How to Address Common Issues in Half Wave Rectifier Circuits?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Background and Objectives

Half-wave rectifiers have been a fundamental component in electronic circuits since the early days of radio and power supply design. These circuits play a crucial role in converting alternating current (AC) to pulsating direct current (DC), serving as the building blocks for more complex power supply systems. The evolution of half-wave rectifiers can be traced back to the invention of the vacuum tube diode in the early 20th century, which paved the way for electronic rectification.

As technology progressed, semiconductor diodes replaced vacuum tubes, leading to more efficient and compact rectifier designs. The development of silicon diodes in the 1950s marked a significant milestone, offering improved performance and reliability. Today, half-wave rectifiers continue to be widely used in various applications, from simple power supplies to more sophisticated electronic devices.

The primary objective of half-wave rectifier technology is to efficiently convert AC to DC while minimizing power loss and distortion. However, several common issues persist in these circuits, including voltage drop across the diode, reverse leakage current, and poor voltage regulation. Addressing these challenges is crucial for improving the overall performance and reliability of half-wave rectifier circuits.

One of the key goals in advancing half-wave rectifier technology is to reduce the forward voltage drop across the diode, which directly impacts the efficiency of the rectification process. This has led to the development of Schottky diodes and other low-dropout rectifiers. Another important objective is to minimize reverse leakage current, which can cause unwanted power dissipation and reduce the overall efficiency of the circuit.

Improving voltage regulation is another critical aim in half-wave rectifier design. The pulsating nature of the output voltage in these circuits can lead to significant ripple, which is undesirable in many applications. Researchers and engineers are continually working on developing better filtering techniques and exploring the use of active components to enhance voltage stability.

As we look towards the future, the objectives for half-wave rectifier technology extend beyond simply addressing current limitations. There is a growing focus on integrating these circuits into more complex power management systems, particularly in the context of renewable energy and smart grid applications. This includes developing rectifiers that can handle higher frequencies and power levels, as well as those that can adapt to varying input conditions.

In conclusion, while half-wave rectifiers have a long history, there remains significant room for innovation and improvement. The ongoing technological evolution in this field aims to address common issues while pushing the boundaries of efficiency, reliability, and versatility in power conversion applications.

As technology progressed, semiconductor diodes replaced vacuum tubes, leading to more efficient and compact rectifier designs. The development of silicon diodes in the 1950s marked a significant milestone, offering improved performance and reliability. Today, half-wave rectifiers continue to be widely used in various applications, from simple power supplies to more sophisticated electronic devices.

The primary objective of half-wave rectifier technology is to efficiently convert AC to DC while minimizing power loss and distortion. However, several common issues persist in these circuits, including voltage drop across the diode, reverse leakage current, and poor voltage regulation. Addressing these challenges is crucial for improving the overall performance and reliability of half-wave rectifier circuits.

One of the key goals in advancing half-wave rectifier technology is to reduce the forward voltage drop across the diode, which directly impacts the efficiency of the rectification process. This has led to the development of Schottky diodes and other low-dropout rectifiers. Another important objective is to minimize reverse leakage current, which can cause unwanted power dissipation and reduce the overall efficiency of the circuit.

Improving voltage regulation is another critical aim in half-wave rectifier design. The pulsating nature of the output voltage in these circuits can lead to significant ripple, which is undesirable in many applications. Researchers and engineers are continually working on developing better filtering techniques and exploring the use of active components to enhance voltage stability.

As we look towards the future, the objectives for half-wave rectifier technology extend beyond simply addressing current limitations. There is a growing focus on integrating these circuits into more complex power management systems, particularly in the context of renewable energy and smart grid applications. This includes developing rectifiers that can handle higher frequencies and power levels, as well as those that can adapt to varying input conditions.

In conclusion, while half-wave rectifiers have a long history, there remains significant room for innovation and improvement. The ongoing technological evolution in this field aims to address common issues while pushing the boundaries of efficiency, reliability, and versatility in power conversion applications.

Market Demand Analysis for Rectifier Circuits

The market demand for rectifier circuits, particularly half-wave rectifiers, continues to grow steadily across various industries. These circuits play a crucial role in power supply systems, signal processing, and energy conversion applications. The global power electronics market, which heavily relies on rectifier technologies, is projected to reach significant growth in the coming years, driven by increasing demand for energy-efficient devices and renewable energy systems.

