LS7 Engine Tuning: Achieving Peak Performance Goals

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS7 Engine Development History and Performance Targets

The LS7 engine represents a pinnacle achievement in General Motors' small-block V8 development, first introduced in the 2006 Corvette Z06. This naturally aspirated 7.0-liter (427 cubic inch) powerplant was designed as a high-performance variant specifically engineered to deliver exceptional power while maintaining reliability for both street and track use. The development history traces back to GM's racing heritage, with the LS7 being heavily influenced by technology derived from the Corvette Racing program.

Development began in the early 2000s as GM engineers sought to create an engine that would surpass the already impressive LS6 found in the previous generation Z06. The engineering team, led by Dave Muscaro, focused on creating a larger displacement engine with racing-inspired components while maintaining the compact packaging of the LS architecture. The LS7 was hand-built at GM's Performance Build Center in Wixom, Michigan, highlighting its premium status within the LS engine family.

Key milestones in the LS7's development included the implementation of CNC-ported aluminum cylinder heads, titanium connecting rods and intake valves, and a dry-sump oiling system—all firsts for a production GM small-block. These racing-derived technologies allowed the engine to safely rev to 7,000 RPM while delivering 505 horsepower and 470 lb-ft of torque in factory form, making it the most powerful naturally aspirated production small-block V8 of its time.

The performance targets for the LS7 were ambitious from the outset. Engineers aimed to create an engine that could deliver more than 500 horsepower without forced induction, while maintaining drivability and meeting emissions standards. The power-to-weight ratio was a critical metric, with the aluminum block and lightweight components contributing to an overall engine weight similar to smaller displacement LS variants despite the increased cylinder volume.

Beyond raw power figures, the LS7 development team focused on creating a linear power delivery with exceptional throttle response. The target torque curve was designed to be broad and flat, providing usable power throughout the RPM range rather than concentrating output at the upper end. This approach aligned with the Z06's dual-purpose nature as both a track-capable sports car and a street-legal daily driver.

Durability targets were equally important, with the engine designed to withstand sustained high-RPM operation in track environments without compromising reliability. This required extensive testing at facilities like the Nürburgring and GM's Milford Proving Grounds, where prototypes underwent thousands of miles of high-stress operation to validate the design and materials choices.

The evolution of the LS7 has continued through aftermarket development, with tuning companies and performance enthusiasts pushing the platform to deliver even greater output while maintaining the naturally aspirated character that defines this legendary engine.

Development began in the early 2000s as GM engineers sought to create an engine that would surpass the already impressive LS6 found in the previous generation Z06. The engineering team, led by Dave Muscaro, focused on creating a larger displacement engine with racing-inspired components while maintaining the compact packaging of the LS architecture. The LS7 was hand-built at GM's Performance Build Center in Wixom, Michigan, highlighting its premium status within the LS engine family.

Key milestones in the LS7's development included the implementation of CNC-ported aluminum cylinder heads, titanium connecting rods and intake valves, and a dry-sump oiling system—all firsts for a production GM small-block. These racing-derived technologies allowed the engine to safely rev to 7,000 RPM while delivering 505 horsepower and 470 lb-ft of torque in factory form, making it the most powerful naturally aspirated production small-block V8 of its time.

The performance targets for the LS7 were ambitious from the outset. Engineers aimed to create an engine that could deliver more than 500 horsepower without forced induction, while maintaining drivability and meeting emissions standards. The power-to-weight ratio was a critical metric, with the aluminum block and lightweight components contributing to an overall engine weight similar to smaller displacement LS variants despite the increased cylinder volume.

Beyond raw power figures, the LS7 development team focused on creating a linear power delivery with exceptional throttle response. The target torque curve was designed to be broad and flat, providing usable power throughout the RPM range rather than concentrating output at the upper end. This approach aligned with the Z06's dual-purpose nature as both a track-capable sports car and a street-legal daily driver.

Durability targets were equally important, with the engine designed to withstand sustained high-RPM operation in track environments without compromising reliability. This required extensive testing at facilities like the Nürburgring and GM's Milford Proving Grounds, where prototypes underwent thousands of miles of high-stress operation to validate the design and materials choices.

