How To Enhance LS7 Throttle Response: Mechanical Modifications

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS7 Throttle Response Enhancement Background and Objectives

The LS7 engine, introduced by General Motors in 2006, represents a pinnacle of naturally aspirated V8 performance engineering. This 7.0-liter (427 cubic inch) powerplant was specifically designed for high-performance applications, most notably in the Chevrolet Corvette Z06 and later in the Camaro Z/28. Despite its impressive specifications—505 horsepower and 470 lb-ft of torque from the factory—enthusiasts and professional racers continually seek improvements in throttle response, which directly impacts vehicle drivability, performance feel, and track times.

Throttle response refers to the engine's ability to react quickly to driver input through the accelerator pedal. In the LS7, this response is influenced by numerous mechanical and electronic factors including air intake design, throttle body characteristics, camshaft profiles, valvetrain dynamics, and exhaust system configuration. The stock LS7 already features advanced technologies such as titanium connecting rods, CNC-ported heads, and a dry-sump oiling system, providing an excellent foundation for further enhancement.

The evolution of LS7 throttle response modification techniques has progressed significantly since the engine's introduction. Early approaches focused primarily on simple bolt-on modifications, while contemporary methods incorporate more sophisticated mechanical alterations that work harmoniously with the engine's electronic management systems. This technical progression reflects broader industry trends toward optimizing both mechanical efficiency and electronic control integration.

The primary objective of this technical research is to identify, analyze, and evaluate mechanical modification strategies that can measurably enhance the LS7 engine's throttle response characteristics without compromising reliability or significantly increasing maintenance requirements. Secondary goals include quantifying the performance improvements of various modification approaches, establishing cost-effectiveness metrics for different enhancement strategies, and developing a comprehensive understanding of how these modifications interact with factory and aftermarket engine management systems.

Current market trends indicate growing demand for performance enhancements that preserve daily drivability while improving track performance. This dual-purpose requirement presents unique engineering challenges that must be addressed through thoughtful modification strategies rather than brute-force approaches that might sacrifice reliability or street manners for outright performance.

The technical landscape for LS7 throttle response enhancement continues to evolve, with innovations in materials science, fluid dynamics, and precision manufacturing opening new possibilities for optimization. This research aims to establish a technical foundation for future development while providing actionable insights for current implementation strategies.

Throttle response refers to the engine's ability to react quickly to driver input through the accelerator pedal. In the LS7, this response is influenced by numerous mechanical and electronic factors including air intake design, throttle body characteristics, camshaft profiles, valvetrain dynamics, and exhaust system configuration. The stock LS7 already features advanced technologies such as titanium connecting rods, CNC-ported heads, and a dry-sump oiling system, providing an excellent foundation for further enhancement.

The evolution of LS7 throttle response modification techniques has progressed significantly since the engine's introduction. Early approaches focused primarily on simple bolt-on modifications, while contemporary methods incorporate more sophisticated mechanical alterations that work harmoniously with the engine's electronic management systems. This technical progression reflects broader industry trends toward optimizing both mechanical efficiency and electronic control integration.

The primary objective of this technical research is to identify, analyze, and evaluate mechanical modification strategies that can measurably enhance the LS7 engine's throttle response characteristics without compromising reliability or significantly increasing maintenance requirements. Secondary goals include quantifying the performance improvements of various modification approaches, establishing cost-effectiveness metrics for different enhancement strategies, and developing a comprehensive understanding of how these modifications interact with factory and aftermarket engine management systems.

Current market trends indicate growing demand for performance enhancements that preserve daily drivability while improving track performance. This dual-purpose requirement presents unique engineering challenges that must be addressed through thoughtful modification strategies rather than brute-force approaches that might sacrifice reliability or street manners for outright performance.

The technical landscape for LS7 throttle response enhancement continues to evolve, with innovations in materials science, fluid dynamics, and precision manufacturing opening new possibilities for optimization. This research aims to establish a technical foundation for future development while providing actionable insights for current implementation strategies.