In the consumer electronics sector, the proliferation of smartphones, laptops, and other portable devices has created a substantial demand for compact and efficient power supply solutions. Half-wave rectifiers, despite their simplicity, find applications in low-power charging systems and small electronic devices where cost and space constraints are paramount.

The automotive industry represents another significant market for rectifier circuits. With the rapid adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is a growing need for high-performance rectifiers in battery charging systems and power converters. The transition to electric mobility is expected to further boost the demand for advanced rectifier solutions in the coming years.

Industrial automation and robotics sectors also contribute to the market demand for rectifier circuits. These applications often require reliable power conversion and control systems, where half-wave rectifiers can serve as components in more complex power management solutions.

The renewable energy sector, particularly solar and wind power generation, presents a substantial opportunity for rectifier circuit manufacturers. As the world shifts towards cleaner energy sources, the demand for efficient power conversion technologies, including advanced rectifier systems, is expected to surge.

In the telecommunications industry, the ongoing expansion of 5G networks and data centers necessitates robust power supply systems, creating additional demand for rectifier circuits. These applications often require high-efficiency power conversion solutions to minimize energy losses and operational costs.

While half-wave rectifiers face competition from more advanced full-wave and bridge rectifier designs in high-power applications, they maintain their relevance in specific niches. Their simplicity, cost-effectiveness, and suitability for low-power applications ensure a continued market presence, especially in emerging economies and cost-sensitive markets.

The market demand analysis also reveals a growing trend towards miniaturization and integration of power electronics components. This trend drives research and development efforts to address common issues in half-wave rectifier circuits, such as improving efficiency, reducing ripple, and enhancing overall performance within compact form factors.

In the consumer electronics sector, the proliferation of smartphones, laptops, and other portable devices has created a substantial demand for compact and efficient power supply solutions. Half-wave rectifiers, despite their simplicity, find applications in low-power charging systems and small electronic devices where cost and space constraints are paramount.

The automotive industry represents another significant market for rectifier circuits. With the rapid adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is a growing need for high-performance rectifiers in battery charging systems and power converters. The transition to electric mobility is expected to further boost the demand for advanced rectifier solutions in the coming years.

Industrial automation and robotics sectors also contribute to the market demand for rectifier circuits. These applications often require reliable power conversion and control systems, where half-wave rectifiers can serve as components in more complex power management solutions.

The renewable energy sector, particularly solar and wind power generation, presents a substantial opportunity for rectifier circuit manufacturers. As the world shifts towards cleaner energy sources, the demand for efficient power conversion technologies, including advanced rectifier systems, is expected to surge.

In the telecommunications industry, the ongoing expansion of 5G networks and data centers necessitates robust power supply systems, creating additional demand for rectifier circuits. These applications often require high-efficiency power conversion solutions to minimize energy losses and operational costs.

While half-wave rectifiers face competition from more advanced full-wave and bridge rectifier designs in high-power applications, they maintain their relevance in specific niches. Their simplicity, cost-effectiveness, and suitability for low-power applications ensure a continued market presence, especially in emerging economies and cost-sensitive markets.

The market demand analysis also reveals a growing trend towards miniaturization and integration of power electronics components. This trend drives research and development efforts to address common issues in half-wave rectifier circuits, such as improving efficiency, reducing ripple, and enhancing overall performance within compact form factors.

Current Challenges in Half Wave Rectifier Design

Half wave rectifier circuits, while fundamental in power electronics, face several challenges that impact their performance and efficiency. One of the primary issues is the low utilization of the input waveform. Since these circuits only rectify one half of the AC cycle, they inherently waste half of the available power, resulting in lower overall efficiency compared to full-wave rectifiers.

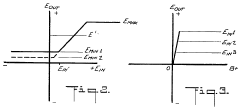

Another significant challenge is the high ripple content in the output voltage. The pulsating nature of the half-wave rectified output leads to a substantial ripple factor, which can be problematic for applications requiring a smooth DC voltage. This ripple not only affects the quality of the output but also increases the complexity of subsequent filtering stages.

The presence of a DC component in the transformer secondary winding is another concern in half-wave rectifier designs. This DC bias can lead to core saturation in the transformer, potentially causing overheating and reduced efficiency. It may also necessitate the use of larger, more expensive transformers to handle the additional magnetic flux.

