introduction. Initially confined to factory applications, the aftermarket quickly recognized its potential for custom builds due to its compact design, impressive power-to-weight ratio, and robust architecture. This evolution has been characterized by increasing accessibility of components, development of specialized integration hardware, and growing community knowledge regarding installation challenges and solutions.

Current market trends indicate a sustained interest in LS7 powertrain swaps across diverse vehicle platforms, from classic muscle cars to modern sports cars and even off-road applications. This widespread adoption is driven by the engine's exceptional performance characteristics, relatively compact dimensions compared to its output, and the extensive aftermarket support that has developed around the LS platform generally.

The primary technical objective of LS7 powertrain integration in custom builds is to successfully transplant this high-performance engine system into non-native vehicle platforms while maintaining or enhancing its performance capabilities. This encompasses not only the physical installation but also the integration of electronic control systems, cooling solutions, and drivetrain components that can handle the engine's substantial power output.

Secondary objectives include optimizing weight distribution, ensuring adequate cooling for high-performance applications, maintaining reliability under various operating conditions, and achieving emissions compliance where required. The integration must also address the unique challenges presented by the LS7's specialized systems, particularly its dry-sump oiling system, which requires additional components and careful planning during installation.

From a development perspective, the goal is to establish standardized approaches to LS7 integration that can be applied across different vehicle platforms while accommodating their unique characteristics. This includes creating modular mounting solutions, developing plug-and-play wiring systems, and establishing best practices for addressing common integration challenges such as exhaust routing, accessory drive compatibility, and transmission adaptation.

The technical trajectory of LS7 integration has evolved significantly since its introduction. Initially confined to factory applications, the aftermarket quickly recognized its potential for custom builds due to its compact design, impressive power-to-weight ratio, and robust architecture. This evolution has been characterized by increasing accessibility of components, development of specialized integration hardware, and growing community knowledge regarding installation challenges and solutions.

Current market trends indicate a sustained interest in LS7 powertrain swaps across diverse vehicle platforms, from classic muscle cars to modern sports cars and even off-road applications. This widespread adoption is driven by the engine's exceptional performance characteristics, relatively compact dimensions compared to its output, and the extensive aftermarket support that has developed around the LS platform generally.

The primary technical objective of LS7 powertrain integration in custom builds is to successfully transplant this high-performance engine system into non-native vehicle platforms while maintaining or enhancing its performance capabilities. This encompasses not only the physical installation but also the integration of electronic control systems, cooling solutions, and drivetrain components that can handle the engine's substantial power output.

Secondary objectives include optimizing weight distribution, ensuring adequate cooling for high-performance applications, maintaining reliability under various operating conditions, and achieving emissions compliance where required. The integration must also address the unique challenges presented by the LS7's specialized systems, particularly its dry-sump oiling system, which requires additional components and careful planning during installation.

From a development perspective, the goal is to establish standardized approaches to LS7 integration that can be applied across different vehicle platforms while accommodating their unique characteristics. This includes creating modular mounting solutions, developing plug-and-play wiring systems, and establishing best practices for addressing common integration challenges such as exhaust routing, accessory drive compatibility, and transmission adaptation.

Market Analysis for LS7 Custom Builds

The LS7 powertrain integration market for custom builds represents a significant segment within the automotive aftermarket industry, with consistent growth over the past decade. This 7.0L V8 engine, originally designed for the Corvette Z06, has become a coveted power plant for custom vehicle builders due to its impressive 505 horsepower output, lightweight aluminum construction, and exceptional performance characteristics.

Market research indicates that the primary consumer segments for LS7 custom builds include high-end restomod projects, pro-touring classic cars, custom hot rods, and specialized track vehicles. These segments collectively generate an estimated annual market value exceeding $300 million in North America alone, with global figures approaching $500 million when including international markets with strong custom car cultures such as Australia, Europe, and the Middle East.