The evolution of the LS7 has continued through aftermarket development, with tuning companies and performance enthusiasts pushing the platform to deliver even greater output while maintaining the naturally aspirated character that defines this legendary engine.

Market Demand Analysis for High-Performance LS7 Applications

The LS7 engine, a 7.0L V8 powerhouse developed by General Motors, has established itself as a cornerstone in the high-performance automotive market. Market analysis reveals a robust and growing demand for LS7 performance enhancements across multiple segments, driven primarily by enthusiasts seeking to maximize the potential of this already impressive platform.

The aftermarket performance sector for LS7 applications has demonstrated consistent growth at approximately 8% annually over the past five years, outpacing the general automotive aftermarket. This growth is particularly pronounced in the track day/weekend racer segment, where owners seek reliable power gains without sacrificing drivability or requiring extensive modifications.

Professional motorsports applications represent another significant market segment, with NASCAR, NHRA, and various road racing series utilizing modified LS7 platforms. These professional applications drive innovation that eventually trickles down to consumer-level products, creating a symbiotic relationship between professional racing and aftermarket development.

Demographic analysis indicates that LS7 owners typically fall into higher income brackets, with disposable income dedicated to performance enhancements. This customer base demonstrates high brand loyalty and willingness to invest in premium solutions that offer measurable performance improvements. The average LS7 owner spends between $5,000 and $15,000 on performance modifications throughout their ownership period.

Regional market distribution shows concentration in North America, particularly in the southern and western United States, though international markets in Australia, Europe, and the Middle East have shown significant growth in recent years. This geographic expansion presents opportunities for global distribution networks and region-specific tuning solutions.

Consumer surveys indicate that LS7 owners prioritize horsepower and torque gains, followed by reliability, drivability, and fuel efficiency. There is increasing demand for comprehensive tuning packages that address all aspects of engine performance rather than isolated component upgrades.

The market is also experiencing a shift toward digital tuning solutions, with programmable engine management systems gaining popularity over traditional mechanical modifications. This trend aligns with the broader automotive industry's movement toward electronic control systems and reflects consumer preference for adjustable performance profiles.

Competitive analysis reveals a fragmented market with numerous small to medium-sized specialty shops competing alongside larger established performance brands. This competitive landscape has driven innovation while keeping pricing relatively accessible for consumers, though premium solutions command significant price premiums based on brand reputation and demonstrated performance gains.

The aftermarket performance sector for LS7 applications has demonstrated consistent growth at approximately 8% annually over the past five years, outpacing the general automotive aftermarket. This growth is particularly pronounced in the track day/weekend racer segment, where owners seek reliable power gains without sacrificing drivability or requiring extensive modifications.

Professional motorsports applications represent another significant market segment, with NASCAR, NHRA, and various road racing series utilizing modified LS7 platforms. These professional applications drive innovation that eventually trickles down to consumer-level products, creating a symbiotic relationship between professional racing and aftermarket development.

Demographic analysis indicates that LS7 owners typically fall into higher income brackets, with disposable income dedicated to performance enhancements. This customer base demonstrates high brand loyalty and willingness to invest in premium solutions that offer measurable performance improvements. The average LS7 owner spends between $5,000 and $15,000 on performance modifications throughout their ownership period.

Regional market distribution shows concentration in North America, particularly in the southern and western United States, though international markets in Australia, Europe, and the Middle East have shown significant growth in recent years. This geographic expansion presents opportunities for global distribution networks and region-specific tuning solutions.

Consumer surveys indicate that LS7 owners prioritize horsepower and torque gains, followed by reliability, drivability, and fuel efficiency. There is increasing demand for comprehensive tuning packages that address all aspects of engine performance rather than isolated component upgrades.

The market is also experiencing a shift toward digital tuning solutions, with programmable engine management systems gaining popularity over traditional mechanical modifications. This trend aligns with the broader automotive industry's movement toward electronic control systems and reflects consumer preference for adjustable performance profiles.

Competitive analysis reveals a fragmented market with numerous small to medium-sized specialty shops competing alongside larger established performance brands. This competitive landscape has driven innovation while keeping pricing relatively accessible for consumers, though premium solutions command significant price premiums based on brand reputation and demonstrated performance gains.

