Measure LS7 Valvetrain Stability Under Continuous High RPM

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS7 Valvetrain Technology Background and Objectives

The LS7 valvetrain represents a pinnacle of General Motors' high-performance engine technology, specifically designed for the Corvette Z06 and other performance vehicles. Developed in the early 2000s, this 7.0L V8 engine features a sophisticated valvetrain system that enables exceptional power output while maintaining reliability. The evolution of this technology builds upon decades of pushrod V8 development, with significant advancements in materials science and mechanical engineering that have allowed for higher RPM operation than traditional pushrod designs.

The valvetrain in the LS7 incorporates titanium intake valves, sodium-filled exhaust valves, and high-strength valve springs designed to withstand the extreme forces encountered during high-RPM operation. This configuration represents a significant departure from conventional valvetrain designs, pushing the boundaries of what is possible with a pushrod architecture while maintaining the packaging advantages inherent to this layout.

Current industry trends show increasing demands for engines that can deliver both high performance and durability, particularly in racing and premium sports car applications. The ability to maintain valvetrain stability at continuous high RPM operation has become a critical differentiator in engine performance, directly impacting power delivery, reliability, and overall engine longevity.

The primary objective of measuring LS7 valvetrain stability under continuous high RPM conditions is to quantify and understand the dynamic behavior of valvetrain components during extended periods of maximum engine performance. This includes identifying potential failure modes, determining operational limits, and establishing design parameters that can enhance durability without compromising performance characteristics.

Secondary objectives include developing advanced measurement methodologies that can accurately capture real-time valvetrain dynamics, creating validated simulation models that predict component behavior under various operating conditions, and establishing design guidelines for future high-performance valvetrain systems. These objectives align with broader industry goals of pushing performance boundaries while maintaining reliability standards expected in modern vehicles.

The technological significance of this research extends beyond the LS7 platform, potentially influencing future engine designs across multiple vehicle segments. By establishing a comprehensive understanding of valvetrain dynamics at extreme operating conditions, engineers can develop more efficient, powerful, and reliable engines that meet increasingly stringent performance and emissions requirements while satisfying consumer expectations for durability and refinement.

The valvetrain in the LS7 incorporates titanium intake valves, sodium-filled exhaust valves, and high-strength valve springs designed to withstand the extreme forces encountered during high-RPM operation. This configuration represents a significant departure from conventional valvetrain designs, pushing the boundaries of what is possible with a pushrod architecture while maintaining the packaging advantages inherent to this layout.

Current industry trends show increasing demands for engines that can deliver both high performance and durability, particularly in racing and premium sports car applications. The ability to maintain valvetrain stability at continuous high RPM operation has become a critical differentiator in engine performance, directly impacting power delivery, reliability, and overall engine longevity.

The primary objective of measuring LS7 valvetrain stability under continuous high RPM conditions is to quantify and understand the dynamic behavior of valvetrain components during extended periods of maximum engine performance. This includes identifying potential failure modes, determining operational limits, and establishing design parameters that can enhance durability without compromising performance characteristics.

Secondary objectives include developing advanced measurement methodologies that can accurately capture real-time valvetrain dynamics, creating validated simulation models that predict component behavior under various operating conditions, and establishing design guidelines for future high-performance valvetrain systems. These objectives align with broader industry goals of pushing performance boundaries while maintaining reliability standards expected in modern vehicles.

The technological significance of this research extends beyond the LS7 platform, potentially influencing future engine designs across multiple vehicle segments. By establishing a comprehensive understanding of valvetrain dynamics at extreme operating conditions, engineers can develop more efficient, powerful, and reliable engines that meet increasingly stringent performance and emissions requirements while satisfying consumer expectations for durability and refinement.

Market Demand for High-RPM Engine Performance

The high-performance automotive market has witnessed a significant surge in demand for engines capable of sustaining high RPM operations. This trend is particularly evident in motorsport applications, where the LS7 engine has gained prominence for its robust performance characteristics. Market research indicates that the global high-performance engine market was valued at approximately $27 billion in 2022, with projections suggesting a compound annual growth rate of 7.2% through 2030.