The demand for LS7 crate engines and related integration components has shown remarkable resilience, maintaining a compound annual growth rate of approximately 6.8% despite economic fluctuations. This growth is primarily driven by the engine's reputation for reliability, substantial aftermarket support, and the increasing popularity of restomod builds that combine classic aesthetics with modern performance.

Consumer demographic analysis reveals that LS7 custom build enthusiasts typically fall into higher income brackets, with most being established professionals aged 35-65 with disposable income dedicated to automotive hobbies. This demographic characteristic has insulated the market somewhat from broader economic downturns, as evidenced by continued strong sales during recent economic challenges.

Regional market distribution shows particular strength in the Southern and Western United States, with Texas, California, and Florida representing the largest state markets. Internationally, Australia has emerged as a particularly strong market for LS7 custom builds, followed by the United Kingdom and Germany.

The competitive landscape features several tiers of suppliers, from OEM General Motors Performance Parts to specialized aftermarket manufacturers like Holley, Tremec, and Wilwood who provide essential integration components. Recent market trends indicate increasing demand for complete "plug-and-play" integration kits that simplify the installation process, suggesting opportunities for comprehensive solution providers.

Price sensitivity analysis shows that while consumers in this market are willing to pay premium prices for quality components, there exists a significant opportunity in the mid-market segment for integration solutions that balance performance with accessibility. The average complete LS7 swap project ranges from $15,000 to $30,000 depending on the level of customization and supporting modifications required.

Market research indicates that the primary consumer segments for LS7 custom builds include high-end restomod projects, pro-touring classic cars, custom hot rods, and specialized track vehicles. These segments collectively generate an estimated annual market value exceeding $300 million in North America alone, with global figures approaching $500 million when including international markets with strong custom car cultures such as Australia, Europe, and the Middle East.

The demand for LS7 crate engines and related integration components has shown remarkable resilience, maintaining a compound annual growth rate of approximately 6.8% despite economic fluctuations. This growth is primarily driven by the engine's reputation for reliability, substantial aftermarket support, and the increasing popularity of restomod builds that combine classic aesthetics with modern performance.

Consumer demographic analysis reveals that LS7 custom build enthusiasts typically fall into higher income brackets, with most being established professionals aged 35-65 with disposable income dedicated to automotive hobbies. This demographic characteristic has insulated the market somewhat from broader economic downturns, as evidenced by continued strong sales during recent economic challenges.

Regional market distribution shows particular strength in the Southern and Western United States, with Texas, California, and Florida representing the largest state markets. Internationally, Australia has emerged as a particularly strong market for LS7 custom builds, followed by the United Kingdom and Germany.

The competitive landscape features several tiers of suppliers, from OEM General Motors Performance Parts to specialized aftermarket manufacturers like Holley, Tremec, and Wilwood who provide essential integration components. Recent market trends indicate increasing demand for complete "plug-and-play" integration kits that simplify the installation process, suggesting opportunities for comprehensive solution providers.

Price sensitivity analysis shows that while consumers in this market are willing to pay premium prices for quality components, there exists a significant opportunity in the mid-market segment for integration solutions that balance performance with accessibility. The average complete LS7 swap project ranges from $15,000 to $30,000 depending on the level of customization and supporting modifications required.

Technical Challenges in LS7 Integration

Integrating the LS7 powertrain into custom builds presents several significant technical challenges that must be addressed for successful implementation. The 7.0L (427 cubic inch) LS7 engine, originally designed for the Corvette Z06, represents one of General Motors' most advanced naturally aspirated V8 engines, delivering 505 horsepower and 470 lb-ft of torque from the factory.

The primary challenge involves the physical dimensions and mounting requirements of the LS7. Unlike standard LS engines, the LS7 features a dry-sump oiling system that requires additional space for the external oil reservoir and associated plumbing. This system, while excellent for maintaining oil pressure during high-G cornering, significantly complicates the integration process in vehicles not originally designed to accommodate such a setup.

Cooling system integration presents another major hurdle. The LS7's high-performance nature generates substantial heat that must be effectively managed. Custom builds often require upgraded radiators, additional oil coolers, and carefully designed airflow management to prevent overheating under demanding conditions. The stock Z06 cooling system is extensively engineered, making replication in custom applications particularly challenging.