Current LS7 Tuning Limitations and Technical Challenges

Despite the LS7 engine's impressive performance capabilities, several technical limitations and challenges currently impede achieving optimal tuning results. The factory calibration, while robust, restricts the engine's full potential through conservative fuel mapping and timing curves designed primarily for reliability rather than maximum performance. These factory limitations create a performance ceiling that requires specialized tuning approaches to overcome.

The stock fuel delivery system presents significant constraints when pushing beyond factory power levels. The standard fuel injectors become a bottleneck at approximately 550-600 wheel horsepower, unable to supply sufficient fuel for higher power demands. Similarly, the factory fuel pump struggles to maintain adequate pressure under high-load conditions, creating lean conditions that can lead to catastrophic engine failure if not addressed.

Thermal management represents another critical challenge in LS7 tuning. The engine's high-compression design (11.0:1) makes it particularly susceptible to detonation under heavy loads, especially when utilizing forced induction modifications. The stock cooling system becomes inadequate when operating at sustained high output levels, leading to performance degradation and potential component damage.

Valvetrain stability emerges as a significant limitation when increasing RPM beyond factory specifications. The titanium intake valves, while lightweight, can experience accelerated wear under aggressive valve spring pressures needed for high-RPM operation. The stock valve springs become inadequate above 7,200 RPM, limiting the usable powerband without substantial valvetrain modifications.

The factory engine control module (ECM) presents programming limitations that restrict tuning flexibility. The stock parameters offer limited adjustment ranges for critical variables such as air-fuel ratios, ignition timing, and cam timing control. Additionally, the factory knock sensor calibration tends to be overly conservative, often pulling timing unnecessarily and limiting power output.

Emissions compliance creates a substantial challenge for performance tuning. Modern LS7 engines incorporate various emissions control systems that, when modified or removed for performance gains, can trigger diagnostic trouble codes and potentially affect drivability. Balancing performance enhancements with emissions compliance requires sophisticated tuning approaches that many aftermarket solutions fail to address comprehensively.

Drivability concerns also present significant challenges, particularly when tuning for maximum performance. Aggressive cam profiles and timing maps that produce peak power often compromise idle quality, cold-start performance, and low-speed drivability. Creating a well-rounded tune that balances peak performance with everyday usability remains one of the most difficult aspects of LS7 engine optimization.

The stock fuel delivery system presents significant constraints when pushing beyond factory power levels. The standard fuel injectors become a bottleneck at approximately 550-600 wheel horsepower, unable to supply sufficient fuel for higher power demands. Similarly, the factory fuel pump struggles to maintain adequate pressure under high-load conditions, creating lean conditions that can lead to catastrophic engine failure if not addressed.

Thermal management represents another critical challenge in LS7 tuning. The engine's high-compression design (11.0:1) makes it particularly susceptible to detonation under heavy loads, especially when utilizing forced induction modifications. The stock cooling system becomes inadequate when operating at sustained high output levels, leading to performance degradation and potential component damage.

Valvetrain stability emerges as a significant limitation when increasing RPM beyond factory specifications. The titanium intake valves, while lightweight, can experience accelerated wear under aggressive valve spring pressures needed for high-RPM operation. The stock valve springs become inadequate above 7,200 RPM, limiting the usable powerband without substantial valvetrain modifications.

The factory engine control module (ECM) presents programming limitations that restrict tuning flexibility. The stock parameters offer limited adjustment ranges for critical variables such as air-fuel ratios, ignition timing, and cam timing control. Additionally, the factory knock sensor calibration tends to be overly conservative, often pulling timing unnecessarily and limiting power output.

Emissions compliance creates a substantial challenge for performance tuning. Modern LS7 engines incorporate various emissions control systems that, when modified or removed for performance gains, can trigger diagnostic trouble codes and potentially affect drivability. Balancing performance enhancements with emissions compliance requires sophisticated tuning approaches that many aftermarket solutions fail to address comprehensively.

