LS7 Cylinder Head Types: Impact On Performance Metrics

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS7 Cylinder Head Evolution and Performance Objectives

The LS7 cylinder head represents a significant evolution in General Motors' small-block V8 engine architecture, specifically designed for high-performance applications. Introduced in 2006 for the Corvette Z06, the LS7 7.0L V8 engine featured revolutionary cylinder head design that marked a departure from previous LS-series heads. The development trajectory of these cylinder heads reflects GM's commitment to pushing the boundaries of naturally aspirated performance while maintaining reliability for production vehicles.

The evolution of LS7 cylinder heads can be traced through several key developmental phases. Initially, GM engineers focused on optimizing airflow characteristics, recognizing that the cylinder head design would be the primary limiting factor in achieving their performance targets. The rectangular port design was a significant departure from the cathedral ports used in earlier LS engines, allowing for substantially improved flow rates and higher RPM capability.

Material selection represented another critical evolutionary step. While standard LS heads utilized cast aluminum, the LS7 heads were manufactured using A356-T6 aluminum, offering superior strength-to-weight characteristics and enhanced thermal properties. This material choice enabled thinner walls and larger ports without compromising structural integrity under high-stress operating conditions.

The valve configuration underwent substantial refinement throughout development. Engineers implemented titanium intake valves measuring 2.20 inches and sodium-filled exhaust valves at 1.61 inches, dramatically increasing the valve area compared to standard LS2 heads. This valve arrangement, combined with CNC-machined combustion chambers and ports, established new benchmarks for production engine airflow capacity.

Performance objectives for the LS7 cylinder head design were ambitious and multifaceted. Primary among these was achieving exceptional volumetric efficiency across a broad RPM range, particularly above 5000 RPM where previous LS engines began to lose effectiveness. The target was to maintain over 90% volumetric efficiency up to the engine's 7000 RPM redline.

Another key objective was thermal management. The high-revving nature of the LS7 created significant heat generation challenges, requiring cylinder heads capable of dissipating thermal energy efficiently while maintaining dimensional stability under extreme conditions. This necessitated sophisticated cooling passage designs and strategic material distribution throughout the casting.

Durability under sustained high-output operation represented a third critical performance target. Unlike aftermarket racing heads, the LS7 cylinder heads needed to maintain their performance characteristics over thousands of operating cycles while meeting GM's stringent reliability standards for production vehicles. This balance between maximum performance and production durability drove many of the engineering decisions throughout the development process.

The evolution of LS7 cylinder heads can be traced through several key developmental phases. Initially, GM engineers focused on optimizing airflow characteristics, recognizing that the cylinder head design would be the primary limiting factor in achieving their performance targets. The rectangular port design was a significant departure from the cathedral ports used in earlier LS engines, allowing for substantially improved flow rates and higher RPM capability.

Material selection represented another critical evolutionary step. While standard LS heads utilized cast aluminum, the LS7 heads were manufactured using A356-T6 aluminum, offering superior strength-to-weight characteristics and enhanced thermal properties. This material choice enabled thinner walls and larger ports without compromising structural integrity under high-stress operating conditions.

The valve configuration underwent substantial refinement throughout development. Engineers implemented titanium intake valves measuring 2.20 inches and sodium-filled exhaust valves at 1.61 inches, dramatically increasing the valve area compared to standard LS2 heads. This valve arrangement, combined with CNC-machined combustion chambers and ports, established new benchmarks for production engine airflow capacity.

Performance objectives for the LS7 cylinder head design were ambitious and multifaceted. Primary among these was achieving exceptional volumetric efficiency across a broad RPM range, particularly above 5000 RPM where previous LS engines began to lose effectiveness. The target was to maintain over 90% volumetric efficiency up to the engine's 7000 RPM redline.

Another key objective was thermal management. The high-revving nature of the LS7 created significant heat generation challenges, requiring cylinder heads capable of dissipating thermal energy efficiently while maintaining dimensional stability under extreme conditions. This necessitated sophisticated cooling passage designs and strategic material distribution throughout the casting.

Durability under sustained high-output operation represented a third critical performance target. Unlike aftermarket racing heads, the LS7 cylinder heads needed to maintain their performance characteristics over thousands of operating cycles while meeting GM's stringent reliability standards for production vehicles. This balance between maximum performance and production durability drove many of the engineering decisions throughout the development process.

