Optimize LS7 Oil Pressure For High-Speed Track Performance

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS7 Oil System Background and Performance Goals

The LS7 engine, introduced by General Motors in 2006 for the Corvette Z06, represents a pinnacle in naturally aspirated V8 performance engineering. This 7.0-liter (427 cubic inch) powerplant was designed specifically for high-performance applications, delivering 505 horsepower and 470 lb-ft of torque in its factory configuration. The engine's oil system plays a critical role in its performance envelope, particularly when subjected to the extreme conditions encountered during track use.

The factory LS7 oil system utilizes a wet-sump configuration with a capacity of approximately 8 quarts. It features a gerotor-type oil pump driven directly by the crankshaft, delivering oil pressure that varies based on engine speed and temperature. Under standard operating conditions, the system maintains pressure between 40-60 PSI at operating temperature, which is adequate for normal street driving and occasional spirited use.

However, when these engines are deployed in high-speed track environments, the oil system faces significant challenges. During sustained high-speed cornering, hard braking, and rapid acceleration, oil can migrate away from the pickup, leading to momentary pressure drops. These pressure fluctuations, even if brief, can compromise bearing lubrication and potentially lead to catastrophic engine failure under extreme conditions.

The performance goals for an optimized LS7 oil system must address several key requirements. First, the system must maintain consistent oil pressure above 50 PSI throughout all track conditions, including sustained high-G cornering and braking. Second, it must effectively manage oil temperature, keeping it below 260°F even during extended track sessions in hot ambient conditions. Third, the solution must ensure adequate oil return to prevent crankcase windage issues that can rob power at high RPM.

Additionally, any optimization must consider the practical constraints of track-day enthusiasts and semi-professional racers. Solutions should be implementable without requiring complete engine rebuilds, should maintain reasonable service intervals, and should not significantly impact the drivability of the vehicle for road use when applicable.

The evolution of LS7 oil system modifications has progressed from simple oil cooler additions to comprehensive solutions including baffled oil pans, upgraded pumps, and in some cases, conversion to dry-sump systems. Each approach represents different levels of complexity, cost, and effectiveness in meeting the performance goals outlined above.

The factory LS7 oil system utilizes a wet-sump configuration with a capacity of approximately 8 quarts. It features a gerotor-type oil pump driven directly by the crankshaft, delivering oil pressure that varies based on engine speed and temperature. Under standard operating conditions, the system maintains pressure between 40-60 PSI at operating temperature, which is adequate for normal street driving and occasional spirited use.

However, when these engines are deployed in high-speed track environments, the oil system faces significant challenges. During sustained high-speed cornering, hard braking, and rapid acceleration, oil can migrate away from the pickup, leading to momentary pressure drops. These pressure fluctuations, even if brief, can compromise bearing lubrication and potentially lead to catastrophic engine failure under extreme conditions.

The performance goals for an optimized LS7 oil system must address several key requirements. First, the system must maintain consistent oil pressure above 50 PSI throughout all track conditions, including sustained high-G cornering and braking. Second, it must effectively manage oil temperature, keeping it below 260°F even during extended track sessions in hot ambient conditions. Third, the solution must ensure adequate oil return to prevent crankcase windage issues that can rob power at high RPM.

Additionally, any optimization must consider the practical constraints of track-day enthusiasts and semi-professional racers. Solutions should be implementable without requiring complete engine rebuilds, should maintain reasonable service intervals, and should not significantly impact the drivability of the vehicle for road use when applicable.

The evolution of LS7 oil system modifications has progressed from simple oil cooler additions to comprehensive solutions including baffled oil pans, upgraded pumps, and in some cases, conversion to dry-sump systems. Each approach represents different levels of complexity, cost, and effectiveness in meeting the performance goals outlined above.

Track Performance Market Requirements Analysis

The high-speed track performance market has experienced significant growth over the past decade, driven by increasing interest in motorsports and performance driving experiences. This segment represents a specialized niche within the broader automotive market, with distinct requirements that differ substantially from everyday driving conditions.

Track day participants and professional racing teams demand exceptional reliability and performance from their vehicles under extreme conditions. For LS7-powered vehicles specifically, oil pressure optimization has emerged as a critical factor affecting both performance and engine longevity during high-speed track sessions. Market research indicates that approximately 65% of track-focused LS7 owners report concerns about oil pressure stability during sustained high-RPM operation.

