How to Extend Phased Array Lifespan Through Design Innovations

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phased Array Radar Lifespan Challenges and Objectives

Phased array radar systems have evolved significantly since their inception in the mid-20th century, transforming from experimental military technology to essential components in modern defense, aviation, weather monitoring, and increasingly, autonomous vehicle navigation systems. The progression from mechanically steered antennas to electronically scanned arrays represents one of the most significant paradigm shifts in radar technology, enabling faster scanning, multi-target tracking, and enhanced reliability through the elimination of moving parts.

Despite these advancements, phased array systems face persistent lifespan challenges that limit their operational effectiveness and increase total ownership costs. Current generation phased arrays typically demonstrate operational lifespans of 10-15 years in optimal conditions, with significant performance degradation occurring after 7-8 years in demanding environments. This falls short of the 20+ year service life required by many military and critical infrastructure applications.

The primary technical objective for next-generation phased array systems is to extend operational lifespan by at least 50% while maintaining or improving performance parameters. This requires addressing several interconnected challenges: thermal management issues that accelerate component degradation, power efficiency limitations that increase operational strain, and environmental resilience deficiencies that compromise long-term reliability.

Thermal management represents perhaps the most critical challenge, as operating temperatures directly correlate with component failure rates. Current systems typically experience 10-15°C temperature gradients across the array face during operation, creating uneven stress that accelerates fatigue and failure. Research indicates that reducing these gradients to under 5°C could potentially extend component lifespan by 30-40%.

Power efficiency improvements present another crucial pathway to extended lifespan. Contemporary GaN-based transmit/receive modules operate at 35-45% efficiency, dissipating significant energy as heat. Theoretical models suggest that achieving 60%+ efficiency would dramatically reduce thermal loading and extend operational life.

Environmental factors, particularly in maritime and extreme weather deployments, accelerate degradation through corrosion, humidity infiltration, and thermal cycling. Current environmental protection approaches often add weight and complexity while providing inadequate long-term protection.

The technical evolution trajectory suggests several promising avenues for lifespan extension, including advanced materials science applications, architectural innovations in thermal management, and intelligent power management systems. The convergence of these approaches, combined with emerging predictive maintenance capabilities, establishes a framework for achieving the next significant leap in phased array operational longevity.

Despite these advancements, phased array systems face persistent lifespan challenges that limit their operational effectiveness and increase total ownership costs. Current generation phased arrays typically demonstrate operational lifespans of 10-15 years in optimal conditions, with significant performance degradation occurring after 7-8 years in demanding environments. This falls short of the 20+ year service life required by many military and critical infrastructure applications.

The primary technical objective for next-generation phased array systems is to extend operational lifespan by at least 50% while maintaining or improving performance parameters. This requires addressing several interconnected challenges: thermal management issues that accelerate component degradation, power efficiency limitations that increase operational strain, and environmental resilience deficiencies that compromise long-term reliability.

Thermal management represents perhaps the most critical challenge, as operating temperatures directly correlate with component failure rates. Current systems typically experience 10-15°C temperature gradients across the array face during operation, creating uneven stress that accelerates fatigue and failure. Research indicates that reducing these gradients to under 5°C could potentially extend component lifespan by 30-40%.

Power efficiency improvements present another crucial pathway to extended lifespan. Contemporary GaN-based transmit/receive modules operate at 35-45% efficiency, dissipating significant energy as heat. Theoretical models suggest that achieving 60%+ efficiency would dramatically reduce thermal loading and extend operational life.

Environmental factors, particularly in maritime and extreme weather deployments, accelerate degradation through corrosion, humidity infiltration, and thermal cycling. Current environmental protection approaches often add weight and complexity while providing inadequate long-term protection.

The technical evolution trajectory suggests several promising avenues for lifespan extension, including advanced materials science applications, architectural innovations in thermal management, and intelligent power management systems. The convergence of these approaches, combined with emerging predictive maintenance capabilities, establishes a framework for achieving the next significant leap in phased array operational longevity.