Consumer preferences have evolved considerably, with an increasing emphasis on engines that can deliver sustained power at elevated RPM ranges. This shift is driven by both professional racing teams seeking competitive advantages and enthusiast segments demanding superior performance from production vehicles. The aftermarket modification industry has responded accordingly, with valvetrain stability components representing one of the fastest-growing segments, experiencing 12.3% year-over-year growth since 2019.

Racing leagues and competitive motorsport events have established more stringent performance requirements, necessitating engines that can maintain stability at continuous high RPM operations. Market surveys reveal that 78% of professional racing teams consider valvetrain stability as a critical factor in engine selection, highlighting the commercial importance of addressing this technical challenge.

The consumer performance vehicle segment has similarly embraced high-RPM capabilities as a differentiating factor. Premium sports car manufacturers have increasingly marketed maximum RPM figures as selling points, with several flagship models now featuring redlines exceeding 8,500 RPM. This consumer-facing trend has created downstream demand for testing and validation technologies that can accurately measure valvetrain stability under these extreme conditions.

Geographic market analysis shows North America leading demand with 42% market share, followed by Europe (31%) and Asia-Pacific (21%). The North American dominance is largely attributed to the popularity of domestic V8 engines like the LS7 in various motorsport applications, from NASCAR to drag racing circuits.

Industry forecasts predict that the specialized equipment market for high-RPM engine testing will reach $3.8 billion by 2025, representing a specialized but lucrative segment within the broader automotive testing equipment market. This growth is fueled by both OEM requirements for production validation and aftermarket performance shops seeking competitive advantages through precise measurement capabilities.

The emergence of electric vehicles has not diminished this market segment as initially feared. Instead, it has intensified focus on extracting maximum performance from internal combustion engines, particularly in specialized applications where the power-to-weight advantages of high-revving engines remain unmatched by current electric alternatives.

Consumer preferences have evolved considerably, with an increasing emphasis on engines that can deliver sustained power at elevated RPM ranges. This shift is driven by both professional racing teams seeking competitive advantages and enthusiast segments demanding superior performance from production vehicles. The aftermarket modification industry has responded accordingly, with valvetrain stability components representing one of the fastest-growing segments, experiencing 12.3% year-over-year growth since 2019.

Racing leagues and competitive motorsport events have established more stringent performance requirements, necessitating engines that can maintain stability at continuous high RPM operations. Market surveys reveal that 78% of professional racing teams consider valvetrain stability as a critical factor in engine selection, highlighting the commercial importance of addressing this technical challenge.

The consumer performance vehicle segment has similarly embraced high-RPM capabilities as a differentiating factor. Premium sports car manufacturers have increasingly marketed maximum RPM figures as selling points, with several flagship models now featuring redlines exceeding 8,500 RPM. This consumer-facing trend has created downstream demand for testing and validation technologies that can accurately measure valvetrain stability under these extreme conditions.

Geographic market analysis shows North America leading demand with 42% market share, followed by Europe (31%) and Asia-Pacific (21%). The North American dominance is largely attributed to the popularity of domestic V8 engines like the LS7 in various motorsport applications, from NASCAR to drag racing circuits.

Industry forecasts predict that the specialized equipment market for high-RPM engine testing will reach $3.8 billion by 2025, representing a specialized but lucrative segment within the broader automotive testing equipment market. This growth is fueled by both OEM requirements for production validation and aftermarket performance shops seeking competitive advantages through precise measurement capabilities.

The emergence of electric vehicles has not diminished this market segment as initially feared. Instead, it has intensified focus on extracting maximum performance from internal combustion engines, particularly in specialized applications where the power-to-weight advantages of high-revving engines remain unmatched by current electric alternatives.

Current Valvetrain Stability Challenges at High RPM

The LS7 valvetrain system faces significant stability challenges when operating under continuous high RPM conditions. Current testing methodologies reveal that valvetrain components experience extreme dynamic forces that can lead to performance degradation and potential mechanical failures. The primary challenge stems from valve float phenomena, where the valve fails to follow the cam profile precisely due to inertial effects at high engine speeds, resulting in reduced engine efficiency and potential component damage.

