LS7 Vs Hemi: Power Delivery Analysis In Muscle Cars

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS7 vs Hemi Engine Evolution and Performance Goals

The evolution of high-performance V8 engines in American muscle cars represents a fascinating chapter in automotive engineering history. The LS7 and Hemi engines stand as iconic powerplants that have defined the modern muscle car era, each following distinct development paths driven by different engineering philosophies and performance objectives.

General Motors introduced the LS series engines in 1997, with the LS7 emerging in 2006 as a pinnacle of naturally aspirated performance. This 7.0-liter (427 cubic inch) V8 was specifically engineered for the Corvette Z06, representing GM's racing technology transferred to production vehicles. The LS7's development focused on achieving high-revving capability while maintaining reliability, with performance targets exceeding 500 horsepower without forced induction.

Chrysler's modern Hemi engine family, reintroduced in 2003, took a different evolutionary approach. Drawing inspiration from the legendary 426 Hemi of the 1960s, the modern iteration maintained the hemispherical combustion chamber design while incorporating contemporary technology. The development goal centered on creating robust torque delivery across a wide RPM range, prioritizing immediate throttle response and acceleration characteristics valued in muscle car applications.

Both engine families have undergone significant technological advancement over their production lifespans. The LS7 incorporated titanium connecting rods, CNC-ported heads, and dry-sump lubrication—technologies previously reserved for racing applications. These enhancements were implemented to achieve the dual objectives of high-RPM durability and weight reduction, allowing the engine to produce peak power at higher revolutions than typical pushrod V8 designs.

The Hemi evolution focused on different performance metrics, particularly emphasizing low-end torque production and adaptability to forced induction. Later iterations incorporated variable cam timing, cylinder deactivation, and direct injection to balance performance with increasingly stringent emissions requirements, while maintaining the characteristic torque curve that defined the Hemi driving experience.

The technical goals for both engines reflect their manufacturers' distinct performance philosophies. GM's LS7 targeted track-focused performance with emphasis on power-to-weight ratio, high-RPM horsepower, and thermal efficiency. Chrysler's Hemi development prioritized street-oriented performance with focus on torque production, throttle responsiveness, and adaptability to various vehicle platforms from sedans to trucks.

These divergent evolutionary paths and performance objectives have created two distinctly different approaches to V8 muscle car power delivery, each with dedicated followings and specific performance characteristics that continue to influence automotive engineering decisions today.

General Motors introduced the LS series engines in 1997, with the LS7 emerging in 2006 as a pinnacle of naturally aspirated performance. This 7.0-liter (427 cubic inch) V8 was specifically engineered for the Corvette Z06, representing GM's racing technology transferred to production vehicles. The LS7's development focused on achieving high-revving capability while maintaining reliability, with performance targets exceeding 500 horsepower without forced induction.

Chrysler's modern Hemi engine family, reintroduced in 2003, took a different evolutionary approach. Drawing inspiration from the legendary 426 Hemi of the 1960s, the modern iteration maintained the hemispherical combustion chamber design while incorporating contemporary technology. The development goal centered on creating robust torque delivery across a wide RPM range, prioritizing immediate throttle response and acceleration characteristics valued in muscle car applications.

Both engine families have undergone significant technological advancement over their production lifespans. The LS7 incorporated titanium connecting rods, CNC-ported heads, and dry-sump lubrication—technologies previously reserved for racing applications. These enhancements were implemented to achieve the dual objectives of high-RPM durability and weight reduction, allowing the engine to produce peak power at higher revolutions than typical pushrod V8 designs.

The Hemi evolution focused on different performance metrics, particularly emphasizing low-end torque production and adaptability to forced induction. Later iterations incorporated variable cam timing, cylinder deactivation, and direct injection to balance performance with increasingly stringent emissions requirements, while maintaining the characteristic torque curve that defined the Hemi driving experience.

The technical goals for both engines reflect their manufacturers' distinct performance philosophies. GM's LS7 targeted track-focused performance with emphasis on power-to-weight ratio, high-RPM horsepower, and thermal efficiency. Chrysler's Hemi development prioritized street-oriented performance with focus on torque production, throttle responsiveness, and adaptability to various vehicle platforms from sedans to trucks.