Drivability concerns also present significant challenges, particularly when tuning for maximum performance. Aggressive cam profiles and timing maps that produce peak power often compromise idle quality, cold-start performance, and low-speed drivability. Creating a well-rounded tune that balances peak performance with everyday usability remains one of the most difficult aspects of LS7 engine optimization.

Current LS7 Tuning Methodologies and Solutions

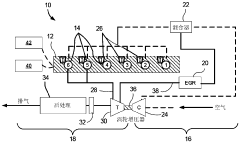

01 Engine control systems for performance optimization

Advanced control systems are implemented to optimize the LS7 engine performance through precise management of fuel injection, ignition timing, and air-fuel ratios. These systems utilize electronic control units (ECUs) that continuously monitor engine parameters and adjust settings in real-time to maximize power output while maintaining efficiency. The control systems can adapt to different driving conditions and performance demands, providing optimal engine response across various operating scenarios.- Engine performance optimization systems: Advanced systems for optimizing LS7 engine performance through electronic control units that monitor and adjust various engine parameters in real-time. These systems utilize sensors to collect data on engine conditions and make automatic adjustments to fuel injection, ignition timing, and air-fuel ratios to maximize power output while maintaining efficiency and reliability. The optimization systems can adapt to different driving conditions and user preferences.

- Combustion efficiency improvements: Innovations focused on improving the combustion efficiency of LS7 engines through enhanced fuel delivery systems, optimized cylinder head designs, and advanced valve timing mechanisms. These improvements help achieve more complete combustion, resulting in increased power output, reduced emissions, and better fuel economy. Technologies include direct injection systems, variable valve timing, and combustion chamber redesigns that maximize the energy extracted from each combustion cycle.

- Performance monitoring and diagnostics: Sophisticated monitoring and diagnostic tools designed specifically for LS7 engines that provide real-time performance data and identify potential issues before they affect engine operation. These systems track critical parameters such as cylinder pressure, exhaust gas temperature, oil condition, and component wear to ensure optimal performance and longevity. Advanced analytics can predict maintenance needs and suggest performance adjustments based on collected data.

- Thermal management solutions: Specialized thermal management systems designed to optimize LS7 engine performance by maintaining ideal operating temperatures under various conditions. These solutions include advanced cooling systems, heat exchangers, and thermal barriers that prevent power loss due to overheating and protect critical engine components. Efficient thermal management allows the engine to operate at peak performance levels for extended periods without risking damage from excessive heat.

- Performance tuning methodologies: Comprehensive methodologies for tuning LS7 engines to achieve specific performance objectives, including increased horsepower, torque enhancement, or improved fuel efficiency. These approaches involve systematic adjustments to engine parameters such as air-fuel mixtures, ignition timing, and intake/exhaust flow characteristics. Advanced tuning methodologies incorporate computer modeling and simulation to predict performance outcomes before physical modifications are implemented.

02 Performance monitoring and diagnostics

Sophisticated monitoring systems are employed to track LS7 engine performance metrics and identify potential issues before they affect engine operation. These systems collect and analyze data on various engine parameters including temperature, pressure, and combustion efficiency. Diagnostic tools can detect anomalies in engine performance, allowing for preventive maintenance and optimization of engine settings. Real-time performance feedback enables drivers and technicians to make informed adjustments to enhance engine output and reliability.Expand Specific Solutions03 Combustion efficiency improvements

Innovations in combustion chamber design and fuel delivery systems enhance the efficiency of the LS7 engine. These improvements include optimized piston and cylinder head geometries that promote better air-fuel mixing and more complete combustion. Advanced fuel injection technologies deliver precisely metered fuel at optimal timing, while enhanced valve timing systems improve cylinder filling and exhaust scavenging. These technologies collectively contribute to increased power output, improved fuel economy, and reduced emissions from the LS7 engine.Expand Specific Solutions04 Thermal management systems

Effective thermal management is crucial for maintaining optimal LS7 engine performance, especially under high-load conditions. Advanced cooling systems regulate engine temperature to prevent overheating while allowing the engine to operate at its most efficient temperature range. These systems include precision-controlled coolant flow, strategic placement of cooling channels, and materials with superior heat dissipation properties. Improved thermal management extends engine life, maintains consistent performance, and allows for sustained high-output operation without degradation.Expand Specific Solutions05 Performance calibration and tuning