Electronics and engine management systems pose sophisticated integration challenges. The LS7 utilizes complex engine control modules (ECMs) with specific calibrations for its high-revving nature and performance characteristics. Custom builders must either adapt the factory ECM or implement aftermarket solutions capable of properly controlling the LS7's advanced features, including variable valve timing and sophisticated fuel delivery systems.

Transmission compatibility represents a significant technical obstacle. The LS7's substantial torque output requires robust transmission solutions that can withstand the power while providing appropriate gearing for the intended application. Whether utilizing manual or automatic options, builders must address clutch capacity, torque converter specifications, or gear ratio selections to match the LS7's power curve.

Exhaust system design presents unique challenges due to the LS7's high-flow requirements and exhaust gas characteristics. Header design, catalytic converter selection, and overall exhaust routing must be carefully engineered to maintain proper back pressure while maximizing performance. Inadequate exhaust systems can significantly reduce power output and potentially cause engine damage.

Fuel delivery systems must be upgraded to support the LS7's requirements. This includes high-flow fuel pumps, properly sized injectors, and fuel lines capable of delivering sufficient volume under all operating conditions. The factory LS7 fuel system is designed for high-performance applications, making replication in custom builds essential for reliable operation.

Finally, chassis and suspension modifications are typically necessary to handle the increased performance capabilities of an LS7-powered vehicle. Upgrading braking systems, reinforcing chassis components, and implementing appropriate suspension tuning are critical to creating a balanced, safe, and enjoyable driving experience that can properly utilize the LS7's performance potential.

The primary challenge involves the physical dimensions and mounting requirements of the LS7. Unlike standard LS engines, the LS7 features a dry-sump oiling system that requires additional space for the external oil reservoir and associated plumbing. This system, while excellent for maintaining oil pressure during high-G cornering, significantly complicates the integration process in vehicles not originally designed to accommodate such a setup.

Cooling system integration presents another major hurdle. The LS7's high-performance nature generates substantial heat that must be effectively managed. Custom builds often require upgraded radiators, additional oil coolers, and carefully designed airflow management to prevent overheating under demanding conditions. The stock Z06 cooling system is extensively engineered, making replication in custom applications particularly challenging.

Electronics and engine management systems pose sophisticated integration challenges. The LS7 utilizes complex engine control modules (ECMs) with specific calibrations for its high-revving nature and performance characteristics. Custom builders must either adapt the factory ECM or implement aftermarket solutions capable of properly controlling the LS7's advanced features, including variable valve timing and sophisticated fuel delivery systems.

Transmission compatibility represents a significant technical obstacle. The LS7's substantial torque output requires robust transmission solutions that can withstand the power while providing appropriate gearing for the intended application. Whether utilizing manual or automatic options, builders must address clutch capacity, torque converter specifications, or gear ratio selections to match the LS7's power curve.

Exhaust system design presents unique challenges due to the LS7's high-flow requirements and exhaust gas characteristics. Header design, catalytic converter selection, and overall exhaust routing must be carefully engineered to maintain proper back pressure while maximizing performance. Inadequate exhaust systems can significantly reduce power output and potentially cause engine damage.

Fuel delivery systems must be upgraded to support the LS7's requirements. This includes high-flow fuel pumps, properly sized injectors, and fuel lines capable of delivering sufficient volume under all operating conditions. The factory LS7 fuel system is designed for high-performance applications, making replication in custom builds essential for reliable operation.

Finally, chassis and suspension modifications are typically necessary to handle the increased performance capabilities of an LS7-powered vehicle. Upgrading braking systems, reinforcing chassis components, and implementing appropriate suspension tuning are critical to creating a balanced, safe, and enjoyable driving experience that can properly utilize the LS7's performance potential.