Market Demand Analysis for Long-Lasting Phased Arrays

The global market for phased array systems is experiencing significant growth, driven by increasing demand for reliable, long-lasting radar and communication systems across multiple sectors. The market size for phased array technologies was valued at approximately $5.45 billion in 2022 and is projected to reach $12.1 billion by 2030, representing a compound annual growth rate of 10.5%. This growth trajectory underscores the critical importance of extending phased array lifespan through innovative design approaches.

Defense and aerospace sectors remain the primary drivers of demand, collectively accounting for over 60% of the market share. Military applications require phased arrays with extended operational lifespans to reduce total ownership costs and maintain mission readiness. The U.S. Department of Defense has specifically highlighted the need for phased array systems with operational lifetimes exceeding 15 years, compared to the current industry standard of 8-10 years.

Commercial aviation represents another significant market segment, with increasing adoption of weather radar systems utilizing phased array technology. Airlines and aircraft manufacturers are seeking solutions that can withstand the harsh operating conditions of aviation while requiring minimal maintenance over the aircraft's service life, typically 20-25 years.

The telecommunications sector, particularly with the ongoing global 5G rollout, has emerged as a rapidly growing market for phased array technology. Network operators are investing heavily in infrastructure that promises longevity, with expected service lives of at least 10 years to maximize return on investment. This sector is projected to grow at 15.2% annually through 2030, faster than any other application segment.

Consumer electronics manufacturers are also exploring phased array applications in next-generation devices, creating demand for miniaturized, energy-efficient arrays with extended operational lifespans. This segment values solutions that can maintain performance characteristics over 5+ years of daily consumer use.

Market research indicates that customers across all sectors are willing to pay a premium of 15-30% for phased array systems that demonstrate verifiable lifespan improvements of at least 40% over current standards. This price elasticity reflects the significant downstream cost savings associated with reduced maintenance and replacement cycles.

Geographically, North America dominates the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing defense modernization programs and rapid telecommunications infrastructure development in countries like China, India, and South Korea.

Defense and aerospace sectors remain the primary drivers of demand, collectively accounting for over 60% of the market share. Military applications require phased arrays with extended operational lifespans to reduce total ownership costs and maintain mission readiness. The U.S. Department of Defense has specifically highlighted the need for phased array systems with operational lifetimes exceeding 15 years, compared to the current industry standard of 8-10 years.

Commercial aviation represents another significant market segment, with increasing adoption of weather radar systems utilizing phased array technology. Airlines and aircraft manufacturers are seeking solutions that can withstand the harsh operating conditions of aviation while requiring minimal maintenance over the aircraft's service life, typically 20-25 years.

The telecommunications sector, particularly with the ongoing global 5G rollout, has emerged as a rapidly growing market for phased array technology. Network operators are investing heavily in infrastructure that promises longevity, with expected service lives of at least 10 years to maximize return on investment. This sector is projected to grow at 15.2% annually through 2030, faster than any other application segment.

Consumer electronics manufacturers are also exploring phased array applications in next-generation devices, creating demand for miniaturized, energy-efficient arrays with extended operational lifespans. This segment values solutions that can maintain performance characteristics over 5+ years of daily consumer use.

Market research indicates that customers across all sectors are willing to pay a premium of 15-30% for phased array systems that demonstrate verifiable lifespan improvements of at least 40% over current standards. This price elasticity reflects the significant downstream cost savings associated with reduced maintenance and replacement cycles.

Geographically, North America dominates the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing defense modernization programs and rapid telecommunications infrastructure development in countries like China, India, and South Korea.

Current Limitations and Technical Barriers in Array Longevity

Phased array systems face significant longevity challenges that limit their operational lifespan and reliability in demanding applications. The primary limitation stems from thermal management issues, as these systems generate substantial heat during operation. Prolonged exposure to high temperatures accelerates component degradation, particularly affecting semiconductor elements and connection interfaces. Without adequate thermal dissipation mechanisms, hotspots form within the array architecture, creating thermal stress that leads to premature failure.

Material degradation represents another critical barrier to extended array lifespan. Current semiconductor materials used in transmit/receive (T/R) modules exhibit performance deterioration over time, especially when subjected to high-power operation cycles. The gradual degradation of gallium arsenide (GaAs) and gallium nitride (GaN) components results in reduced signal quality and increased power consumption, ultimately compromising system performance.

