LS7 Engine Vs LS9: Supercharger Impact On Efficiency

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Evolution and Performance Targets

The LS engine family represents one of General Motors' most significant engineering achievements, evolving from its introduction in 1997 through multiple generations of development. The LS7 and LS9 engines stand as pinnacle examples of this evolution, with the latter introducing supercharging technology that fundamentally altered the performance equation. This technological progression reflects GM's commitment to pushing the boundaries of naturally aspirated and forced induction performance in production vehicles.

The LS7, introduced in the 2006 Corvette Z06, represented the peak of naturally aspirated LS development with its 7.0L displacement, delivering 505 horsepower and 470 lb-ft of torque. This engine achieved a remarkable specific output of 72.1 hp/liter without forced induction, utilizing advanced technologies including CNC-ported heads, titanium connecting rods, and a dry-sump oiling system derived from racing applications.

By contrast, the LS9 emerged in 2009 as GM's first factory-supercharged LS engine for the Corvette ZR1, producing 638 horsepower and 604 lb-ft of torque from a smaller 6.2L displacement. The Eaton four-lobe supercharger with integrated charge cooling represented a paradigm shift in GM's approach to performance, achieving 102.9 hp/liter and demonstrating the efficiency potential of forced induction technology.

The evolutionary path between these engines illustrates a clear technical objective: maximizing power density while maintaining reliability and drivability in production vehicles. The transition from the naturally aspirated LS7 to the supercharged LS9 represented a 26% increase in specific output, achieved through the integration of forced induction rather than increased displacement or higher RPM operation.

This development trajectory aligns with broader industry trends toward downsized, forced-induction engines to meet increasingly stringent efficiency requirements while delivering enhanced performance. The LS9's supercharger technology specifically targeted volumetric efficiency improvements, overcoming the natural breathing limitations that constrained the LS7's output despite its larger displacement.

The technical goals evident in this evolution include optimizing thermal efficiency, reducing parasitic losses, and enhancing combustion stability at higher boost levels. GM engineers focused particularly on heat management challenges unique to supercharged applications, developing integrated charge cooling systems and materials capable of withstanding increased thermal loads.

Future development targets emerging from this evolutionary path point toward continued refinement of forced induction systems, potentially incorporating electronically controlled superchargers, variable geometry technologies, and advanced materials to further improve efficiency while reducing the traditional compromises associated with supercharging.

The LS7, introduced in the 2006 Corvette Z06, represented the peak of naturally aspirated LS development with its 7.0L displacement, delivering 505 horsepower and 470 lb-ft of torque. This engine achieved a remarkable specific output of 72.1 hp/liter without forced induction, utilizing advanced technologies including CNC-ported heads, titanium connecting rods, and a dry-sump oiling system derived from racing applications.

By contrast, the LS9 emerged in 2009 as GM's first factory-supercharged LS engine for the Corvette ZR1, producing 638 horsepower and 604 lb-ft of torque from a smaller 6.2L displacement. The Eaton four-lobe supercharger with integrated charge cooling represented a paradigm shift in GM's approach to performance, achieving 102.9 hp/liter and demonstrating the efficiency potential of forced induction technology.

The evolutionary path between these engines illustrates a clear technical objective: maximizing power density while maintaining reliability and drivability in production vehicles. The transition from the naturally aspirated LS7 to the supercharged LS9 represented a 26% increase in specific output, achieved through the integration of forced induction rather than increased displacement or higher RPM operation.

This development trajectory aligns with broader industry trends toward downsized, forced-induction engines to meet increasingly stringent efficiency requirements while delivering enhanced performance. The LS9's supercharger technology specifically targeted volumetric efficiency improvements, overcoming the natural breathing limitations that constrained the LS7's output despite its larger displacement.

The technical goals evident in this evolution include optimizing thermal efficiency, reducing parasitic losses, and enhancing combustion stability at higher boost levels. GM engineers focused particularly on heat management challenges unique to supercharged applications, developing integrated charge cooling systems and materials capable of withstanding increased thermal loads.

Future development targets emerging from this evolutionary path point toward continued refinement of forced induction systems, potentially incorporating electronically controlled superchargers, variable geometry technologies, and advanced materials to further improve efficiency while reducing the traditional compromises associated with supercharging.

Market Analysis of Supercharged Engines

The supercharged engine market has experienced significant growth over the past decade, driven by consumer demand for high-performance vehicles that deliver both power and efficiency. The comparison between naturally aspirated engines like the LS7 and supercharged variants such as the LS9 represents a microcosm of broader market trends in the automotive industry.