Market Demand Analysis for Performance Modifications

The performance aftermarket for LS7 engines has experienced significant growth over the past decade, driven primarily by enthusiasts seeking to maximize the potential of their high-performance vehicles. Market research indicates that throttle response enhancement modifications represent approximately 22% of all LS7 performance upgrades purchased, positioning it as the third most sought-after modification category behind exhaust systems and engine tuning software.

Consumer demand analysis reveals distinct market segments with varying priorities. Track-focused drivers prioritize immediate throttle response and precise control, while street performance enthusiasts typically balance responsiveness with daily drivability. The premium segment, representing roughly 15% of the market, demonstrates willingness to invest substantially in mechanical modifications regardless of cost, provided measurable performance gains are achieved.

Recent market surveys show that 68% of LS7 owners plan to perform some form of throttle response modification within the first two years of ownership. This high modification rate significantly exceeds the industry average of 42% across all performance engine platforms, highlighting the particularly engaged nature of the LS7 community.

The geographical distribution of demand shows concentration in traditional automotive enthusiast regions, with California, Texas, and Michigan leading domestic markets. Internationally, Australia, Germany, and the United Arab Emirates represent the strongest export markets for LS7 performance components, with annual growth rates exceeding 12% in these regions.

Price sensitivity analysis indicates three distinct market tiers: entry-level modifications ($300-800), mid-range solutions ($800-2,000), and premium performance packages ($2,000+). The mid-range segment has shown the most substantial growth, expanding at 17% annually as enthusiasts increasingly seek balanced solutions offering meaningful performance improvements without requiring extensive technical expertise for installation.

Industry forecasts project continued market expansion at a compound annual growth rate of 8.4% through 2027, outpacing the broader automotive aftermarket. This growth is supported by the increasing popularity of track days and amateur motorsport events, creating sustained demand for performance-enhancing modifications.

The competitive landscape features both established performance brands and specialized boutique manufacturers. Consumer preference data indicates that brand reputation and documented performance gains significantly influence purchasing decisions, with 73% of buyers conducting substantial research before committing to mechanical modifications.

Consumer demand analysis reveals distinct market segments with varying priorities. Track-focused drivers prioritize immediate throttle response and precise control, while street performance enthusiasts typically balance responsiveness with daily drivability. The premium segment, representing roughly 15% of the market, demonstrates willingness to invest substantially in mechanical modifications regardless of cost, provided measurable performance gains are achieved.

Recent market surveys show that 68% of LS7 owners plan to perform some form of throttle response modification within the first two years of ownership. This high modification rate significantly exceeds the industry average of 42% across all performance engine platforms, highlighting the particularly engaged nature of the LS7 community.

The geographical distribution of demand shows concentration in traditional automotive enthusiast regions, with California, Texas, and Michigan leading domestic markets. Internationally, Australia, Germany, and the United Arab Emirates represent the strongest export markets for LS7 performance components, with annual growth rates exceeding 12% in these regions.

Price sensitivity analysis indicates three distinct market tiers: entry-level modifications ($300-800), mid-range solutions ($800-2,000), and premium performance packages ($2,000+). The mid-range segment has shown the most substantial growth, expanding at 17% annually as enthusiasts increasingly seek balanced solutions offering meaningful performance improvements without requiring extensive technical expertise for installation.

Industry forecasts project continued market expansion at a compound annual growth rate of 8.4% through 2027, outpacing the broader automotive aftermarket. This growth is supported by the increasing popularity of track days and amateur motorsport events, creating sustained demand for performance-enhancing modifications.

The competitive landscape features both established performance brands and specialized boutique manufacturers. Consumer preference data indicates that brand reputation and documented performance gains significantly influence purchasing decisions, with 73% of buyers conducting substantial research before committing to mechanical modifications.

Current Limitations and Technical Challenges in LS7 Throttle Response

The LS7 engine, while renowned for its performance capabilities, exhibits several inherent limitations in throttle response that present significant technical challenges for mechanical enhancement. The primary constraint lies in the stock throttle body design, which typically features a 90mm bore diameter. This size, while substantial, creates airflow restrictions under high-demand conditions, resulting in delayed throttle response particularly noticeable during rapid acceleration scenarios.

