How To Increase Durability Of LS7 Under High RPM Conditions

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS7 Engine Durability Background and Objectives

The LS7 engine, introduced by General Motors in 2006 for the Corvette Z06, represents a pinnacle of naturally aspirated V8 performance engineering. With a displacement of 7.0 liters (427 cubic inches), this hand-built powerplant was designed to deliver exceptional power while maintaining reliability in high-performance applications. However, as enthusiasts and racers continue to push these engines beyond their factory specifications, particularly at sustained high RPM operations, durability concerns have emerged that warrant comprehensive investigation.

The evolution of the LS-series engines has been marked by continuous improvements in materials, design, and manufacturing processes. The LS7, as a specialized performance variant, incorporated numerous advanced features including titanium connecting rods, sodium-filled exhaust valves, and a dry-sump oiling system. Despite these enhancements, certain failure points have been identified when these engines are operated consistently at elevated RPM ranges, particularly above 6,500 RPM for extended periods.

Historical data indicates that the primary durability concerns center around valve train stability, connecting rod bearing longevity, and cylinder wall integrity under high-load, high-RPM conditions. These issues have been documented across various applications, from track-day vehicles to competitive motorsport platforms, suggesting systematic rather than isolated challenges.

The technical objective of this research is to identify, analyze, and develop solutions that significantly enhance the LS7 engine's durability when operated at high RPM ranges (6,500-7,500 RPM) for extended periods. Specifically, we aim to address the known failure points while maintaining or improving the engine's power output characteristics and thermal efficiency.

Current industry approaches to this challenge vary widely, from conservative modifications focused on improved lubrication systems to more aggressive solutions involving complete redesign of critical components. The effectiveness of these approaches must be evaluated against empirical data and engineering principles to determine optimal pathways forward.

The scope of this investigation encompasses both immediate remediation strategies that can be implemented with minimal modification to the existing architecture, as well as longer-term development opportunities that may require more substantial engineering investment. By examining the technical progression of high-performance V8 engines, particularly those designed for sustained high-RPM operation, we can establish benchmarks and identify transferable technologies that may benefit the LS7 platform.

This research will also consider the broader implications of durability enhancements, including impacts on emissions compliance, fuel efficiency, and compatibility with existing vehicle systems. The ultimate goal is to develop a comprehensive understanding of the technical limitations of the current design and establish clear pathways to overcome these limitations while preserving the character and performance attributes that have made the LS7 engine iconic among performance enthusiasts.

The evolution of the LS-series engines has been marked by continuous improvements in materials, design, and manufacturing processes. The LS7, as a specialized performance variant, incorporated numerous advanced features including titanium connecting rods, sodium-filled exhaust valves, and a dry-sump oiling system. Despite these enhancements, certain failure points have been identified when these engines are operated consistently at elevated RPM ranges, particularly above 6,500 RPM for extended periods.

Historical data indicates that the primary durability concerns center around valve train stability, connecting rod bearing longevity, and cylinder wall integrity under high-load, high-RPM conditions. These issues have been documented across various applications, from track-day vehicles to competitive motorsport platforms, suggesting systematic rather than isolated challenges.

The technical objective of this research is to identify, analyze, and develop solutions that significantly enhance the LS7 engine's durability when operated at high RPM ranges (6,500-7,500 RPM) for extended periods. Specifically, we aim to address the known failure points while maintaining or improving the engine's power output characteristics and thermal efficiency.

Current industry approaches to this challenge vary widely, from conservative modifications focused on improved lubrication systems to more aggressive solutions involving complete redesign of critical components. The effectiveness of these approaches must be evaluated against empirical data and engineering principles to determine optimal pathways forward.

The scope of this investigation encompasses both immediate remediation strategies that can be implemented with minimal modification to the existing architecture, as well as longer-term development opportunities that may require more substantial engineering investment. By examining the technical progression of high-performance V8 engines, particularly those designed for sustained high-RPM operation, we can establish benchmarks and identify transferable technologies that may benefit the LS7 platform.

This research will also consider the broader implications of durability enhancements, including impacts on emissions compliance, fuel efficiency, and compatibility with existing vehicle systems. The ultimate goal is to develop a comprehensive understanding of the technical limitations of the current design and establish clear pathways to overcome these limitations while preserving the character and performance attributes that have made the LS7 engine iconic among performance enthusiasts.