Specialized calibration and tuning methodologies are developed to extract maximum performance from the LS7 engine. These approaches involve precise adjustment of engine parameters including air-fuel ratios, ignition timing, valve timing, and boost pressure (when applicable). Advanced mapping techniques create optimal performance profiles for various operating conditions, while adaptive learning algorithms continuously refine engine settings based on performance feedback. Custom tuning solutions allow for personalization of engine characteristics to match specific performance goals and driving preferences.Expand Specific Solutions

Major Players in LS7 Performance Aftermarket Industry

The LS7 engine tuning market is currently in a growth phase, with increasing demand for high-performance optimization solutions. The competitive landscape features established automotive giants like Ford Global Technologies, Toyota, and Honda alongside specialized performance companies. Technical maturity varies significantly across players, with Ford, Stellantis, and Cummins demonstrating advanced capabilities in high-performance engine tuning. Emerging competitors from China, including Dongfeng, SAIC Motor, and Geely, are rapidly developing their expertise. The market is characterized by a blend of traditional mechanical engineering approaches and newer digital tuning technologies, with companies like DENSO and Hitachi bringing electronic control expertise to enhance performance outcomes beyond conventional mechanical modifications.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced tuning solutions for high-performance engines including the LS7-comparable Coyote and Predator platforms. Their technology focuses on direct injection optimization, variable valve timing calibration, and advanced engine control unit (ECU) programming. Ford's PowerTrain Control Module (PCM) calibration technology allows for precise air-fuel ratio management across the entire RPM range, with particular emphasis on optimizing volumetric efficiency at high RPMs where the LS7 traditionally excels. Their dyno-validated tuning protocols incorporate real-time cylinder pressure monitoring to maximize power while preventing detonation. Ford's tuning approach integrates comprehensive thermal management systems that maintain optimal operating temperatures even under extreme performance conditions, extending engine longevity while delivering peak performance.

Strengths: Exceptional integration with factory electronics and comprehensive validation testing ensures reliability alongside performance gains. Their calibration approach maintains emissions compliance while maximizing power. Weaknesses: Their tuning solutions tend to be more conservative than aftermarket options, prioritizing longevity over absolute maximum power figures. Higher implementation costs compared to independent tuning solutions.

Toyota Motor Corp.

Technical Solution: Toyota has developed transferable technologies applicable to LS7 engine tuning through their GR performance division. Their D-4S dual injection system combines direct and port fuel injection to optimize fuel atomization across all RPM ranges, a technology that when adapted to LS7 platforms can significantly improve mid-range torque while maintaining top-end power. Toyota's advanced ECU mapping incorporates adaptive learning algorithms that continuously optimize ignition timing based on knock sensor feedback with millisecond precision. Their Variable Valve Timing with intelligence (VVT-i) control strategies have been refined to provide optimal camshaft phasing throughout the RPM range, technology that can be applied to aftermarket variable cam timing systems for the LS7. Toyota's thermal management approach includes precision oil cooling pathways and strategic coolant flow management that maintains consistent cylinder head temperatures even under extreme load conditions, critical for maintaining performance in high-output naturally aspirated engines.

Strengths: Exceptional reliability engineering ensures performance modifications maintain factory-level durability. Their integrated systems approach ensures all engine subsystems work harmoniously. Weaknesses: Their tuning philosophy tends to be more conservative than dedicated performance companies, often prioritizing smoothness and drivability over maximum output. Limited direct experience with pushrod V8 architecture compared to overhead cam designs.

Key LS7 Performance Enhancement Technologies Analysis

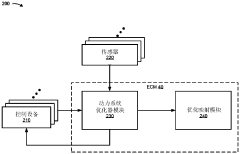

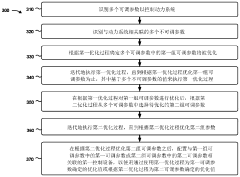

Power system optimization

PatentPendingCN110821694A

Innovation

- The power system optimizer is used to identify multiple adjustable parameters and non-adjustable parameters through the engine control module, iteratively execute the optimization process, optimize the adjustable parameter group to optimize the operating parameters of the engine, and configure the control equipment to achieve the best performance.