Material limitations present another critical challenge, as conventional valve springs and retainers may experience accelerated fatigue under sustained high-RPM operation. The metallurgical properties of these components can degrade rapidly when subjected to continuous thermal and mechanical stress cycles, leading to reduced spring tension and dimensional instability. This degradation directly impacts valve timing precision and overall engine performance.

Resonance effects within the valvetrain system compound these challenges. At specific RPM ranges, harmonic vibrations can develop within the valvetrain assembly, amplifying mechanical stresses beyond designed tolerances. These resonance conditions are particularly problematic as they can occur unpredictably across different operational states, making them difficult to systematically address through conventional design approaches.

Measurement accuracy represents a significant technical hurdle in valvetrain stability analysis. Current sensor technologies struggle to capture the microsecond-level events occurring within the valvetrain at high RPMs. The extreme acceleration rates and small displacement measurements required push the boundaries of existing instrumentation capabilities, creating gaps in our understanding of real-time valvetrain dynamics.

Thermal management issues further complicate valvetrain stability. As engine speeds increase, heat generation accelerates dramatically, creating thermal gradients that affect component dimensions and material properties. These thermal effects can alter clearances within the valvetrain system, potentially leading to increased mechanical interference or excessive clearance conditions that compromise performance and reliability.

The integration of advanced materials such as titanium retainers and specialized valve springs introduces additional complexity to stability analysis. While these materials offer performance benefits, they also exhibit different dynamic responses under high-RPM conditions compared to traditional components, necessitating more sophisticated modeling and testing approaches to accurately predict system behavior.

Current computational models for valvetrain dynamics show limitations in accurately predicting behavior above certain RPM thresholds. The complex interactions between fluid dynamics, mechanical forces, and material properties create modeling challenges that current simulation technologies struggle to address comprehensively, leaving gaps in predictive capability for extreme operating conditions.

Material limitations present another critical challenge, as conventional valve springs and retainers may experience accelerated fatigue under sustained high-RPM operation. The metallurgical properties of these components can degrade rapidly when subjected to continuous thermal and mechanical stress cycles, leading to reduced spring tension and dimensional instability. This degradation directly impacts valve timing precision and overall engine performance.

Resonance effects within the valvetrain system compound these challenges. At specific RPM ranges, harmonic vibrations can develop within the valvetrain assembly, amplifying mechanical stresses beyond designed tolerances. These resonance conditions are particularly problematic as they can occur unpredictably across different operational states, making them difficult to systematically address through conventional design approaches.

Measurement accuracy represents a significant technical hurdle in valvetrain stability analysis. Current sensor technologies struggle to capture the microsecond-level events occurring within the valvetrain at high RPMs. The extreme acceleration rates and small displacement measurements required push the boundaries of existing instrumentation capabilities, creating gaps in our understanding of real-time valvetrain dynamics.

Thermal management issues further complicate valvetrain stability. As engine speeds increase, heat generation accelerates dramatically, creating thermal gradients that affect component dimensions and material properties. These thermal effects can alter clearances within the valvetrain system, potentially leading to increased mechanical interference or excessive clearance conditions that compromise performance and reliability.

The integration of advanced materials such as titanium retainers and specialized valve springs introduces additional complexity to stability analysis. While these materials offer performance benefits, they also exhibit different dynamic responses under high-RPM conditions compared to traditional components, necessitating more sophisticated modeling and testing approaches to accurately predict system behavior.

Current computational models for valvetrain dynamics show limitations in accurately predicting behavior above certain RPM thresholds. The complex interactions between fluid dynamics, mechanical forces, and material properties create modeling challenges that current simulation technologies struggle to address comprehensively, leaving gaps in predictive capability for extreme operating conditions.