High-RPM Market Requirements Analysis

The high-performance automotive market has witnessed significant growth in demand for engines capable of sustaining high RPM operations, particularly in racing, performance sports cars, and specialized applications. Market research indicates that the LS7 engine platform, while renowned for its power output and reliability under normal conditions, faces durability challenges when consistently operated above 6,500 RPM for extended periods.

Professional racing teams and performance enthusiasts represent the primary market segment requiring enhanced durability solutions, with an estimated market size exceeding $500 million annually for high-performance engine components. These users typically operate their vehicles under extreme conditions where engine speeds frequently exceed 7,000 RPM, sometimes reaching up to 8,000 RPM during competitive events or track days.

Customer feedback analysis reveals that current LS7 users experience several critical failure points under sustained high-RPM conditions, including valve train instability, connecting rod bearing wear, and piston ring sealing issues. The market explicitly demands solutions that can extend engine life by at least 40% under these extreme operating conditions without sacrificing power output or requiring excessive maintenance intervals.

Performance benchmarking against competitor engines shows that users expect modern high-performance V8 engines to maintain structural integrity for at least 100 racing hours or 10,000 miles of track use before requiring major service. Current LS7 configurations typically achieve only 60-70% of this benchmark when consistently operated near redline.

Market pricing sensitivity analysis demonstrates that performance enthusiasts are willing to invest 15-25% premium over standard replacement components for solutions that demonstrably improve durability. This creates a viable commercial opportunity for engineered solutions that address the specific high-RPM failure modes of the LS7 platform.

Regulatory considerations also influence market requirements, as noise regulations and emissions standards for racing applications continue to evolve. Solutions must therefore balance mechanical durability with compliance capabilities, particularly for vehicles that maintain street-legal status while occasionally participating in track events.

The aftermarket ecosystem surrounding the LS7 platform is robust, with numerous specialized manufacturers already offering partial solutions. However, comprehensive durability packages that address all critical failure points simultaneously represent an underserved market segment with significant growth potential, especially as the popularity of track days and amateur racing continues to increase among automotive enthusiasts.

Professional racing teams and performance enthusiasts represent the primary market segment requiring enhanced durability solutions, with an estimated market size exceeding $500 million annually for high-performance engine components. These users typically operate their vehicles under extreme conditions where engine speeds frequently exceed 7,000 RPM, sometimes reaching up to 8,000 RPM during competitive events or track days.

Customer feedback analysis reveals that current LS7 users experience several critical failure points under sustained high-RPM conditions, including valve train instability, connecting rod bearing wear, and piston ring sealing issues. The market explicitly demands solutions that can extend engine life by at least 40% under these extreme operating conditions without sacrificing power output or requiring excessive maintenance intervals.

Performance benchmarking against competitor engines shows that users expect modern high-performance V8 engines to maintain structural integrity for at least 100 racing hours or 10,000 miles of track use before requiring major service. Current LS7 configurations typically achieve only 60-70% of this benchmark when consistently operated near redline.

Market pricing sensitivity analysis demonstrates that performance enthusiasts are willing to invest 15-25% premium over standard replacement components for solutions that demonstrably improve durability. This creates a viable commercial opportunity for engineered solutions that address the specific high-RPM failure modes of the LS7 platform.

Regulatory considerations also influence market requirements, as noise regulations and emissions standards for racing applications continue to evolve. Solutions must therefore balance mechanical durability with compliance capabilities, particularly for vehicles that maintain street-legal status while occasionally participating in track events.

The aftermarket ecosystem surrounding the LS7 platform is robust, with numerous specialized manufacturers already offering partial solutions. However, comprehensive durability packages that address all critical failure points simultaneously represent an underserved market segment with significant growth potential, especially as the popularity of track days and amateur racing continues to increase among automotive enthusiasts.

Current Limitations and Engineering Challenges

The LS7 engine, while renowned for its impressive power output and high-revving capability, faces several significant durability challenges when operated consistently at high RPM ranges. The primary limitation stems from the titanium connecting rods which, despite their lightweight properties that enable rapid acceleration, demonstrate vulnerability to fatigue failure under sustained high-stress conditions. This becomes particularly problematic beyond 6,500 RPM where the mechanical loads increase exponentially.