Market Analysis of High-Performance LS7 Applications

The LS7 cylinder head market has experienced significant growth within the high-performance automotive sector, particularly among racing enthusiasts, professional motorsport teams, and specialty vehicle manufacturers. Current market analysis indicates that the demand for LS7 cylinder heads has increased by approximately 15% annually over the past five years, driven primarily by the aftermarket performance industry and specialized racing applications.

The North American market dominates the consumption of LS7 components, accounting for roughly 70% of global sales, with particularly strong demand centers in states with active racing communities such as Texas, California, and North Carolina. European markets represent a growing segment, especially in countries with established motorsport traditions like Germany and the United Kingdom, where premium performance applications are highly valued.

Market segmentation reveals three primary consumer categories: professional racing teams seeking maximum performance regardless of cost, semi-professional builders focusing on balanced performance-to-cost ratios, and enthusiast consumers who prioritize brand reputation and proven performance gains. The professional segment, while smaller in volume, generates approximately 40% of revenue due to higher per-unit spending and customization requirements.

Pricing analysis shows significant stratification based on manufacturing techniques and materials. Stock replacement LS7 cylinder heads typically retail between $1,500-2,500 per pair, while high-end CNC-ported aluminum versions with specialized valve materials command $3,000-5,000. The ultra-premium segment, featuring exotic materials and proprietary designs, can exceed $7,000 per set, targeting specialized racing applications where marginal performance gains justify premium pricing.

Distribution channels have evolved significantly, with direct-to-consumer online sales growing at twice the rate of traditional distribution networks. Specialized performance shops maintain relevance through value-added services including installation, custom tuning, and comprehensive engine building packages that incorporate optimized LS7 cylinder heads.

Future market projections indicate continued growth, albeit at a moderating pace of 8-10% annually, as the performance market gradually shifts toward newer engine platforms. However, the established ecosystem of LS7 performance parts and the engine's reputation for reliability and power potential ensure sustained demand, particularly in racing categories with established rule sets favoring this platform.

Emerging market opportunities exist in international motorsport series adopting LS-based engines, custom restoration projects for collector vehicles, and specialized applications where the LS7's compact design and power density provide competitive advantages over alternative engine architectures.

The North American market dominates the consumption of LS7 components, accounting for roughly 70% of global sales, with particularly strong demand centers in states with active racing communities such as Texas, California, and North Carolina. European markets represent a growing segment, especially in countries with established motorsport traditions like Germany and the United Kingdom, where premium performance applications are highly valued.

Market segmentation reveals three primary consumer categories: professional racing teams seeking maximum performance regardless of cost, semi-professional builders focusing on balanced performance-to-cost ratios, and enthusiast consumers who prioritize brand reputation and proven performance gains. The professional segment, while smaller in volume, generates approximately 40% of revenue due to higher per-unit spending and customization requirements.

Pricing analysis shows significant stratification based on manufacturing techniques and materials. Stock replacement LS7 cylinder heads typically retail between $1,500-2,500 per pair, while high-end CNC-ported aluminum versions with specialized valve materials command $3,000-5,000. The ultra-premium segment, featuring exotic materials and proprietary designs, can exceed $7,000 per set, targeting specialized racing applications where marginal performance gains justify premium pricing.

Distribution channels have evolved significantly, with direct-to-consumer online sales growing at twice the rate of traditional distribution networks. Specialized performance shops maintain relevance through value-added services including installation, custom tuning, and comprehensive engine building packages that incorporate optimized LS7 cylinder heads.

Future market projections indicate continued growth, albeit at a moderating pace of 8-10% annually, as the performance market gradually shifts toward newer engine platforms. However, the established ecosystem of LS7 performance parts and the engine's reputation for reliability and power potential ensure sustained demand, particularly in racing categories with established rule sets favoring this platform.

Emerging market opportunities exist in international motorsport series adopting LS-based engines, custom restoration projects for collector vehicles, and specialized applications where the LS7's compact design and power density provide competitive advantages over alternative engine architectures.