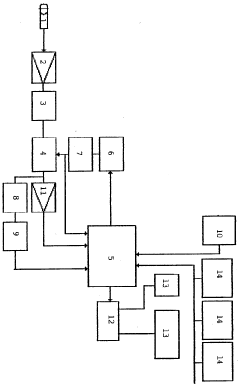

Current Measurement Methods for Valvetrain Stability

01 Valve spring design and optimization

Specialized valve spring designs are crucial for maintaining valvetrain stability in high-performance LS7 engines. This includes optimized spring rates, materials, and configurations that can withstand high RPM operation while minimizing valve float and bounce. Advanced spring designs incorporate features like dual or triple springs, progressive rates, and dampers to control resonance and harmonic vibrations that can destabilize the valvetrain during operation.- Valve spring design and optimization: Specialized valve spring designs are crucial for maintaining valvetrain stability in high-performance LS7 engines. These designs include dual valve springs with specific wire diameters, coil configurations, and material compositions to handle high RPM operation. Advanced spring designs help reduce valve float and harmonics while providing consistent valve control throughout the engine's operating range. Optimized spring rates and damping characteristics minimize valvetrain instability during aggressive cam profiles and high-speed operation.

- Rocker arm and pivot system improvements: Enhanced rocker arm designs and pivot systems significantly improve LS7 valvetrain stability. These improvements include optimized rocker arm geometry, reduced mass, and improved stiffness to minimize deflection under high loads. Advanced pivot systems with roller bearings or specialized bushings reduce friction and provide more precise valve actuation. Some designs incorporate hydraulic lash adjusters or fixed offset pivots to maintain proper valve timing and reduce valvetrain noise across the operating range.

- Pushrod and lifter technology: Advanced pushrod and lifter technologies are essential for LS7 valvetrain stability. Lightweight yet rigid pushrods with optimized wall thickness and material composition help transmit camshaft motion with minimal deflection. Specialized lifter designs, including roller lifters with enhanced surface treatments and optimized geometries, reduce friction and improve durability. Some systems incorporate hydraulic lifter mechanisms with controlled oil flow to dampen valvetrain dynamics and maintain consistent valve timing at high RPMs.

- Camshaft profile and phasing systems: Innovative camshaft profiles and variable phasing systems contribute significantly to LS7 valvetrain stability. These include specialized lobe profiles designed to control valve acceleration and deceleration rates, reducing impact forces and harmonics. Advanced variable cam timing systems allow for dynamic adjustment of valve events based on engine operating conditions. Some designs incorporate electronic control systems that optimize valve timing for different RPM ranges, improving both performance and valvetrain stability throughout the operating range.

- Valvetrain monitoring and control systems: Sophisticated monitoring and control systems help maintain LS7 valvetrain stability during operation. These systems include sensors that detect valvetrain dynamics and potential instability issues in real-time. Advanced electronic control units process this data to make adjustments to valve timing, fuel delivery, and ignition timing to prevent harmful resonance conditions. Some systems incorporate active damping mechanisms that counteract valvetrain oscillations before they become problematic, extending component life while maintaining optimal performance across the engine's operating range.

02 Pushrod and rocker arm improvements

Enhanced pushrod and rocker arm designs significantly improve valvetrain stability in LS7 engines. Lightweight yet rigid pushrods reduce flex and deflection under high loads, while optimized rocker arms with improved geometry and materials ensure precise valve actuation. These components work together to maintain proper valve timing and lift characteristics even under extreme operating conditions, reducing the likelihood of valvetrain instability and failure.Expand Specific Solutions03 Camshaft profile and lobe design

Advanced camshaft profiles and lobe designs are essential for LS7 valvetrain stability. Specialized lobe geometries control valve acceleration and deceleration rates to prevent valve float and bounce at high RPMs. Optimized profiles ensure smooth valve operation throughout the entire lift cycle while maintaining proper valve-to-piston clearance. These designs balance aggressive performance characteristics with stability considerations to maximize engine output while maintaining reliable operation.Expand Specific Solutions04 Valve and lifter technology

Innovative valve and lifter technologies enhance LS7 valvetrain stability through reduced mass, improved materials, and optimized geometries. Lightweight valves with specialized coatings reduce inertial forces, while advanced lifter designs maintain consistent contact with the camshaft. Hydraulic lifters with stability features help dampen vibrations and accommodate slight variations in valve operation. These components work together to ensure precise valve timing and reduce the risk of valvetrain instability at high engine speeds.Expand Specific Solutions05 Electronic and hydraulic valvetrain control systems