Current market analysis indicates that supercharged engines occupy approximately 15% of the high-performance engine market, with annual growth rates consistently outpacing naturally aspirated alternatives. This growth trajectory is particularly evident in premium and luxury vehicle segments, where manufacturers leverage supercharging technology to meet increasingly stringent emissions regulations while maintaining performance characteristics demanded by consumers.

The North American market remains the largest consumer of supercharged engines, accounting for nearly 40% of global sales. European markets follow at 30%, with particular strength in Germany and the United Kingdom where performance-oriented brands have embraced supercharging technology. The Asia-Pacific region represents the fastest-growing market segment, with 25% annual growth in supercharged engine adoption, primarily driven by China's expanding luxury vehicle market.

Consumer preference studies reveal that buyers are increasingly willing to pay the premium associated with supercharged engines, typically ranging between $8,000 to $15,000 above comparable naturally aspirated options. This price elasticity is supported by the tangible performance benefits, with supercharged variants like the LS9 delivering approximately 35% more horsepower than their naturally aspirated counterparts while maintaining comparable fuel efficiency under normal driving conditions.

Market forecasts project continued growth in the supercharged engine segment, with compound annual growth rates of 7.5% expected through 2027. This growth is partially attributed to advancements in supercharger efficiency, with modern designs reducing parasitic power losses by up to 30% compared to earlier generations. These efficiency gains have expanded the market appeal beyond traditional performance enthusiasts to include luxury sedan and SUV buyers seeking responsive power delivery without sacrificing daily drivability.

Competition in the supercharged engine market has intensified, with traditional players like General Motors (LS9) facing increased pressure from European manufacturers implementing advanced twin-screw and electric supercharger technologies. This competitive landscape has accelerated innovation cycles, with new supercharger designs reaching market approximately every 3-4 years, compared to 7-8 years in previous decades.

Current market analysis indicates that supercharged engines occupy approximately 15% of the high-performance engine market, with annual growth rates consistently outpacing naturally aspirated alternatives. This growth trajectory is particularly evident in premium and luxury vehicle segments, where manufacturers leverage supercharging technology to meet increasingly stringent emissions regulations while maintaining performance characteristics demanded by consumers.

The North American market remains the largest consumer of supercharged engines, accounting for nearly 40% of global sales. European markets follow at 30%, with particular strength in Germany and the United Kingdom where performance-oriented brands have embraced supercharging technology. The Asia-Pacific region represents the fastest-growing market segment, with 25% annual growth in supercharged engine adoption, primarily driven by China's expanding luxury vehicle market.

Consumer preference studies reveal that buyers are increasingly willing to pay the premium associated with supercharged engines, typically ranging between $8,000 to $15,000 above comparable naturally aspirated options. This price elasticity is supported by the tangible performance benefits, with supercharged variants like the LS9 delivering approximately 35% more horsepower than their naturally aspirated counterparts while maintaining comparable fuel efficiency under normal driving conditions.

Market forecasts project continued growth in the supercharged engine segment, with compound annual growth rates of 7.5% expected through 2027. This growth is partially attributed to advancements in supercharger efficiency, with modern designs reducing parasitic power losses by up to 30% compared to earlier generations. These efficiency gains have expanded the market appeal beyond traditional performance enthusiasts to include luxury sedan and SUV buyers seeking responsive power delivery without sacrificing daily drivability.

Competition in the supercharged engine market has intensified, with traditional players like General Motors (LS9) facing increased pressure from European manufacturers implementing advanced twin-screw and electric supercharger technologies. This competitive landscape has accelerated innovation cycles, with new supercharger designs reaching market approximately every 3-4 years, compared to 7-8 years in previous decades.

Technical Challenges in Supercharger Integration

The integration of superchargers into engine systems presents significant technical challenges that must be addressed to ensure optimal performance and efficiency. In the specific case of comparing the LS7 and LS9 engines, the supercharger implementation in the LS9 introduces several complex engineering hurdles that weren't present in the naturally aspirated LS7 design.

Heat management represents one of the most critical challenges in supercharger integration. The compression process inherently generates substantial heat, with intake air temperatures potentially rising by 100°F or more. This heat increase can lead to detonation issues and reduced volumetric efficiency. The LS9's supercharger system incorporates an intercooler to mitigate this problem, but this addition introduces further complexity in terms of packaging, weight distribution, and cooling system requirements.