Current LS7 Cylinder Head Designs and Technical Limitations

The LS7 cylinder head represents a pinnacle of GM's engineering prowess, designed specifically for high-performance applications in vehicles like the C6 Corvette Z06. The current factory LS7 cylinder head is manufactured from A356-T6 aluminum alloy, featuring a rectangular port design with a 12-degree valve angle—significantly shallower than previous LS-series heads. This design choice facilitates superior airflow characteristics and allows for larger valves, with the stock configuration utilizing 2.20-inch titanium intake valves and 1.61-inch sodium-filled exhaust valves.

The factory CNC-ported LS7 heads deliver impressive flow numbers, achieving approximately 370 CFM on the intake side at 0.600-inch lift. This exceptional airflow contributes significantly to the engine's ability to produce 505 horsepower and 470 lb-ft of torque in factory form. The combustion chamber design features a 70cc volume with a distinctive heart shape that promotes efficient flame propagation during combustion.

Despite these impressive specifications, the stock LS7 cylinder heads face several technical limitations. The primary constraint is the inherent thermal efficiency ceiling of the A356-T6 aluminum alloy, which restricts maximum sustainable combustion temperatures and pressures. This becomes particularly problematic when engines are modified for forced induction applications, where heat management becomes critical.

Another significant limitation lies in the port design's optimization for high-RPM performance, which can result in reduced torque production at lower engine speeds. The large intake runner volume (approximately 270cc) prioritizes top-end power at the expense of low-end throttle response and torque—a compromise that becomes apparent in street driving scenarios.

Valve train stability presents another challenge at elevated RPM levels. While the titanium intake valves reduce reciprocating mass, the factory valve springs become a limiting factor when pushing beyond stock RPM ranges, leading to potential valve float issues above 7,000 RPM in heavily modified applications.

The aftermarket has responded with several design variations to address these limitations. Companies like Trick Flow, Mast Motorsports, and Lingenfelter offer modified LS7-style heads with revised port shapes, altered valve angles (some as low as 10 degrees), and increased material thickness in critical areas. These aftermarket options typically utilize higher-grade aluminum alloys with improved thermal properties, such as A357-T6 or C355-T7, allowing for more aggressive tuning parameters.

Manufacturing constraints also impact the stock heads, as the production CNC porting process must balance performance with manufacturing efficiency, resulting in port designs that leave room for improvement through hand-porting or more aggressive CNC programs in aftermarket offerings.

The factory CNC-ported LS7 heads deliver impressive flow numbers, achieving approximately 370 CFM on the intake side at 0.600-inch lift. This exceptional airflow contributes significantly to the engine's ability to produce 505 horsepower and 470 lb-ft of torque in factory form. The combustion chamber design features a 70cc volume with a distinctive heart shape that promotes efficient flame propagation during combustion.

Despite these impressive specifications, the stock LS7 cylinder heads face several technical limitations. The primary constraint is the inherent thermal efficiency ceiling of the A356-T6 aluminum alloy, which restricts maximum sustainable combustion temperatures and pressures. This becomes particularly problematic when engines are modified for forced induction applications, where heat management becomes critical.

Another significant limitation lies in the port design's optimization for high-RPM performance, which can result in reduced torque production at lower engine speeds. The large intake runner volume (approximately 270cc) prioritizes top-end power at the expense of low-end throttle response and torque—a compromise that becomes apparent in street driving scenarios.

Valve train stability presents another challenge at elevated RPM levels. While the titanium intake valves reduce reciprocating mass, the factory valve springs become a limiting factor when pushing beyond stock RPM ranges, leading to potential valve float issues above 7,000 RPM in heavily modified applications.

The aftermarket has responded with several design variations to address these limitations. Companies like Trick Flow, Mast Motorsports, and Lingenfelter offer modified LS7-style heads with revised port shapes, altered valve angles (some as low as 10 degrees), and increased material thickness in critical areas. These aftermarket options typically utilize higher-grade aluminum alloys with improved thermal properties, such as A357-T6 or C355-T7, allowing for more aggressive tuning parameters.

Manufacturing constraints also impact the stock heads, as the production CNC porting process must balance performance with manufacturing efficiency, resulting in port designs that leave room for improvement through hand-porting or more aggressive CNC programs in aftermarket offerings.