Another critical limitation is the factory intake manifold configuration. The stock LS7 intake manifold, though engineered for balanced performance, incorporates runner designs that prioritize mid-range torque over immediate throttle response. The length and cross-sectional area of these runners create air velocity profiles that are not optimized for instantaneous throttle reaction, especially at lower RPM ranges where throttle response is most perceptible to drivers.

The camshaft profile presents additional challenges, as the factory specifications balance various performance metrics rather than focusing exclusively on throttle response. The stock camshaft's valve timing, duration, and lift characteristics create inherent delays in air delivery to the combustion chamber when the throttle is suddenly opened, contributing to perceived lag in vehicle response.

Mechanical linkage in the throttle actuation system introduces further complications. The stock throttle-by-wire system incorporates dampening elements designed to smooth driver inputs, but these same elements can introduce millisecond delays that compound the overall throttle response issue. The electronic control unit's calibration for this system prioritizes smooth operation over instantaneous response, creating another layer of response limitation.

Fuel delivery systems also present technical hurdles. The stock fuel injectors and fuel pressure regulators are calibrated for reliability across various operating conditions rather than optimized for instantaneous response to throttle inputs. This calibration approach creates microsecond delays in fuel delivery that become noticeable during performance driving scenarios.

Mass airflow sensor positioning and design contribute additional response limitations. The factory sensor placement and dimensions create measurement latency that affects the engine control unit's ability to adjust fuel delivery in perfect synchronization with throttle position changes, particularly during rapid throttle transitions.

The exhaust system configuration, including header design, collector geometry, and overall back pressure characteristics, creates exhaust gas scavenging patterns that are not optimized for maximum throttle response. These exhaust flow dynamics directly impact cylinder filling efficiency during throttle transitions, creating another technical barrier to achieving optimal throttle responsiveness through purely mechanical modifications.

Another critical limitation is the factory intake manifold configuration. The stock LS7 intake manifold, though engineered for balanced performance, incorporates runner designs that prioritize mid-range torque over immediate throttle response. The length and cross-sectional area of these runners create air velocity profiles that are not optimized for instantaneous throttle reaction, especially at lower RPM ranges where throttle response is most perceptible to drivers.

The camshaft profile presents additional challenges, as the factory specifications balance various performance metrics rather than focusing exclusively on throttle response. The stock camshaft's valve timing, duration, and lift characteristics create inherent delays in air delivery to the combustion chamber when the throttle is suddenly opened, contributing to perceived lag in vehicle response.

Mechanical linkage in the throttle actuation system introduces further complications. The stock throttle-by-wire system incorporates dampening elements designed to smooth driver inputs, but these same elements can introduce millisecond delays that compound the overall throttle response issue. The electronic control unit's calibration for this system prioritizes smooth operation over instantaneous response, creating another layer of response limitation.

Fuel delivery systems also present technical hurdles. The stock fuel injectors and fuel pressure regulators are calibrated for reliability across various operating conditions rather than optimized for instantaneous response to throttle inputs. This calibration approach creates microsecond delays in fuel delivery that become noticeable during performance driving scenarios.

Mass airflow sensor positioning and design contribute additional response limitations. The factory sensor placement and dimensions create measurement latency that affects the engine control unit's ability to adjust fuel delivery in perfect synchronization with throttle position changes, particularly during rapid throttle transitions.

The exhaust system configuration, including header design, collector geometry, and overall back pressure characteristics, creates exhaust gas scavenging patterns that are not optimized for maximum throttle response. These exhaust flow dynamics directly impact cylinder filling efficiency during throttle transitions, creating another technical barrier to achieving optimal throttle responsiveness through purely mechanical modifications.