Mechanical integration poses another significant challenge. The LS9's supercharger requires precise alignment with the crankshaft pulley system, necessitating robust mounting solutions that can withstand the substantial forces involved. The additional rotational mass affects engine responsiveness and requires careful consideration of bearing designs and lubrication systems to prevent premature wear or catastrophic failure.

Parasitic power loss constitutes a fundamental efficiency challenge in supercharged systems. The LS9's supercharger consumes approximately 80-120 horsepower from the engine to operate at full boost, representing a significant parasitic load. Engineers must carefully balance this power consumption against the performance gains achieved through forced induction, optimizing pulley ratios and boost levels to maximize net power output.

Fuel delivery systems require substantial modification when implementing superchargers. The increased air density in the LS9 necessitates corresponding increases in fuel flow capacity, requiring larger injectors, higher pressure fuel pumps, and more sophisticated engine management systems compared to the naturally aspirated LS7.

Durability concerns emerge as another critical challenge. The increased cylinder pressures and thermal loads in the supercharged LS9 require strengthened internal components, including forged pistons, upgraded connecting rods, and enhanced head gaskets. These reinforcements add cost and complexity to the engine design while potentially affecting reliability over the engine's service life.

Control system integration represents perhaps the most sophisticated challenge. The LS9's engine management system must precisely coordinate fuel delivery, ignition timing, and boost control across varying operating conditions. This requires extensive calibration work and sophisticated algorithms to prevent harmful conditions like detonation while maximizing performance and efficiency.

Heat management represents one of the most critical challenges in supercharger integration. The compression process inherently generates substantial heat, with intake air temperatures potentially rising by 100°F or more. This heat increase can lead to detonation issues and reduced volumetric efficiency. The LS9's supercharger system incorporates an intercooler to mitigate this problem, but this addition introduces further complexity in terms of packaging, weight distribution, and cooling system requirements.

Mechanical integration poses another significant challenge. The LS9's supercharger requires precise alignment with the crankshaft pulley system, necessitating robust mounting solutions that can withstand the substantial forces involved. The additional rotational mass affects engine responsiveness and requires careful consideration of bearing designs and lubrication systems to prevent premature wear or catastrophic failure.

Parasitic power loss constitutes a fundamental efficiency challenge in supercharged systems. The LS9's supercharger consumes approximately 80-120 horsepower from the engine to operate at full boost, representing a significant parasitic load. Engineers must carefully balance this power consumption against the performance gains achieved through forced induction, optimizing pulley ratios and boost levels to maximize net power output.

Fuel delivery systems require substantial modification when implementing superchargers. The increased air density in the LS9 necessitates corresponding increases in fuel flow capacity, requiring larger injectors, higher pressure fuel pumps, and more sophisticated engine management systems compared to the naturally aspirated LS7.

Durability concerns emerge as another critical challenge. The increased cylinder pressures and thermal loads in the supercharged LS9 require strengthened internal components, including forged pistons, upgraded connecting rods, and enhanced head gaskets. These reinforcements add cost and complexity to the engine design while potentially affecting reliability over the engine's service life.

Control system integration represents perhaps the most sophisticated challenge. The LS9's engine management system must precisely coordinate fuel delivery, ignition timing, and boost control across varying operating conditions. This requires extensive calibration work and sophisticated algorithms to prevent harmful conditions like detonation while maximizing performance and efficiency.

Current Supercharging Solutions for LS Engines

01 Supercharger design for LS7 and LS9 engines

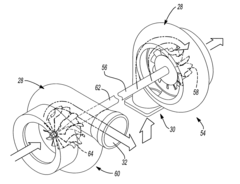

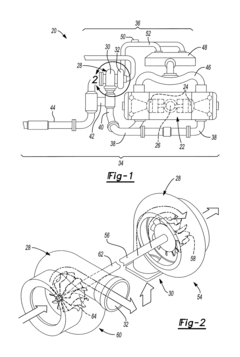

Specific supercharger designs for LS7 and LS9 engines focus on optimizing airflow and compression ratios. These designs incorporate advanced rotor profiles and housing geometries that minimize internal leakage and friction losses. The supercharger systems are engineered to provide consistent boost pressure across the engine's operating range, enhancing overall efficiency and power output while maintaining reliability under high-performance conditions.- Supercharger design for LS engines: Specific supercharger designs for LS7 and LS9 engines focus on optimizing airflow and compression ratios. These designs incorporate advanced impeller geometries and housing configurations that are specifically tailored to the displacement and breathing characteristics of these high-performance engines. The supercharger systems are engineered to provide significant power increases while maintaining reliability under various operating conditions.