Voltage regulation is a persistent challenge in half-wave rectifier circuits. The output voltage tends to vary significantly with changes in load current, making it difficult to maintain a stable DC output without additional regulation circuitry. This poor voltage regulation can be particularly problematic in applications where a consistent voltage is critical.

The reverse recovery time of the rectifying diode presents another design challenge. During the negative half-cycle, the diode must quickly transition from conducting to blocking state. Slow recovery can lead to reverse current flow, reducing efficiency and potentially damaging the diode.

Power factor is also a concern in half-wave rectifier circuits. The non-linear nature of the rectification process introduces harmonic distortion into the AC supply, leading to a poor power factor. This not only reduces the overall system efficiency but can also cause issues with power quality in the electrical grid.

Thermal management is another critical challenge, particularly in high-power applications. The pulsating current flow through the rectifying diode can lead to significant heat generation, necessitating careful thermal design and potentially limiting the maximum power handling capability of the circuit.

Addressing these challenges often requires trade-offs between performance, cost, and complexity. Engineers must carefully consider the specific requirements of their application when designing half-wave rectifier circuits and may need to implement additional components or control strategies to mitigate these issues effectively.

Another significant challenge is the high ripple content in the output voltage. The pulsating nature of the half-wave rectified output leads to a substantial ripple factor, which can be problematic for applications requiring a smooth DC voltage. This ripple not only affects the quality of the output but also increases the complexity of subsequent filtering stages.

The presence of a DC component in the transformer secondary winding is another concern in half-wave rectifier designs. This DC bias can lead to core saturation in the transformer, potentially causing overheating and reduced efficiency. It may also necessitate the use of larger, more expensive transformers to handle the additional magnetic flux.

Voltage regulation is a persistent challenge in half-wave rectifier circuits. The output voltage tends to vary significantly with changes in load current, making it difficult to maintain a stable DC output without additional regulation circuitry. This poor voltage regulation can be particularly problematic in applications where a consistent voltage is critical.

The reverse recovery time of the rectifying diode presents another design challenge. During the negative half-cycle, the diode must quickly transition from conducting to blocking state. Slow recovery can lead to reverse current flow, reducing efficiency and potentially damaging the diode.

Power factor is also a concern in half-wave rectifier circuits. The non-linear nature of the rectification process introduces harmonic distortion into the AC supply, leading to a poor power factor. This not only reduces the overall system efficiency but can also cause issues with power quality in the electrical grid.

Thermal management is another critical challenge, particularly in high-power applications. The pulsating current flow through the rectifying diode can lead to significant heat generation, necessitating careful thermal design and potentially limiting the maximum power handling capability of the circuit.

Addressing these challenges often requires trade-offs between performance, cost, and complexity. Engineers must carefully consider the specific requirements of their application when designing half-wave rectifier circuits and may need to implement additional components or control strategies to mitigate these issues effectively.

Existing Solutions for Half Wave Rectifier Issues

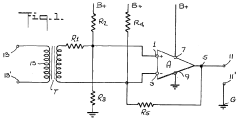

01 Basic half-wave rectifier circuit design

Half-wave rectifier circuits are fundamental in converting AC to pulsating DC. They typically consist of a diode and a load resistor. The diode allows current to flow in one direction during the positive half-cycle of the AC input, while blocking current flow during the negative half-cycle. This results in a pulsating DC output that can be further smoothed with additional components.- Basic half-wave rectifier circuit design: Half-wave rectifier circuits are fundamental in converting AC to pulsating DC. They typically consist of a diode and a load resistor. The diode allows current to flow in one direction during the positive half-cycle of the AC input, while blocking current flow during the negative half-cycle. This results in a pulsating DC output that can be further smoothed with additional components.

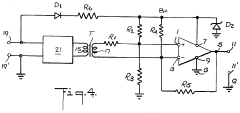

- Improved efficiency and power factor correction: Advanced half-wave rectifier designs focus on improving efficiency and power factor correction. These circuits may incorporate additional components such as inductors, capacitors, or active switching elements to reduce harmonic distortion and increase overall system performance. Some designs also implement control strategies to optimize power conversion and reduce losses.

- Integration with voltage regulation and protection: Many half-wave rectifier circuits are integrated with voltage regulation and protection features. These designs may include components such as Zener diodes, voltage regulators, or microcontrollers to maintain a stable output voltage and protect against overvoltage or overcurrent conditions. Some circuits also incorporate feedback mechanisms to adjust the rectification process based on load requirements.