These divergent evolutionary paths and performance objectives have created two distinctly different approaches to V8 muscle car power delivery, each with dedicated followings and specific performance characteristics that continue to influence automotive engineering decisions today.

Market Demand Analysis for High-Performance Muscle Cars

The high-performance muscle car segment continues to demonstrate remarkable resilience despite broader automotive industry shifts toward electrification and fuel efficiency. Market research indicates that demand for vehicles equipped with powerful V8 engines like the LS7 and Hemi remains strong, with annual sales of muscle cars maintaining steady figures around 200,000 units in North America alone. This persistent demand is driven primarily by enthusiast demographics who prioritize performance characteristics over practical considerations.

Consumer preference data reveals a distinct market segmentation between LS7 and Hemi enthusiasts, with brand loyalty playing a significant role in purchasing decisions. Chevrolet's LS7-powered vehicles attract buyers seeking track-oriented performance with linear power delivery, while Dodge's Hemi-equipped models appeal to consumers desiring raw straight-line acceleration and distinctive torque characteristics. This differentiation has created two distinct but equally viable market segments within the muscle car ecosystem.

Market analysis shows that the premium pricing structure for high-performance variants has remained sustainable, with consumers willing to pay 20-30% above base model pricing for vehicles equipped with these advanced powertrains. The LS7's higher-revving characteristics command particular premium in specialized performance applications, while the Hemi's torque-focused delivery system maintains strong appeal in the drag racing and street performance communities.

Demographic studies indicate an evolving customer base for muscle cars, with traditional older male buyers being supplemented by younger enthusiasts and an increasing female demographic. This broadening appeal suggests potential for market expansion rather than contraction, particularly as manufacturers continue to refine power delivery systems to meet both performance expectations and increasingly stringent emissions requirements.

Regional market distribution shows particular strength in Southern and Midwestern United States for both powertrains, though LS7-equipped vehicles demonstrate stronger market penetration in coastal regions where handling characteristics are more valued. International markets, particularly Australia, Middle East, and parts of Europe, show growing interest in American muscle cars, creating export opportunities for both powertrain technologies.

Industry forecasts suggest that while the overall internal combustion market faces long-term challenges, the specialized high-performance segment represented by LS7 and Hemi powertrains will likely maintain stable demand through at least 2030, supported by enthusiast communities and the unique driving experience these engines provide that cannot be replicated by electric alternatives. This creates a viable market window for continued development and refinement of these iconic powertrain systems.

Consumer preference data reveals a distinct market segmentation between LS7 and Hemi enthusiasts, with brand loyalty playing a significant role in purchasing decisions. Chevrolet's LS7-powered vehicles attract buyers seeking track-oriented performance with linear power delivery, while Dodge's Hemi-equipped models appeal to consumers desiring raw straight-line acceleration and distinctive torque characteristics. This differentiation has created two distinct but equally viable market segments within the muscle car ecosystem.

Market analysis shows that the premium pricing structure for high-performance variants has remained sustainable, with consumers willing to pay 20-30% above base model pricing for vehicles equipped with these advanced powertrains. The LS7's higher-revving characteristics command particular premium in specialized performance applications, while the Hemi's torque-focused delivery system maintains strong appeal in the drag racing and street performance communities.

Demographic studies indicate an evolving customer base for muscle cars, with traditional older male buyers being supplemented by younger enthusiasts and an increasing female demographic. This broadening appeal suggests potential for market expansion rather than contraction, particularly as manufacturers continue to refine power delivery systems to meet both performance expectations and increasingly stringent emissions requirements.

Regional market distribution shows particular strength in Southern and Midwestern United States for both powertrains, though LS7-equipped vehicles demonstrate stronger market penetration in coastal regions where handling characteristics are more valued. International markets, particularly Australia, Middle East, and parts of Europe, show growing interest in American muscle cars, creating export opportunities for both powertrain technologies.