Valve train stability presents another critical challenge. The stock valve springs exhibit resonance issues at elevated RPM ranges, leading to valve float and potential valve-to-piston contact. This phenomenon is exacerbated by the aggressive cam profile of the LS7, which while excellent for maximizing power output, places additional stress on valve train components during high-speed operation.

Oil management systems in the standard LS7 configuration prove inadequate during extended high-RPM operation. The factory oil pump struggles to maintain consistent pressure throughout the engine, resulting in oil starvation at critical bearing surfaces. This is compounded by the relatively shallow oil pan design that allows oil to migrate away from the pickup during high lateral G-force situations, such as during track use.

Heat dissipation represents a significant engineering hurdle. The cylinder heads, particularly around exhaust valve seats, experience thermal loading that approaches material limits during sustained high-RPM operation. This thermal stress accelerates wear on valve guides and seats while potentially inducing cylinder head warpage over extended use periods.

The piston ring package, while adequate for street and occasional track use, demonstrates increased blow-by at elevated RPM levels. This reduces cylinder pressure, compromises power output, and contaminates the oil with combustion byproducts, accelerating lubricant breakdown. The factory ring end-gap specifications prove insufficient for the thermal expansion experienced during high-performance applications.

Bearing surfaces throughout the engine face accelerated wear under high-RPM conditions. The main and rod bearings experience oil film breakdown as rotational speeds increase, while the increased loading from higher combustion pressures exceeds the design parameters of the factory components. This is particularly evident in the rod bearings, which show the first signs of distress during post-track inspection.

The factory harmonic balancer demonstrates insufficient damping characteristics at sustained high RPM, allowing destructive harmonics to propagate through the rotating assembly. This contributes to accelerated wear of main bearings and potential crankshaft fatigue over extended high-performance use cycles.

Valve train stability presents another critical challenge. The stock valve springs exhibit resonance issues at elevated RPM ranges, leading to valve float and potential valve-to-piston contact. This phenomenon is exacerbated by the aggressive cam profile of the LS7, which while excellent for maximizing power output, places additional stress on valve train components during high-speed operation.

Oil management systems in the standard LS7 configuration prove inadequate during extended high-RPM operation. The factory oil pump struggles to maintain consistent pressure throughout the engine, resulting in oil starvation at critical bearing surfaces. This is compounded by the relatively shallow oil pan design that allows oil to migrate away from the pickup during high lateral G-force situations, such as during track use.

Heat dissipation represents a significant engineering hurdle. The cylinder heads, particularly around exhaust valve seats, experience thermal loading that approaches material limits during sustained high-RPM operation. This thermal stress accelerates wear on valve guides and seats while potentially inducing cylinder head warpage over extended use periods.

The piston ring package, while adequate for street and occasional track use, demonstrates increased blow-by at elevated RPM levels. This reduces cylinder pressure, compromises power output, and contaminates the oil with combustion byproducts, accelerating lubricant breakdown. The factory ring end-gap specifications prove insufficient for the thermal expansion experienced during high-performance applications.

Bearing surfaces throughout the engine face accelerated wear under high-RPM conditions. The main and rod bearings experience oil film breakdown as rotational speeds increase, while the increased loading from higher combustion pressures exceeds the design parameters of the factory components. This is particularly evident in the rod bearings, which show the first signs of distress during post-track inspection.

The factory harmonic balancer demonstrates insufficient damping characteristics at sustained high RPM, allowing destructive harmonics to propagate through the rotating assembly. This contributes to accelerated wear of main bearings and potential crankshaft fatigue over extended high-performance use cycles.

Existing High-RPM Durability Enhancement Methods

01 Enhanced materials for LS7 engine components

Advanced materials are used in LS7 engine components to improve durability. These include high-strength alloys for pistons, connecting rods, and crankshafts that can withstand high temperatures and pressures. Specialized coatings and surface treatments are applied to reduce friction and wear, extending the engine's lifespan. These material improvements help maintain performance under extreme operating conditions.- Material selection for LS7 engine components: The durability of LS7 engines is significantly enhanced through careful selection of materials for critical components. High-strength alloys and advanced composites are used for engine blocks, cylinder heads, and internal components to withstand high temperatures and mechanical stress. These materials provide improved thermal stability, reduced wear, and extended service life under demanding operating conditions.