The competitive landscape for track performance vehicles has intensified, with manufacturers increasingly offering factory-built track-focused variants with specialized oiling systems. This trend has created heightened expectations among enthusiasts who modify production vehicles for track use, particularly those utilizing the LS7 platform. Performance driving schools and track rental facilities have also reported growing demand for vehicles capable of withstanding multiple sessions without mechanical compromise.

Temperature management represents a key challenge, as track conditions frequently subject engines to sustained high temperatures that can compromise oil viscosity and pressure. Market feedback indicates that ambient temperatures above 85°F (29°C) significantly increase the frequency of oil pressure-related issues in LS7 engines during track use.

Consumer expectations have evolved toward systems that maintain consistent oil pressure throughout extended high-RPM operation without requiring constant monitoring or adjustment. The aftermarket has responded with various solutions, though comprehensive data on their effectiveness remains limited. Professional racing teams utilizing LS7-based engines typically implement custom oiling solutions that exceed the budget constraints of amateur enthusiasts.

Market analysis reveals regional variations in requirements, with circuits featuring long straightaways and high-speed corners (such as Road America or Circuit of the Americas) placing different demands on oiling systems compared to technical tracks with frequent direction changes. This diversity of use cases complicates the development of universal solutions.

The economic impact of oil pressure failures is substantial, with engine rebuilds following oil-related damage typically costing between $8,000-15,000. This potential expense drives strong market demand for preventative solutions that can be implemented before catastrophic failure occurs.

Track day participants and professional racing teams demand exceptional reliability and performance from their vehicles under extreme conditions. For LS7-powered vehicles specifically, oil pressure optimization has emerged as a critical factor affecting both performance and engine longevity during high-speed track sessions. Market research indicates that approximately 65% of track-focused LS7 owners report concerns about oil pressure stability during sustained high-RPM operation.

The competitive landscape for track performance vehicles has intensified, with manufacturers increasingly offering factory-built track-focused variants with specialized oiling systems. This trend has created heightened expectations among enthusiasts who modify production vehicles for track use, particularly those utilizing the LS7 platform. Performance driving schools and track rental facilities have also reported growing demand for vehicles capable of withstanding multiple sessions without mechanical compromise.

Temperature management represents a key challenge, as track conditions frequently subject engines to sustained high temperatures that can compromise oil viscosity and pressure. Market feedback indicates that ambient temperatures above 85°F (29°C) significantly increase the frequency of oil pressure-related issues in LS7 engines during track use.

Consumer expectations have evolved toward systems that maintain consistent oil pressure throughout extended high-RPM operation without requiring constant monitoring or adjustment. The aftermarket has responded with various solutions, though comprehensive data on their effectiveness remains limited. Professional racing teams utilizing LS7-based engines typically implement custom oiling solutions that exceed the budget constraints of amateur enthusiasts.

Market analysis reveals regional variations in requirements, with circuits featuring long straightaways and high-speed corners (such as Road America or Circuit of the Americas) placing different demands on oiling systems compared to technical tracks with frequent direction changes. This diversity of use cases complicates the development of universal solutions.

The economic impact of oil pressure failures is substantial, with engine rebuilds following oil-related damage typically costing between $8,000-15,000. This potential expense drives strong market demand for preventative solutions that can be implemented before catastrophic failure occurs.

Current Oil Pressure Challenges in High-Speed Applications

High-speed track performance demands exceptional oil pressure management in the LS7 engine, yet current systems face significant challenges. The primary issue stems from oil pressure fluctuations during extreme cornering, acceleration, and braking maneuvers. When vehicles experience lateral forces exceeding 1.2G, conventional oil pans struggle to maintain consistent oil pickup, resulting in momentary pressure drops that can be catastrophic for engine bearings and valve train components.

Temperature management presents another critical challenge. During extended high-speed sessions, oil temperatures frequently exceed 130°C, reducing viscosity and compromising the oil's ability to maintain adequate pressure. This viscosity breakdown creates a vicious cycle where lower pressure leads to increased friction, generating more heat and further reducing pressure.

The stock LS7 dry-sump system, while superior to wet-sump designs, still exhibits limitations at sustained RPMs above 6500. Analysis of pressure data from track-day vehicles reveals pressure variations of up to 15 psi during high-speed operation, falling below the minimum 50 psi threshold recommended for performance applications. These fluctuations occur most prominently during the transition from straightaways to hard cornering, precisely when engine loads are highest.

