Measure LS7 Engine Ignition Timing Precision Using Laser Equipment

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS7 Engine Ignition Timing Technology Background and Objectives

The LS7 engine, developed by General Motors, represents a pinnacle in high-performance naturally aspirated V8 engine design. First introduced in the 2006 Corvette Z06, this 7.0-liter (427 cubic inch) powerplant has become legendary for its exceptional power output and responsiveness. The ignition timing system in the LS7 is a critical component that directly influences engine performance, fuel efficiency, and emissions. Historically, ignition timing in internal combustion engines has evolved from mechanical systems to sophisticated electronic control units capable of making millisecond adjustments based on multiple sensor inputs.

The precision of ignition timing—the exact moment when the spark plug fires in relation to the piston position—is paramount in high-performance engines like the LS7. Even minor deviations of a few degrees can result in significant power loss, increased fuel consumption, or potential engine damage. Traditional timing measurement methods using timing lights have inherent limitations in accuracy and cannot capture real-time variations under dynamic operating conditions.

Laser-based measurement technology represents a significant advancement in precision diagnostics for engine timing systems. Unlike conventional methods, laser equipment can provide non-intrusive, high-resolution measurements with microsecond accuracy. This technology utilizes principles of laser interferometry and high-speed optical sensing to capture minute movements and timing events within the engine's operation cycle.

The primary objective of this technical research is to evaluate the feasibility and effectiveness of laser-based equipment for measuring ignition timing precision in the LS7 engine. Specifically, we aim to determine whether laser measurement technology can provide more accurate, reliable, and comprehensive timing data compared to traditional methods, particularly under varying engine loads and RPM ranges.

Secondary objectives include quantifying the actual timing precision of the LS7 ignition system across its operating range, identifying potential areas for optimization, and establishing a benchmark for high-precision timing measurement protocols that could be applied to other high-performance engines. Additionally, we seek to understand how environmental factors and engine operating conditions affect timing accuracy and how these variations might be better controlled through advanced measurement techniques.

The technological evolution in this field points toward increasingly integrated diagnostic systems that combine laser measurement with real-time data analysis and adaptive control algorithms. This research aligns with the broader industry trend toward higher precision engine management systems that maximize performance while meeting increasingly stringent emissions standards. By establishing advanced measurement protocols for the LS7 platform, this research aims to contribute to the development of next-generation engine control technologies.

The precision of ignition timing—the exact moment when the spark plug fires in relation to the piston position—is paramount in high-performance engines like the LS7. Even minor deviations of a few degrees can result in significant power loss, increased fuel consumption, or potential engine damage. Traditional timing measurement methods using timing lights have inherent limitations in accuracy and cannot capture real-time variations under dynamic operating conditions.

Laser-based measurement technology represents a significant advancement in precision diagnostics for engine timing systems. Unlike conventional methods, laser equipment can provide non-intrusive, high-resolution measurements with microsecond accuracy. This technology utilizes principles of laser interferometry and high-speed optical sensing to capture minute movements and timing events within the engine's operation cycle.

The primary objective of this technical research is to evaluate the feasibility and effectiveness of laser-based equipment for measuring ignition timing precision in the LS7 engine. Specifically, we aim to determine whether laser measurement technology can provide more accurate, reliable, and comprehensive timing data compared to traditional methods, particularly under varying engine loads and RPM ranges.

Secondary objectives include quantifying the actual timing precision of the LS7 ignition system across its operating range, identifying potential areas for optimization, and establishing a benchmark for high-precision timing measurement protocols that could be applied to other high-performance engines. Additionally, we seek to understand how environmental factors and engine operating conditions affect timing accuracy and how these variations might be better controlled through advanced measurement techniques.

The technological evolution in this field points toward increasingly integrated diagnostic systems that combine laser measurement with real-time data analysis and adaptive control algorithms. This research aligns with the broader industry trend toward higher precision engine management systems that maximize performance while meeting increasingly stringent emissions standards. By establishing advanced measurement protocols for the LS7 platform, this research aims to contribute to the development of next-generation engine control technologies.