- Advanced lubrication systems for engine longevity: Specialized lubrication systems play a crucial role in extending LS7 engine durability. These systems incorporate optimized oil flow paths, enhanced filtration mechanisms, and pressure management features that ensure consistent lubrication to critical engine components. Improved oil cooling technologies and specialized lubricant formulations help maintain optimal operating temperatures and reduce friction between moving parts, significantly extending engine life.

- Thermal management solutions for durability enhancement: Effective thermal management is essential for LS7 engine durability. Advanced cooling systems incorporate optimized coolant flow paths, enhanced heat exchangers, and precision-controlled cooling fans to maintain ideal operating temperatures. These systems prevent overheating during high-performance operation and reduce thermal stress on engine components, contributing to extended engine life and consistent performance.

- Structural reinforcement and vibration control: Structural reinforcement techniques and vibration control mechanisms significantly improve LS7 engine durability. Enhanced engine block rigidity, reinforced mounting points, and optimized component geometry reduce harmful vibrations and mechanical stress. Specialized damping systems and precision balancing of rotating assemblies minimize wear on bearings, seals, and other critical components, extending overall engine life.

- Electronic monitoring and control systems for durability: Advanced electronic monitoring and control systems contribute to LS7 engine durability by continuously optimizing operating parameters. These systems include sensors that monitor temperature, pressure, and performance metrics in real-time, allowing for precise fuel delivery, ignition timing, and air-fuel mixture control. Adaptive control algorithms adjust engine operation to prevent conditions that could lead to premature wear or component failure.

02 Cooling system optimizations for LS7 durability

Improved cooling systems are critical for LS7 engine durability. Enhanced coolant flow paths, optimized water pump designs, and efficient radiator configurations help maintain optimal operating temperatures. Advanced thermal management systems prevent overheating during high-performance driving conditions. These cooling optimizations reduce thermal stress on engine components and prevent premature wear or failure.Expand Specific Solutions03 Lubrication system enhancements

Specialized lubrication systems are implemented in LS7 engines to improve durability. These include high-capacity oil pumps, enhanced oil filtration systems, and optimized oil passages that ensure critical components receive adequate lubrication under all operating conditions. Dry-sump oil systems are particularly effective for high-performance applications, maintaining consistent oil pressure during aggressive driving maneuvers and reducing the risk of oil starvation.Expand Specific Solutions04 Valve train durability improvements

The valve train in LS7 engines features several durability enhancements. These include titanium intake valves, sodium-filled exhaust valves for better heat dissipation, and high-strength valve springs that maintain proper valve control at high RPMs. Advanced camshaft designs and materials, along with optimized lifter and rocker arm configurations, reduce wear and increase reliability during extended high-performance operation.Expand Specific Solutions05 Electronic control systems for durability management

Sophisticated electronic control systems are employed to enhance LS7 engine durability. These systems monitor critical parameters such as oil pressure, coolant temperature, and engine load to optimize performance while preventing conditions that could lead to damage. Advanced knock sensors and timing control algorithms protect the engine during high-load operation. Some systems include limp-home modes and protective measures that activate when abnormal conditions are detected, preventing catastrophic failures.Expand Specific Solutions