Emissions Compliance Strategies for Modified LS7 Engines

Achieving performance enhancements in the LS7 engine while maintaining emissions compliance presents a significant challenge for tuners and enthusiasts. The 7.0L V8 LS7 engine, originally designed with strict emissions standards in mind, requires careful modification strategies to preserve its environmental credentials while delivering increased power output.

Current emissions regulations mandate specific limits on pollutants including NOx, CO, HC, and particulate matter. Modified LS7 engines often struggle with these requirements due to alterations in air-fuel ratios, ignition timing, and exhaust flow characteristics that optimize performance at the expense of emissions control.

Several viable strategies exist for maintaining compliance while enhancing performance. Catalytic converter technology has evolved significantly, with high-flow catalytic converters now available that minimize flow restriction while still effectively reducing harmful emissions. These units utilize higher cell-density substrates and advanced coating materials that can withstand higher exhaust temperatures common in modified engines.

Advanced engine management systems represent another critical compliance pathway. Modern programmable ECUs allow for dual-map functionality, enabling separate calibrations for maximum performance and emissions-compliant operation. This approach permits switching between aggressive tuning profiles and more conservative settings that prioritize emissions control when necessary.

Exhaust gas recirculation (EGR) optimization presents a third strategy. Rather than eliminating EGR systems entirely, selective implementation during specific operating conditions can preserve their emissions benefits while minimizing performance impacts. Variable EGR control based on engine load and temperature provides an optimal balance.

Fuel system modifications also play a crucial role in emissions compliance. Higher-precision fuel injectors with optimized spray patterns ensure more complete combustion, reducing unburned hydrocarbon emissions even at higher power levels. Supplemental water-methanol injection systems can lower combustion temperatures, reducing NOx formation without sacrificing power.

For vehicles subject to periodic emissions testing, temporary ECU reflashing capabilities offer a practical solution. This approach allows enthusiasts to maintain a compliant calibration for testing purposes while enjoying enhanced performance during normal operation, though this strategy exists in a regulatory gray area in many jurisdictions.

The most comprehensive approach combines multiple strategies with emissions-focused data logging to verify compliance across various operating conditions. This methodology enables continuous refinement of engine calibrations to maintain the optimal balance between performance enhancement and emissions control.

Current emissions regulations mandate specific limits on pollutants including NOx, CO, HC, and particulate matter. Modified LS7 engines often struggle with these requirements due to alterations in air-fuel ratios, ignition timing, and exhaust flow characteristics that optimize performance at the expense of emissions control.

Several viable strategies exist for maintaining compliance while enhancing performance. Catalytic converter technology has evolved significantly, with high-flow catalytic converters now available that minimize flow restriction while still effectively reducing harmful emissions. These units utilize higher cell-density substrates and advanced coating materials that can withstand higher exhaust temperatures common in modified engines.

Advanced engine management systems represent another critical compliance pathway. Modern programmable ECUs allow for dual-map functionality, enabling separate calibrations for maximum performance and emissions-compliant operation. This approach permits switching between aggressive tuning profiles and more conservative settings that prioritize emissions control when necessary.

Exhaust gas recirculation (EGR) optimization presents a third strategy. Rather than eliminating EGR systems entirely, selective implementation during specific operating conditions can preserve their emissions benefits while minimizing performance impacts. Variable EGR control based on engine load and temperature provides an optimal balance.

Fuel system modifications also play a crucial role in emissions compliance. Higher-precision fuel injectors with optimized spray patterns ensure more complete combustion, reducing unburned hydrocarbon emissions even at higher power levels. Supplemental water-methanol injection systems can lower combustion temperatures, reducing NOx formation without sacrificing power.

For vehicles subject to periodic emissions testing, temporary ECU reflashing capabilities offer a practical solution. This approach allows enthusiasts to maintain a compliant calibration for testing purposes while enjoying enhanced performance during normal operation, though this strategy exists in a regulatory gray area in many jurisdictions.

The most comprehensive approach combines multiple strategies with emissions-focused data logging to verify compliance across various operating conditions. This methodology enables continuous refinement of engine calibrations to maintain the optimal balance between performance enhancement and emissions control.