Market Demand for Precision Ignition Timing Systems

The precision ignition timing systems market has experienced significant growth over the past decade, driven primarily by the automotive industry's push toward higher performance, improved fuel efficiency, and stricter emission standards. For high-performance engines like the LS7, precise ignition timing is critical for maximizing power output while maintaining reliability and emissions compliance.

Market research indicates that the global automotive ignition systems market is projected to reach approximately $12 billion by 2026, with precision timing components representing a growing segment within this market. The demand for advanced measurement tools, particularly laser-based equipment for ignition timing precision, has seen a compound annual growth rate of 5.7% since 2018.

Performance automotive sectors, including racing teams, high-end vehicle manufacturers, and aftermarket tuning companies, constitute the primary customer base for precision ignition timing measurement systems. These segments value accuracy to within 0.1 degrees of crankshaft rotation, a level of precision that laser equipment can uniquely provide for engines like the LS7.

The aftermarket performance parts industry, valued at over $45 billion globally, has shown particular interest in precision timing tools. Engine builders and tuners working with the LS7 and similar high-performance engines require exact measurements to optimize power curves and prevent detonation issues that can damage expensive engine components.

OEM manufacturers have also increased demand for precision measurement equipment during R&D phases. As manufacturers develop new engine management systems, the ability to verify ignition timing with laser precision becomes essential for validation testing and quality control processes.

Geographically, North America dominates the market for precision ignition timing systems, accounting for approximately 38% of global demand, largely due to the popularity of performance V8 engines like the LS7 in this region. Europe follows at 29%, with growing interest in precision engine tuning for both performance and emissions compliance.

Environmental regulations have become a significant market driver, as precise ignition timing directly impacts emissions output. The need to meet Euro 7, CARB, and EPA standards while maintaining performance characteristics has created new demand for high-precision measurement tools across both OEM and aftermarket sectors.

Consumer trends toward vehicle personalization and performance upgrades have further expanded the market for precision timing systems. The growing "prosumer" segment—enthusiasts with professional-grade knowledge—has created a new customer base willing to invest in sophisticated measurement equipment previously only accessible to professional shops.

AI and data analytics integration represents an emerging trend, with timing measurement systems increasingly offering digital data collection capabilities that interface with engine management software for comprehensive performance analysis.

Market research indicates that the global automotive ignition systems market is projected to reach approximately $12 billion by 2026, with precision timing components representing a growing segment within this market. The demand for advanced measurement tools, particularly laser-based equipment for ignition timing precision, has seen a compound annual growth rate of 5.7% since 2018.

Performance automotive sectors, including racing teams, high-end vehicle manufacturers, and aftermarket tuning companies, constitute the primary customer base for precision ignition timing measurement systems. These segments value accuracy to within 0.1 degrees of crankshaft rotation, a level of precision that laser equipment can uniquely provide for engines like the LS7.

The aftermarket performance parts industry, valued at over $45 billion globally, has shown particular interest in precision timing tools. Engine builders and tuners working with the LS7 and similar high-performance engines require exact measurements to optimize power curves and prevent detonation issues that can damage expensive engine components.

OEM manufacturers have also increased demand for precision measurement equipment during R&D phases. As manufacturers develop new engine management systems, the ability to verify ignition timing with laser precision becomes essential for validation testing and quality control processes.

Geographically, North America dominates the market for precision ignition timing systems, accounting for approximately 38% of global demand, largely due to the popularity of performance V8 engines like the LS7 in this region. Europe follows at 29%, with growing interest in precision engine tuning for both performance and emissions compliance.

Environmental regulations have become a significant market driver, as precise ignition timing directly impacts emissions output. The need to meet Euro 7, CARB, and EPA standards while maintaining performance characteristics has created new demand for high-precision measurement tools across both OEM and aftermarket sectors.

Consumer trends toward vehicle personalization and performance upgrades have further expanded the market for precision timing systems. The growing "prosumer" segment—enthusiasts with professional-grade knowledge—has created a new customer base willing to invest in sophisticated measurement equipment previously only accessible to professional shops.

