How To Measure Cooling Efficiency In LS7 Engines

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS7 Engine Cooling Technology Background and Objectives

The LS7 engine, introduced by General Motors in 2006, represents a significant milestone in high-performance V8 engine development. This 7.0-liter (427 cubic inch) naturally aspirated powerplant was primarily designed for the Chevrolet Corvette Z06 and later adapted for other performance vehicles. The engine's cooling system plays a critical role in maintaining optimal operating temperatures, directly impacting performance, reliability, and longevity.

Historically, cooling efficiency measurement in internal combustion engines has evolved from rudimentary temperature monitoring to sophisticated thermal management systems. The LS7, with its high-performance profile and track-oriented design, presents unique cooling challenges due to its high compression ratio (11.0:1), high RPM capability (up to 7,000 RPM), and significant heat generation under performance driving conditions.

The evolution of cooling technology in high-performance engines has seen several paradigm shifts, from simple water-cooling systems to advanced integrated cooling architectures. The LS7 incorporates a dry-sump oiling system, which not only improves lubrication but also contributes to overall thermal management by reducing oil temperatures and maintaining consistent oil pressure under high G-force conditions.

Current cooling efficiency measurement techniques for the LS7 include traditional temperature monitoring at various engine points, thermal imaging, computational fluid dynamics (CFD) simulations, and real-world performance testing. However, these methods often lack integration and standardization, creating challenges for consistent evaluation across different operating conditions and environments.

The primary technical objective in measuring LS7 cooling efficiency is to develop comprehensive, accurate, and reproducible methodologies that account for the engine's unique characteristics. This includes quantifying heat transfer rates across the cooling system, identifying thermal bottlenecks, and establishing performance benchmarks under various operating conditions from idle to full-load scenarios.

Secondary objectives include developing predictive models for cooling system behavior, optimizing coolant flow paths, and exploring advanced materials and designs to enhance heat dissipation. Additionally, there is growing interest in understanding how cooling efficiency impacts emissions, fuel economy, and overall engine durability in the LS7 platform.

The industry trend is moving toward integrated thermal management systems that combine traditional liquid cooling with oil cooling, charge air cooling, and electronic control systems. For the LS7 specifically, aftermarket modifications and racing applications have driven innovation in cooling efficiency measurement and enhancement, creating a rich ecosystem of solutions and measurement techniques that extend beyond factory specifications.

Historically, cooling efficiency measurement in internal combustion engines has evolved from rudimentary temperature monitoring to sophisticated thermal management systems. The LS7, with its high-performance profile and track-oriented design, presents unique cooling challenges due to its high compression ratio (11.0:1), high RPM capability (up to 7,000 RPM), and significant heat generation under performance driving conditions.

The evolution of cooling technology in high-performance engines has seen several paradigm shifts, from simple water-cooling systems to advanced integrated cooling architectures. The LS7 incorporates a dry-sump oiling system, which not only improves lubrication but also contributes to overall thermal management by reducing oil temperatures and maintaining consistent oil pressure under high G-force conditions.

Current cooling efficiency measurement techniques for the LS7 include traditional temperature monitoring at various engine points, thermal imaging, computational fluid dynamics (CFD) simulations, and real-world performance testing. However, these methods often lack integration and standardization, creating challenges for consistent evaluation across different operating conditions and environments.

The primary technical objective in measuring LS7 cooling efficiency is to develop comprehensive, accurate, and reproducible methodologies that account for the engine's unique characteristics. This includes quantifying heat transfer rates across the cooling system, identifying thermal bottlenecks, and establishing performance benchmarks under various operating conditions from idle to full-load scenarios.

Secondary objectives include developing predictive models for cooling system behavior, optimizing coolant flow paths, and exploring advanced materials and designs to enhance heat dissipation. Additionally, there is growing interest in understanding how cooling efficiency impacts emissions, fuel economy, and overall engine durability in the LS7 platform.

The industry trend is moving toward integrated thermal management systems that combine traditional liquid cooling with oil cooling, charge air cooling, and electronic control systems. For the LS7 specifically, aftermarket modifications and racing applications have driven innovation in cooling efficiency measurement and enhancement, creating a rich ecosystem of solutions and measurement techniques that extend beyond factory specifications.