Power distribution networks within phased arrays present significant reliability challenges. Voltage fluctuations and power surges create electrical stress on components, while inadequate power conditioning accelerates wear on sensitive electronic elements. The complex power distribution architecture required for large-scale arrays introduces multiple potential failure points that are difficult to isolate and address during maintenance.

Environmental factors pose substantial barriers to array longevity, particularly in aerospace, maritime, and outdoor installations. Exposure to moisture, salt, temperature extremes, and radiation accelerates corrosion and material breakdown. Current protective measures provide insufficient defense against these environmental stressors, resulting in accelerated aging and performance degradation in field deployments.

Manufacturing inconsistencies create inherent vulnerabilities in array systems. Variations in component quality and assembly precision lead to uneven performance and reliability across the array. Microscopic defects introduced during fabrication processes often remain undetected until they manifest as operational failures, complicating quality control efforts and reducing overall system reliability.

Signal integrity degradation over time represents a subtle but significant limitation. As components age, signal path characteristics change, introducing phase and amplitude errors that compromise beam forming accuracy. Current calibration systems struggle to compensate for these gradual changes, resulting in diminished performance long before catastrophic failure occurs.

Maintenance accessibility presents practical barriers to extending array lifespan. The dense integration of components in modern phased arrays makes targeted repairs challenging, often necessitating replacement of entire modules rather than individual failed components. This approach increases lifecycle costs and reduces the economic viability of array systems in cost-sensitive applications.

Material degradation represents another critical barrier to extended array lifespan. Current semiconductor materials used in transmit/receive (T/R) modules exhibit performance deterioration over time, especially when subjected to high-power operation cycles. The gradual degradation of gallium arsenide (GaAs) and gallium nitride (GaN) components results in reduced signal quality and increased power consumption, ultimately compromising system performance.

Power distribution networks within phased arrays present significant reliability challenges. Voltage fluctuations and power surges create electrical stress on components, while inadequate power conditioning accelerates wear on sensitive electronic elements. The complex power distribution architecture required for large-scale arrays introduces multiple potential failure points that are difficult to isolate and address during maintenance.

Environmental factors pose substantial barriers to array longevity, particularly in aerospace, maritime, and outdoor installations. Exposure to moisture, salt, temperature extremes, and radiation accelerates corrosion and material breakdown. Current protective measures provide insufficient defense against these environmental stressors, resulting in accelerated aging and performance degradation in field deployments.

Manufacturing inconsistencies create inherent vulnerabilities in array systems. Variations in component quality and assembly precision lead to uneven performance and reliability across the array. Microscopic defects introduced during fabrication processes often remain undetected until they manifest as operational failures, complicating quality control efforts and reducing overall system reliability.

Signal integrity degradation over time represents a subtle but significant limitation. As components age, signal path characteristics change, introducing phase and amplitude errors that compromise beam forming accuracy. Current calibration systems struggle to compensate for these gradual changes, resulting in diminished performance long before catastrophic failure occurs.

Maintenance accessibility presents practical barriers to extending array lifespan. The dense integration of components in modern phased arrays makes targeted repairs challenging, often necessitating replacement of entire modules rather than individual failed components. This approach increases lifecycle costs and reduces the economic viability of array systems in cost-sensitive applications.

Existing Lifespan Extension Techniques and Methodologies

01 Thermal management for extended phased array lifespan

Effective thermal management is crucial for extending the lifespan of phased array systems. Heat dissipation techniques, including advanced cooling systems and thermal interface materials, help prevent component degradation due to excessive heat. Proper thermal design ensures stable operation of semiconductor elements in the array, reducing thermal stress and preventing premature failure of critical components.- Extending phased array lifespan through thermal management: Thermal management is crucial for extending the lifespan of phased array systems. Excessive heat can degrade electronic components and reduce operational life. Advanced cooling techniques, heat dissipation materials, and thermal design considerations help maintain optimal operating temperatures, preventing premature failure and extending the useful life of phased array systems in various applications including radar and communications.