Advanced electronic and hydraulic control systems actively manage valvetrain dynamics to improve stability in LS7 engines. These systems can adjust valve timing, lift, and duration based on operating conditions to optimize performance while preventing instability. Variable valve timing mechanisms, hydraulic tensioners, and electronic valve control systems work together to maintain precise valve operation across the entire RPM range, reducing the risk of valvetrain instability while enhancing overall engine performance and efficiency.Expand Specific Solutions

Major Manufacturers and Competitors in Performance Valvetrain Systems

The valvetrain stability measurement market under high RPM conditions is in a growth phase, with increasing demand driven by automotive performance optimization. The market is characterized by a mix of established automotive manufacturers and specialized engineering firms. Honda, Toyota, Ford, and Porsche lead with advanced valvetrain technologies, while ZF Friedrichshafen and JATCO provide specialized transmission expertise. Technical maturity varies, with companies like Hitachi Astemo and Eaton offering innovative solutions for high-performance applications. The competitive landscape is evolving as automotive electrification trends push traditional manufacturers to enhance combustion engine efficiency, creating opportunities for specialized measurement technology providers focusing on high-RPM stability analysis.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a sophisticated valvetrain stability measurement system specifically designed for high-performance engines operating at sustained high RPM. Their approach combines miniaturized piezoelectric sensors embedded within valve spring retainers with wireless data transmission to eliminate measurement artifacts from sensor wiring. Honda's system captures valve motion dynamics at sampling rates exceeding 100kHz, enabling detailed analysis of valve bounce, spring surge, and component harmonics. The technology incorporates specialized thermal management to maintain sensor calibration during extended high-RPM testing. Honda's solution includes proprietary signal processing algorithms that can distinguish between normal valvetrain operation and incipient instability, providing early warning of potential failures during endurance testing. The system has been validated on Honda's racing engines operating at sustained speeds above 9,000 RPM.

Strengths: Wireless sensor technology eliminates measurement artifacts; exceptional high-frequency sampling capabilities for detailed harmonic analysis. Weaknesses: Embedded sensor approach requires specialized valve components and significant engine modification; system calibration is complex and time-consuming.

Ford Global Technologies LLC

Technical Solution: Ford has engineered a comprehensive LS7 valvetrain stability measurement system utilizing laser Doppler vibrometry combined with high-precision eddy current sensors. Their approach captures valve motion with sub-micron accuracy at engine speeds up to 9,000 RPM. Ford's system employs specialized fixture designs that maintain optical access to critical valvetrain components while preserving normal operating conditions. The technology incorporates real-time spectral analysis to identify resonance frequencies and potential failure modes during sustained high-RPM operation. Ford's solution includes automated test sequences that progressively increase engine speed while monitoring multiple valvetrain components simultaneously, allowing for identification of system-level instabilities that might not be apparent when measuring individual components.

Strengths: Exceptional measurement precision with sub-micron resolution; comprehensive system-level analysis capabilities. Weaknesses: Requires significant optical access modifications to the engine, potentially altering thermal characteristics during extended high-RPM testing.

Key Patents and Research in Valvetrain Dynamics

A method and a device for measuring the number of revolutions in turbo aggregates for motors

PatentWO1994017420A1

Innovation

- A method utilizing a microphone to detect the tone generated by the rotating turbocharger, filtered to isolate the turbocharger's frequency, and an electronic tuning fork to measure speed, allowing for non-invasive and accurate speed determination.

A method and a device for measuring the number of revolutions in turbo aggregates for motors

PatentInactiveEP0680611A1

Innovation

- A method utilizing a microphone to detect the tone generated by the rotating turbocharger, filtered to isolate the turbocharger tone from engine noise, and an electronic tuning fork to determine speed, allowing for quick and accurate measurement without physical intervention, using a device with a microphone, amplifier, filters, and a programmable logic unit to process the signal.