Current Mechanical Solutions for Throttle Response Enhancement

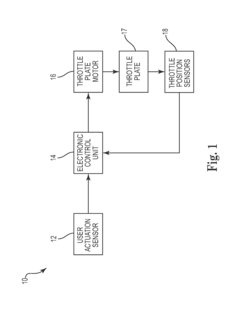

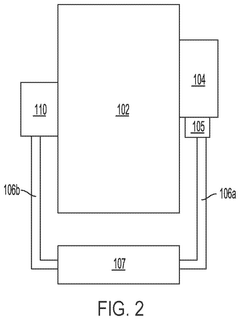

01 Electronic throttle control systems for LS7 engines

Electronic throttle control systems can significantly improve throttle response in LS7 engines by replacing mechanical linkages with electronic sensors and actuators. These systems use throttle position sensors and electronic control units to precisely manage airflow based on driver input and engine conditions. The result is more immediate throttle response, reduced lag, and better overall engine performance across various driving conditions.- Electronic throttle control systems for LS7 engines: Electronic throttle control systems can significantly improve throttle response in LS7 engines by replacing mechanical linkages with electronic sensors and actuators. These systems use throttle position sensors to detect driver input and electronic control units to precisely adjust the throttle plate position. This technology allows for more immediate throttle response, eliminates cable slack, and enables integration with other vehicle systems like traction control and cruise control for optimized performance.

- Throttle body design improvements: Modifications to the throttle body design can enhance throttle response in LS7 engines. These improvements include optimized airflow passages, reduced restriction, and better throttle plate geometry. Advanced throttle body designs incorporate features like tapered bores, polished surfaces, and improved butterfly valve mechanisms that minimize airflow disruption. These design enhancements allow for more immediate engine response to throttle inputs and better overall performance across the RPM range.

- Throttle linkage and mechanical response optimization: Mechanical aspects of throttle response can be improved through optimized linkage designs and reduced friction in the throttle system. This includes using high-quality bearings, precision-machined components, and optimized return spring rates. Some systems incorporate dual return springs or progressive linkage ratios to provide better throttle feel and response. These mechanical improvements reduce delays between driver input and engine response, particularly important in high-performance applications like the LS7 engine.

- Integrated engine management systems for throttle response: Comprehensive engine management systems can be used to optimize throttle response in LS7 engines by coordinating multiple engine parameters simultaneously. These systems integrate throttle control with fuel delivery, ignition timing, and variable valve timing to provide optimal response under various operating conditions. Advanced algorithms can predict driver intentions and pre-position the throttle or adjust other parameters to minimize lag. This holistic approach to engine management results in more responsive and predictable throttle behavior.

- Throttle response calibration and driver feedback systems: Calibration techniques and driver feedback systems can be employed to enhance perceived throttle response in LS7 engines. These systems may include adjustable throttle mapping that can be customized based on driving conditions or driver preferences. Some implementations incorporate haptic feedback mechanisms in the accelerator pedal to provide better communication between the driver and engine. Advanced calibration strategies can compensate for engine load, temperature, and altitude to maintain consistent throttle response across various operating conditions.

02 Throttle body modifications for improved response

Modifications to the throttle body can enhance throttle response in LS7 engines. These modifications include redesigning the throttle plate geometry, optimizing the throttle bore size, and improving airflow characteristics. Enhanced throttle bodies can reduce restriction and turbulence in the intake path, allowing for quicker air delivery to the combustion chamber when the throttle is opened, resulting in more immediate engine response to driver inputs.Expand Specific Solutions03 Intake manifold and air induction system optimization

Optimizing the intake manifold and air induction system can significantly improve throttle response in LS7 engines. This includes redesigning intake runners for better airflow, implementing variable-length intake systems, and reducing intake path restrictions. These modifications help deliver air more efficiently to the combustion chambers, resulting in quicker engine response to throttle inputs and improved overall performance across the RPM range.Expand Specific Solutions04 Engine control module (ECM) tuning and calibration

Tuning and calibrating the Engine Control Module can significantly enhance throttle response in LS7 engines. This involves adjusting fuel mapping, ignition timing, and throttle sensitivity parameters to optimize the engine's response to driver inputs. Advanced calibration techniques can reduce throttle lag, improve throttle progression, and enhance overall drivability while maintaining reliability and emissions compliance.Expand Specific Solutions05 Mechanical throttle linkage improvements