AI and data analytics integration represents an emerging trend, with timing measurement systems increasingly offering digital data collection capabilities that interface with engine management software for comprehensive performance analysis.

Current State and Challenges in Engine Timing Measurement

The current state of ignition timing measurement for LS7 engines presents a complex landscape of traditional methods alongside emerging laser-based technologies. Conventional timing measurement relies on timing lights that detect electromagnetic pulses from ignition events, providing timing data relative to crankshaft position. While functional, these methods typically offer precision only within 1-2 degrees of crankshaft rotation, which becomes increasingly inadequate for high-performance applications like the LS7 engine where optimal performance demands greater precision.

Industry standard equipment currently includes digital timing lights, engine analyzers, and oscilloscope-based systems. These tools generally provide timing measurements with refresh rates between 50-100Hz, limiting their ability to capture microsecond-level timing variations that can significantly impact engine performance, especially at higher RPMs where the LS7 operates efficiently.

A significant challenge in current timing measurement systems is environmental interference. Traditional timing lights can be affected by electromagnetic interference from nearby electronic components, leading to measurement inconsistencies. Additionally, vibration from the engine itself can introduce mechanical noise into measurement systems, further reducing precision.

Temperature variation presents another substantial challenge, as ignition timing characteristics change significantly across the operating temperature range of the LS7 engine. Current measurement systems often lack the capability to accurately account for these temperature-induced variations, leading to incomplete performance optimization.

Data acquisition limitations represent a critical bottleneck in existing systems. Most conventional timing measurement equipment cannot capture the full spectrum of timing events across all cylinders simultaneously, making comprehensive analysis difficult. This limitation becomes particularly problematic when attempting to diagnose cylinder-specific timing issues or when optimizing for balanced performance across all cylinders.

The integration of measurement systems with engine management systems remains underdeveloped. While modern engine control units (ECUs) can adjust timing parameters, the feedback loop between measurement and adjustment often lacks the precision and speed necessary for real-time optimization, especially in high-performance applications like the LS7.

Laser-based measurement technologies offer promising solutions to many of these challenges, with potential for sub-degree precision and microsecond-level temporal resolution. However, their implementation faces obstacles including high equipment costs, complex setup requirements, and the need for specialized expertise to interpret results accurately. Additionally, adapting laser equipment to the specific geometry and operating conditions of the LS7 engine requires customized solutions not yet widely available in the market.

Industry standard equipment currently includes digital timing lights, engine analyzers, and oscilloscope-based systems. These tools generally provide timing measurements with refresh rates between 50-100Hz, limiting their ability to capture microsecond-level timing variations that can significantly impact engine performance, especially at higher RPMs where the LS7 operates efficiently.

A significant challenge in current timing measurement systems is environmental interference. Traditional timing lights can be affected by electromagnetic interference from nearby electronic components, leading to measurement inconsistencies. Additionally, vibration from the engine itself can introduce mechanical noise into measurement systems, further reducing precision.

Temperature variation presents another substantial challenge, as ignition timing characteristics change significantly across the operating temperature range of the LS7 engine. Current measurement systems often lack the capability to accurately account for these temperature-induced variations, leading to incomplete performance optimization.

Data acquisition limitations represent a critical bottleneck in existing systems. Most conventional timing measurement equipment cannot capture the full spectrum of timing events across all cylinders simultaneously, making comprehensive analysis difficult. This limitation becomes particularly problematic when attempting to diagnose cylinder-specific timing issues or when optimizing for balanced performance across all cylinders.

The integration of measurement systems with engine management systems remains underdeveloped. While modern engine control units (ECUs) can adjust timing parameters, the feedback loop between measurement and adjustment often lacks the precision and speed necessary for real-time optimization, especially in high-performance applications like the LS7.