Industry forecasts suggest that while the overall internal combustion market faces long-term challenges, the specialized high-performance segment represented by LS7 and Hemi powertrains will likely maintain stable demand through at least 2030, supported by enthusiast communities and the unique driving experience these engines provide that cannot be replicated by electric alternatives. This creates a viable market window for continued development and refinement of these iconic powertrain systems.

Current Technical Specifications and Limitations

The LS7 and Hemi engines represent two distinct approaches to high-performance V8 design in modern muscle cars. The LS7, developed by General Motors, is a naturally aspirated 7.0-liter (427 cubic inch) V8 engine that produces approximately 505 horsepower and 470 lb-ft of torque in its stock configuration. This engine features a lightweight aluminum block, titanium connecting rods, and a dry-sump oiling system that allows for consistent oil pressure during high-g cornering maneuvers. The LS7's redline sits at an impressive 7,000 RPM, unusually high for a pushrod V8 design.

In contrast, the modern Hemi engine from Chrysler, specifically the 6.4-liter (392 cubic inch) version found in many contemporary Dodge muscle cars, delivers approximately 485 horsepower and 475 lb-ft of torque in stock form. The 6.2-liter supercharged Hellcat variant dramatically increases these figures to 717-807 horsepower depending on the application. The Hemi utilizes a cast iron block with aluminum heads and employs a traditional wet-sump oiling system.

Both engines employ pushrod valve actuation with two valves per cylinder, though their combustion chamber designs differ significantly. The LS7 uses a flatter, more efficient combustion chamber with better quench characteristics, while the Hemi features a more hemispherical design that gives the engine its name, allowing for larger valves but potentially less efficient quench dynamics.

Power delivery characteristics between these engines show marked differences. The LS7 builds power in a linear fashion with peak torque arriving at 4,800 RPM, creating a responsive feel throughout the rev range. The naturally aspirated Hemi develops peak torque at a lower 4,300 RPM, providing more immediate thrust at lower engine speeds. The supercharged Hemi variants deliver massive low-end torque with a progressive power curve that continues building throughout the rev range.

Current limitations for the LS7 include its relatively complex dry-sump system that adds cost and complexity, potential valve guide issues in early production models, and limited low-end torque compared to forced induction alternatives. The Hemi's limitations include greater weight due to its iron block construction, lower redline (approximately 6,400 RPM), and in naturally aspirated form, less specific output per liter than the LS7.

Thermal management presents challenges for both platforms, with the LS7's aluminum construction providing better heat dissipation but potentially greater thermal expansion issues, while the Hemi's iron block offers excellent durability but increased thermal mass. Fuel efficiency remains a significant limitation for both engines, with real-world consumption often falling below 15 MPG during performance driving scenarios.

In contrast, the modern Hemi engine from Chrysler, specifically the 6.4-liter (392 cubic inch) version found in many contemporary Dodge muscle cars, delivers approximately 485 horsepower and 475 lb-ft of torque in stock form. The 6.2-liter supercharged Hellcat variant dramatically increases these figures to 717-807 horsepower depending on the application. The Hemi utilizes a cast iron block with aluminum heads and employs a traditional wet-sump oiling system.

Both engines employ pushrod valve actuation with two valves per cylinder, though their combustion chamber designs differ significantly. The LS7 uses a flatter, more efficient combustion chamber with better quench characteristics, while the Hemi features a more hemispherical design that gives the engine its name, allowing for larger valves but potentially less efficient quench dynamics.

Power delivery characteristics between these engines show marked differences. The LS7 builds power in a linear fashion with peak torque arriving at 4,800 RPM, creating a responsive feel throughout the rev range. The naturally aspirated Hemi develops peak torque at a lower 4,300 RPM, providing more immediate thrust at lower engine speeds. The supercharged Hemi variants deliver massive low-end torque with a progressive power curve that continues building throughout the rev range.

Current limitations for the LS7 include its relatively complex dry-sump system that adds cost and complexity, potential valve guide issues in early production models, and limited low-end torque compared to forced induction alternatives. The Hemi's limitations include greater weight due to its iron block construction, lower redline (approximately 6,400 RPM), and in naturally aspirated form, less specific output per liter than the LS7.