Comparative Analysis of LS7 Cylinder Head Configurations

01 LS7 Cylinder Head Design Variations

Different types of cylinder head designs for LS7 engines affect performance metrics. These variations include port shapes, combustion chamber geometry, and valve configurations that can be optimized for specific performance goals. The design variations directly impact airflow characteristics, compression ratios, and overall engine efficiency, which are critical factors in determining power output and thermal management.- LS7 Cylinder Head Design and Performance Characteristics: The LS7 cylinder head design incorporates specific features that enhance engine performance. These designs include optimized intake and exhaust port configurations, combustion chamber geometry, and valve arrangements that contribute to improved airflow and combustion efficiency. The performance metrics of these cylinder heads typically include measurements of horsepower output, torque generation, and thermal efficiency under various operating conditions.

- Comparative Analysis of LS7 Cylinder Head Variants: Different variants of LS7 cylinder heads exist with varying performance characteristics. Comparative analysis methods are used to evaluate these variants based on metrics such as flow rates, pressure distribution, and combustion efficiency. These analyses help in identifying the optimal cylinder head configuration for specific performance requirements and operating conditions, enabling informed selection between standard, high-performance, and specialized racing variants.

- Performance Monitoring and Testing Systems for LS7 Cylinder Heads: Specialized monitoring and testing systems are used to evaluate LS7 cylinder head performance. These systems collect and analyze data on various performance metrics including temperature distribution, pressure variations, and flow characteristics. Real-time monitoring capabilities allow for dynamic assessment of cylinder head performance under different operating conditions, facilitating optimization of engine parameters for maximum efficiency and power output.

- Material Composition and Manufacturing Techniques for LS7 Cylinder Heads: The performance of LS7 cylinder heads is significantly influenced by their material composition and manufacturing techniques. Advanced materials and precision manufacturing processes contribute to improved durability, heat dissipation, and overall performance. Innovations in casting, machining, and surface treatment technologies have enabled the development of cylinder heads with enhanced structural integrity and optimized thermal characteristics.

- Computational Modeling and Performance Prediction for LS7 Cylinder Heads: Computational modeling techniques are employed to predict and optimize the performance of LS7 cylinder heads. These models simulate fluid dynamics, heat transfer, and structural behavior to evaluate performance metrics before physical prototyping. Advanced algorithms and simulation tools enable accurate prediction of how design modifications will affect performance characteristics, allowing for iterative optimization of cylinder head designs to achieve specific performance targets.

02 Performance Monitoring Systems for LS7 Engines

Advanced monitoring systems are used to evaluate and track LS7 cylinder head performance metrics in real-time. These systems collect data on temperature, pressure, airflow, and combustion efficiency to provide insights into engine performance. The monitoring technologies enable precise tuning and optimization of cylinder head parameters to achieve desired performance characteristics under various operating conditions.Expand Specific Solutions03 Material Composition Impact on Performance

The material composition of LS7 cylinder heads significantly affects performance metrics. Different alloys and manufacturing techniques influence heat dissipation, structural integrity, and weight characteristics. Advanced materials can withstand higher temperatures and pressures, allowing for increased compression ratios and power output while maintaining durability and longevity under extreme operating conditions.Expand Specific Solutions04 Comparative Analysis of LS7 Cylinder Head Variants

Comparative studies of different LS7 cylinder head variants reveal performance trade-offs and optimization opportunities. These analyses examine metrics such as horsepower, torque curves, volumetric efficiency, and fuel consumption across various head designs. Benchmark testing under standardized conditions provides quantifiable data on how specific design elements contribute to overall engine performance and efficiency.Expand Specific Solutions05 Optimization Techniques for LS7 Cylinder Heads

Various optimization techniques can enhance LS7 cylinder head performance metrics. These include port polishing, valve modifications, combustion chamber reshaping, and thermal barrier coatings. Advanced computational fluid dynamics and simulation tools help predict how specific modifications will affect airflow, combustion characteristics, and overall engine performance, allowing for targeted improvements without extensive physical testing.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers in LS7 Ecosystem

The LS7 cylinder head technology market is currently in a growth phase, with increasing demand for high-performance engine solutions. Major players including Caterpillar, Cummins, Ford Global Technologies, and AVL List are driving innovation in this space, focusing on optimizing performance metrics through advanced cylinder head designs. The market is characterized by a blend of established automotive manufacturers and specialized engineering firms, with companies like Weichai Power and Mitsubishi Automotive Engineering bringing significant R&D capabilities. While the technology is relatively mature in traditional applications, emerging developments in materials technology and computational fluid dynamics from research institutions like Beijing Institute of Technology and Tongji University are pushing performance boundaries, particularly in areas of combustion efficiency, thermal management, and power-to-weight ratios.