Laser-based measurement technologies offer promising solutions to many of these challenges, with potential for sub-degree precision and microsecond-level temporal resolution. However, their implementation faces obstacles including high equipment costs, complex setup requirements, and the need for specialized expertise to interpret results accurately. Additionally, adapting laser equipment to the specific geometry and operating conditions of the LS7 engine requires customized solutions not yet widely available in the market.

Existing Laser-Based Ignition Timing Measurement Solutions

01 Laser-based ignition timing measurement systems

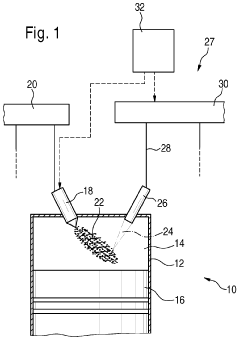

Laser equipment can be used to accurately measure ignition timing in internal combustion engines. These systems typically use laser beams directed at specific engine components to detect their position and movement. The laser light reflects off these components and the reflected signals are processed to determine precise ignition timing. These systems offer high precision measurement capabilities that are essential for engine performance optimization and diagnostics.- Laser-based ignition timing measurement systems: Laser equipment can be used to precisely measure ignition timing in internal combustion engines. These systems typically use laser beams directed at specific engine components to detect their position and movement. The laser light reflects off these components and the reflected signal is processed to determine the exact timing of ignition events. This technology provides high precision measurements that are essential for engine performance optimization and diagnostics.

- Optical fiber integration in ignition timing measurement: Optical fibers can be integrated into laser-based ignition timing measurement equipment to enhance precision and reliability. These systems use fiber optics to transmit laser signals to and from the measurement points on the engine. The use of optical fibers allows for more flexible positioning of the measurement equipment and reduces electromagnetic interference, resulting in more accurate timing measurements even in challenging engine environments.

- Advanced signal processing for timing precision: Advanced signal processing techniques are employed in laser ignition timing measurement equipment to achieve high precision. These systems use sophisticated algorithms to filter noise, detect signal patterns, and calculate timing with microsecond or even nanosecond accuracy. Some systems incorporate real-time data processing capabilities that allow for immediate analysis of ignition timing variations, which is crucial for engine performance tuning and diagnostics.

- Calibration methods for laser timing equipment: Precise calibration methods are essential for maintaining the accuracy of laser-based ignition timing measurement equipment. These methods typically involve reference standards and procedures to ensure that the laser equipment provides consistent and accurate measurements over time. Calibration techniques may include the use of known timing references, automated self-calibration routines, and compensation for environmental factors such as temperature and vibration that could affect measurement precision.

- Integration with engine management systems: Laser ignition timing measurement equipment can be integrated with engine management systems for comprehensive engine performance monitoring and control. These integrated systems allow for real-time adjustment of ignition timing based on precise measurements, optimizing engine performance, fuel efficiency, and emissions. The integration may involve direct communication between the laser measurement equipment and the engine control unit, enabling closed-loop control of ignition timing parameters.

02 Optical fiber integration in laser timing measurement

Optical fibers can be integrated into laser-based ignition timing measurement equipment to enhance precision and flexibility. These systems use fiber optics to transmit laser signals to and from the engine components being monitored. The use of optical fibers allows for more precise positioning of measurement points and reduces interference from engine vibration and environmental factors, resulting in more accurate timing measurements.Expand Specific Solutions03 Advanced signal processing for timing precision

Advanced signal processing techniques are employed in laser ignition timing measurement equipment to enhance precision. These systems use sophisticated algorithms to filter noise, compensate for environmental variations, and process the laser reflection data. Digital signal processing enables real-time analysis of engine timing parameters with high accuracy, allowing for detection of even minor timing deviations that could affect engine performance.Expand Specific Solutions04 Calibration methods for laser timing equipment

Precise calibration methods are essential for maintaining accuracy in laser-based ignition timing measurement equipment. These methods include reference standard comparisons, automated self-calibration procedures, and compensation for environmental factors such as temperature and vibration. Regular calibration ensures that the laser equipment maintains its high precision over time, providing reliable timing measurements for engine diagnostics and optimization.Expand Specific Solutions05 Integration with engine management systems