- Application-specific half-wave rectifier designs: Half-wave rectifier circuits are often tailored for specific applications such as power supplies, battery chargers, or signal processing. These specialized designs may incorporate unique features like high-frequency operation, low-noise performance, or miniaturization techniques. Some circuits are optimized for use in renewable energy systems, automotive electronics, or telecommunications equipment.

- Novel materials and components in half-wave rectifiers: Research in half-wave rectifier circuits explores the use of novel materials and components to enhance performance. This includes the integration of wide-bandgap semiconductors, advanced magnetic materials, or emerging passive components. Some designs investigate the use of nanostructured materials or novel fabrication techniques to improve rectification efficiency and reduce parasitic effects.

02 Improved efficiency and power factor correction

Advanced half-wave rectifier designs focus on improving efficiency and power factor correction. These circuits may incorporate additional components such as inductors, capacitors, or active switching elements to reduce harmonic distortion and improve overall performance. Some designs also implement control strategies to optimize power conversion and reduce losses.Expand Specific Solutions03 Application in display technologies

Half-wave rectifier circuits find applications in display technologies, particularly in driving backlight systems for LCD panels. These circuits can be designed to provide stable power supply and precise control for LED backlights, ensuring uniform brightness and reducing power consumption in display devices.Expand Specific Solutions04 Integration with protection and control features

Modern half-wave rectifier designs often incorporate protection and control features. These may include overvoltage protection, current limiting, temperature compensation, and feedback mechanisms. Such features enhance the reliability and safety of the circuit, making it suitable for a wide range of applications in power electronics and consumer devices.Expand Specific Solutions05 Miniaturization and integration

There is a trend towards miniaturization and integration of half-wave rectifier circuits. This involves designing compact circuits that can be easily integrated into larger systems or implemented as part of integrated circuits. These designs often focus on reducing component count, improving thermal management, and enhancing overall system efficiency.Expand Specific Solutions

Key Players in Power Electronics Industry

The half wave rectifier circuit technology is in a mature stage of development, with a well-established market and widespread applications in power electronics. The global market for rectifier circuits is substantial, driven by the growing demand for power supplies in various industries. Companies like Semiconductor Energy Laboratory, Panasonic Holdings, and Siemens AG are key players, leveraging their expertise in semiconductor technology and electrical engineering to address common issues such as voltage drop, reverse leakage current, and efficiency improvements. The technology's maturity is evident in the diverse range of solutions offered by these companies, including advanced semiconductor materials, improved circuit designs, and integrated control systems to enhance performance and reliability.

Siemens Corp.

Technical Solution: Siemens has developed advanced half-wave rectifier circuits with improved efficiency and reduced harmonic distortion. Their approach involves using high-frequency switching techniques and advanced semiconductor materials to minimize voltage drops and increase power conversion efficiency. Siemens has implemented a novel control algorithm that dynamically adjusts the rectification timing to optimize performance under varying load conditions[1]. Additionally, they have integrated advanced filtering techniques to reduce electromagnetic interference (EMI) and improve overall power quality[3].

Strengths: High efficiency, reduced harmonics, and EMI suppression. Weaknesses: Potentially higher cost due to advanced components and complexity in implementation.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has focused on addressing thermal management issues in half-wave rectifier circuits, particularly for high-power applications. They have developed a novel cooling system that integrates phase-change materials (PCMs) with traditional heat sinks to provide more effective and uniform cooling of rectifier components[8]. This approach helps to mitigate thermal runaway and extends the operational life of the rectifier. DAIKIN has also implemented advanced insulation techniques and materials to improve voltage isolation and reduce parasitic capacitances in their rectifier designs[9].

Strengths: Excellent thermal management, improved reliability in high-power applications. Weaknesses: Potentially bulkier designs, may be over-engineered for low-power applications.

Core Innovations in Rectifier Circuit Design

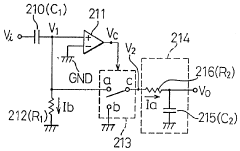

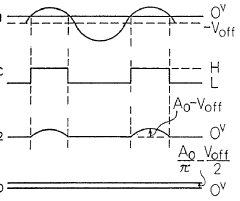

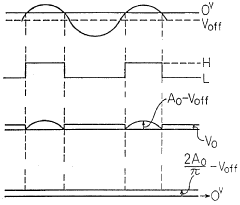

Half-wave rectifier circuit

PatentInactiveUS5579214A

Innovation

- The proposed half-wave rectifier circuit design includes a capacitor to remove DC components, a comparator with an operational amplifier and capacitor to accumulate offset voltage, and a switch circuit with high input impedance during the OFF state to eliminate the influence of offset voltage, ensuring accurate output voltage generation.