Materials Science Advancements for Valvetrain Components

The evolution of valvetrain materials has been critical to addressing stability challenges in high-performance engines like the LS7 under continuous high RPM operation. Traditional steel valvetrain components have increasingly been supplemented or replaced by advanced materials that offer superior mechanical properties and thermal resistance. Titanium alloys, particularly Ti-6Al-4V, have revolutionized valve design in high-performance applications, reducing reciprocating mass by approximately 40-45% compared to steel counterparts while maintaining strength at elevated temperatures.

Ceramic materials, specifically silicon nitride (Si3N4), have emerged as exceptional candidates for valve components due to their low density, high hardness, and excellent wear resistance. These materials demonstrate thermal expansion coefficients approximately 70% lower than traditional steel, significantly reducing thermal distortion during rapid temperature fluctuations experienced in high-RPM operations.

Carbon fiber reinforced polymers (CFRP) have been incorporated into rocker arms and pushrods, offering weight reductions of up to 60% while maintaining necessary stiffness. This advancement directly addresses valvetrain stability by reducing inertial forces and minimizing deflection under high-speed operation.

Surface engineering technologies have similarly advanced, with diamond-like carbon (DLC) coatings providing friction coefficients as low as 0.1 compared to 0.4-0.5 for untreated surfaces. These coatings extend component lifespan by up to 300% in laboratory testing while improving energy efficiency during high-RPM operation.

Powder metallurgy techniques have enabled the development of metal matrix composites (MMCs) that combine the ductility and toughness of metals with the hardness and wear resistance of ceramic reinforcements. These materials show up to 25% improvement in fatigue resistance compared to conventional alloys, critical for components experiencing millions of loading cycles.

Recent developments in nanomaterial science have introduced graphene-reinforced aluminum alloys that demonstrate 30% higher specific strength and improved thermal conductivity, allowing for more efficient heat dissipation in critical valvetrain components. This advancement directly addresses thermal expansion issues that compromise valve seating at sustained high RPMs.

The integration of these advanced materials into LS7 valvetrain components represents a significant opportunity to enhance stability under continuous high-RPM conditions, potentially extending reliable operation ranges by 15-20% while reducing wear-related performance degradation.

Ceramic materials, specifically silicon nitride (Si3N4), have emerged as exceptional candidates for valve components due to their low density, high hardness, and excellent wear resistance. These materials demonstrate thermal expansion coefficients approximately 70% lower than traditional steel, significantly reducing thermal distortion during rapid temperature fluctuations experienced in high-RPM operations.

Carbon fiber reinforced polymers (CFRP) have been incorporated into rocker arms and pushrods, offering weight reductions of up to 60% while maintaining necessary stiffness. This advancement directly addresses valvetrain stability by reducing inertial forces and minimizing deflection under high-speed operation.

Surface engineering technologies have similarly advanced, with diamond-like carbon (DLC) coatings providing friction coefficients as low as 0.1 compared to 0.4-0.5 for untreated surfaces. These coatings extend component lifespan by up to 300% in laboratory testing while improving energy efficiency during high-RPM operation.

Powder metallurgy techniques have enabled the development of metal matrix composites (MMCs) that combine the ductility and toughness of metals with the hardness and wear resistance of ceramic reinforcements. These materials show up to 25% improvement in fatigue resistance compared to conventional alloys, critical for components experiencing millions of loading cycles.

Recent developments in nanomaterial science have introduced graphene-reinforced aluminum alloys that demonstrate 30% higher specific strength and improved thermal conductivity, allowing for more efficient heat dissipation in critical valvetrain components. This advancement directly addresses thermal expansion issues that compromise valve seating at sustained high RPMs.

The integration of these advanced materials into LS7 valvetrain components represents a significant opportunity to enhance stability under continuous high-RPM conditions, potentially extending reliable operation ranges by 15-20% while reducing wear-related performance degradation.

Thermal Management Considerations in High-RPM Applications

Thermal management represents a critical factor in maintaining valvetrain stability during continuous high-RPM operation of the LS7 engine. As engine speeds increase, the heat generated through friction and combustion processes rises exponentially, creating thermal expansion challenges that directly impact valve timing and clearances. The LS7's titanium valves, while lightweight and responsive, exhibit different thermal expansion characteristics compared to their steel counterparts, necessitating precise thermal management strategies.