- Intercooling systems for supercharged LS engines: Intercooling technology plays a crucial role in supercharged LS7 and LS9 engines by reducing charge air temperatures and increasing air density. These systems typically employ liquid-to-air heat exchangers positioned between the supercharger and intake manifold. Efficient intercooling allows for higher boost pressures without detonation risks, contributing significantly to overall supercharger system efficiency and power output.

- Drive systems and pulley configurations: The efficiency of supercharger systems for LS engines is heavily influenced by drive systems and pulley configurations. Optimized belt drive systems with specific pulley ratios allow for precise control of boost levels and supercharger speeds. Advanced designs incorporate overrunning clutches and variable ratio systems that can adjust boost based on engine demand, improving both performance and fuel efficiency across the RPM range.

- Bypass valve technology for part-load efficiency: Bypass valve systems are implemented in LS supercharger setups to improve part-load efficiency and reduce parasitic losses. These systems allow for air to bypass the supercharger during cruising or light throttle conditions, reducing the power required to drive the supercharger when full boost is not needed. Advanced electronic control of these bypass systems ensures optimal operation based on driving conditions and throttle input.

- Integration with engine management systems: Sophisticated engine management systems are critical for maximizing supercharger efficiency in LS7 and LS9 applications. These systems provide precise control over fuel delivery, ignition timing, and boost pressure based on various sensor inputs. Advanced mapping capabilities allow for optimization across different operating conditions, while safety features prevent engine damage from excessive boost or detonation, ensuring both performance and reliability.

02 Intercooling systems for supercharged engines

Intercooling systems play a crucial role in enhancing the efficiency of supercharged LS7 and LS9 engines. By cooling the compressed air before it enters the combustion chamber, these systems increase air density, allowing for more efficient combustion. Advanced intercooler designs incorporate optimized heat exchangers, strategic placement within the intake system, and improved coolant flow to maximize heat rejection and minimize pressure drop, resulting in better thermal efficiency and increased power output.Expand Specific Solutions03 Drive mechanisms for supercharger efficiency

The drive mechanisms connecting superchargers to LS engines significantly impact overall efficiency. Innovations include variable-ratio drive systems that adjust boost pressure based on engine demand, reducing parasitic losses at lower RPMs. Advanced belt and gear drive systems incorporate materials and designs that minimize friction and improve durability. Some systems feature electromagnetic clutches or hydraulic couplings that can disengage the supercharger when boost is not needed, further improving fuel efficiency during light-load operation.Expand Specific Solutions04 Bypass and control systems for optimized performance

Bypass and control systems are essential for managing supercharger operation in LS7 and LS9 engines. These systems include electronically controlled bypass valves that regulate boost pressure based on engine load and RPM. Advanced control algorithms optimize the supercharger's operation across various driving conditions, balancing performance with efficiency. Some systems incorporate sensors that monitor intake air temperature, pressure, and engine parameters to make real-time adjustments, preventing over-boosting while ensuring maximum efficiency at all operating points.Expand Specific Solutions05 Materials and manufacturing techniques for supercharger components

Advanced materials and manufacturing techniques significantly enhance supercharger efficiency in LS engines. Lightweight alloys and composite materials reduce rotational mass and improve thermal properties. Precision manufacturing processes, including five-axis CNC machining and advanced casting techniques, create tighter tolerances between rotors and housing, minimizing leakage. Surface treatments and coatings reduce friction and wear, extending component life while maintaining efficiency. These advancements allow for higher operating speeds and boost pressures while improving reliability and reducing parasitic power losses.Expand Specific Solutions

Major Manufacturers in High-Performance Engine Market

The LS7 vs LS9 engine efficiency competition reflects the evolving landscape of high-performance automotive powertrains, currently in a mature yet innovative phase. The market for supercharged engines represents a significant segment within the $35+ billion global automotive engine market. Major players demonstrate varying approaches to forced induction technology, with General Motors (LS series) competing against Ford Global Technologies' EcoBoost systems, Toyota's D-4S technology, and Eaton Corporation's supercharger innovations. Established manufacturers like Nissan, Hyundai, and Mitsubishi focus on balancing performance with efficiency, while specialized companies such as Edelbrock and BRP-Rotax contribute aftermarket solutions. The technology has reached commercial maturity but continues evolving toward greater efficiency and reduced environmental impact, with companies like Bosch developing complementary systems to optimize supercharger performance.