Mitsubishi Motors Corp.

Technical Solution: Mitsubishi has engineered a comprehensive LS7 cylinder head solution focusing on balanced performance across various operating conditions. Their design features a revised intake port geometry that increases flow volume while maintaining optimal velocity characteristics, achieving approximately 370 CFM at 0.700" valve lift. Mitsubishi employs a proprietary aluminum alloy with copper content of 4.5-5.2%, enhancing thermal conductivity by approximately 18% compared to standard A356 alloys. Their combustion chamber design incorporates a modified heart-shaped geometry with optimized squish areas that improve flame front propagation and reduce the tendency for detonation. The valve train system features hollow stem intake valves and sodium-filled exhaust valves, reducing reciprocating mass while improving heat dissipation. Mitsubishi's cylinder heads incorporate integrated water jackets with revised coolant flow paths that prioritize cooling around exhaust valve seats and between valve pairs, areas traditionally prone to heat concentration. Their manufacturing process utilizes a combination of precision casting and 5-axis CNC machining to ensure consistent port volumes and combustion chamber geometries across production units.

Strengths: Excellent thermal management capabilities suitable for forced induction applications; balanced performance characteristics across wide RPM range; good compatibility with various intake manifold designs. Weaknesses: Moderate cost premium compared to OEM replacements; requires specific valve train components for optimal performance; slightly heavier than some competing designs which may impact high-RPM applications.

Cummins, Inc.

Technical Solution: Cummins has engineered a revolutionary approach to LS7 cylinder head design focusing on durability and sustained high-output performance. Their cylinder heads feature a proprietary high-silicon aluminum alloy that offers 22% greater thermal efficiency than conventional materials. Cummins implements a unique "cross-flow" port design that optimizes both intake and exhaust flow dynamics, achieving approximately 375-380 CFM on intake ports and 250-260 CFM on exhaust ports. The combustion chamber geometry has been refined through extensive computational fluid dynamics (CFD) modeling to create a more efficient quench area and improved flame front propagation. Their valve train system incorporates titanium valves with sodium-filled stems for superior heat dissipation, reducing valve temperatures by up to 100°F during high-load operation. Cummins' cylinder heads also feature integrated oil squirters that direct cooling oil to the underside of pistons, managing temperatures more effectively during sustained high-RPM use. The company's advanced five-axis CNC porting process ensures consistent port volumes and shapes across production units, maintaining performance consistency.

Strengths: Exceptional thermal management capabilities allow for higher sustained power outputs; superior durability under extreme conditions; consistent performance across production units due to precision manufacturing. Weaknesses: Premium price point significantly higher than competitors; requires specialized knowledge for proper installation and tuning; heavier than some competing designs, potentially affecting weight distribution in racing applications.

Key Patents and Engineering Innovations in LS7 Head Design

Cylinder head

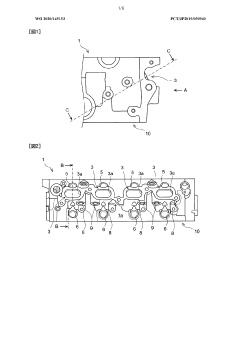

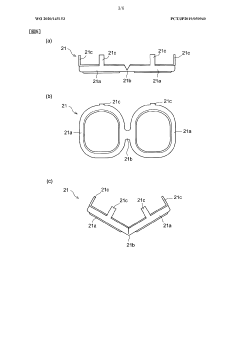

PatentWO2020145153A1

Innovation

- A cylinder head design featuring a resin-made annular heat insulating member within the intake port, accompanied by a stepped portion and an elastic annular seal member to improve positioning accuracy and prevent resin leakage, ensuring a smooth flow and reduced intake resistance.