Half-wave rectifier circuit

PatentInactiveUS3936720A

Innovation

- A high-gain differential amplifier-based half-wave rectifier circuit operating from a single power supply, eliminating the need for voltage regulation and reducing temperature dependence, with resistor ratios optimized to minimize errors and achieve minimal output voltage drop.

Efficiency and Power Quality Considerations

Half-wave rectifier circuits, while simple in design, face several challenges in terms of efficiency and power quality. These issues significantly impact their performance and applicability in various electronic systems. One of the primary concerns is the low efficiency of half-wave rectifiers, typically ranging from 40% to 50%. This inefficiency stems from the circuit's inherent nature of utilizing only one half of the AC input cycle, effectively wasting half of the available power.

The power quality considerations for half-wave rectifiers are equally critical. The output of these circuits contains a substantial amount of ripple, which can lead to unwanted noise and distortion in the load circuit. This ripple is a result of the intermittent nature of the rectification process, where current flows only during positive half-cycles of the input AC waveform. Consequently, the output voltage fluctuates significantly, requiring additional filtering to achieve a smoother DC output.

Another significant issue is the generation of harmonics in the input current waveform. Half-wave rectifiers draw current in short pulses, leading to a non-sinusoidal input current with high harmonic content. These harmonics can cause electromagnetic interference (EMI) and reduce the power factor of the system, potentially violating power quality standards and regulations.

The poor utilization of transformer capacity is an additional concern in half-wave rectifier applications. Since current flows only during half of each cycle, the transformer core is not used efficiently, leading to larger and more expensive transformers for a given power output. This inefficiency not only increases costs but also contributes to higher losses in the transformer itself.

To address these efficiency and power quality issues, several strategies can be employed. Implementing a center-tapped transformer with two diodes can convert the half-wave rectifier into a full-wave rectifier, significantly improving efficiency and reducing ripple. Adding capacitive filtering can further smooth the output voltage, reducing ripple and improving overall power quality. For more demanding applications, active power factor correction (PFC) circuits can be integrated to mitigate harmonic distortion and improve the power factor.

Advanced control techniques, such as pulse-width modulation (PWM) and synchronous rectification, can also be applied to enhance the performance of rectifier circuits. These methods can significantly reduce switching losses and improve overall efficiency. Furthermore, the use of high-frequency switching techniques can reduce the size of filtering components, leading to more compact and cost-effective designs.

The power quality considerations for half-wave rectifiers are equally critical. The output of these circuits contains a substantial amount of ripple, which can lead to unwanted noise and distortion in the load circuit. This ripple is a result of the intermittent nature of the rectification process, where current flows only during positive half-cycles of the input AC waveform. Consequently, the output voltage fluctuates significantly, requiring additional filtering to achieve a smoother DC output.

Another significant issue is the generation of harmonics in the input current waveform. Half-wave rectifiers draw current in short pulses, leading to a non-sinusoidal input current with high harmonic content. These harmonics can cause electromagnetic interference (EMI) and reduce the power factor of the system, potentially violating power quality standards and regulations.

The poor utilization of transformer capacity is an additional concern in half-wave rectifier applications. Since current flows only during half of each cycle, the transformer core is not used efficiently, leading to larger and more expensive transformers for a given power output. This inefficiency not only increases costs but also contributes to higher losses in the transformer itself.

To address these efficiency and power quality issues, several strategies can be employed. Implementing a center-tapped transformer with two diodes can convert the half-wave rectifier into a full-wave rectifier, significantly improving efficiency and reducing ripple. Adding capacitive filtering can further smooth the output voltage, reducing ripple and improving overall power quality. For more demanding applications, active power factor correction (PFC) circuits can be integrated to mitigate harmonic distortion and improve the power factor.

Advanced control techniques, such as pulse-width modulation (PWM) and synchronous rectification, can also be applied to enhance the performance of rectifier circuits. These methods can significantly reduce switching losses and improve overall efficiency. Furthermore, the use of high-frequency switching techniques can reduce the size of filtering components, leading to more compact and cost-effective designs.