Thermal management presents challenges for both platforms, with the LS7's aluminum construction providing better heat dissipation but potentially greater thermal expansion issues, while the Hemi's iron block offers excellent durability but increased thermal mass. Fuel efficiency remains a significant limitation for both engines, with real-world consumption often falling below 15 MPG during performance driving scenarios.

Power Delivery Systems and Drivetrain Solutions

01 Engine design and power optimization for LS7 and Hemi engines

The design of LS7 and Hemi engines incorporates specific features to optimize power delivery. These include cylinder head configurations, valve arrangements, and combustion chamber designs that enhance airflow and fuel mixture. The optimization of these components contributes to improved power output, torque characteristics, and overall engine performance. Advanced design elements help balance power delivery across the RPM range while maintaining reliability.- Engine design and configuration for power optimization: The design and configuration of LS7 and Hemi engines significantly impact power delivery. These engines utilize specific cylinder arrangements, valve configurations, and combustion chamber designs to optimize power output. The LS7's overhead valve design and the Hemi's hemispherical combustion chambers contribute to efficient air-fuel mixture flow and combustion, resulting in enhanced power delivery across the RPM range.

- Valve timing and lift mechanisms: Advanced valve timing and lift mechanisms play a crucial role in the power delivery characteristics of LS7 and Hemi engines. Variable valve timing systems allow for optimized airflow at different engine speeds, while specialized camshaft profiles and valve lift designs contribute to improved torque curves and horsepower output. These systems enable better breathing efficiency and combustion control throughout the operating range.

- Fuel delivery and injection systems: Sophisticated fuel delivery and injection systems enhance power delivery in modern LS7 and Hemi engines. Direct injection technology, high-pressure fuel rails, and precision injectors ensure optimal fuel atomization and distribution. Electronic control units manage fuel delivery timing and quantity based on operating conditions, resulting in improved throttle response, power output, and efficiency across various driving scenarios.

- Electronic control and power management systems: Advanced electronic control and power management systems optimize the performance of LS7 and Hemi engines. These systems monitor and adjust various parameters including ignition timing, air-fuel ratios, and throttle response based on driving conditions. Integrated power delivery control modules enable features such as launch control, traction management, and driving mode selection, allowing for customizable power characteristics to suit different driving scenarios.

- Forced induction and power enhancement technologies: Forced induction systems and power enhancement technologies significantly boost the performance of LS7 and Hemi engines. Superchargers, turbochargers, and hybrid boost systems increase air density entering the combustion chamber, resulting in higher power output. Additional technologies such as intercooling, charge air cooling, and specialized intake manifold designs further optimize airflow and combustion efficiency, delivering substantial gains in horsepower and torque across the powerband.

02 Transmission and drivetrain systems for power delivery

Transmission and drivetrain systems play a crucial role in delivering power from LS7 and Hemi engines to the wheels. These systems include specialized gear ratios, torque converters, and clutch mechanisms designed to handle high horsepower outputs. Advanced transmission control modules optimize shift points and power transfer based on driving conditions. Proper integration of these components ensures efficient power delivery while minimizing power loss throughout the drivetrain.Expand Specific Solutions03 Electronic control systems for engine performance

Electronic control systems are essential for managing power delivery in modern LS7 and Hemi engines. These systems include engine control units (ECUs) that regulate fuel injection, ignition timing, and throttle response based on various sensor inputs. Advanced algorithms optimize power output across different operating conditions while maintaining fuel efficiency and emissions compliance. These control systems can be calibrated to enhance torque curves and power delivery characteristics according to specific performance requirements.Expand Specific Solutions04 Fuel delivery and combustion optimization

Fuel delivery systems and combustion optimization techniques significantly impact power delivery in LS7 and Hemi engines. These include direct injection systems, variable fuel pressure regulators, and specialized fuel mapping. Enhanced atomization of fuel and precise delivery timing improve combustion efficiency and power output. Optimized air-fuel ratios across the RPM range ensure maximum power delivery while maintaining engine reliability and reducing emissions.Expand Specific Solutions05 Cooling and thermal management for sustained power