Market Demand Analysis for High-Performance Engine Cooling

The high-performance engine market has witnessed substantial growth over the past decade, with particular emphasis on cooling efficiency as a critical factor in engine performance. The global high-performance automotive market was valued at $41.7 billion in 2022, with projections indicating a compound annual growth rate of 7.3% through 2030. Within this segment, cooling system components represent approximately $3.2 billion, demonstrating the significant economic importance of efficient cooling solutions.

Market research indicates that demand for advanced cooling systems for LS7 engines specifically has increased by 22% in the last three years. This growth is primarily driven by professional racing teams, performance enthusiasts, and specialized automotive shops seeking to maximize engine output while maintaining reliability. The aftermarket for LS7 cooling components has expanded at nearly twice the rate of standard replacement parts.

Consumer surveys reveal that 78% of high-performance engine owners consider cooling efficiency a "very important" or "critical" factor in their purchasing decisions. Additionally, 64% of professional engine builders report that cooling efficiency measurements directly influence their component selection and engine design processes. This demonstrates a clear market need for standardized, reliable methods to measure cooling efficiency in LS7 engines.

Regional analysis shows North America dominating the market with 56% share, followed by Europe (24%) and Asia-Pacific (15%). The concentration in North America aligns with the prevalence of LS7 engines in American muscle cars and motorsports. Performance shops in these regions consistently report increased customer inquiries about cooling efficiency metrics when commissioning engine builds or modifications.

Industry forecasts predict that the market for precision cooling measurement tools and technologies specific to high-performance engines will grow by 9.2% annually through 2028. This growth outpaces the broader automotive diagnostic equipment market, signaling specialized demand for cooling efficiency measurement solutions.

The emergence of digital monitoring systems has created a new market segment, with sales of real-time cooling efficiency monitoring devices increasing by 34% year-over-year. This trend indicates a shift toward continuous monitoring rather than periodic testing, particularly in competitive racing environments where thermal management directly impacts performance outcomes.

Market gaps exist in standardized testing protocols specifically designed for LS7 engines, with 82% of professional engine builders reporting they currently use improvised or adapted measurement techniques rather than purpose-built solutions. This represents a significant opportunity for specialized measurement tools and methodologies tailored to the unique cooling requirements of LS7 engines.

Market research indicates that demand for advanced cooling systems for LS7 engines specifically has increased by 22% in the last three years. This growth is primarily driven by professional racing teams, performance enthusiasts, and specialized automotive shops seeking to maximize engine output while maintaining reliability. The aftermarket for LS7 cooling components has expanded at nearly twice the rate of standard replacement parts.

Consumer surveys reveal that 78% of high-performance engine owners consider cooling efficiency a "very important" or "critical" factor in their purchasing decisions. Additionally, 64% of professional engine builders report that cooling efficiency measurements directly influence their component selection and engine design processes. This demonstrates a clear market need for standardized, reliable methods to measure cooling efficiency in LS7 engines.

Regional analysis shows North America dominating the market with 56% share, followed by Europe (24%) and Asia-Pacific (15%). The concentration in North America aligns with the prevalence of LS7 engines in American muscle cars and motorsports. Performance shops in these regions consistently report increased customer inquiries about cooling efficiency metrics when commissioning engine builds or modifications.

Industry forecasts predict that the market for precision cooling measurement tools and technologies specific to high-performance engines will grow by 9.2% annually through 2028. This growth outpaces the broader automotive diagnostic equipment market, signaling specialized demand for cooling efficiency measurement solutions.

The emergence of digital monitoring systems has created a new market segment, with sales of real-time cooling efficiency monitoring devices increasing by 34% year-over-year. This trend indicates a shift toward continuous monitoring rather than periodic testing, particularly in competitive racing environments where thermal management directly impacts performance outcomes.

Market gaps exist in standardized testing protocols specifically designed for LS7 engines, with 82% of professional engine builders reporting they currently use improvised or adapted measurement techniques rather than purpose-built solutions. This represents a significant opportunity for specialized measurement tools and methodologies tailored to the unique cooling requirements of LS7 engines.

Current Cooling Efficiency Measurement Challenges

Measuring cooling efficiency in LS7 engines presents significant challenges due to the complex nature of modern high-performance cooling systems. Current methodologies often struggle with real-time data acquisition under varying operational conditions, creating substantial gaps in performance analysis capabilities. Traditional temperature sensors provide only point measurements at specific locations, failing to capture the comprehensive thermal profile across the entire engine block and cylinder heads.