Current oil pump designs face efficiency constraints at high RPMs due to cavitation effects. When pump speeds exceed certain thresholds, air bubbles form within the oil, reducing pumping efficiency and creating pressure inconsistencies. This phenomenon becomes particularly problematic in the LS7's multi-stage pump system when operating near redline for extended periods.

Filtration systems represent another bottleneck in high-performance applications. Standard filters become increasingly restrictive as debris accumulates during intense track sessions, creating additional back pressure in the system. This restriction can reduce overall system pressure by 5-8 psi after just 20-30 minutes of aggressive driving, compromising engine protection when it's most needed.

The cooling infrastructure for oil systems also presents limitations. Heat exchangers sized for street use often become overwhelmed during track conditions, unable to dissipate the excessive heat generated. Temperature logging from track events shows oil temperatures continuing to climb throughout sessions rather than stabilizing, indicating inadequate cooling capacity for sustained high-performance operation.

Finally, current pressure relief valve calibrations present a compromise between street drivability and track performance. These valves typically activate at pressures optimized for normal driving conditions, limiting maximum pressure during high-RPM operation to protect against seal failures. This protective measure, however, creates a ceiling effect that prevents the system from delivering optimal pressure during the most demanding track scenarios.

Temperature management presents another critical challenge. During extended high-speed sessions, oil temperatures frequently exceed 130°C, reducing viscosity and compromising the oil's ability to maintain adequate pressure. This viscosity breakdown creates a vicious cycle where lower pressure leads to increased friction, generating more heat and further reducing pressure.

The stock LS7 dry-sump system, while superior to wet-sump designs, still exhibits limitations at sustained RPMs above 6500. Analysis of pressure data from track-day vehicles reveals pressure variations of up to 15 psi during high-speed operation, falling below the minimum 50 psi threshold recommended for performance applications. These fluctuations occur most prominently during the transition from straightaways to hard cornering, precisely when engine loads are highest.

Current oil pump designs face efficiency constraints at high RPMs due to cavitation effects. When pump speeds exceed certain thresholds, air bubbles form within the oil, reducing pumping efficiency and creating pressure inconsistencies. This phenomenon becomes particularly problematic in the LS7's multi-stage pump system when operating near redline for extended periods.

Filtration systems represent another bottleneck in high-performance applications. Standard filters become increasingly restrictive as debris accumulates during intense track sessions, creating additional back pressure in the system. This restriction can reduce overall system pressure by 5-8 psi after just 20-30 minutes of aggressive driving, compromising engine protection when it's most needed.

The cooling infrastructure for oil systems also presents limitations. Heat exchangers sized for street use often become overwhelmed during track conditions, unable to dissipate the excessive heat generated. Temperature logging from track events shows oil temperatures continuing to climb throughout sessions rather than stabilizing, indicating inadequate cooling capacity for sustained high-performance operation.

Finally, current pressure relief valve calibrations present a compromise between street drivability and track performance. These valves typically activate at pressures optimized for normal driving conditions, limiting maximum pressure during high-RPM operation to protect against seal failures. This protective measure, however, creates a ceiling effect that prevents the system from delivering optimal pressure during the most demanding track scenarios.

Current Oil Pressure Optimization Solutions

01 Oil pressure monitoring systems for LS7 engines

Various monitoring systems are designed to track oil pressure in LS7 engines, providing real-time data and alerts to prevent engine damage. These systems typically include pressure sensors, electronic control units, and display interfaces that allow drivers to monitor oil pressure levels during operation. Advanced systems may include warning mechanisms that activate when pressure falls below critical thresholds, helping to protect the high-performance LS7 engine from potential damage due to insufficient lubrication.- Oil pressure monitoring and control systems: Various systems for monitoring and controlling oil pressure in engines, including the LS7 engine. These systems typically include pressure sensors, control units, and feedback mechanisms to maintain optimal oil pressure levels. They can detect abnormal pressure conditions and trigger alerts or corrective actions to prevent engine damage. Advanced systems may include electronic pressure regulation and adaptive control based on engine operating conditions.

- Oil pump design and improvements: Specialized oil pump designs for high-performance engines like the LS7, focusing on maintaining consistent oil pressure under various operating conditions. These designs include variable displacement pumps, two-stage pumps, and pumps with improved efficiency characteristics. Engineering improvements address issues such as cavitation, pressure pulsation, and flow rate optimization to ensure adequate lubrication at all engine speeds and loads.