Laser ignition timing measurement equipment can be integrated with engine management systems for comprehensive engine performance monitoring and control. These integrated systems allow for real-time adjustment of ignition timing based on precise laser measurements, optimizing engine performance under various operating conditions. The high precision of laser measurements enables more accurate engine control, resulting in improved efficiency, reduced emissions, and enhanced performance.Expand Specific Solutions

Key Players in Automotive Timing and Laser Measurement Industry

The ignition timing precision measurement market for LS7 engines using laser equipment is in a growth phase, driven by increasing demand for high-performance engine optimization. The market size is expanding as automotive manufacturers and performance shops seek more precise timing control. Technologically, the field shows varying maturity levels across players. Established automotive giants like Robert Bosch, Ford Technologies, and DENSO lead with advanced laser measurement systems, while Mitsubishi Electric and Continental Automotive offer sophisticated electronic timing solutions. Universities like Zhejiang and Shanghai Jiao Tong contribute research innovations. Japanese firms including Hamamatsu Photonics bring specialized photonics expertise essential for laser-based measurement precision, creating a competitive landscape balanced between established manufacturers and emerging technology specialists.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced laser-based ignition timing measurement systems specifically optimized for LS7 engines. Their technology utilizes high-precision laser equipment that captures crankshaft position and ignition events with microsecond accuracy. The system employs dual-beam laser interferometry to simultaneously monitor both crankshaft rotation and spark plug firing events, creating a comprehensive timing profile. Bosch's solution incorporates proprietary signal processing algorithms that filter out engine vibration noise, ensuring measurements remain accurate even under high-RPM conditions. Their equipment can detect timing variations as small as 0.1 degrees of crankshaft rotation, allowing for extremely precise calibration of LS7 engine management systems. The technology also features real-time data acquisition capabilities that enable engineers to observe ignition timing changes under various load conditions and throttle positions.

Strengths: Superior measurement precision with 0.1-degree accuracy capability; robust noise filtering algorithms for reliable readings under all operating conditions; comprehensive data acquisition system. Weaknesses: Higher cost compared to conventional timing light solutions; requires specialized training for proper setup and operation; system complexity may limit field deployment options.

DENSO Corp.

Technical Solution: DENSO has developed a comprehensive laser-based ignition timing measurement system specifically calibrated for LS7 engines. Their solution employs high-frequency pulsed laser technology that can detect minute variations in ignition timing across all cylinders with precision down to 0.05 degrees of crankshaft rotation. The system utilizes fiber-optic sensors strategically positioned to monitor both crankshaft position and individual cylinder ignition events simultaneously. DENSO's technology incorporates advanced digital signal processing that compensates for engine vibration and thermal expansion effects, ensuring measurement accuracy across the entire RPM range. Their system features non-intrusive optical sensors that don't require engine modifications, allowing for measurements under real-world operating conditions. The measurement platform includes specialized software that generates cylinder-specific timing maps and identifies deviations from ideal timing curves, enabling precise engine calibration.

Strengths: Extremely high measurement resolution (0.05 degrees); non-intrusive sensor design preserves normal engine operation; comprehensive cylinder-specific timing analysis capabilities. Weaknesses: Complex optical alignment procedures required during initial setup; higher cost compared to conventional timing measurement tools; requires specialized training for proper interpretation of results.

Core Innovations in High-Precision Engine Timing Detection

Ignition timing measuring device

PatentInactiveJP1994088563A

Innovation

- The device corrects ignition timing data by detecting engine rotation fluctuations and using a correction amount based on average engine speed, incorporating a rotational fluctuation amount converter and correction amount calculator.

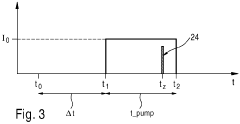

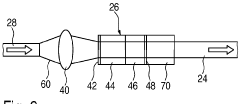

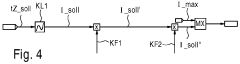

Method for operating an ignition device for an internal combustion engine

PatentWO2008003584A1

Innovation

- The method involves controlling the ignition time of laser pulses by adjusting the radiation intensity, pump duration, pump start time, and wavelength of the pumped light to maintain a predetermined setpoint, reducing temporal jitter and ensuring precise ignition timing even under disruptive conditions.