Current LS7 Integration Solutions

01 Engine and transmission integration for LS7 powertrains

Integration of LS7 engines with compatible transmissions involves specialized mounting systems and adapters to ensure proper alignment and function. These systems typically include custom bellhousing designs, torque converter connections, and electronic control interfaces that allow the high-performance LS7 engine to work optimally with various transmission types. The integration focuses on managing the significant power output of the LS7 while maintaining drivability and reliability.- Engine and transmission integration for LS7 powertrains: Integration of LS7 engines with transmission systems involves specialized mounting solutions, adapter plates, and electronic control systems to ensure optimal power transfer. These integration methods focus on aligning the engine with various transmission types while maintaining proper torque management and shift quality. The integration also addresses thermal management and vibration isolation between the powerful LS7 engine and the transmission components.

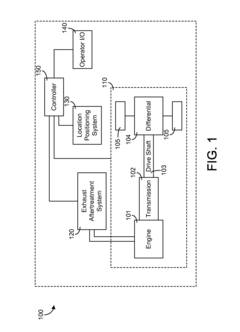

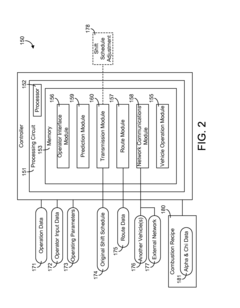

- Electronic control systems for LS7 powertrain management: Advanced electronic control systems are essential for managing the high-performance characteristics of LS7 powertrains. These systems include engine control modules, transmission control units, and integrated powertrain controllers that optimize fuel delivery, ignition timing, and shift patterns. The electronic architecture enables real-time adjustments based on driving conditions, performance demands, and efficiency requirements while maintaining reliability under high-load conditions.

- Cooling and thermal management for LS7 powertrain systems: Thermal management solutions for LS7 powertrains address the significant heat generated by these high-performance engines. These systems include specialized cooling circuits, heat exchangers, and oil coolers designed to maintain optimal operating temperatures under various load conditions. Advanced cooling strategies focus on targeted temperature control for critical components such as cylinder heads, transmission fluid, and electronic control modules to ensure durability and consistent performance.

- Vehicle chassis integration for LS7 powertrain applications: Integrating LS7 powertrains into vehicle chassis requires specialized mounting systems, structural reinforcements, and weight distribution strategies. These integration methods address the high torque output of the LS7 engine while maintaining vehicle dynamics, handling characteristics, and safety requirements. Solutions include custom subframes, engine mounts with specific stiffness properties, and drivetrain alignment systems that accommodate the dimensional and performance characteristics of the LS7 powertrain.

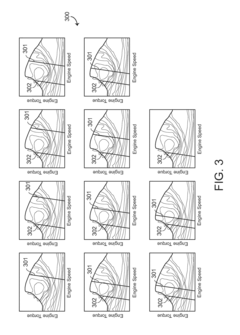

- Performance optimization and tuning for LS7 powertrain systems: Performance optimization for LS7 powertrains involves specialized tuning methodologies, calibration techniques, and component matching to maximize power output, efficiency, and drivability. These approaches include air intake system design, exhaust flow optimization, and fuel delivery calibration specific to the LS7 architecture. Advanced tuning strategies also address torque management, power delivery characteristics, and integration with vehicle dynamics control systems to harness the full potential of the LS7 engine.

02 Electronic control systems for LS7 powertrain management

Advanced electronic control systems are essential for managing LS7 powertrain performance. These systems include specialized engine control modules (ECMs), transmission control units, and integrated powertrain controllers that optimize fuel delivery, ignition timing, and shift patterns. The control architecture enables features such as performance modes, traction management, and diagnostic capabilities while handling the high-performance characteristics of the LS7 engine.Expand Specific Solutions03 Cooling and thermal management for LS7 powertrain systems

Thermal management solutions for LS7 powertrains address the significant heat generated by these high-performance engines. These systems include specialized radiators, oil coolers, and integrated cooling circuits designed to maintain optimal operating temperatures under various load conditions. Advanced cooling strategies may incorporate electronic fan control, precision thermostat operation, and dedicated transmission cooling to ensure reliability and consistent performance.Expand Specific Solutions04 Hybrid and electrification integration with LS7 architecture