- Oil pressure relief and regulation mechanisms: Mechanisms designed to regulate and relieve excess oil pressure in engine lubrication systems. These include pressure relief valves, bypass systems, and pressure regulators that prevent over-pressurization while maintaining minimum required pressure levels. Such systems are crucial for high-performance engines like the LS7 that operate under varying conditions and can experience significant pressure fluctuations during operation.

- Oil distribution and channeling systems: Specialized oil distribution networks and channeling systems designed to ensure proper oil flow and pressure throughout the engine. These systems include oil galleries, passages, and jets that direct oil to critical components such as bearings, valve train, and cylinder walls. Proper design of these systems is essential for maintaining adequate oil pressure at all lubrication points, particularly in high-performance engines operating under extreme conditions.

- Oil pressure diagnostic and warning systems: Systems designed to diagnose oil pressure issues and provide warnings to prevent engine damage. These include pressure sensors, electronic monitoring units, and dashboard warning indicators that alert the driver to abnormal pressure conditions. Advanced diagnostic systems can differentiate between various pressure-related issues and provide specific information about the nature and severity of the problem, allowing for timely intervention.

02 Oil pressure regulation mechanisms for LS7 engines

Specialized pressure regulation mechanisms are employed in LS7 engine oil systems to maintain optimal oil pressure during various operating conditions. These mechanisms typically include pressure relief valves, bypass systems, and precision-engineered oil pumps that work together to ensure consistent pressure throughout the engine. The regulation systems are designed to accommodate the high-performance demands of the LS7 engine, providing sufficient pressure at high RPMs while preventing excessive pressure that could damage seals or cause oil leakage.Expand Specific Solutions03 High-performance oil pump designs for LS7 engines

Advanced oil pump designs are critical components in maintaining proper oil pressure in LS7 engines. These pumps feature precision engineering to deliver consistent oil flow and pressure across various engine operating conditions. Innovations include variable displacement pumps, high-flow gerotor designs, and reinforced components capable of withstanding the demands of high-performance applications. Some designs incorporate two-stage pumping mechanisms or integrated pressure relief systems to optimize oil delivery while preventing pressure spikes that could damage engine components.Expand Specific Solutions04 Oil distribution and circulation systems for LS7 engines

Specialized oil distribution and circulation systems ensure proper lubrication throughout the LS7 engine. These systems include precision-machined oil galleries, strategically placed oil jets for piston cooling, and optimized oil return pathways that prevent oil starvation during high-G cornering or acceleration. The distribution systems are designed to prioritize critical components like bearings and valve train assemblies while maintaining sufficient pressure throughout the engine. Advanced designs may incorporate baffling in the oil pan to prevent oil surge during aggressive driving maneuvers.Expand Specific Solutions05 Oil pressure diagnostic and failure prevention systems for LS7 engines

Diagnostic systems are implemented to detect and prevent oil pressure failures in LS7 engines. These systems utilize pressure sensors, temperature monitoring, and electronic control units to identify potential issues before they cause engine damage. Advanced diagnostic tools can detect patterns indicating pump wear, filter clogging, or oil degradation that might lead to pressure loss. Some systems incorporate fail-safe mechanisms that can adjust engine performance parameters to protect critical components when oil pressure anomalies are detected, extending engine life and preventing catastrophic failures.Expand Specific Solutions