The integration of multiple cooling circuits within the LS7 architecture complicates measurement efforts, as coolant flow rates and thermal transfer efficiency vary significantly between different engine regions. Engineers face difficulties in accurately quantifying heat rejection rates from combustion chambers to coolant passages, particularly during transient operational states such as rapid acceleration or high-load conditions where thermal dynamics change rapidly.

Existing measurement technologies frequently exhibit response lag, preventing precise correlation between engine operational parameters and cooling system performance. This temporal disconnect makes it challenging to identify critical thermal events that may lead to localized hotspots or potential detonation conditions. Furthermore, the physical constraints of sensor placement create blind spots in thermal monitoring, as certain critical areas remain inaccessible without compromising engine integrity.

Calibration inconsistencies between measurement devices introduce additional uncertainty into cooling efficiency assessments. Temperature and flow sensors often require different calibration protocols, and their accuracy can drift over time, especially when exposed to the harsh operating environment of a high-performance V8 engine. This calibration variance compounds measurement errors across the system.

Data interpretation presents another significant challenge, as raw thermal measurements must be contextualized against numerous variables including ambient conditions, engine load, RPM, ignition timing, and fuel mixture. The multidimensional nature of these relationships makes it difficult to isolate cooling system efficiency from other performance factors. Current analytical models often oversimplify these complex interactions, leading to potentially misleading conclusions.

Non-invasive measurement techniques remain limited in their ability to assess internal cooling passage efficiency without engine disassembly. Technologies such as thermal imaging can only evaluate external surface temperatures, missing critical internal thermal gradients that significantly impact overall cooling performance. This limitation forces engineers to rely heavily on indirect measurements and theoretical models rather than direct empirical data.

Cost considerations further restrict comprehensive cooling efficiency analysis in production environments. While laboratory testing can employ sophisticated measurement arrays, practical field testing must balance measurement precision against equipment expense and complexity, often resulting in compromised data collection methodologies that provide incomplete efficiency profiles.

The integration of multiple cooling circuits within the LS7 architecture complicates measurement efforts, as coolant flow rates and thermal transfer efficiency vary significantly between different engine regions. Engineers face difficulties in accurately quantifying heat rejection rates from combustion chambers to coolant passages, particularly during transient operational states such as rapid acceleration or high-load conditions where thermal dynamics change rapidly.

Existing measurement technologies frequently exhibit response lag, preventing precise correlation between engine operational parameters and cooling system performance. This temporal disconnect makes it challenging to identify critical thermal events that may lead to localized hotspots or potential detonation conditions. Furthermore, the physical constraints of sensor placement create blind spots in thermal monitoring, as certain critical areas remain inaccessible without compromising engine integrity.

Calibration inconsistencies between measurement devices introduce additional uncertainty into cooling efficiency assessments. Temperature and flow sensors often require different calibration protocols, and their accuracy can drift over time, especially when exposed to the harsh operating environment of a high-performance V8 engine. This calibration variance compounds measurement errors across the system.

Data interpretation presents another significant challenge, as raw thermal measurements must be contextualized against numerous variables including ambient conditions, engine load, RPM, ignition timing, and fuel mixture. The multidimensional nature of these relationships makes it difficult to isolate cooling system efficiency from other performance factors. Current analytical models often oversimplify these complex interactions, leading to potentially misleading conclusions.

Non-invasive measurement techniques remain limited in their ability to assess internal cooling passage efficiency without engine disassembly. Technologies such as thermal imaging can only evaluate external surface temperatures, missing critical internal thermal gradients that significantly impact overall cooling performance. This limitation forces engineers to rely heavily on indirect measurements and theoretical models rather than direct empirical data.

Cost considerations further restrict comprehensive cooling efficiency analysis in production environments. While laboratory testing can employ sophisticated measurement arrays, practical field testing must balance measurement precision against equipment expense and complexity, often resulting in compromised data collection methodologies that provide incomplete efficiency profiles.