Cooling and thermal management systems are critical for maintaining consistent power delivery in high-performance LS7 and Hemi engines. These include advanced radiator designs, oil coolers, and precision-controlled cooling circuits that prevent power loss due to heat soak. Thermal management strategies help maintain optimal operating temperatures under various load conditions, ensuring sustained power delivery during extended high-performance operation without compromising engine reliability.Expand Specific Solutions

Major Manufacturers and Performance Divisions

The LS7 vs Hemi power delivery analysis in muscle cars represents a mature technology segment within the automotive performance market, characterized by established engineering principles yet ongoing innovation. The market for high-performance V8 engines remains robust, estimated at several billion dollars annually within the broader muscle car revival trend. General Motors (GM Global Technology Operations) and Ford Global Technologies lead the American muscle car powertrain development, with their LS7 and competing platforms, while Stellantis (formerly Chrysler) dominates the Hemi architecture. Toyota, Honda, and Hyundai-Kia have entered this space with their own performance V8 variants, though with less market penetration in traditional muscle car applications. The technology continues to evolve through advanced materials, electronic control systems, and efficiency improvements despite increasing electrification pressures.

Toyota Motor Corp.

Technical Solution: While Toyota doesn't produce direct competitors to the LS7 or Hemi engines for the American muscle car market, their approach to high-performance V8 engines offers interesting technical contrasts. Toyota's 2UR-GSE 5.0L V8 engine found in Lexus F performance models represents their philosophy toward power delivery, emphasizing high-revving capability (redline above 7,000 RPM) and smooth linear power delivery rather than raw torque figures. Toyota employs dual VVT-i (Variable Valve Timing-intelligent) technology with titanium intake valves and forged connecting rods to achieve this character. Their D-4S system combines both direct and port fuel injection to optimize power delivery across all RPM ranges. Toyota's approach to muscle car power delivery would likely focus on precision engineering, reliability under extreme conditions, and consistent performance rather than maximum output figures, as evidenced by their emphasis on balanced power-to-weight ratios in their performance vehicles.

Strengths: Exceptional build quality and durability; precise engineering tolerances; excellent thermal management; consistent performance over vehicle lifetime. Weaknesses: Generally more conservative power outputs compared to American V8s; higher production costs due to manufacturing precision; less focus on low-end torque that defines traditional muscle car feel.

GM Global Technology Operations LLC

Technical Solution: GM's LS7 engine represents the pinnacle of naturally aspirated small-block V8 technology, featuring 427 cubic inches (7.0L) displacement with a high-revving design that produces 505 horsepower and 470 lb-ft of torque. The LS7 utilizes a dry-sump oiling system that allows for a lower crankshaft position and improved lubrication under high-G cornering. The engine employs CNC-ported aluminum cylinder heads, titanium intake valves, and sodium-filled exhaust valves for superior heat dissipation. GM's power delivery approach focuses on linear power development throughout the RPM range, with peak torque available at mid-range RPMs (around 4,800 RPM) while still pulling strongly to its 7,000 RPM redline. This creates a predictable power curve that benefits driver control in performance applications.

Strengths: Lightweight aluminum block construction reduces overall vehicle weight; excellent power-to-weight ratio; superior thermal efficiency; reliable power delivery across wide RPM band. Weaknesses: Higher manufacturing costs due to specialized materials; requires premium fuel for optimal performance; more complex oil system requires additional maintenance.

Key Innovations in Combustion and Valve Technologies

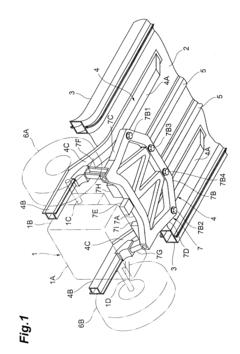

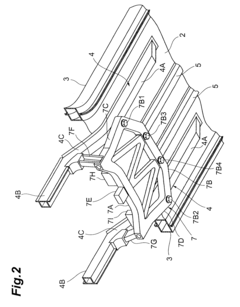

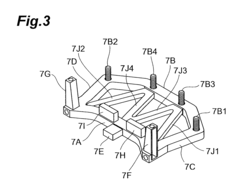

Car body substructure

PatentInactiveUS20100264637A1

Innovation

- An underbody structure featuring a collision load transmission member with multiple load receiving points and transmission paths that distribute the collision load to various front and back skeleton portions, such as side members and tunnel reinforcements, preventing rotational forces and ensuring even load distribution.