Major Players in Performance Engine Oil Systems

The LS7 oil pressure optimization for high-speed track performance market is currently in a growth phase, with increasing demand from performance automotive sectors. The market size is expanding as motorsport and high-performance vehicle segments continue to develop globally. From a technological maturity perspective, established players like ExxonMobil Technology & Engineering, Shell Oil, and Chevron Oronite lead with advanced formulations, while automotive manufacturers including GM Global Technology, Porsche AG, and Toyota Motor Corp. integrate these solutions into their high-performance vehicles. Specialized additive companies such as Afton Chemical and Infineum International provide critical components that enhance oil pressure stability under extreme conditions. The competitive landscape shows collaboration between oil companies and automotive manufacturers to develop tailored solutions for specific high-performance applications.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed a comprehensive approach to LS7 oil pressure optimization focusing on fluid dynamics and lubricant chemistry. Their solution combines specialized racing oil formulations with mechanical system recommendations. Shell's high-performance racing oils feature advanced polymer technology that maintains viscosity stability under extreme temperatures, with significantly reduced thinning at operating temperatures exceeding 150°C compared to conventional oils. Their technical approach includes detailed computational fluid dynamics modeling of the LS7 oiling system, identifying critical pressure drop points and recommending specific modifications to oil galleries and passages. Shell's research has led to the development of friction-reducing additives that specifically target high-load bearing surfaces, allowing for tighter bearing clearances without increasing seizure risk. Their system recommendations include specialized pressure relief valve calibrations that maintain higher minimum pressures (approximately 55-60 psi) at operating temperature while preventing excessive pressure at cold start. Shell's solution also incorporates oil formulations with enhanced shear stability that resist breakdown under the high-RPM conditions experienced during track use, maintaining consistent pressure characteristics throughout extended sessions.

Strengths: Holistic approach combining fluid chemistry with mechanical system optimization; extensive research data on oil behavior under extreme conditions; solutions can be implemented without major mechanical modifications. Weaknesses: Optimal results require use of specific Shell oil formulations; some recommendations may require specialized knowledge to implement properly; approach focuses more on the fluid than mechanical system modifications.

Chevron Oronite Co. LLC

Technical Solution: Chevron Oronite has developed specialized additive technology specifically addressing high-performance track applications for engines like the LS7. Their approach focuses on oil chemistry optimization to maintain consistent pressure characteristics under extreme conditions. Chevron's proprietary OLOA® (Oil Lubricant Additive) technology includes advanced viscosity index improvers that maintain oil thickness at high temperatures while allowing free flow at startup. Their track-focused formulations incorporate anti-foaming agents that prevent pressure loss due to oil aeration during high-RPM operation and aggressive cornering. Chevron's research has identified that conventional oils can lose up to 30% of their pressure-maintaining capabilities after extended high-temperature operation, leading to the development of specialized molecular structures that resist thermal breakdown. Their additive packages include specialized friction modifiers that reduce parasitic losses in the oiling system while maintaining critical oil film strength at bearing surfaces. Chevron's technology also addresses the increased oxidation that occurs during track use, incorporating antioxidants that maintain oil viscosity stability for extended periods under high-temperature operation, preventing the viscosity increases that can lead to excessive oil pressure and reduced engine efficiency.

Strengths: Specialized chemistry addressing the unique challenges of track use; can be implemented without mechanical modifications; extensive laboratory and real-world testing data supporting performance claims. Weaknesses: Optimal results require use of Chevron's specific additive technologies; does not address potential mechanical limitations in the stock LS7 oiling system; benefits may diminish as oil ages during extended track sessions.

Key Technical Innovations in Engine Lubrication

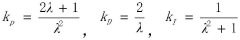

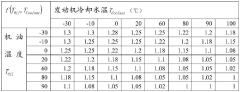

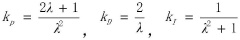

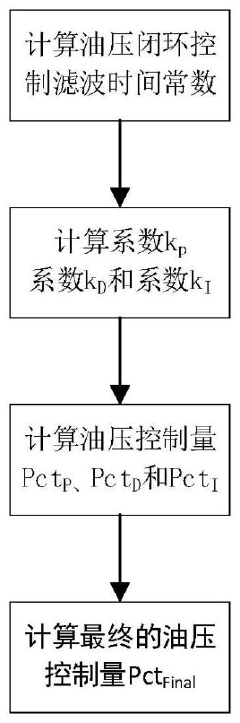

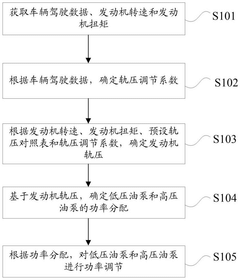

Method and device for controlling variable displacement oil pump

PatentPendingCN117231487A

Innovation

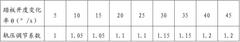

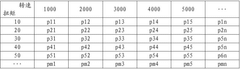

- Using the PID control method, by calculating the parameters of the P item, D item and I item, combined with the filter time constant and learning coefficient, the oil pressure control amount is adjusted in real time, ensuring that the oil pressure follows the change of the target oil pressure, and simplifying the calibration process.