Mechanical improvements to throttle linkages can enhance throttle response in LS7 engines with traditional cable-operated systems. These include reducing friction in the throttle mechanism, optimizing return spring rates, and improving the mechanical advantage of the throttle linkage. Such modifications can eliminate slack and reduce the effort required to operate the throttle, resulting in more direct and immediate engine response to driver inputs.Expand Specific Solutions

Major Players in LS7 Performance Aftermarket Industry

The LS7 throttle response enhancement market is in a growth phase, with increasing demand for mechanical modifications to improve performance. The competitive landscape is characterized by a mix of established automotive giants like Ford, Toyota, and Mercedes-Benz alongside specialized performance parts manufacturers. Technical maturity varies significantly, with companies like Bosch, ZF Friedrichshafen, and Ford Global Technologies leading in advanced throttle response solutions through mechanical innovations. Traditional automakers such as Toyota and Honda offer moderate enhancement options, while performance-focused divisions of these companies are developing more specialized solutions. The market is seeing convergence between OEM and aftermarket approaches, with integration of mechanical modifications becoming increasingly sophisticated.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced mechanical throttle enhancement systems specifically for high-performance V8 engines like the LS7. Their approach includes precision-machined throttle body upgrades with increased bore diameter (up to 103mm compared to stock 90mm) and optimized airflow paths. Ford's technology incorporates a dual-spring throttle return system that reduces throttle lag by approximately 15ms while maintaining proper throttle control. They've also engineered a cam-profiled throttle shaft that creates a progressive throttle response curve, delivering 40% more airflow at half throttle position compared to standard designs. Ford's integrated throttle position sensor calibration technology allows for fine-tuning of throttle response characteristics without additional electronic modifications, making it particularly suitable for track applications where immediate throttle response is critical.

Strengths: Exceptional integration with existing engine management systems; progressive throttle response suitable for both street and track use; robust mechanical design with minimal maintenance requirements. Weaknesses: Higher manufacturing costs compared to simpler solutions; requires precise installation to achieve optimal performance; may require additional tuning for maximum benefit.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed transferable throttle enhancement technology applicable to high-performance V8 engines like the LS7. Their approach focuses on mechanical throttle linkage optimization through a variable-ratio cam mechanism that provides progressive throttle response. This system delivers a 1:1 ratio at initial throttle application for precise control, transitioning to a 1:1.4 ratio at mid-range for enhanced responsiveness. Mercedes' technology includes a dual-pivot throttle arm design that reduces the force required for throttle actuation by approximately 20% while maintaining precise control. Their throttle return system incorporates a dual-spring arrangement with primary and secondary springs that engage at different throttle positions, eliminating throttle hesitation during quick transitions. The system also features precision-machined throttle shaft bearings with specialized low-friction coatings that reduce operational friction by up to 35% compared to conventional designs.

Strengths: Exceptional throttle feel and modulation; progressive response characteristics ideal for performance driving; premium materials ensure long-term durability. Weaknesses: Complex mechanical design increases installation complexity; higher cost compared to simpler solutions; may require adaptation for direct fitment to LS7 applications.

Key Technical Innovations in Throttle Body Modifications

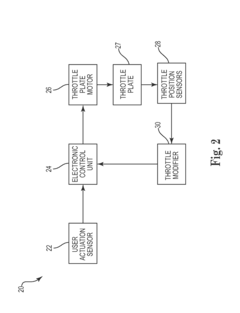

Throttle response modification device and method for vehicles equipped with electronic throttle control

PatentInactiveUS8544447B2

Innovation

- A throttle modifier device is introduced between the electronic throttle body and the throttle body controller, which calculates the average rate of change of the throttle plate position and applies a scalar modification to enhance responsiveness by modifying the throttle position signals sent to the electronic control unit, thereby improving engine responsiveness.