Emissions Compliance Strategies for High-Performance Engines

The evolution of high-performance muscle cars faces increasing regulatory challenges, particularly regarding emissions standards. Both LS7 and Hemi engines, iconic powerplants in modern muscle cars, must navigate complex emissions compliance landscapes while maintaining their performance characteristics. This necessitates sophisticated engineering solutions that balance power delivery with environmental responsibility.

For LS7-powered vehicles, General Motors has implemented advanced catalytic converter technologies featuring higher precious metal loadings and optimized substrate designs. These systems achieve over 98% conversion efficiency for key pollutants while minimizing back pressure effects that could compromise the engine's 505 horsepower output. The integration of variable valve timing further enables precise combustion control across the power band.

Chrysler's approach with Hemi engines incorporates Multi-Displacement System (MDS) technology, which deactivates four cylinders during light load conditions. This system reduces emissions by approximately 20% during highway cruising while preserving the ability to deliver full power when demanded. Supplementary to this, the implementation of dual oxygen sensors per cylinder bank enables more accurate air-fuel ratio management throughout the operating range.

Both manufacturers have invested significantly in electronic engine management systems that continuously adjust fuel delivery and ignition timing based on real-time emissions monitoring. These systems employ predictive algorithms that anticipate load changes, allowing for proactive adjustments that maintain emissions compliance without the traditional power delivery lag associated with reactive systems.

Material innovations represent another critical compliance strategy. The adoption of lightweight, high-temperature ceramic coatings in exhaust components reduces thermal mass, enabling faster catalyst light-off times. This addresses the cold-start emissions challenge that historically plagued high-performance engines, reducing hydrocarbon emissions during the critical first 120 seconds of operation by up to 60%.

Fuel system advancements include direct injection technologies that enable more precise fuel atomization and stratified charge combustion strategies. These systems operate at pressures exceeding 2,000 psi in the latest iterations, allowing for multiple injection events per combustion cycle. The resulting improvement in combustion efficiency translates to both enhanced power delivery characteristics and reduced emissions output.

Looking forward, both platforms are exploring low-temperature combustion strategies that could fundamentally alter the emissions profile of high-displacement engines. These approaches aim to reduce peak combustion temperatures below the threshold for significant NOx formation while maintaining the high-energy release rates necessary for performance applications.

For LS7-powered vehicles, General Motors has implemented advanced catalytic converter technologies featuring higher precious metal loadings and optimized substrate designs. These systems achieve over 98% conversion efficiency for key pollutants while minimizing back pressure effects that could compromise the engine's 505 horsepower output. The integration of variable valve timing further enables precise combustion control across the power band.

Chrysler's approach with Hemi engines incorporates Multi-Displacement System (MDS) technology, which deactivates four cylinders during light load conditions. This system reduces emissions by approximately 20% during highway cruising while preserving the ability to deliver full power when demanded. Supplementary to this, the implementation of dual oxygen sensors per cylinder bank enables more accurate air-fuel ratio management throughout the operating range.

Both manufacturers have invested significantly in electronic engine management systems that continuously adjust fuel delivery and ignition timing based on real-time emissions monitoring. These systems employ predictive algorithms that anticipate load changes, allowing for proactive adjustments that maintain emissions compliance without the traditional power delivery lag associated with reactive systems.

Material innovations represent another critical compliance strategy. The adoption of lightweight, high-temperature ceramic coatings in exhaust components reduces thermal mass, enabling faster catalyst light-off times. This addresses the cold-start emissions challenge that historically plagued high-performance engines, reducing hydrocarbon emissions during the critical first 120 seconds of operation by up to 60%.