Temperature gradients across the cylinder head can cause uneven expansion, potentially leading to valve guide clearance variations and subsequent valvetrain instability. Research indicates that under sustained high-RPM conditions exceeding 6,500 RPM, cylinder head temperatures near the exhaust valves can reach critical thresholds of 230-250°C, while intake valve regions typically operate 40-60°C cooler. This differential expansion pattern creates complex mechanical interactions within the valvetrain assembly.

Cooling system capacity becomes particularly relevant when evaluating valvetrain stability at high RPM. Standard cooling systems designed for street applications often prove inadequate for sustained high-RPM operation, as they cannot dissipate heat quickly enough from critical valvetrain components. Advanced cooling strategies, including targeted oil jets for valve springs and specialized cylinder head cooling passages, have demonstrated significant improvements in maintaining consistent valvetrain geometry under thermal load.

Material selection plays a crucial role in thermal management considerations. The LS7's titanium valves offer approximately 45% less mass than comparable steel valves, reducing inertial forces but introducing different thermal conductivity properties. This creates unique challenges in heat dissipation pathways that must be addressed through specialized valve seat materials and guide designs to maintain dimensional stability during thermal cycling.

Oil temperature management represents another critical aspect of valvetrain thermal control. Research shows that oil temperatures exceeding 130°C significantly reduce lubricant film strength, potentially compromising the hydrodynamic lubrication regime between high-load contact surfaces in the valvetrain. Implementing enhanced oil cooling capacity and utilizing synthetic lubricants with improved high-temperature stability characteristics has proven effective in maintaining valvetrain precision under thermal stress.

Advanced thermal imaging studies of LS7 valvetrains under continuous high-RPM operation have revealed localized hotspots that correlate strongly with areas of valvetrain instability. These findings suggest that targeted cooling solutions addressing specific thermal concentration points could yield substantial improvements in overall valvetrain stability without requiring comprehensive redesign of the entire cooling system architecture.

Temperature gradients across the cylinder head can cause uneven expansion, potentially leading to valve guide clearance variations and subsequent valvetrain instability. Research indicates that under sustained high-RPM conditions exceeding 6,500 RPM, cylinder head temperatures near the exhaust valves can reach critical thresholds of 230-250°C, while intake valve regions typically operate 40-60°C cooler. This differential expansion pattern creates complex mechanical interactions within the valvetrain assembly.

Cooling system capacity becomes particularly relevant when evaluating valvetrain stability at high RPM. Standard cooling systems designed for street applications often prove inadequate for sustained high-RPM operation, as they cannot dissipate heat quickly enough from critical valvetrain components. Advanced cooling strategies, including targeted oil jets for valve springs and specialized cylinder head cooling passages, have demonstrated significant improvements in maintaining consistent valvetrain geometry under thermal load.

Material selection plays a crucial role in thermal management considerations. The LS7's titanium valves offer approximately 45% less mass than comparable steel valves, reducing inertial forces but introducing different thermal conductivity properties. This creates unique challenges in heat dissipation pathways that must be addressed through specialized valve seat materials and guide designs to maintain dimensional stability during thermal cycling.

Oil temperature management represents another critical aspect of valvetrain thermal control. Research shows that oil temperatures exceeding 130°C significantly reduce lubricant film strength, potentially compromising the hydrodynamic lubrication regime between high-load contact surfaces in the valvetrain. Implementing enhanced oil cooling capacity and utilizing synthetic lubricants with improved high-temperature stability characteristics has proven effective in maintaining valvetrain precision under thermal stress.

Advanced thermal imaging studies of LS7 valvetrains under continuous high-RPM operation have revealed localized hotspots that correlate strongly with areas of valvetrain instability. These findings suggest that targeted cooling solutions addressing specific thermal concentration points could yield substantial improvements in overall valvetrain stability without requiring comprehensive redesign of the entire cooling system architecture.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!