Thermal Management Strategies for Rectifier Circuits

Thermal management is a critical aspect of rectifier circuit design, particularly for half-wave rectifiers, which are prone to heat-related issues due to their inherent inefficiency. Effective thermal management strategies are essential to ensure the longevity, reliability, and optimal performance of these circuits. One primary approach involves the selection of appropriate heat sinks to dissipate excess thermal energy generated by the rectifier diodes. Heat sinks with optimized fin designs and materials with high thermal conductivity, such as aluminum or copper, can significantly enhance heat dissipation.

Another crucial strategy is the implementation of forced-air cooling systems. By incorporating fans or blowers, the airflow across the rectifier components can be increased, facilitating more efficient heat removal. This method is particularly effective in high-power applications where natural convection alone may be insufficient. In some cases, liquid cooling systems may be employed for extreme thermal management requirements, offering superior heat transfer capabilities compared to air-based solutions.

Proper component selection and layout also play vital roles in thermal management. Utilizing diodes with lower forward voltage drops and higher temperature ratings can reduce heat generation at the source. Additionally, strategic placement of heat-generating components on the PCB, with adequate spacing and thermal vias, can improve overall heat distribution and dissipation. Thermal interface materials, such as thermally conductive pads or pastes, can be applied between components and heat sinks to enhance thermal conductivity and reduce thermal resistance.

Advanced thermal management techniques may include the use of temperature sensors and feedback control systems. These systems can monitor the circuit's temperature in real-time and adjust cooling mechanisms or circuit operation accordingly. For instance, variable-speed fans can be controlled based on temperature readings, optimizing cooling efficiency while minimizing noise and power consumption.

In some applications, the implementation of soft-switching techniques or resonant topologies can help reduce switching losses and, consequently, heat generation in rectifier circuits. These approaches can be particularly beneficial in high-frequency applications where switching losses become more significant. Furthermore, the use of synchronous rectification, where MOSFETs replace diodes, can lead to reduced power dissipation and improved thermal performance, especially in low-voltage, high-current applications.

Lastly, thermal simulation and modeling tools play a crucial role in the design phase of rectifier circuits. These tools allow engineers to predict thermal behavior, identify potential hotspots, and optimize component placement and cooling strategies before physical prototyping. By leveraging computational fluid dynamics (CFD) and finite element analysis (FEA), designers can iteratively refine their thermal management approaches, ensuring robust and efficient rectifier circuit designs.

Another crucial strategy is the implementation of forced-air cooling systems. By incorporating fans or blowers, the airflow across the rectifier components can be increased, facilitating more efficient heat removal. This method is particularly effective in high-power applications where natural convection alone may be insufficient. In some cases, liquid cooling systems may be employed for extreme thermal management requirements, offering superior heat transfer capabilities compared to air-based solutions.

Proper component selection and layout also play vital roles in thermal management. Utilizing diodes with lower forward voltage drops and higher temperature ratings can reduce heat generation at the source. Additionally, strategic placement of heat-generating components on the PCB, with adequate spacing and thermal vias, can improve overall heat distribution and dissipation. Thermal interface materials, such as thermally conductive pads or pastes, can be applied between components and heat sinks to enhance thermal conductivity and reduce thermal resistance.

Advanced thermal management techniques may include the use of temperature sensors and feedback control systems. These systems can monitor the circuit's temperature in real-time and adjust cooling mechanisms or circuit operation accordingly. For instance, variable-speed fans can be controlled based on temperature readings, optimizing cooling efficiency while minimizing noise and power consumption.

In some applications, the implementation of soft-switching techniques or resonant topologies can help reduce switching losses and, consequently, heat generation in rectifier circuits. These approaches can be particularly beneficial in high-frequency applications where switching losses become more significant. Furthermore, the use of synchronous rectification, where MOSFETs replace diodes, can lead to reduced power dissipation and improved thermal performance, especially in low-voltage, high-current applications.

Lastly, thermal simulation and modeling tools play a crucial role in the design phase of rectifier circuits. These tools allow engineers to predict thermal behavior, identify potential hotspots, and optimize component placement and cooling strategies before physical prototyping. By leveraging computational fluid dynamics (CFD) and finite element analysis (FEA), designers can iteratively refine their thermal management approaches, ensuring robust and efficient rectifier circuit designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!