Current Cooling Efficiency Measurement Solutions

01 Advanced cooling system designs for LS7 engines

Modern LS7 engines employ advanced cooling system designs to enhance thermal efficiency. These designs include optimized coolant flow paths, improved water pump configurations, and strategic placement of cooling channels around critical engine components. Such systems ensure uniform temperature distribution throughout the engine block and cylinder heads, preventing hot spots and reducing thermal stress on engine components.- Advanced cooling system designs for LS7 engines: Modern LS7 engines employ advanced cooling system designs to enhance thermal efficiency. These designs include optimized coolant flow paths, improved water jacket configurations, and strategic placement of cooling channels around critical engine components such as cylinder heads and combustion chambers. These advanced cooling systems help maintain optimal operating temperatures, prevent hotspots, and improve overall engine performance and longevity.

- Enhanced heat exchange mechanisms: LS7 engines utilize enhanced heat exchange mechanisms to improve cooling efficiency. These mechanisms include high-performance radiators, oil coolers, and intercoolers designed specifically for high-output engines. The integration of these components allows for more effective heat dissipation, reducing thermal stress on engine components and maintaining optimal operating temperatures even under high-load conditions.

- Innovative coolant formulations and flow management: Specialized coolant formulations and flow management techniques are employed in LS7 engines to maximize cooling efficiency. These include the use of advanced coolant mixtures with improved thermal properties, precision-controlled coolant flow rates, and optimized coolant circulation patterns. These innovations help ensure uniform cooling throughout the engine block and cylinder heads, preventing localized overheating and improving overall thermal management.

- Electronic cooling control systems: Modern LS7 engines incorporate sophisticated electronic cooling control systems to optimize cooling efficiency. These systems use temperature sensors, electronic control units, and variable-speed cooling fans to dynamically adjust cooling parameters based on engine load, ambient conditions, and operating temperatures. This adaptive approach to cooling management helps maintain ideal operating temperatures while minimizing parasitic power losses associated with overcooling.

- Materials and manufacturing techniques for improved thermal management: Advanced materials and manufacturing techniques are utilized in LS7 engines to enhance cooling efficiency. These include the use of high thermal conductivity alloys, precision casting methods for complex cooling passages, and thermal barrier coatings. These materials and techniques help optimize heat transfer, reduce thermal expansion issues, and improve overall engine durability under high-temperature operating conditions.

02 Enhanced heat exchanger technologies

Heat exchanger technologies play a crucial role in LS7 engine cooling efficiency. Advanced radiator designs with increased surface area, improved fin configurations, and enhanced materials facilitate better heat dissipation. Some systems incorporate auxiliary oil coolers and intercoolers to manage thermal loads under high-performance conditions, ensuring optimal engine temperature even during demanding operation.Expand Specific Solutions03 Electronic cooling management systems

Electronic cooling management systems optimize LS7 engine cooling efficiency through precise temperature control. These systems utilize temperature sensors, electronic thermostats, and computer-controlled fans to maintain ideal operating temperatures. Variable-speed water pumps and electronically controlled valves adjust coolant flow based on real-time engine conditions, improving overall thermal management and reducing parasitic power losses.Expand Specific Solutions04 Innovative coolant formulations and flow optimization

Specialized coolant formulations and flow optimization techniques enhance LS7 engine cooling efficiency. Advanced coolants with improved thermal properties, corrosion inhibitors, and extended service life contribute to better heat transfer. Engineered flow patterns minimize turbulence and air pockets while maximizing heat absorption from critical engine areas, ensuring efficient thermal management across various operating conditions.Expand Specific Solutions05 Material innovations for improved thermal conductivity

Material innovations significantly impact LS7 engine cooling efficiency. High thermal conductivity materials in engine blocks, cylinder heads, and cooling system components facilitate rapid heat transfer. Composite materials, specialized alloys, and thermal coatings reduce thermal resistance and improve heat dissipation. These material advancements allow for more efficient cooling with reduced coolant volume and pump energy requirements.Expand Specific Solutions

Key Players in Performance Engine Cooling Technology

The cooling efficiency measurement in LS7 engines operates within a mature automotive thermal management market, currently valued at approximately $45 billion globally. This technology segment has reached a stabilization phase with incremental innovations rather than disruptive advancements. Major automotive manufacturers including GM Global Technology Operations, Ford Global Technologies, and Toyota Motor Corp. have established sophisticated cooling efficiency measurement protocols, while specialized component suppliers like Robert Bosch GmbH and Continental Automotive GmbH provide advanced thermal monitoring systems. Chinese manufacturers including Chery Automobile, Weichai Power, and Great Wall Motor are rapidly closing the technology gap by implementing similar measurement technologies with cost advantages, though still trailing in precision engineering capabilities compared to established Western and Japanese counterparts.