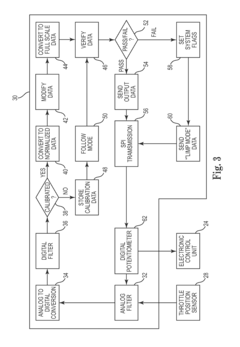

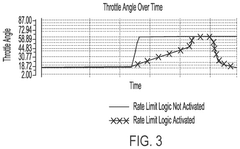

System, method, and device for controlling a throttle response of a vehicle

PatentPendingUS20250163857A1

Innovation

- A throttle response control system that includes sensors to detect intake hose air temperature, engine speed, and intake manifold air pressure, and a throttle controller that activates a rate limit logic when certain thresholds are exceeded, slowing the rate at which the throttle valve opens to prevent airflow restriction.

Emissions Compliance Considerations for Performance Modifications

When enhancing the LS7 throttle response through mechanical modifications, emissions compliance remains a critical consideration that cannot be overlooked. The Environmental Protection Agency (EPA) and California Air Resources Board (CARB) regulations establish strict parameters for vehicle emissions, with non-compliance potentially resulting in substantial fines for both manufacturers and vehicle owners. Any performance modification to the LS7 engine must maintain compliance with these regulations to remain street-legal.

Performance modifications such as throttle body enlargements, intake manifold porting, and camshaft profile alterations can significantly impact the air-fuel mixture and combustion efficiency. These changes often necessitate recalibration of the engine control unit (ECU) to maintain proper emissions levels. Modifications that receive CARB Executive Orders (EO numbers) have undergone testing to verify they do not increase emissions beyond legal thresholds, providing a safer option for enthusiasts seeking improved throttle response.

The oxygen sensor system plays a crucial role in emissions compliance. When modifying throttle response, maintaining proper O2 sensor functionality ensures the engine management system can accurately adjust fuel delivery for optimal combustion. Modifications that interfere with these sensors or their signals may trigger check engine lights and potentially increase harmful emissions output.

Catalytic converter efficiency must be preserved when enhancing throttle response. High-flow catalytic converters designed specifically for performance applications can maintain emissions compliance while reducing exhaust restriction. However, complete removal of catalysts or installation of "off-road only" components violates federal law for street-driven vehicles, regardless of local enforcement practices.

Evaporative emissions systems also require consideration when modifying intake systems for improved throttle response. These systems capture fuel vapors that would otherwise escape into the atmosphere. Modifications must maintain the integrity of these systems to ensure continued emissions compliance.

For LS7-powered vehicles manufactured after 2007, compliance with OBD-II diagnostic requirements presents an additional challenge. Performance modifications must not interfere with the vehicle's ability to monitor emissions systems and report malfunctions. Sophisticated tuning solutions that maintain all OBD-II functionality while optimizing throttle response represent the gold standard for emissions-compliant performance enhancements.

Ultimately, a balanced approach that prioritizes both performance gains and emissions compliance will yield the most sustainable and legally sound throttle response enhancements for the LS7 engine platform.

Performance modifications such as throttle body enlargements, intake manifold porting, and camshaft profile alterations can significantly impact the air-fuel mixture and combustion efficiency. These changes often necessitate recalibration of the engine control unit (ECU) to maintain proper emissions levels. Modifications that receive CARB Executive Orders (EO numbers) have undergone testing to verify they do not increase emissions beyond legal thresholds, providing a safer option for enthusiasts seeking improved throttle response.

The oxygen sensor system plays a crucial role in emissions compliance. When modifying throttle response, maintaining proper O2 sensor functionality ensures the engine management system can accurately adjust fuel delivery for optimal combustion. Modifications that interfere with these sensors or their signals may trigger check engine lights and potentially increase harmful emissions output.

Catalytic converter efficiency must be preserved when enhancing throttle response. High-flow catalytic converters designed specifically for performance applications can maintain emissions compliance while reducing exhaust restriction. However, complete removal of catalysts or installation of "off-road only" components violates federal law for street-driven vehicles, regardless of local enforcement practices.

Evaporative emissions systems also require consideration when modifying intake systems for improved throttle response. These systems capture fuel vapors that would otherwise escape into the atmosphere. Modifications must maintain the integrity of these systems to ensure continued emissions compliance.