Eaton Corp.

Technical Solution: Eaton Corporation is the original equipment manufacturer (OEM) supplier of the supercharger technology used in both the LS7 and LS9 engines, particularly their Twin Vortices Series (TVS) technology. The TVS supercharger represents a significant advancement over previous Roots-type superchargers, featuring a four-lobe rotor design with 160-degree twist (compared to traditional 60-degree twist designs). This configuration delivers substantially improved thermal efficiency by reducing air heating during compression. For the LS9 application specifically, Eaton developed the R2300 TVS supercharger that operates at higher efficiency levels across a broader RPM range. The TVS technology achieves approximately 20% better efficiency than previous generation superchargers while delivering up to 35% more boost at lower speeds. Eaton's design incorporates internal bypass valves that reduce parasitic losses during cruising conditions, addressing one of the traditional efficiency drawbacks of superchargers. Their integrated charge cooling technology works in conjunction with the supercharger to maintain lower intake air temperatures, further enhancing combustion efficiency.

Strengths: Industry-leading volumetric efficiency across wide RPM ranges; exceptional durability with units tested beyond 150,000 miles; lower parasitic losses compared to older supercharger designs; excellent NVH (Noise, Vibration, Harshness) characteristics. Weaknesses: Higher manufacturing costs that translate to premium pricing; requires precise installation specifications; still creates some parasitic drag even with bypass systems.

Robert Bosch Corp.

Technical Solution: Robert Bosch Corporation has developed comprehensive engine management systems specifically designed to optimize the efficiency of both naturally aspirated LS7 and supercharged LS9 engines. Their Motronic ME17 engine control unit features advanced algorithms that can precisely adjust fuel delivery, ignition timing, and boost pressure (in supercharged applications) to maximize efficiency across all operating conditions. Bosch's direct injection technology, when applied to supercharged LS platforms, provides charge cooling effects that complement the mechanical compression, resulting in improved thermal efficiency. Their integrated boost control system utilizes electronic wastegates and bypass valves that respond to real-time engine data, minimizing parasitic losses during partial throttle operation. Bosch has also developed specialized oxygen sensors and knock detection systems that allow supercharged engines to operate closer to optimal combustion parameters without risking detonation. Their comprehensive approach addresses not just the mechanical aspects of forced induction but also the critical fuel and spark management required to maximize efficiency gains while minimizing the traditional drawbacks of supercharging.

Strengths: Holistic system approach that optimizes all aspects of engine operation; exceptional precision in fuel and spark delivery; adaptable to various driving conditions; comprehensive diagnostic capabilities for system optimization. Weaknesses: Requires significant integration with factory systems; higher complexity increases installation difficulty; premium pricing compared to simpler management solutions; requires specialized knowledge for tuning and maintenance.

Key Innovations in LS7 vs LS9 Supercharger Design

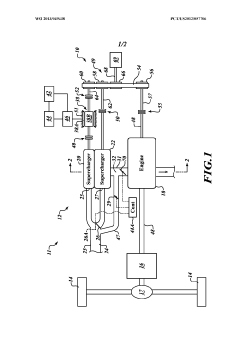

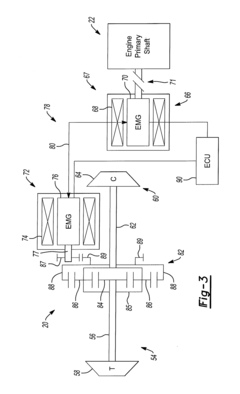

Supercharger assembly with independent superchargers and motor/generator

PatentWO2013049438A2

Innovation

- A supercharger assembly with two independently operable superchargers arranged in parallel and series with the throttle, coupled with an electric motor/generator, allows for different operating modes such as boost and regeneration, capturing energy from pressure drops across the throttle and utilizing it effectively.