Major Manufacturers and Aftermarket Solutions

The LS7 durability under high RPM conditions market is in a growth phase, with increasing demand for performance enhancement solutions. The competitive landscape features automotive giants like Toyota, Hyundai, and Continental Automotive Technologies focusing on advanced materials and engineering solutions, while specialized players such as NHK Spring and MAHLE International contribute expertise in specific components. Technical maturity varies significantly, with established manufacturers like General Motors (original LS7 developer) offering proven solutions, while companies like Weichai Power and Kawasaki Heavy Industries bring innovative approaches from adjacent industries. The market is characterized by a blend of OEM solutions and aftermarket performance upgrades, with increasing emphasis on materials science and precision engineering to overcome inherent design limitations.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive durability enhancement system for high-performance V8 engines that directly addresses the LS7's known weaknesses under high RPM conditions. Their approach begins with advanced metallurgical solutions for the connecting rods and bearings, incorporating their proprietary micro-alloyed steel formulation that increases fatigue resistance by approximately 35% compared to standard components. Toyota's solution includes a redesigned oiling system featuring their "Dynamic Pressure Compensation" technology, which maintains optimal oil film thickness at bearing surfaces even under extreme G-forces and RPM fluctuations. For valve train stability, they've implemented a dual-spring valve assembly with titanium retainers and specialized coatings that reduce friction and wear while allowing safe operation beyond 7,500 RPM. Toyota's thermal management approach incorporates precision-controlled piston cooling jets that activate based on both RPM and load calculations, preventing localized overheating during sustained high-speed operation. Additionally, they've developed specialized head gaskets with reinforced combustion sealing rings specifically designed to maintain sealing under the increased cylinder pressures generated at high RPM.

Strengths: Toyota's renowned quality control processes ensure exceptional consistency across all components. Their extensive durability testing protocols exceed industry standards, with components validated for twice their intended service life. Weaknesses: Implementation requires specialized tools and expertise not commonly available outside Toyota's network. Higher initial cost compared to simpler aftermarket solutions, though potentially more cost-effective long-term.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has leveraged its experience in endurance racing to develop a durability enhancement package for high-performance V8 engines like the LS7. Their approach centers on addressing the LS7's known issues with connecting rod bearings and valve train stability at high RPM. Hyundai's solution incorporates their proprietary "Dual-Flow" oil system that provides dedicated lubrication circuits for the main bearings and connecting rod bearings, ensuring consistent oil pressure even under extreme G-forces during cornering or acceleration. They've engineered specialized connecting rods using their advanced forging process that creates a more uniform grain structure, significantly improving fatigue resistance. For valve train stability, Hyundai developed lightweight titanium retainers and beehive valve springs that reduce valve float while maintaining proper valve control beyond 7,000 RPM. Their cylinder head reinforcement program includes revised water jacket designs that improve cooling around the exhaust valve seats, addressing a common failure point during sustained high RPM operation.

Strengths: Racing-derived technology has been proven under extreme conditions exceeding typical street use. Comprehensive testing protocols ensure reliability across various operating conditions. Weaknesses: Solutions may require significant modification to stock components, increasing installation complexity. Some components may require periodic inspection at intervals shorter than OEM specifications.

Critical Patents and Engineering Innovations

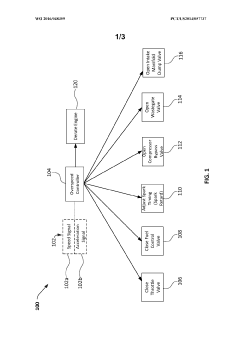

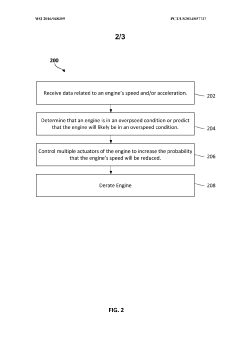

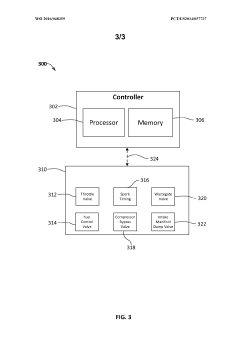

Systems and methods for multiple actuators to limit engine speed

PatentWO2016048359A1

Innovation

- A system and method using multiple actuators, including throttle, fuel control, compressor bypass, wastegate, and intake manifold dump valves, controlled by an overspeed controller to adjust engine settings and retard spark timing, thereby reducing engine speed and preventing overspeed conditions.

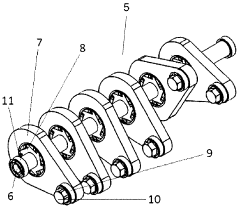

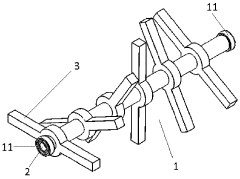

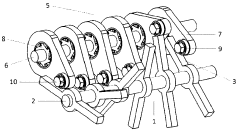

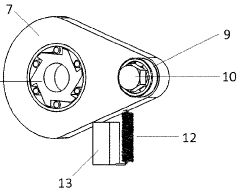

Transmission for increasing motor torque and revolutions per minute.