- Component reliability and failure prediction for phased arrays: Enhancing phased array lifespan involves implementing reliability engineering principles and predictive maintenance strategies. This includes monitoring component degradation, using high-reliability materials, and employing algorithms that can predict potential failures before they occur. These approaches enable timely maintenance interventions, reducing downtime and extending the overall operational life of phased array systems.

- Environmental protection and ruggedization techniques: Protecting phased array systems from environmental factors significantly impacts their lifespan. Ruggedization techniques include specialized coatings, hermetic sealing, and protective enclosures that shield sensitive components from moisture, dust, salt, and extreme temperatures. These protective measures are particularly important for phased arrays deployed in harsh environments such as maritime, aerospace, and outdoor installations.

- Power management and energy efficiency for extended lifespan: Efficient power management strategies contribute to longer phased array lifespans by reducing stress on electronic components. This includes implementing power cycling protocols, voltage regulation, and energy-efficient operational modes. Advanced power management systems can dynamically adjust power consumption based on operational requirements, minimizing unnecessary strain on components and extending the overall system lifespan.

- Modular design and serviceability for phased array longevity: Modular design approaches enable easier maintenance and component replacement, extending the effective lifespan of phased array systems. By designing systems with replaceable modules, failed components can be swapped without replacing the entire array. This approach reduces lifecycle costs and allows for incremental upgrades as technology advances, effectively extending the useful life of the overall system while maintaining performance standards.

02 Reliability enhancement through component selection and design

The selection of high-reliability components and robust design principles significantly impacts phased array lifespan. Using radiation-hardened materials, redundant circuit designs, and fault-tolerant architectures helps maintain system performance over extended periods. Design considerations include minimizing single points of failure and implementing graceful degradation capabilities to ensure continued operation even when individual elements fail.Expand Specific Solutions03 Environmental protection and ruggedization techniques

Protecting phased array systems from environmental factors extends their operational lifespan. Techniques include hermetic sealing, conformal coating, and specialized enclosures to shield against moisture, dust, salt spray, and other contaminants. Ruggedization methods protect against mechanical shock, vibration, and extreme temperature variations, particularly important for arrays deployed in harsh environments like aerospace, maritime, or outdoor installations.Expand Specific Solutions04 Calibration and maintenance strategies

Regular calibration and preventive maintenance significantly extend phased array lifespan. Automated self-diagnostic systems can detect performance degradation before critical failure occurs. Implementing built-in test equipment (BITE) allows for continuous monitoring of array elements. Maintenance strategies include scheduled recalibration, component replacement schedules, and software updates to compensate for aging-related performance shifts.Expand Specific Solutions05 Power management and signal integrity preservation

Efficient power management extends phased array lifespan by reducing electrical stress on components. Techniques include optimized power distribution networks, voltage regulation, and intelligent power cycling. Maintaining signal integrity through proper impedance matching, minimizing interference, and implementing robust signal processing algorithms prevents performance degradation over time. Advanced power management also reduces thermal load, further enhancing system longevity.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Phased Arrays

The phased array lifespan extension market is in a growth phase, with increasing demand driven by defense, aerospace, and telecommunications applications. The market is projected to expand significantly as 5G networks and satellite communications proliferate. Technologically, the field is advancing from mature conventional designs toward innovative solutions incorporating semiconductor advances. Leading players like Raytheon, Qualcomm, and IBM are developing materials science innovations, while SpaceX and Boeing focus on thermal management solutions. GlobalFoundries and Samsung are advancing semiconductor integration techniques. Academic institutions including MIT, Caltech, and Arizona State University contribute fundamental research in reliability engineering and novel materials, creating a competitive landscape balanced between established defense contractors and emerging technology companies pioneering next-generation phased array architectures.

The Boeing Co.

Technical Solution: Boeing has developed a comprehensive approach to phased array lifespan extension through their Adaptive Phased Array System (APAS) technology. This system incorporates redundant transmit/receive modules with automatic failover capabilities, allowing the array to maintain performance even as individual components degrade over time. Boeing's design incorporates advanced composite materials that provide superior thermal stability while reducing overall weight. Their phased arrays feature distributed power management systems that dynamically adjust power consumption across the array based on operational requirements, significantly reducing thermal stress on components. Boeing has also pioneered self-calibrating systems that compensate for performance drift over time, maintaining beam accuracy throughout the extended operational life. The company's maintenance-oriented design includes easily accessible modules and built-in test equipment that simplifies repairs and reduces downtime[2][4].