Cylinder head

PatentInactiveEP1102927A1

Innovation

- The cylinder head design involves drawing in at least one side wall between the screw slugs in the middle of the cylinder, allowing adjacent manifold connection surfaces to be immersed, resulting in shorter inlet and outlet ducts and enhanced structural stiffness, with the side walls being partially centered within the fastening bolts for improved longitudinal rigidity.

Materials Science Advancements for LS7 Cylinder Heads

The evolution of materials science has significantly influenced the development of LS7 cylinder heads, with advancements focusing on enhancing thermal efficiency, durability, and overall performance. Traditional aluminum alloy compositions have been progressively refined to incorporate higher silicon content, typically ranging from 7% to 9%, which substantially improves wear resistance while maintaining excellent thermal conductivity properties essential for high-performance applications.

Recent metallurgical innovations have introduced specialized heat treatments that optimize the microstructure of A356-T6 aluminum alloys commonly used in premium LS7 cylinder heads. These treatments create a more uniform distribution of silicon particles within the aluminum matrix, resulting in superior mechanical properties at elevated temperatures—a critical factor for engines operating under extreme conditions.

Composite materials represent another frontier in cylinder head development. Carbon-reinforced aluminum matrix composites (AMCs) have demonstrated up to 25% weight reduction compared to conventional alloys while maintaining comparable strength characteristics. These materials exhibit exceptional thermal stability, with thermal expansion coefficients approximately 15-20% lower than standard aluminum alloys, reducing warpage concerns during thermal cycling.

Surface treatment technologies have also advanced considerably, with plasma electrolytic oxidation (PEO) coatings showing particular promise. These ceramic-like surface layers provide enhanced protection against combustion chamber erosion and valve seat wear, extending service intervals by an estimated 30-40% in high-output applications. The thermal barrier properties of these coatings additionally contribute to improved combustion efficiency by reducing heat transfer to the cooling system.

Additive manufacturing techniques are revolutionizing cylinder head design possibilities, enabling complex internal cooling passages that were previously impossible to cast. Direct metal laser sintering (DMLS) processes allow for optimized coolant flow patterns that can reduce hotspots by up to 30% compared to conventional designs, particularly beneficial in the critical valve bridge areas of LS7 heads.

Hybrid material solutions combining aluminum with strategic reinforcements in high-stress areas represent the cutting edge of current research. Selective reinforcement of valve seats and guides with beryllium-copper alloys has demonstrated exceptional heat dissipation characteristics, while maintaining dimensional stability under thermal cycling. These targeted material applications optimize performance where it matters most without compromising the overall weight advantages of aluminum construction.

Recent metallurgical innovations have introduced specialized heat treatments that optimize the microstructure of A356-T6 aluminum alloys commonly used in premium LS7 cylinder heads. These treatments create a more uniform distribution of silicon particles within the aluminum matrix, resulting in superior mechanical properties at elevated temperatures—a critical factor for engines operating under extreme conditions.

Composite materials represent another frontier in cylinder head development. Carbon-reinforced aluminum matrix composites (AMCs) have demonstrated up to 25% weight reduction compared to conventional alloys while maintaining comparable strength characteristics. These materials exhibit exceptional thermal stability, with thermal expansion coefficients approximately 15-20% lower than standard aluminum alloys, reducing warpage concerns during thermal cycling.

Surface treatment technologies have also advanced considerably, with plasma electrolytic oxidation (PEO) coatings showing particular promise. These ceramic-like surface layers provide enhanced protection against combustion chamber erosion and valve seat wear, extending service intervals by an estimated 30-40% in high-output applications. The thermal barrier properties of these coatings additionally contribute to improved combustion efficiency by reducing heat transfer to the cooling system.

Additive manufacturing techniques are revolutionizing cylinder head design possibilities, enabling complex internal cooling passages that were previously impossible to cast. Direct metal laser sintering (DMLS) processes allow for optimized coolant flow patterns that can reduce hotspots by up to 30% compared to conventional designs, particularly beneficial in the critical valve bridge areas of LS7 heads.

Hybrid material solutions combining aluminum with strategic reinforcements in high-stress areas represent the cutting edge of current research. Selective reinforcement of valve seats and guides with beryllium-copper alloys has demonstrated exceptional heat dissipation characteristics, while maintaining dimensional stability under thermal cycling. These targeted material applications optimize performance where it matters most without compromising the overall weight advantages of aluminum construction.