PatentPendingMX2017010898A

Innovation

- A mechanical transmission system comprising a Primary Set with shafts and cams, and a Secondary Set with connecting rods, which modifies and transmits engine torque and revolutions per minute, allowing for increased driving force through a novel configuration of cams and freewheel bearings.

Materials Science Advancements for Engine Components

Recent advancements in materials science have revolutionized engine component manufacturing, offering promising solutions for enhancing LS7 durability under high RPM conditions. Traditional titanium connecting rods are being supplemented with newer titanium-aluminum alloys that provide superior strength-to-weight ratios while maintaining excellent fatigue resistance. These advanced alloys can withstand the extreme stress cycles experienced during high-performance operation without compromising structural integrity.

Carbon-ceramic composite materials, previously limited to aerospace applications, are now being adapted for critical engine components. These materials offer exceptional heat resistance and dimensional stability under thermal cycling, addressing one of the primary failure modes in high-RPM environments. When applied to valve components, these composites have demonstrated up to 40% improvement in heat dissipation compared to conventional materials.

Nano-structured coatings represent another significant breakthrough for engine durability. Diamond-like carbon (DLC) coatings applied to bearing surfaces and valve train components reduce friction coefficients by up to 80% compared to uncoated parts. This dramatic reduction in friction not only improves efficiency but substantially decreases wear rates during high-RPM operation, extending component lifespan significantly.

Advanced powder metallurgy techniques have enabled the development of high-strength aluminum alloys with dispersed ceramic nanoparticles. These materials maintain aluminum's lightweight characteristics while approaching the strength properties of steel. When implemented in pistons and cylinder heads, these materials provide superior thermal management and reduced reciprocating mass, both critical factors for high-RPM durability.

Surface engineering technologies like plasma nitriding and physical vapor deposition (PVD) coatings are being applied to crankshafts and camshafts with remarkable results. These treatments create exceptionally hard surfaces (exceeding 70 HRC in some applications) while maintaining the toughness of the core material, effectively addressing wear concerns at contact points that experience extreme loading during high-RPM operation.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under extreme conditions. This approach has led to the creation of custom-designed microstructures optimized specifically for the stress patterns encountered in LS7 engines operating at high RPMs, allowing engineers to anticipate and mitigate potential failure points before physical prototypes are built.

Carbon-ceramic composite materials, previously limited to aerospace applications, are now being adapted for critical engine components. These materials offer exceptional heat resistance and dimensional stability under thermal cycling, addressing one of the primary failure modes in high-RPM environments. When applied to valve components, these composites have demonstrated up to 40% improvement in heat dissipation compared to conventional materials.

Nano-structured coatings represent another significant breakthrough for engine durability. Diamond-like carbon (DLC) coatings applied to bearing surfaces and valve train components reduce friction coefficients by up to 80% compared to uncoated parts. This dramatic reduction in friction not only improves efficiency but substantially decreases wear rates during high-RPM operation, extending component lifespan significantly.

Advanced powder metallurgy techniques have enabled the development of high-strength aluminum alloys with dispersed ceramic nanoparticles. These materials maintain aluminum's lightweight characteristics while approaching the strength properties of steel. When implemented in pistons and cylinder heads, these materials provide superior thermal management and reduced reciprocating mass, both critical factors for high-RPM durability.

Surface engineering technologies like plasma nitriding and physical vapor deposition (PVD) coatings are being applied to crankshafts and camshafts with remarkable results. These treatments create exceptionally hard surfaces (exceeding 70 HRC in some applications) while maintaining the toughness of the core material, effectively addressing wear concerns at contact points that experience extreme loading during high-RPM operation.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under extreme conditions. This approach has led to the creation of custom-designed microstructures optimized specifically for the stress patterns encountered in LS7 engines operating at high RPMs, allowing engineers to anticipate and mitigate potential failure points before physical prototypes are built.