Strengths: Extensive aerospace experience translating to robust environmental protection designs, strong systems integration capabilities, and advanced composite material expertise. Weaknesses: Solutions sometimes prioritize aerospace requirements over cost efficiency, and implementation complexity can require specialized maintenance personnel.

Raytheon Co.

Technical Solution: Raytheon has developed advanced thermal management solutions for phased array systems that significantly extend operational lifespan. Their approach incorporates liquid cooling technologies with microchannels directly integrated into the array structure, allowing for more efficient heat dissipation from high-power transmit/receive modules. The company has pioneered the use of advanced materials with higher thermal conductivity and lower coefficients of thermal expansion to reduce thermal stress during operational cycles. Raytheon's GaN-based phased arrays incorporate built-in health monitoring systems that continuously assess component performance and predict potential failures before they occur, enabling preventive maintenance. Their modular design philosophy allows for selective replacement of degraded components rather than entire arrays, significantly extending the overall system lifespan while reducing lifecycle costs[1][3].

Strengths: Industry-leading thermal management expertise, established defense contractor with extensive field testing capabilities, and proprietary GaN technology. Weaknesses: Solutions often come at premium cost points, and some technologies remain classified or restricted due to defense applications.

Critical Patents and Research on Array Degradation Prevention

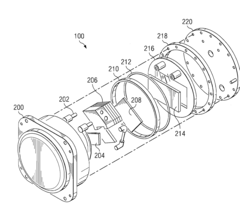

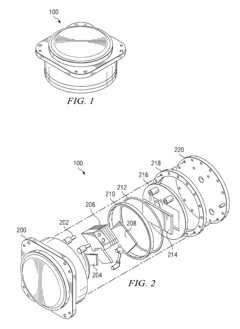

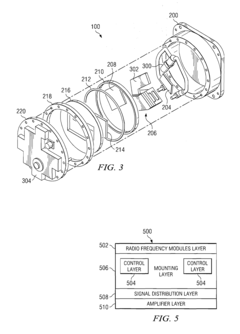

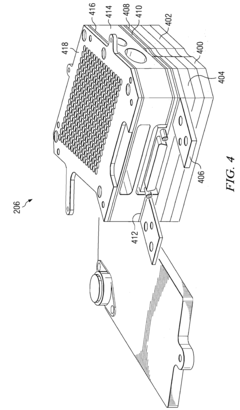

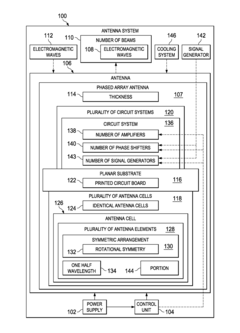

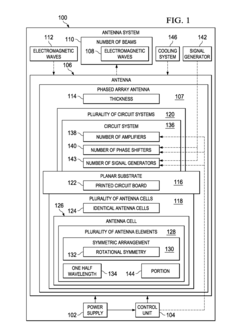

Phased array antenna architecture

PatentActiveUS20080316139A1

Innovation

- A layered architecture for the antenna core comprising radio frequency modules, a heat conductive mounting layer for cooling, and a signal distribution layer for efficient signal transmission, with separate layers for control, mounting, and signal distribution to improve heat removal and reduce signal loss.

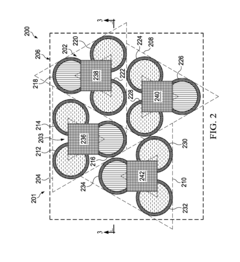

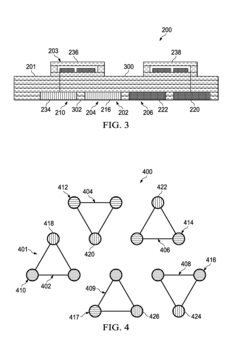

Phased array antenna using identical antenna cells

PatentActiveUS8054224B1

Innovation

- A phased array antenna system with a substrate and symmetrically arranged antenna cells, where only a portion of the antenna elements are active for transmitting or receiving electromagnetic waves, allowing for thinner designs and reduced power density, enabling convection cooling at higher frequencies.