Integration of hybrid and electric components with LS7 powertrain systems involves combining traditional combustion engine power with electric propulsion. These systems may include electric motors, battery packs, and power electronics designed to work in harmony with the LS7 engine. The integration focuses on power blending strategies, regenerative braking capabilities, and electronic control systems that optimize performance while potentially improving fuel efficiency.Expand Specific Solutions05 Chassis and drivetrain adaptation for LS7 powertrain installation

Adapting vehicle chassis and drivetrain components for LS7 powertrain installation requires specialized mounting solutions, driveshaft modifications, and structural reinforcements. These adaptations account for the unique dimensions, weight distribution, and power characteristics of the LS7 engine. Integration solutions may include custom subframes, strengthened differential housings, and upgraded axle components designed to handle the increased torque and horsepower of the LS7 powertrain.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers

The LS7 powertrain integration market is currently in a growth phase, with increasing demand from custom automotive builders seeking high-performance engine solutions. The competitive landscape features established OEMs like GM Global Technology Operations, Ford Global Technologies, and Volkswagen AG, who possess advanced integration technologies and comprehensive powertrain expertise. Aftermarket specialists including BorgWarner and Schaeffler Technologies are gaining market share by offering specialized components and integration solutions. The technology maturity varies significantly, with major automotive manufacturers demonstrating sophisticated systems integration capabilities, while smaller players focus on niche applications. This market is expected to expand as performance enthusiasts and custom builders continue seeking reliable methods to incorporate LS7 powertrains into diverse vehicle platforms.

Ford Global Technologies LLC

Technical Solution: Ford's approach to LS7 powertrain integration in custom builds involves their Control Pack system, which provides a comprehensive solution for adapting GM's LS7 engine into various vehicle platforms. Their technology focuses on cross-platform integration, utilizing advanced wiring harnesses and controller systems that can communicate with both Ford and GM components. Ford's solution includes specialized mounting systems designed to accommodate the LS7's unique dimensions and weight distribution characteristics. Their integration package features adaptive calibration technology that automatically adjusts engine parameters based on detected vehicle configurations, simplifying the installation process. Ford also provides detailed technical documentation and 3D CAD models to assist builders with packaging considerations for intake, exhaust, and cooling systems.

Strengths: Excellent cross-platform compatibility with Ford chassis; sophisticated adaptive calibration technology; comprehensive documentation and support. Weaknesses: Less optimized for GM's LS7 than native GM solutions; requires additional adaptation for certain vehicle systems; higher complexity for DIY builders.

GM Global Technology Operations LLC

Technical Solution: GM's LS7 powertrain integration solution centers around their Connect & Cruise crate powertrain systems, specifically designed for custom builds. The LS7 7.0L V8 engine (427 cubic inches) produces 505 horsepower and 470 lb-ft of torque in factory form, making it ideal for high-performance applications. GM's integration approach includes comprehensive controller packages with pre-programmed Engine Control Modules (ECMs) that eliminate the need for aftermarket tuning. Their system includes purpose-designed engine mounts, transmission adapters, and wiring harnesses specifically engineered for the LS7's unique requirements. GM also provides detailed installation documentation and technical support resources through their Performance Parts division, enabling builders to properly address cooling, exhaust, and fuel system requirements for optimal performance.

Strengths: Factory-engineered components ensure perfect compatibility; pre-programmed ECUs eliminate complex tuning requirements; comprehensive technical support network. Weaknesses: Higher cost compared to aftermarket solutions; less flexibility for extreme modifications; limited customization options for specialized applications.

Key Engineering Innovations for LS7 Swaps

Integrated powertrain system

PatentActiveUS20150330503A1

Innovation

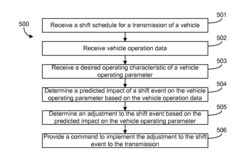

- A controller is integrated with the powertrain system to receive and analyze data from both the engine and transmission in real-time, dynamically adjusting shift schedules based on vehicle operation data, route information, and desired operating characteristics to optimize parameters like fuel consumption and emissions.