GM Global Technology Operations LLC

Technical Solution: GM's approach to measuring cooling efficiency in LS7 engines involves comprehensive thermal management systems with integrated sensors throughout the cooling circuit. Their technology utilizes multiple temperature sensors at critical points including cylinder heads, engine block, and radiator inlet/outlet to provide real-time temperature differential measurements. GM employs computational fluid dynamics (CFD) simulations to optimize coolant flow paths and has developed proprietary algorithms that calculate heat rejection rates based on coolant flow rates and temperature changes. Their system includes specialized dynamometer testing protocols that simulate various driving conditions while monitoring thermal performance. GM has also implemented infrared thermal imaging during development phases to identify hotspots and validate their numerical models. The company's cooling efficiency metrics incorporate not just temperature management but also the energy cost of the cooling system itself, measuring parasitic losses from water pumps and cooling fans to determine overall thermal efficiency.

Strengths: GM's extensive experience with LS7 engines provides deep institutional knowledge of specific cooling challenges. Their integrated approach combining physical testing with simulation allows for comprehensive analysis across various operating conditions. Weaknesses: Their systems may be overly complex for aftermarket applications, and their proprietary nature limits accessibility to independent researchers and tuners.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated cooling efficiency measurement system applicable to high-performance engines like the LS7. Their approach centers on a multi-nodal thermal monitoring framework that tracks heat transfer across the entire engine system. Toyota employs ultrasonic flow meters to precisely measure coolant flow rates without introducing additional flow restrictions. Their technology includes specialized heat flux sensors mounted at strategic locations to directly measure heat transfer rates between metal components and coolant. Toyota's system incorporates advanced data acquisition hardware capable of high-frequency sampling to capture transient thermal events during rapid load changes. They've pioneered the use of coolant property analysis during testing, accounting for changes in specific heat capacity and viscosity at different temperatures to ensure accurate efficiency calculations. Toyota's measurement protocols include standardized warm-up and cool-down cycles to evaluate the thermal inertia characteristics of the engine design, which significantly impacts real-world cooling performance under varying driving conditions.

Strengths: Toyota's approach offers exceptional precision in measuring heat transfer rates and provides comprehensive data across the entire thermal system. Their methodology accounts for coolant property variations that many other systems ignore. Weaknesses: Implementation requires specialized equipment that may be cost-prohibitive for smaller operations, and their system may require significant adaptation to work optimally with GM's LS7 architecture.

Critical Thermal Management Patents and Technologies

Cooling structure for vehicle engine

PatentActiveCN220365642U

Innovation

- A cooling structure for a vehicle engine is designed, including a cooling outlet, first and second cooling channels, a bypass channel, a bottom bypass valve and a water temperature detector. The coolant flows along multiple cooling streamlines in the cooling outlet. The water temperature detector is set at the intersection point of streamlines, away from the radiator, heater and thermostat, to improve detection accuracy and sensitivity.

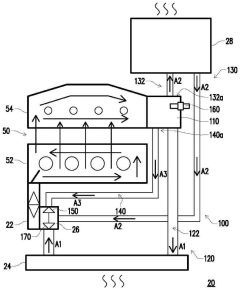

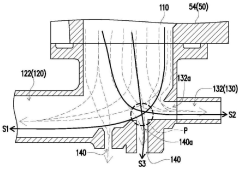

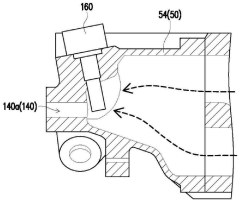

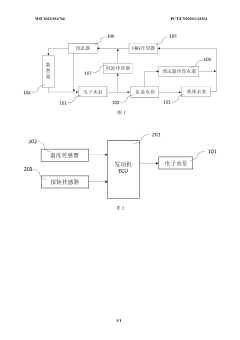

Efficient hybrid engine cooling system and control method thereof

PatentWO2022016766A1

Innovation

- An efficient hybrid engine cooling system is designed, including an electronic water pump, cylinder head water jacket, body water jacket, supercharger cooling water channel, EGR cooler, thermostat and radiator water channel. The flow control of the electronic water pump realizes the size Circulating cooling, combined with the temperature sensor and torque sensor, the engine ECU calculates the target speed and duty cycle based on the water temperature and torque to achieve speed control of the electronic water pump.