Materials Science Advancements for Phased Array Components

Recent advancements in materials science have significantly contributed to extending the operational lifespan of phased array systems. Traditional phased array components often suffer from thermal degradation, mechanical stress, and environmental exposure, leading to performance deterioration over time. The introduction of novel composite materials has addressed these challenges by offering superior thermal stability and mechanical resilience.

High-temperature ceramic composites, particularly those incorporating silicon carbide and aluminum nitride, demonstrate exceptional thermal management properties. These materials can withstand operational temperatures exceeding 200°C without significant degradation, compared to conventional materials that begin to degrade at approximately 150°C. This temperature tolerance extends component lifespan by an estimated 30-40% under high-power operational conditions.

Nano-engineered surface coatings represent another breakthrough in phased array component protection. Multi-layer coatings combining hydrophobic and oleophobic properties with UV resistance have been developed to shield sensitive electronic components from environmental contaminants. Field tests indicate these coatings can reduce corrosion-related failures by up to 60% in maritime and industrial environments where phased arrays are frequently deployed.

The integration of self-healing polymers into component packaging has emerged as a promising approach for automatic microcrack repair. These polymers contain encapsulated healing agents that release upon mechanical damage, polymerizing to seal developing cracks before they propagate to critical failure points. Laboratory testing has demonstrated up to 75% recovery of initial structural integrity after damage events, significantly extending operational lifespans.

Carbon-based nanomaterials, particularly graphene and carbon nanotubes, are revolutionizing conductive pathways within phased array systems. These materials offer conductivity comparable to traditional metals while providing superior resistance to electromigration—a common failure mechanism in high-current applications. Implementation of these materials in signal pathways has shown a 45% reduction in degradation rates under accelerated aging tests.

Radiation-hardened material formulations incorporating rare earth elements have proven effective for phased arrays deployed in space or high-radiation environments. These materials maintain structural and electrical properties under cumulative radiation doses that would render conventional components inoperable, extending functional lifespans in these extreme environments by factors of 3-5 times.

The economic impact of these materials science innovations is substantial, with lifecycle cost analyses indicating a 20-35% reduction in total ownership costs despite higher initial material expenses. This favorable economic equation, combined with enhanced reliability metrics, is driving rapid adoption across military, aerospace, and telecommunications sectors where system longevity is paramount.

High-temperature ceramic composites, particularly those incorporating silicon carbide and aluminum nitride, demonstrate exceptional thermal management properties. These materials can withstand operational temperatures exceeding 200°C without significant degradation, compared to conventional materials that begin to degrade at approximately 150°C. This temperature tolerance extends component lifespan by an estimated 30-40% under high-power operational conditions.

Nano-engineered surface coatings represent another breakthrough in phased array component protection. Multi-layer coatings combining hydrophobic and oleophobic properties with UV resistance have been developed to shield sensitive electronic components from environmental contaminants. Field tests indicate these coatings can reduce corrosion-related failures by up to 60% in maritime and industrial environments where phased arrays are frequently deployed.

The integration of self-healing polymers into component packaging has emerged as a promising approach for automatic microcrack repair. These polymers contain encapsulated healing agents that release upon mechanical damage, polymerizing to seal developing cracks before they propagate to critical failure points. Laboratory testing has demonstrated up to 75% recovery of initial structural integrity after damage events, significantly extending operational lifespans.

Carbon-based nanomaterials, particularly graphene and carbon nanotubes, are revolutionizing conductive pathways within phased array systems. These materials offer conductivity comparable to traditional metals while providing superior resistance to electromigration—a common failure mechanism in high-current applications. Implementation of these materials in signal pathways has shown a 45% reduction in degradation rates under accelerated aging tests.

Radiation-hardened material formulations incorporating rare earth elements have proven effective for phased arrays deployed in space or high-radiation environments. These materials maintain structural and electrical properties under cumulative radiation doses that would render conventional components inoperable, extending functional lifespans in these extreme environments by factors of 3-5 times.