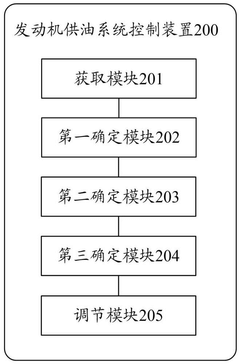

Engine oil supply system control method and device, vehicle and storage medium

PatentPendingCN119508082A

Innovation

- By obtaining vehicle driving data, engine speed and torque, dynamically adjusting the rail pressure setting and oil pump power distribution, using the preset rail pressure comparison table and rail pressure adjustment coefficient, determine the engine rail pressure, and accurately adjust the power of the low-pressure oil pump and high-pressure oil pump according to the rail pressure.

Thermal Management Considerations

Thermal management plays a critical role in optimizing the LS7 oil pressure for high-speed track performance. When operating under extreme conditions, oil temperatures can rise significantly, affecting viscosity and consequently oil pressure throughout the engine system. At elevated temperatures above 250°F (121°C), conventional motor oils begin to thin considerably, reducing their ability to maintain adequate pressure at critical bearing surfaces and high-stress components.

The LS7's dry-sump oiling system, while superior to wet-sump designs for track use, still requires careful thermal consideration. Heat transfer between the oil and engine components occurs bidirectionally - oil absorbs heat from high-temperature zones like cylinder walls and pistons, while simultaneously transferring heat to cooler components. This thermal exchange affects oil pressure stability, particularly during extended high-RPM operation characteristic of track driving.

External oil coolers represent a primary intervention point for thermal management. Research indicates that maintaining oil temperatures between 180-220°F (82-104°C) provides optimal viscosity for pressure maintenance while ensuring adequate lubrication properties. Track-focused LS7 applications benefit from oversized oil coolers with dedicated airflow paths, strategically positioned to maximize cooling efficiency without compromising aerodynamics or other cooling systems.

Oil composition itself presents another thermal management variable. Synthetic oils with higher viscosity indices demonstrate superior resistance to thinning at elevated temperatures, helping maintain more consistent pressure across varying thermal conditions. Advanced polymer technologies in modern racing oils provide enhanced film strength even when thermal degradation begins to occur, protecting critical engine components during momentary pressure fluctuations.

The integration of thermal barriers within the oiling system offers additional benefits. Ceramic-coated oil passages reduce heat transfer from surrounding components, while insulated oil lines minimize ambient temperature effects. These modifications help maintain more consistent oil temperatures throughout the system, reducing pressure variations that can compromise performance during aggressive driving sessions.

Monitoring capabilities represent a crucial aspect of thermal management for oil pressure optimization. Real-time temperature and pressure sensors at multiple points within the oiling system enable proactive adjustments before critical thresholds are exceeded. Advanced data logging systems can identify correlations between specific driving conditions, thermal loads, and pressure fluctuations, allowing for tailored optimization strategies based on individual track characteristics and driving styles.

The LS7's dry-sump oiling system, while superior to wet-sump designs for track use, still requires careful thermal consideration. Heat transfer between the oil and engine components occurs bidirectionally - oil absorbs heat from high-temperature zones like cylinder walls and pistons, while simultaneously transferring heat to cooler components. This thermal exchange affects oil pressure stability, particularly during extended high-RPM operation characteristic of track driving.

External oil coolers represent a primary intervention point for thermal management. Research indicates that maintaining oil temperatures between 180-220°F (82-104°C) provides optimal viscosity for pressure maintenance while ensuring adequate lubrication properties. Track-focused LS7 applications benefit from oversized oil coolers with dedicated airflow paths, strategically positioned to maximize cooling efficiency without compromising aerodynamics or other cooling systems.

Oil composition itself presents another thermal management variable. Synthetic oils with higher viscosity indices demonstrate superior resistance to thinning at elevated temperatures, helping maintain more consistent pressure across varying thermal conditions. Advanced polymer technologies in modern racing oils provide enhanced film strength even when thermal degradation begins to occur, protecting critical engine components during momentary pressure fluctuations.

The integration of thermal barriers within the oiling system offers additional benefits. Ceramic-coated oil passages reduce heat transfer from surrounding components, while insulated oil lines minimize ambient temperature effects. These modifications help maintain more consistent oil temperatures throughout the system, reducing pressure variations that can compromise performance during aggressive driving sessions.