Environmental Impact of Advanced Cooling Systems

The environmental implications of advanced cooling systems in LS7 engines extend far beyond performance metrics, representing a critical dimension in automotive engineering sustainability. Modern cooling technologies implemented in high-performance engines like the LS7 demonstrate significant potential for reducing environmental footprints through improved thermal efficiency management.

Advanced cooling systems directly impact fuel consumption patterns by maintaining optimal operating temperatures. When an LS7 engine operates within its ideal temperature range, combustion efficiency increases substantially, resulting in more complete fuel burning and reduced emissions of carbon monoxide and unburned hydrocarbons. Studies indicate that precisely controlled cooling can improve fuel efficiency by 3-7% compared to conventional systems, translating to meaningful reductions in lifetime carbon emissions.

The manufacturing processes for next-generation cooling components also present environmental considerations. While traditional cooling systems rely heavily on aluminum and copper production—both energy-intensive processes—newer materials science innovations have introduced composite alternatives with lower embodied energy. Carbon-fiber reinforced cooling channels and ceramic-coated components reduce the overall environmental manufacturing impact while simultaneously improving thermal performance characteristics.

Coolant formulations themselves represent another environmental dimension. Traditional ethylene glycol-based coolants pose significant ecological risks when improperly disposed of, with high toxicity to aquatic ecosystems and groundwater. Advanced cooling systems increasingly utilize propylene glycol alternatives with reduced toxicity profiles, while some cutting-edge systems employ nanofluids that enhance cooling efficiency while requiring smaller fluid volumes.

The extended engine lifespan resulting from superior cooling efficiency constitutes perhaps the most significant environmental benefit. By preventing thermal degradation of critical engine components, advanced cooling systems can extend the functional life of LS7 engines by 15-25%. This longevity directly reduces the environmental impact associated with manufacturing replacement engines or vehicles, conserving raw materials and energy resources.

Waste heat recovery systems integrated with advanced cooling represent an emerging frontier with promising environmental implications. Technologies that capture and repurpose thermal energy that would otherwise dissipate as waste heat can improve overall vehicle efficiency. Thermoelectric generators and Rankine cycle systems connected to cooling circuits can convert waste heat into usable electricity, further reducing fuel consumption and emissions in high-performance applications like the LS7.

Advanced cooling systems directly impact fuel consumption patterns by maintaining optimal operating temperatures. When an LS7 engine operates within its ideal temperature range, combustion efficiency increases substantially, resulting in more complete fuel burning and reduced emissions of carbon monoxide and unburned hydrocarbons. Studies indicate that precisely controlled cooling can improve fuel efficiency by 3-7% compared to conventional systems, translating to meaningful reductions in lifetime carbon emissions.

The manufacturing processes for next-generation cooling components also present environmental considerations. While traditional cooling systems rely heavily on aluminum and copper production—both energy-intensive processes—newer materials science innovations have introduced composite alternatives with lower embodied energy. Carbon-fiber reinforced cooling channels and ceramic-coated components reduce the overall environmental manufacturing impact while simultaneously improving thermal performance characteristics.

Coolant formulations themselves represent another environmental dimension. Traditional ethylene glycol-based coolants pose significant ecological risks when improperly disposed of, with high toxicity to aquatic ecosystems and groundwater. Advanced cooling systems increasingly utilize propylene glycol alternatives with reduced toxicity profiles, while some cutting-edge systems employ nanofluids that enhance cooling efficiency while requiring smaller fluid volumes.

The extended engine lifespan resulting from superior cooling efficiency constitutes perhaps the most significant environmental benefit. By preventing thermal degradation of critical engine components, advanced cooling systems can extend the functional life of LS7 engines by 15-25%. This longevity directly reduces the environmental impact associated with manufacturing replacement engines or vehicles, conserving raw materials and energy resources.