Emissions Compliance Strategies

Achieving emissions compliance represents a critical challenge when integrating LS7 powertrains into custom builds. Modern performance engines must balance power output with increasingly stringent environmental regulations across different jurisdictions. The EPA Tier 3 standards and California Air Resources Board (CARB) requirements present particular hurdles for custom builders utilizing the high-performance LS7 platform.

Custom builders must first determine the regulatory framework applicable to their specific build. Street-legal vehicles typically require full emissions compliance, while off-road or competition-only vehicles may qualify for exemptions. Understanding these distinctions is essential before proceeding with powertrain integration planning.

Catalytic converter selection and placement represents a primary compliance strategy. For LS7 installations, high-flow catalytic converters that maintain acceptable backpressure while meeting emissions standards are recommended. Dual catalytic converter setups often provide the optimal balance between performance and emissions control, particularly when positioned at the correct distance from exhaust ports to ensure proper light-off temperatures.

Electronic engine management systems play a crucial role in emissions compliance. Modern programmable ECUs can be calibrated specifically for emissions-compliant operation while maintaining performance characteristics. Closed-loop oxygen sensor feedback systems must be properly implemented to ensure stoichiometric air-fuel ratios during normal operation, with appropriate enrichment only during high-load conditions.

Positive Crankcase Ventilation (PCV) systems require careful integration in custom builds. The factory LS7 PCV system can be adapted to most custom applications, but modifications must maintain the system's functionality to prevent crankcase emissions. Similarly, evaporative emissions control systems must be properly transferred or equivalent systems implemented to capture fuel vapors.

Exhaust Gas Recirculation (EGR) presents particular challenges in custom applications. While some builders attempt to eliminate EGR systems to maximize performance, maintaining some level of exhaust gas recirculation is often necessary for NOx control and emissions compliance. Modern variable EGR systems can be tuned to minimize performance impacts while maintaining compliance.

Documentation and certification represent the final hurdle in emissions compliance. Builders should maintain comprehensive records of all emissions-related components and modifications. In some jurisdictions, independent emissions testing and certification may be required before a custom build can be registered for street use. Professional emissions testing services can provide valuable guidance throughout this process.

Custom builders must first determine the regulatory framework applicable to their specific build. Street-legal vehicles typically require full emissions compliance, while off-road or competition-only vehicles may qualify for exemptions. Understanding these distinctions is essential before proceeding with powertrain integration planning.

Catalytic converter selection and placement represents a primary compliance strategy. For LS7 installations, high-flow catalytic converters that maintain acceptable backpressure while meeting emissions standards are recommended. Dual catalytic converter setups often provide the optimal balance between performance and emissions control, particularly when positioned at the correct distance from exhaust ports to ensure proper light-off temperatures.

Electronic engine management systems play a crucial role in emissions compliance. Modern programmable ECUs can be calibrated specifically for emissions-compliant operation while maintaining performance characteristics. Closed-loop oxygen sensor feedback systems must be properly implemented to ensure stoichiometric air-fuel ratios during normal operation, with appropriate enrichment only during high-load conditions.

Positive Crankcase Ventilation (PCV) systems require careful integration in custom builds. The factory LS7 PCV system can be adapted to most custom applications, but modifications must maintain the system's functionality to prevent crankcase emissions. Similarly, evaporative emissions control systems must be properly transferred or equivalent systems implemented to capture fuel vapors.

Exhaust Gas Recirculation (EGR) presents particular challenges in custom applications. While some builders attempt to eliminate EGR systems to maximize performance, maintaining some level of exhaust gas recirculation is often necessary for NOx control and emissions compliance. Modern variable EGR systems can be tuned to minimize performance impacts while maintaining compliance.

Documentation and certification represent the final hurdle in emissions compliance. Builders should maintain comprehensive records of all emissions-related components and modifications. In some jurisdictions, independent emissions testing and certification may be required before a custom build can be registered for street use. Professional emissions testing services can provide valuable guidance throughout this process.