Cost-Benefit Analysis of LS7 Performance Modifications

When evaluating performance modifications for the LS7 engine, a comprehensive cost-benefit analysis reveals significant insights for enthusiasts and professional tuners alike. The financial investment required for various modifications ranges considerably, with basic bolt-on upgrades starting at approximately $2,000-3,000, while comprehensive builds involving internal engine components can exceed $15,000. These costs must be weighed against measurable performance gains to determine true value.

Intake and exhaust modifications represent the entry point for many enthusiasts, offering modest power increases of 15-25 horsepower at relatively low cost ($500-1,500). The return on investment here is generally favorable, with minimal risk to engine reliability and immediate performance benefits. However, the performance ceiling is quickly reached with these modifications alone.

Camshaft upgrades present a more substantial cost-benefit proposition, typically ranging from $1,800-2,500 installed. These modifications can yield 30-50 horsepower gains when properly matched to the engine's breathing characteristics. The cost per horsepower ratio becomes more attractive at this modification level, though installation complexity increases substantially.

Forced induction represents the most dramatic performance enhancement option, with supercharger kits for the LS7 ranging from $6,000-9,000 installed. While expensive, these systems can deliver 150-200+ additional horsepower, resulting in a relatively efficient cost-per-horsepower metric. However, supporting modifications become necessary, creating a cascade of additional expenses that must be factored into the total investment calculation.

The analysis must also consider non-monetary factors such as reliability implications, warranty considerations, and vehicle resale impact. High-quality, professionally installed modifications tend to preserve more vehicle value than budget-oriented alternatives. Additionally, certain modifications may require more frequent maintenance or specialized service, creating ongoing costs that extend beyond the initial investment.

Dyno testing data indicates diminishing returns as modification investment increases. The first $3,000 spent typically yields approximately 40-60 horsepower gains, while the next $3,000 might only add an additional 30-40 horsepower. This non-linear relationship between investment and performance gains necessitates careful planning to optimize resource allocation based on specific performance goals.

For track-focused applications, the cost-benefit equation shifts significantly toward modifications that enhance durability and consistent performance rather than peak power figures. Cooling system upgrades, oiling system improvements, and chassis reinforcements may deliver better lap time improvements per dollar than pure horsepower additions in many cases.

Intake and exhaust modifications represent the entry point for many enthusiasts, offering modest power increases of 15-25 horsepower at relatively low cost ($500-1,500). The return on investment here is generally favorable, with minimal risk to engine reliability and immediate performance benefits. However, the performance ceiling is quickly reached with these modifications alone.

Camshaft upgrades present a more substantial cost-benefit proposition, typically ranging from $1,800-2,500 installed. These modifications can yield 30-50 horsepower gains when properly matched to the engine's breathing characteristics. The cost per horsepower ratio becomes more attractive at this modification level, though installation complexity increases substantially.

Forced induction represents the most dramatic performance enhancement option, with supercharger kits for the LS7 ranging from $6,000-9,000 installed. While expensive, these systems can deliver 150-200+ additional horsepower, resulting in a relatively efficient cost-per-horsepower metric. However, supporting modifications become necessary, creating a cascade of additional expenses that must be factored into the total investment calculation.

The analysis must also consider non-monetary factors such as reliability implications, warranty considerations, and vehicle resale impact. High-quality, professionally installed modifications tend to preserve more vehicle value than budget-oriented alternatives. Additionally, certain modifications may require more frequent maintenance or specialized service, creating ongoing costs that extend beyond the initial investment.

Dyno testing data indicates diminishing returns as modification investment increases. The first $3,000 spent typically yields approximately 40-60 horsepower gains, while the next $3,000 might only add an additional 30-40 horsepower. This non-linear relationship between investment and performance gains necessitates careful planning to optimize resource allocation based on specific performance goals.

For track-focused applications, the cost-benefit equation shifts significantly toward modifications that enhance durability and consistent performance rather than peak power figures. Cooling system upgrades, oiling system improvements, and chassis reinforcements may deliver better lap time improvements per dollar than pure horsepower additions in many cases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!