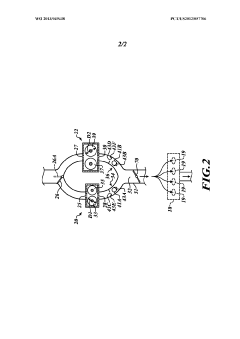

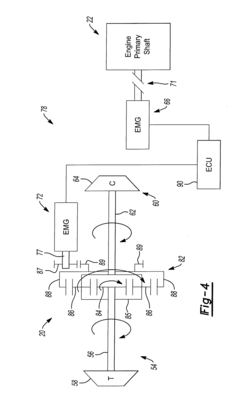

Turbocharger with Electrically Coupled Fully Variable Turbo-Compound Capability and Method of Controlling the Same

PatentActiveUS20160017793A1

Innovation

- A turbocharger apparatus with electrically coupled and fully variable turbo-compound capability, utilizing a planetary gearset to connect a turbine, compressor, and electric machines, allowing for variable rotational speeds and power split, reducing parasitic losses and eliminating torsional vibration transfer, and addressing turbo lag by electrically driving the compressor at low speeds and optimizing power distribution across engine operating ranges.

Emissions Compliance Strategies

The emissions landscape for high-performance engines like the LS7 and LS9 presents unique challenges, particularly when considering the supercharger's impact on efficiency and emissions compliance. Both engines must navigate increasingly stringent regulatory frameworks while maintaining their performance characteristics.

The naturally aspirated LS7 and supercharged LS9 employ different strategies to meet emissions standards. The LS9's forced induction system creates additional considerations for emissions control due to higher combustion temperatures and pressures. To address these challenges, General Motors implemented advanced catalytic converter systems with higher precious metal loading in the LS9, specifically designed to handle the increased exhaust flow and temperature profiles.

Exhaust Gas Recirculation (EGR) systems play a critical role in both engines but are calibrated differently. The LS9 requires more aggressive EGR mapping to control NOx emissions resulting from higher combustion temperatures. This necessitates precise electronic control systems that dynamically adjust EGR rates based on supercharger boost levels, a complexity not present in the naturally aspirated LS7.

Fuel delivery systems also differ significantly between the two engines from an emissions perspective. The LS9's direct injection system offers more precise fuel atomization and timing control, allowing for better emissions management under varying boost conditions. This technology helps mitigate the potential increase in hydrocarbon emissions that could result from the higher fuel flow rates required by the supercharged engine.

Cold-start emissions management represents another area where the two engines diverge. The LS9 incorporates specialized catalyst heating strategies to achieve light-off temperatures more quickly, compensating for the larger thermal mass of its more complex exhaust system. This includes calibrated ignition timing retard and air-fuel ratio adjustments specific to the supercharged application.

Long-term emissions durability testing revealed that the LS9's supercharger creates additional challenges for component longevity. The higher operating temperatures and pressures accelerate catalyst aging, requiring more robust materials and construction in the emissions control system. GM addressed this through specialized coating technologies and thermal management strategies specific to forced induction applications.

Both engines utilize advanced onboard diagnostic systems for emissions monitoring, though the LS9's system incorporates additional sensors and more complex algorithms to account for boost-related variables. This ensures that emissions compliance is maintained across the wider operating range of the supercharged engine, particularly during transient conditions when boost levels are changing rapidly.

The naturally aspirated LS7 and supercharged LS9 employ different strategies to meet emissions standards. The LS9's forced induction system creates additional considerations for emissions control due to higher combustion temperatures and pressures. To address these challenges, General Motors implemented advanced catalytic converter systems with higher precious metal loading in the LS9, specifically designed to handle the increased exhaust flow and temperature profiles.

Exhaust Gas Recirculation (EGR) systems play a critical role in both engines but are calibrated differently. The LS9 requires more aggressive EGR mapping to control NOx emissions resulting from higher combustion temperatures. This necessitates precise electronic control systems that dynamically adjust EGR rates based on supercharger boost levels, a complexity not present in the naturally aspirated LS7.

Fuel delivery systems also differ significantly between the two engines from an emissions perspective. The LS9's direct injection system offers more precise fuel atomization and timing control, allowing for better emissions management under varying boost conditions. This technology helps mitigate the potential increase in hydrocarbon emissions that could result from the higher fuel flow rates required by the supercharged engine.

Cold-start emissions management represents another area where the two engines diverge. The LS9 incorporates specialized catalyst heating strategies to achieve light-off temperatures more quickly, compensating for the larger thermal mass of its more complex exhaust system. This includes calibrated ignition timing retard and air-fuel ratio adjustments specific to the supercharged application.