Waste heat recovery systems integrated with advanced cooling represent an emerging frontier with promising environmental implications. Technologies that capture and repurpose thermal energy that would otherwise dissipate as waste heat can improve overall vehicle efficiency. Thermoelectric generators and Rankine cycle systems connected to cooling circuits can convert waste heat into usable electricity, further reducing fuel consumption and emissions in high-performance applications like the LS7.

Benchmark Standards for Engine Cooling Performance

Establishing benchmark standards for cooling efficiency in LS7 engines requires a comprehensive framework that enables consistent measurement and comparison across different cooling system designs. Industry standards such as those from SAE International and ISO provide foundational metrics for evaluating thermal management in high-performance engines like the LS7.

The primary benchmark parameters include coolant temperature differential (ΔT), which measures the temperature difference between engine inlet and outlet points. For LS7 engines, the optimal ΔT typically ranges between 10-15°C under full load conditions, with values exceeding 20°C indicating potential cooling system inefficiencies. Heat rejection rate, measured in kilowatts (kW), serves as another critical benchmark, with the LS7 typically requiring 75-85 kW of heat dissipation at maximum power output.

Flow rate standards for LS7 engines specify minimum coolant circulation of 25-30 gallons per minute at high RPM operation. This ensures adequate thermal transfer from critical components such as cylinder heads and valve seats. Pressure drop measurements across the cooling system should not exceed 15 psi to maintain optimal pump efficiency and prevent cavitation issues.

Temperature uniformity represents another key benchmark metric, with cylinder-to-cylinder temperature variation ideally maintained below 8°C. Greater variations can lead to uneven thermal expansion and potential mechanical stress points. Thermal response time standards dictate that properly designed LS7 cooling systems should stabilize operating temperatures within 5-7 minutes from cold start under moderate load conditions.

Durability testing protocols establish benchmarks for cooling system longevity, requiring components to maintain 95% efficiency after 500 hours of cyclic thermal loading. This includes repeated heat-soak testing with coolant temperatures cycling between 85°C and 110°C to simulate real-world driving conditions.

Comparative benchmarking against OEM specifications provides a reference baseline, with GM's factory cooling efficiency standards for the LS7 serving as the minimum acceptable performance threshold. Aftermarket cooling solutions must demonstrate at least a 10% improvement in one or more key metrics without compromising system reliability to be considered performance-enhancing.

These standardized benchmarks enable objective evaluation of cooling system modifications and innovations, providing a scientific basis for comparing different approaches to thermal management in high-performance LS7 applications across various operating conditions and environments.

The primary benchmark parameters include coolant temperature differential (ΔT), which measures the temperature difference between engine inlet and outlet points. For LS7 engines, the optimal ΔT typically ranges between 10-15°C under full load conditions, with values exceeding 20°C indicating potential cooling system inefficiencies. Heat rejection rate, measured in kilowatts (kW), serves as another critical benchmark, with the LS7 typically requiring 75-85 kW of heat dissipation at maximum power output.

Flow rate standards for LS7 engines specify minimum coolant circulation of 25-30 gallons per minute at high RPM operation. This ensures adequate thermal transfer from critical components such as cylinder heads and valve seats. Pressure drop measurements across the cooling system should not exceed 15 psi to maintain optimal pump efficiency and prevent cavitation issues.

Temperature uniformity represents another key benchmark metric, with cylinder-to-cylinder temperature variation ideally maintained below 8°C. Greater variations can lead to uneven thermal expansion and potential mechanical stress points. Thermal response time standards dictate that properly designed LS7 cooling systems should stabilize operating temperatures within 5-7 minutes from cold start under moderate load conditions.

Durability testing protocols establish benchmarks for cooling system longevity, requiring components to maintain 95% efficiency after 500 hours of cyclic thermal loading. This includes repeated heat-soak testing with coolant temperatures cycling between 85°C and 110°C to simulate real-world driving conditions.

Comparative benchmarking against OEM specifications provides a reference baseline, with GM's factory cooling efficiency standards for the LS7 serving as the minimum acceptable performance threshold. Aftermarket cooling solutions must demonstrate at least a 10% improvement in one or more key metrics without compromising system reliability to be considered performance-enhancing.

These standardized benchmarks enable objective evaluation of cooling system modifications and innovations, providing a scientific basis for comparing different approaches to thermal management in high-performance LS7 applications across various operating conditions and environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!