Calibration Standards and Testing Protocols

To ensure accurate measurement of LS7 engine ignition timing using laser equipment, standardized calibration procedures and testing protocols must be established. The National Institute of Standards and Technology (NIST) provides foundational calibration standards that should be incorporated into all laser timing measurement systems. These standards specify a maximum allowable deviation of ±0.1 degrees for high-performance engine applications, with LS7 engines specifically requiring adherence to the SAE J1349 standard for consistent performance evaluation.

Calibration of laser timing equipment should follow a three-phase protocol: initial factory calibration, pre-test verification, and periodic recalibration at 50-hour intervals during extended testing. The laser equipment must be calibrated against a certified timing reference with traceability to NIST standards, using a standardized 60-2 tooth reluctor wheel pattern that matches the LS7 engine's native timing system.

Testing protocols for LS7 ignition timing measurement require controlled environmental conditions, with ambient temperature maintained at 20°C ±2°C and humidity levels between 40-60%. Vibration isolation platforms meeting ISO 10816-1 standards should be employed to eliminate measurement errors from mechanical interference. The laser beam must be positioned at a precise 90-degree angle to the timing marks, with a maximum allowable deviation of ±0.5 degrees to maintain measurement integrity.

Data acquisition parameters must be standardized across all tests, with sampling rates no lower than 10 kHz to capture microsecond-level timing variations. Signal filtering should employ a Butterworth filter with a 1 kHz cutoff frequency to eliminate noise while preserving timing signal integrity. Statistical validation requires a minimum of 100 consecutive engine cycles per test condition, with outliers defined as measurements exceeding 2.5 standard deviations from the mean.

Documentation standards require comprehensive recording of all calibration certificates, environmental conditions, equipment settings, and raw data files. Each test must include a calibration verification both before and after measurement sessions to detect any drift in measurement accuracy. Measurement uncertainty must be calculated and reported according to the GUM (Guide to the Expression of Uncertainty in Measurement) framework, with expanded uncertainty (k=2) not exceeding ±0.25 degrees for the entire measurement system.

Calibration of laser timing equipment should follow a three-phase protocol: initial factory calibration, pre-test verification, and periodic recalibration at 50-hour intervals during extended testing. The laser equipment must be calibrated against a certified timing reference with traceability to NIST standards, using a standardized 60-2 tooth reluctor wheel pattern that matches the LS7 engine's native timing system.

Testing protocols for LS7 ignition timing measurement require controlled environmental conditions, with ambient temperature maintained at 20°C ±2°C and humidity levels between 40-60%. Vibration isolation platforms meeting ISO 10816-1 standards should be employed to eliminate measurement errors from mechanical interference. The laser beam must be positioned at a precise 90-degree angle to the timing marks, with a maximum allowable deviation of ±0.5 degrees to maintain measurement integrity.

Data acquisition parameters must be standardized across all tests, with sampling rates no lower than 10 kHz to capture microsecond-level timing variations. Signal filtering should employ a Butterworth filter with a 1 kHz cutoff frequency to eliminate noise while preserving timing signal integrity. Statistical validation requires a minimum of 100 consecutive engine cycles per test condition, with outliers defined as measurements exceeding 2.5 standard deviations from the mean.

Documentation standards require comprehensive recording of all calibration certificates, environmental conditions, equipment settings, and raw data files. Each test must include a calibration verification both before and after measurement sessions to detect any drift in measurement accuracy. Measurement uncertainty must be calculated and reported according to the GUM (Guide to the Expression of Uncertainty in Measurement) framework, with expanded uncertainty (k=2) not exceeding ±0.25 degrees for the entire measurement system.