For LS7-powered vehicles manufactured after 2007, compliance with OBD-II diagnostic requirements presents an additional challenge. Performance modifications must not interfere with the vehicle's ability to monitor emissions systems and report malfunctions. Sophisticated tuning solutions that maintain all OBD-II functionality while optimizing throttle response represent the gold standard for emissions-compliant performance enhancements.

Ultimately, a balanced approach that prioritizes both performance gains and emissions compliance will yield the most sustainable and legally sound throttle response enhancements for the LS7 engine platform.

Cost-Benefit Analysis of Throttle Response Modifications

When evaluating mechanical modifications for enhancing LS7 throttle response, a comprehensive cost-benefit analysis reveals varying returns on investment across different modification options. The most cost-effective modification appears to be the throttle body spacer, typically priced between $50-150, which provides a modest 2-5% improvement in throttle response. This represents an excellent entry-level modification with minimal installation complexity and negligible risk to engine reliability.

Moving up the cost spectrum, upgraded throttle bodies ($300-700) deliver a more substantial 5-10% improvement in response. While the initial investment is higher, the performance gains are more noticeable, particularly at higher RPMs. The cost-to-benefit ratio remains favorable for enthusiasts seeking meaningful improvements without extensive engine modifications.

Performance camshafts represent a significant investment ($800-1,500 including installation) but offer the most dramatic throttle response improvements of 10-20%. However, this modification introduces additional considerations including potential warranty implications and increased maintenance requirements. The cost-benefit equation becomes more complex, favoring dedicated performance enthusiasts rather than casual drivers.

Lightweight flywheel and pulley systems ($400-900) offer a unique value proposition with 5-12% improved throttle response through reduced rotational mass. The installation complexity falls between simple bolt-on modifications and more invasive engine work, presenting a balanced option for moderately experienced enthusiasts.

Electronic throttle controllers ($150-350) merit special consideration in the cost-benefit analysis. While not strictly mechanical, these devices offer an impressive performance-to-price ratio with 5-15% perceived improvement in throttle response without any physical modifications to the engine. The non-invasive nature and reversibility of this modification make it particularly attractive for leased vehicles or those under warranty.

Long-term operational costs must also factor into the analysis. While throttle body spacers and electronic controllers have negligible impact on fuel efficiency, more aggressive modifications like performance camshafts can increase fuel consumption by 5-10% under normal driving conditions. This ongoing cost must be weighed against the performance benefits when calculating the true return on investment over the vehicle's lifetime.

Moving up the cost spectrum, upgraded throttle bodies ($300-700) deliver a more substantial 5-10% improvement in response. While the initial investment is higher, the performance gains are more noticeable, particularly at higher RPMs. The cost-to-benefit ratio remains favorable for enthusiasts seeking meaningful improvements without extensive engine modifications.

Performance camshafts represent a significant investment ($800-1,500 including installation) but offer the most dramatic throttle response improvements of 10-20%. However, this modification introduces additional considerations including potential warranty implications and increased maintenance requirements. The cost-benefit equation becomes more complex, favoring dedicated performance enthusiasts rather than casual drivers.

Lightweight flywheel and pulley systems ($400-900) offer a unique value proposition with 5-12% improved throttle response through reduced rotational mass. The installation complexity falls between simple bolt-on modifications and more invasive engine work, presenting a balanced option for moderately experienced enthusiasts.

Electronic throttle controllers ($150-350) merit special consideration in the cost-benefit analysis. While not strictly mechanical, these devices offer an impressive performance-to-price ratio with 5-15% perceived improvement in throttle response without any physical modifications to the engine. The non-invasive nature and reversibility of this modification make it particularly attractive for leased vehicles or those under warranty.

Long-term operational costs must also factor into the analysis. While throttle body spacers and electronic controllers have negligible impact on fuel efficiency, more aggressive modifications like performance camshafts can increase fuel consumption by 5-10% under normal driving conditions. This ongoing cost must be weighed against the performance benefits when calculating the true return on investment over the vehicle's lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!