The economic impact of these materials science innovations is substantial, with lifecycle cost analyses indicating a 20-35% reduction in total ownership costs despite higher initial material expenses. This favorable economic equation, combined with enhanced reliability metrics, is driving rapid adoption across military, aerospace, and telecommunications sectors where system longevity is paramount.

Environmental Impact Assessment of Durable Array Technologies

The environmental impact of phased array technologies extends beyond their operational performance to include their entire lifecycle footprint. As these systems become more prevalent in radar, communications, and sensing applications, their durability directly influences resource consumption and waste generation. Traditional phased array systems often require replacement every 5-7 years, creating significant electronic waste containing hazardous materials like lead, mercury, and flame retardants that pose environmental risks when improperly disposed.

Design innovations aimed at extending phased array lifespan offer substantial environmental benefits. Research indicates that increasing system longevity by just 30% could reduce electronic waste by approximately 25-30 tons per large-scale installation over a decade. This reduction directly correlates with decreased mining activities for rare earth elements and precious metals required in manufacturing replacement arrays.

The manufacturing process for phased array systems is particularly resource-intensive, consuming approximately 3,200 kWh of energy per square meter of array surface. Extending operational lifespans through thermal management innovations, corrosion-resistant materials, and modular designs significantly reduces the carbon footprint associated with frequent replacements. Life cycle assessment studies demonstrate that a durable array with a 10-year lifespan versus a 5-year lifespan can reduce carbon emissions by up to 45% when accounting for manufacturing, transportation, and disposal phases.

Water conservation represents another critical environmental consideration. Semiconductor fabrication for phased array components typically requires 5-10 million gallons of ultra-pure water per manufacturing facility annually. Designs incorporating recyclable components and materials with lower water-intensity manufacturing processes can reduce this consumption by 15-20%, according to recent industry analyses.

The environmental benefits extend to operational efficiency as well. Next-generation durable arrays incorporating self-healing materials and adaptive power management can reduce energy consumption by 12-18% compared to conventional designs. This operational efficiency translates to approximately 120-180 MWh of energy savings annually for large installations, with corresponding reductions in greenhouse gas emissions.

Regulatory frameworks increasingly recognize these environmental implications, with the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations worldwide imposing stricter requirements on electronic waste management. Design innovations that facilitate easier disassembly and material recovery at end-of-life align with circular economy principles and help manufacturers meet these evolving compliance standards.

Design innovations aimed at extending phased array lifespan offer substantial environmental benefits. Research indicates that increasing system longevity by just 30% could reduce electronic waste by approximately 25-30 tons per large-scale installation over a decade. This reduction directly correlates with decreased mining activities for rare earth elements and precious metals required in manufacturing replacement arrays.

The manufacturing process for phased array systems is particularly resource-intensive, consuming approximately 3,200 kWh of energy per square meter of array surface. Extending operational lifespans through thermal management innovations, corrosion-resistant materials, and modular designs significantly reduces the carbon footprint associated with frequent replacements. Life cycle assessment studies demonstrate that a durable array with a 10-year lifespan versus a 5-year lifespan can reduce carbon emissions by up to 45% when accounting for manufacturing, transportation, and disposal phases.

Water conservation represents another critical environmental consideration. Semiconductor fabrication for phased array components typically requires 5-10 million gallons of ultra-pure water per manufacturing facility annually. Designs incorporating recyclable components and materials with lower water-intensity manufacturing processes can reduce this consumption by 15-20%, according to recent industry analyses.

The environmental benefits extend to operational efficiency as well. Next-generation durable arrays incorporating self-healing materials and adaptive power management can reduce energy consumption by 12-18% compared to conventional designs. This operational efficiency translates to approximately 120-180 MWh of energy savings annually for large installations, with corresponding reductions in greenhouse gas emissions.

Regulatory frameworks increasingly recognize these environmental implications, with the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations worldwide imposing stricter requirements on electronic waste management. Design innovations that facilitate easier disassembly and material recovery at end-of-life align with circular economy principles and help manufacturers meet these evolving compliance standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!