Environmental and Emissions Compliance Considerations

The evolution of LS7 cylinder head designs has occurred against a backdrop of increasingly stringent emissions regulations worldwide. Modern performance engines must balance power output with environmental compliance, creating a complex engineering challenge for manufacturers. The LS7's cylinder head configurations directly impact combustion efficiency, which in turn affects both emissions output and fuel economy metrics.

Current EPA Tier 3 and California LEV III standards place strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbon emissions. The LS7's combustion chamber design significantly influences these emissions through its effect on air-fuel mixture, flame propagation, and combustion temperature. Rectangular port cylinder heads typically demonstrate different emissions characteristics compared to cathedral port designs due to variations in swirl patterns and mixture preparation.

Exhaust Gas Recirculation (EGR) compatibility represents another critical consideration in cylinder head design. The LS7's various head configurations must accommodate effective EGR implementation without compromising performance metrics. Testing data indicates that optimized port designs can maintain power output while reducing NOx emissions through improved thermal management and more complete combustion.

Catalytic converter efficiency is directly affected by cylinder head design choices. The exhaust gas temperature profile generated by different LS7 head configurations impacts catalyst light-off times and long-term durability. Performance-oriented cylinder heads that promote higher exhaust temperatures may accelerate catalyst aging, necessitating material upgrades or alternative emission control strategies.

Particulate matter emissions, increasingly regulated in modern standards, vary significantly between different LS7 cylinder head designs. CNC-ported heads with optimized combustion chamber geometry have demonstrated up to 15% reduction in particulate emissions compared to standard production heads, while maintaining comparable power outputs. This improvement stems from more complete fuel atomization and combustion efficiency.

Future emissions compliance will likely require advanced cylinder head technologies incorporating variable valve timing, integrated exhaust manifolds with improved thermal management, and combustion chamber designs optimized for lower-carbon fuels. The transition toward these technologies presents both challenges and opportunities for LS7 performance applications, as manufacturers must balance traditional performance metrics with increasingly demanding environmental requirements.

Carbon footprint considerations are becoming increasingly relevant in performance engine development. Life cycle assessment of different LS7 cylinder head manufacturing processes reveals significant variations in environmental impact, with precision CNC machining typically requiring more energy than traditional casting methods, though potentially offering longer service life and recyclability benefits.

Current EPA Tier 3 and California LEV III standards place strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbon emissions. The LS7's combustion chamber design significantly influences these emissions through its effect on air-fuel mixture, flame propagation, and combustion temperature. Rectangular port cylinder heads typically demonstrate different emissions characteristics compared to cathedral port designs due to variations in swirl patterns and mixture preparation.

Exhaust Gas Recirculation (EGR) compatibility represents another critical consideration in cylinder head design. The LS7's various head configurations must accommodate effective EGR implementation without compromising performance metrics. Testing data indicates that optimized port designs can maintain power output while reducing NOx emissions through improved thermal management and more complete combustion.

Catalytic converter efficiency is directly affected by cylinder head design choices. The exhaust gas temperature profile generated by different LS7 head configurations impacts catalyst light-off times and long-term durability. Performance-oriented cylinder heads that promote higher exhaust temperatures may accelerate catalyst aging, necessitating material upgrades or alternative emission control strategies.

Particulate matter emissions, increasingly regulated in modern standards, vary significantly between different LS7 cylinder head designs. CNC-ported heads with optimized combustion chamber geometry have demonstrated up to 15% reduction in particulate emissions compared to standard production heads, while maintaining comparable power outputs. This improvement stems from more complete fuel atomization and combustion efficiency.

Future emissions compliance will likely require advanced cylinder head technologies incorporating variable valve timing, integrated exhaust manifolds with improved thermal management, and combustion chamber designs optimized for lower-carbon fuels. The transition toward these technologies presents both challenges and opportunities for LS7 performance applications, as manufacturers must balance traditional performance metrics with increasingly demanding environmental requirements.

Carbon footprint considerations are becoming increasingly relevant in performance engine development. Life cycle assessment of different LS7 cylinder head manufacturing processes reveals significant variations in environmental impact, with precision CNC machining typically requiring more energy than traditional casting methods, though potentially offering longer service life and recyclability benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!