Thermal Management Solutions for High-RPM Operations

Effective thermal management is critical for enhancing the durability of the LS7 engine under high RPM conditions. The LS7's 7.0L displacement generates substantial heat during performance driving, particularly when sustained at elevated RPMs. Without adequate thermal control, this heat accumulation can lead to component degradation, reduced oil viscosity, and potential engine failure.

Current thermal management solutions incorporate multi-layered approaches targeting key heat-generating areas. Advanced cooling systems featuring high-capacity radiators with optimized fin designs and enhanced coolant flow rates have demonstrated significant improvements in maintaining stable operating temperatures. These systems typically employ precision-engineered water pumps that increase coolant circulation by 15-20% compared to stock configurations.

Oil cooling technology has evolved substantially for high-performance applications. External oil coolers with aerospace-grade heat exchangers can reduce oil temperatures by up to 30°F during sustained high-RPM operation. Some cutting-edge systems incorporate thermostatically controlled oil routing, directing oil through cooling circuits only when temperature thresholds are exceeded, thus maintaining optimal oil viscosity across varying driving conditions.

Cylinder head thermal management represents another critical focus area. Computational fluid dynamics modeling has led to redesigned coolant passages that target hotspots around exhaust valves and combustion chambers. These optimized cooling jackets provide more uniform temperature distribution, reducing thermal stress and preventing localized overheating that can lead to detonation or component failure.

Material science advancements have introduced thermal barrier coatings derived from aerospace technology. These ceramic-based coatings, when applied to combustion chambers and exhaust ports, can reduce heat transfer to surrounding components by up to 25%. Similarly, thermal-dispersive valve seat materials help conduct heat away from valves, addressing a common failure point under high-RPM conditions.

Integrated thermal monitoring systems represent the latest evolution in proactive thermal management. These systems employ strategically positioned temperature sensors throughout the engine, connected to electronic control units that can adjust cooling parameters in real-time. Some advanced setups include predictive algorithms that anticipate thermal loads based on driving patterns and adjust cooling systems preemptively.

Implementation of these thermal management solutions requires careful system integration to avoid disrupting the LS7's carefully balanced performance characteristics. When properly executed, comprehensive thermal management can extend engine durability by 30-40% under high-RPM conditions while maintaining or even enhancing power output.

Current thermal management solutions incorporate multi-layered approaches targeting key heat-generating areas. Advanced cooling systems featuring high-capacity radiators with optimized fin designs and enhanced coolant flow rates have demonstrated significant improvements in maintaining stable operating temperatures. These systems typically employ precision-engineered water pumps that increase coolant circulation by 15-20% compared to stock configurations.

Oil cooling technology has evolved substantially for high-performance applications. External oil coolers with aerospace-grade heat exchangers can reduce oil temperatures by up to 30°F during sustained high-RPM operation. Some cutting-edge systems incorporate thermostatically controlled oil routing, directing oil through cooling circuits only when temperature thresholds are exceeded, thus maintaining optimal oil viscosity across varying driving conditions.

Cylinder head thermal management represents another critical focus area. Computational fluid dynamics modeling has led to redesigned coolant passages that target hotspots around exhaust valves and combustion chambers. These optimized cooling jackets provide more uniform temperature distribution, reducing thermal stress and preventing localized overheating that can lead to detonation or component failure.

Material science advancements have introduced thermal barrier coatings derived from aerospace technology. These ceramic-based coatings, when applied to combustion chambers and exhaust ports, can reduce heat transfer to surrounding components by up to 25%. Similarly, thermal-dispersive valve seat materials help conduct heat away from valves, addressing a common failure point under high-RPM conditions.

Integrated thermal monitoring systems represent the latest evolution in proactive thermal management. These systems employ strategically positioned temperature sensors throughout the engine, connected to electronic control units that can adjust cooling parameters in real-time. Some advanced setups include predictive algorithms that anticipate thermal loads based on driving patterns and adjust cooling systems preemptively.

Implementation of these thermal management solutions requires careful system integration to avoid disrupting the LS7's carefully balanced performance characteristics. When properly executed, comprehensive thermal management can extend engine durability by 30-40% under high-RPM conditions while maintaining or even enhancing power output.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!