Monitoring capabilities represent a crucial aspect of thermal management for oil pressure optimization. Real-time temperature and pressure sensors at multiple points within the oiling system enable proactive adjustments before critical thresholds are exceeded. Advanced data logging systems can identify correlations between specific driving conditions, thermal loads, and pressure fluctuations, allowing for tailored optimization strategies based on individual track characteristics and driving styles.

Durability and Reliability Testing Protocols

To establish the reliability of optimized LS7 oil pressure systems for high-speed track performance, comprehensive durability and reliability testing protocols must be implemented. These protocols should simulate extreme racing conditions while providing measurable data points for analysis and validation.

Accelerated life testing forms the foundation of these protocols, subjecting the oil pressure system to conditions exceeding normal operational parameters. This includes extended operation at maximum RPM ranges (6500-7000 RPM) for periods of 24-48 hours continuously, with oil temperatures maintained between 110-130°C to replicate severe track conditions. Such testing accelerates wear mechanisms and identifies potential failure points that might only emerge after extensive track use.

Thermal cycle testing represents another critical protocol component, rapidly transitioning the engine between cold starts (ambient temperature) and full operating temperature (100°C+) repeatedly. This process should be executed through 500-1000 cycles to evaluate the oil pressure system's response to thermal expansion and contraction stresses, particularly focusing on pressure regulation consistency across temperature ranges.

Vibration and shock testing must simulate the harsh mechanical environment of track racing. Using specialized test rigs, the oil pressure system should undergo vibration profiles matching those recorded from actual track sessions, with frequencies ranging from 10-2000 Hz and acceleration forces up to 10G. This testing reveals potential weaknesses in mounting points, connections, and internal components that could lead to pressure fluctuations or failures.

Oil contamination resistance testing evaluates system performance when exposed to particulate matter, moisture, and fuel dilution. Introducing controlled amounts of contaminants while monitoring pressure consistency helps establish the system's robustness against real-world track conditions where oil purity cannot always be guaranteed.

Endurance validation represents the final phase, combining all stressors in a comprehensive test protocol. This involves running the engine through simulated race conditions for the equivalent of 10-15 complete race events, including warm-up, qualifying, and race distances. Throughout this testing, oil pressure must maintain consistent values within ±5% of target specifications across all operating conditions.

Data acquisition systems should continuously monitor critical parameters including oil pressure at multiple points in the system, oil temperature, engine RPM, bearing clearances, and oil flow rates. This data should be analyzed using statistical process control methods to identify any trends indicating degradation or inconsistency in pressure regulation.

Accelerated life testing forms the foundation of these protocols, subjecting the oil pressure system to conditions exceeding normal operational parameters. This includes extended operation at maximum RPM ranges (6500-7000 RPM) for periods of 24-48 hours continuously, with oil temperatures maintained between 110-130°C to replicate severe track conditions. Such testing accelerates wear mechanisms and identifies potential failure points that might only emerge after extensive track use.

Thermal cycle testing represents another critical protocol component, rapidly transitioning the engine between cold starts (ambient temperature) and full operating temperature (100°C+) repeatedly. This process should be executed through 500-1000 cycles to evaluate the oil pressure system's response to thermal expansion and contraction stresses, particularly focusing on pressure regulation consistency across temperature ranges.

Vibration and shock testing must simulate the harsh mechanical environment of track racing. Using specialized test rigs, the oil pressure system should undergo vibration profiles matching those recorded from actual track sessions, with frequencies ranging from 10-2000 Hz and acceleration forces up to 10G. This testing reveals potential weaknesses in mounting points, connections, and internal components that could lead to pressure fluctuations or failures.

Oil contamination resistance testing evaluates system performance when exposed to particulate matter, moisture, and fuel dilution. Introducing controlled amounts of contaminants while monitoring pressure consistency helps establish the system's robustness against real-world track conditions where oil purity cannot always be guaranteed.

Endurance validation represents the final phase, combining all stressors in a comprehensive test protocol. This involves running the engine through simulated race conditions for the equivalent of 10-15 complete race events, including warm-up, qualifying, and race distances. Throughout this testing, oil pressure must maintain consistent values within ±5% of target specifications across all operating conditions.

Data acquisition systems should continuously monitor critical parameters including oil pressure at multiple points in the system, oil temperature, engine RPM, bearing clearances, and oil flow rates. This data should be analyzed using statistical process control methods to identify any trends indicating degradation or inconsistency in pressure regulation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!