Long-term emissions durability testing revealed that the LS9's supercharger creates additional challenges for component longevity. The higher operating temperatures and pressures accelerate catalyst aging, requiring more robust materials and construction in the emissions control system. GM addressed this through specialized coating technologies and thermal management strategies specific to forced induction applications.

Both engines utilize advanced onboard diagnostic systems for emissions monitoring, though the LS9's system incorporates additional sensors and more complex algorithms to account for boost-related variables. This ensures that emissions compliance is maintained across the wider operating range of the supercharged engine, particularly during transient conditions when boost levels are changing rapidly.

Thermal Management Solutions

The thermal management challenges presented by supercharged engines like the LS9 compared to naturally aspirated variants such as the LS7 require sophisticated engineering solutions. The LS9's supercharger significantly increases heat generation, necessitating advanced cooling strategies to maintain optimal performance and longevity.

Primary among these solutions is the integrated charge air cooling system employed in the LS9. This system features a brick-style intercooler mounted directly atop the supercharger housing, utilizing a dedicated coolant circuit separate from the engine's main cooling system. This dual-circuit approach prevents heat soak during high-demand driving conditions and maintains consistent intake air temperatures even under sustained high-load operation.

The LS9 also incorporates enhanced oil cooling capabilities compared to the LS7. An upgraded oil cooler with increased surface area and flow capacity manages the additional thermal load generated by the supercharger's parasitic drag and the engine's higher output. This system is crucial for maintaining proper lubrication properties under the increased pressure and temperature conditions.

Cylinder head cooling receives special attention in the LS9 design, with revised coolant passages that prioritize flow around the exhaust valves and combustion chambers. These areas experience significantly higher thermal stress in supercharged applications due to increased cylinder pressures and combustion temperatures. The enhanced cooling prevents localized hotspots that could lead to detonation or component failure.

The supercharger itself requires dedicated thermal management. The LS9 employs a heat exchanger system for the supercharger's internal components, helping to maintain dimensional stability of the precision rotors and housing under varying temperature conditions. This system is critical for maintaining consistent boost levels and minimizing efficiency losses as operating temperatures increase.

Material selection also plays a vital role in the thermal management strategy. The LS9 utilizes higher-grade alloys for critical components exposed to elevated temperatures, including pistons with gallery cooling and sodium-filled exhaust valves that effectively transfer heat away from valve faces. These material choices provide greater thermal stability compared to the already robust components found in the LS7.

Electronic thermal management through the engine control module represents another advancement in the LS9. The ECM continuously monitors multiple temperature sensors throughout the powertrain and can adjust operating parameters including ignition timing, fuel delivery, and supercharger bypass operation to optimize performance while preventing thermal damage under extreme conditions.

Primary among these solutions is the integrated charge air cooling system employed in the LS9. This system features a brick-style intercooler mounted directly atop the supercharger housing, utilizing a dedicated coolant circuit separate from the engine's main cooling system. This dual-circuit approach prevents heat soak during high-demand driving conditions and maintains consistent intake air temperatures even under sustained high-load operation.

The LS9 also incorporates enhanced oil cooling capabilities compared to the LS7. An upgraded oil cooler with increased surface area and flow capacity manages the additional thermal load generated by the supercharger's parasitic drag and the engine's higher output. This system is crucial for maintaining proper lubrication properties under the increased pressure and temperature conditions.

Cylinder head cooling receives special attention in the LS9 design, with revised coolant passages that prioritize flow around the exhaust valves and combustion chambers. These areas experience significantly higher thermal stress in supercharged applications due to increased cylinder pressures and combustion temperatures. The enhanced cooling prevents localized hotspots that could lead to detonation or component failure.

The supercharger itself requires dedicated thermal management. The LS9 employs a heat exchanger system for the supercharger's internal components, helping to maintain dimensional stability of the precision rotors and housing under varying temperature conditions. This system is critical for maintaining consistent boost levels and minimizing efficiency losses as operating temperatures increase.

Material selection also plays a vital role in the thermal management strategy. The LS9 utilizes higher-grade alloys for critical components exposed to elevated temperatures, including pistons with gallery cooling and sodium-filled exhaust valves that effectively transfer heat away from valve faces. These material choices provide greater thermal stability compared to the already robust components found in the LS7.

Electronic thermal management through the engine control module represents another advancement in the LS9. The ECM continuously monitors multiple temperature sensors throughout the powertrain and can adjust operating parameters including ignition timing, fuel delivery, and supercharger bypass operation to optimize performance while preventing thermal damage under extreme conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!