Fabrication and Fitment Considerations

Successful integration of the LS7 powertrain into custom builds requires meticulous attention to fabrication and fitment considerations. The physical dimensions of the LS7 engine, measuring approximately 29 inches in length, 24.7 inches in width, and 26 inches in height, necessitate careful planning of the engine bay layout. Custom motor mounts must be fabricated to accommodate the specific mounting points of the LS7, which differ from traditional small-block Chevrolet engines despite sharing the same basic architecture.

Material selection plays a crucial role in ensuring structural integrity and heat management. High-grade steel (typically 1/4" to 3/8" thickness) is recommended for motor mount fabrication, while aluminum components may be utilized for weight reduction in non-critical areas. The transmission tunnel often requires modification to accommodate the T-56 or 6L80E transmissions commonly paired with the LS7, with clearance requirements of approximately 1-2 inches around all sides of the transmission case.

Exhaust system fabrication presents significant challenges due to the LS7's unique exhaust port design and high-flow requirements. Custom headers with 1 7/8" to 2" primary tubes are typically necessary to maximize performance while ensuring proper fitment within the chassis constraints. The exhaust routing must account for the LS7's dry-sump oiling system, which occupies additional space compared to wet-sump configurations.

Cooling system integration demands careful consideration, as the LS7 generates substantial heat under performance conditions. A minimum radiator capacity of 650-700 square inches of core surface area is recommended, with dual high-flow electric fans capable of moving at least 2,500 CFM. Custom fabricated aluminum shrouds are often necessary to optimize airflow through the radiator.

Wiring harness modification represents another critical fabrication challenge. The LS7's electronic control systems require integration with the vehicle's existing electrical architecture. This typically involves creating a custom harness or adapting the factory PCM harness, with particular attention to proper grounding, shielding of sensitive circuits, and strategic routing to avoid heat sources and moving components.

Drivetrain alignment is paramount for reliable operation. Precision measurements using laser alignment tools are recommended to ensure the engine, transmission, and rear differential are properly aligned within 0.5 degrees. Custom driveshaft fabrication is typically required, with 3-inch diameter aluminum or carbon fiber construction recommended for high-performance applications to withstand the LS7's torque output while minimizing rotational mass.

Material selection plays a crucial role in ensuring structural integrity and heat management. High-grade steel (typically 1/4" to 3/8" thickness) is recommended for motor mount fabrication, while aluminum components may be utilized for weight reduction in non-critical areas. The transmission tunnel often requires modification to accommodate the T-56 or 6L80E transmissions commonly paired with the LS7, with clearance requirements of approximately 1-2 inches around all sides of the transmission case.

Exhaust system fabrication presents significant challenges due to the LS7's unique exhaust port design and high-flow requirements. Custom headers with 1 7/8" to 2" primary tubes are typically necessary to maximize performance while ensuring proper fitment within the chassis constraints. The exhaust routing must account for the LS7's dry-sump oiling system, which occupies additional space compared to wet-sump configurations.

Cooling system integration demands careful consideration, as the LS7 generates substantial heat under performance conditions. A minimum radiator capacity of 650-700 square inches of core surface area is recommended, with dual high-flow electric fans capable of moving at least 2,500 CFM. Custom fabricated aluminum shrouds are often necessary to optimize airflow through the radiator.

Wiring harness modification represents another critical fabrication challenge. The LS7's electronic control systems require integration with the vehicle's existing electrical architecture. This typically involves creating a custom harness or adapting the factory PCM harness, with particular attention to proper grounding, shielding of sensitive circuits, and strategic routing to avoid heat sources and moving components.

Drivetrain alignment is paramount for reliable operation. Precision measurements using laser alignment tools are recommended to ensure the engine, transmission, and rear differential are properly aligned within 0.5 degrees. Custom driveshaft fabrication is typically required, with 3-inch diameter aluminum or carbon fiber construction recommended for high-performance applications to withstand the LS7's torque output while minimizing rotational mass.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!