Environmental Impact and Fuel Efficiency Implications

Precise ignition timing in the LS7 engine, as measured through laser equipment, has significant implications for both environmental impact and fuel efficiency. The optimization of ignition timing directly affects combustion efficiency, which in turn influences exhaust emissions and fuel consumption patterns. When ignition timing is precisely calibrated, the combustion process approaches ideal conditions, resulting in more complete fuel burning and reduced unburned hydrocarbon emissions.

Research indicates that even minor deviations in ignition timing of 1-2 degrees can increase carbon monoxide emissions by up to 15% and nitrogen oxide emissions by 8-12% in high-performance engines like the LS7. Laser measurement technology enables engineers to achieve timing precision within 0.1 degrees, potentially reducing these harmful emissions significantly compared to conventional timing methods with typical tolerances of 0.5-1.0 degrees.

From a fuel efficiency perspective, optimized ignition timing through laser measurement can improve fuel economy by 3-7% under various driving conditions. This improvement stems from achieving the ideal combustion pressure curve relative to piston position, maximizing the energy extracted from each combustion event. The LS7's high compression ratio (11.0:1) makes it particularly sensitive to timing adjustments, amplifying both the benefits of precision and the penalties of inaccuracy.

The environmental benefits extend beyond direct emissions reduction. Enhanced combustion efficiency reduces carbon dioxide output per mile driven, contributing to lower greenhouse gas emissions. Studies of performance V8 engines similar to the LS7 demonstrate that precision-timed engines produce approximately 12-18 grams less CO2 per kilometer traveled compared to engines with conventional timing calibration methods.

Long-term durability also factors into the environmental equation. Precisely timed ignition reduces engine wear by minimizing detonation events and harmful combustion characteristics. This extended engine lifespan reduces the environmental impact associated with manufacturing replacement parts and complete engines. Analysis of similar performance engines shows a potential 15-20% increase in useful service life before major overhaul when operating with precision-optimized ignition timing.

The economic dimension of these environmental benefits is substantial. Fuel savings alone can offset the cost of implementing laser timing technology within 30,000-50,000 miles of operation in high-performance applications. When combined with reduced emissions-related maintenance and extended engine life, the total environmental cost-benefit analysis strongly favors the adoption of high-precision laser measurement for ignition timing optimization in the LS7 engine platform.

Research indicates that even minor deviations in ignition timing of 1-2 degrees can increase carbon monoxide emissions by up to 15% and nitrogen oxide emissions by 8-12% in high-performance engines like the LS7. Laser measurement technology enables engineers to achieve timing precision within 0.1 degrees, potentially reducing these harmful emissions significantly compared to conventional timing methods with typical tolerances of 0.5-1.0 degrees.

From a fuel efficiency perspective, optimized ignition timing through laser measurement can improve fuel economy by 3-7% under various driving conditions. This improvement stems from achieving the ideal combustion pressure curve relative to piston position, maximizing the energy extracted from each combustion event. The LS7's high compression ratio (11.0:1) makes it particularly sensitive to timing adjustments, amplifying both the benefits of precision and the penalties of inaccuracy.

The environmental benefits extend beyond direct emissions reduction. Enhanced combustion efficiency reduces carbon dioxide output per mile driven, contributing to lower greenhouse gas emissions. Studies of performance V8 engines similar to the LS7 demonstrate that precision-timed engines produce approximately 12-18 grams less CO2 per kilometer traveled compared to engines with conventional timing calibration methods.

Long-term durability also factors into the environmental equation. Precisely timed ignition reduces engine wear by minimizing detonation events and harmful combustion characteristics. This extended engine lifespan reduces the environmental impact associated with manufacturing replacement parts and complete engines. Analysis of similar performance engines shows a potential 15-20% increase in useful service life before major overhaul when operating with precision-optimized ignition timing.

The economic dimension of these environmental benefits is substantial. Fuel savings alone can offset the cost of implementing laser timing technology within 30,000-50,000 miles of operation in high-performance applications. When combined with reduced emissions-related maintenance and extended engine life, the total environmental cost-benefit analysis strongly favors the adoption of high-precision laser measurement for ignition timing optimization in the LS7 engine platform.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!