Fuel system advancements include direct injection technologies that enable more precise fuel atomization and stratified charge combustion strategies. These systems operate at pressures exceeding 2,000 psi in the latest iterations, allowing for multiple injection events per combustion cycle. The resulting improvement in combustion efficiency translates to both enhanced power delivery characteristics and reduced emissions output.

Looking forward, both platforms are exploring low-temperature combustion strategies that could fundamentally alter the emissions profile of high-displacement engines. These approaches aim to reduce peak combustion temperatures below the threshold for significant NOx formation while maintaining the high-energy release rates necessary for performance applications.

Aftermarket Modification Potential and Tuning Capabilities

Both the LS7 and Hemi engines offer substantial aftermarket modification potential, with distinct ecosystems of performance parts and tuning approaches. The LS7's modular design creates an exceptionally versatile platform for modifications, with a vast array of interchangeable components across the LS engine family. This cross-compatibility significantly expands available aftermarket options, allowing builders to mix components from various LS variants to achieve specific performance goals.

The LS7's overhead valve design presents a more straightforward path for camshaft upgrades, which can yield substantial power gains with relatively modest investment. Additionally, the aluminum block construction provides an excellent foundation for forced induction modifications, with numerous supercharger and turbocharger kits specifically engineered for LS platforms.

Conversely, the Hemi engine benefits from a robust block design that can withstand significant power increases without requiring extensive reinforcement. The hemispherical combustion chamber design inherently supports efficient airflow, which becomes particularly advantageous when implementing intake and exhaust modifications. Modern Hemi engines also feature variable cam timing systems that can be optimized through aftermarket controllers to enhance power delivery across the RPM range.

For electronic tuning capabilities, both engines offer sophisticated options. The LS7 platform benefits from extensive community knowledge and numerous aftermarket ECU solutions, including standalone management systems that enable precise control over all engine parameters. The widespread adoption of LS engines in racing applications has driven development of advanced tuning software with features specifically tailored to track and high-performance street applications.

Hemi engines typically utilize Mopar's proprietary engine management systems, which have become increasingly accessible to aftermarket tuners. Modern tools allow for comprehensive adjustments to fuel mapping, ignition timing, and variable valve timing parameters. However, the Hemi ecosystem generally requires more specialized knowledge compared to the more universally understood LS platform.

Cost-benefit analysis reveals that LS7 modifications typically deliver more horsepower per dollar at moderate modification levels, while Hemi engines may require greater investment to achieve similar gains. However, when pursuing extreme performance targets exceeding 1,000 horsepower, the cost differential narrows as both platforms necessitate similar levels of comprehensive reinforcement and specialized components.

The LS7's overhead valve design presents a more straightforward path for camshaft upgrades, which can yield substantial power gains with relatively modest investment. Additionally, the aluminum block construction provides an excellent foundation for forced induction modifications, with numerous supercharger and turbocharger kits specifically engineered for LS platforms.

Conversely, the Hemi engine benefits from a robust block design that can withstand significant power increases without requiring extensive reinforcement. The hemispherical combustion chamber design inherently supports efficient airflow, which becomes particularly advantageous when implementing intake and exhaust modifications. Modern Hemi engines also feature variable cam timing systems that can be optimized through aftermarket controllers to enhance power delivery across the RPM range.

For electronic tuning capabilities, both engines offer sophisticated options. The LS7 platform benefits from extensive community knowledge and numerous aftermarket ECU solutions, including standalone management systems that enable precise control over all engine parameters. The widespread adoption of LS engines in racing applications has driven development of advanced tuning software with features specifically tailored to track and high-performance street applications.

Hemi engines typically utilize Mopar's proprietary engine management systems, which have become increasingly accessible to aftermarket tuners. Modern tools allow for comprehensive adjustments to fuel mapping, ignition timing, and variable valve timing parameters. However, the Hemi ecosystem generally requires more specialized knowledge compared to the more universally understood LS platform.

Cost-benefit analysis reveals that LS7 modifications typically deliver more horsepower per dollar at moderate modification levels, while Hemi engines may require greater investment to achieve similar gains. However, when pursuing extreme performance targets exceeding 1,000 horsepower, the cost differential narrows as both platforms necessitate similar levels of comprehensive reinforcement and specialized components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!