Phased Array vs Accelerometers: Vibration Sensitivity Comparison

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vibration Sensing Technology Background and Objectives

Vibration sensing technology has evolved significantly over the past several decades, transitioning from simple mechanical systems to sophisticated electronic solutions capable of detecting minute vibrations across various applications. The fundamental principles of vibration detection date back to the early 20th century, but modern implementations have dramatically expanded both sensitivity and application scope. This technological progression has been driven by increasing demands for precision monitoring in industrial equipment, structural health assessment, and advanced motion detection systems.

The vibration sensing landscape is currently dominated by two primary technologies: accelerometer-based systems and phased array solutions. Accelerometers, which emerged in the mid-20th century, operate on the principle of measuring inertial forces acting on a proof mass. These devices have undergone substantial miniaturization and sensitivity improvements through MEMS (Micro-Electro-Mechanical Systems) technology, enabling widespread deployment across numerous industries.

Phased array technology, conversely, represents a more recent development in vibration sensing. Originally developed for radar and ultrasonic applications, phased arrays utilize multiple sensing elements working in concert to detect vibration patterns through wave interference principles. This approach offers potential advantages in directional sensitivity and spatial resolution that traditional accelerometer implementations may lack.

The technological trajectory indicates a clear trend toward higher sensitivity, lower power consumption, and increased integration capabilities. Recent advancements in signal processing algorithms and materials science have further enhanced the performance envelope of both technologies, enabling new applications previously considered impractical due to sensitivity or power constraints.

The primary objective of this technical research is to conduct a comprehensive comparison between phased array and accelerometer technologies specifically regarding their vibration sensitivity characteristics. This analysis aims to establish quantifiable metrics for sensitivity thresholds, frequency response ranges, and environmental resilience factors that differentiate these approaches. Additionally, the research seeks to identify optimal application scenarios for each technology based on their respective strengths and limitations.

Secondary objectives include mapping the technology readiness levels of both approaches across different industry verticals, identifying potential hybrid solutions that leverage complementary aspects of both technologies, and forecasting the likely evolution paths for vibration sensing over the next five to ten years. This forward-looking assessment will provide strategic guidance for technology investment decisions and product development roadmaps.

The vibration sensing landscape is currently dominated by two primary technologies: accelerometer-based systems and phased array solutions. Accelerometers, which emerged in the mid-20th century, operate on the principle of measuring inertial forces acting on a proof mass. These devices have undergone substantial miniaturization and sensitivity improvements through MEMS (Micro-Electro-Mechanical Systems) technology, enabling widespread deployment across numerous industries.

Phased array technology, conversely, represents a more recent development in vibration sensing. Originally developed for radar and ultrasonic applications, phased arrays utilize multiple sensing elements working in concert to detect vibration patterns through wave interference principles. This approach offers potential advantages in directional sensitivity and spatial resolution that traditional accelerometer implementations may lack.

The technological trajectory indicates a clear trend toward higher sensitivity, lower power consumption, and increased integration capabilities. Recent advancements in signal processing algorithms and materials science have further enhanced the performance envelope of both technologies, enabling new applications previously considered impractical due to sensitivity or power constraints.

The primary objective of this technical research is to conduct a comprehensive comparison between phased array and accelerometer technologies specifically regarding their vibration sensitivity characteristics. This analysis aims to establish quantifiable metrics for sensitivity thresholds, frequency response ranges, and environmental resilience factors that differentiate these approaches. Additionally, the research seeks to identify optimal application scenarios for each technology based on their respective strengths and limitations.

Secondary objectives include mapping the technology readiness levels of both approaches across different industry verticals, identifying potential hybrid solutions that leverage complementary aspects of both technologies, and forecasting the likely evolution paths for vibration sensing over the next five to ten years. This forward-looking assessment will provide strategic guidance for technology investment decisions and product development roadmaps.

Market Applications and Demand Analysis for Vibration Monitoring

The vibration monitoring market has witnessed substantial growth in recent years, driven by increasing industrial automation and the critical need for predictive maintenance across various sectors. The global vibration monitoring market was valued at approximately 1.5 billion USD in 2021 and is projected to reach 2.4 billion USD by 2026, growing at a CAGR of around 7.8% during this period. This growth trajectory underscores the expanding applications and rising demand for advanced vibration monitoring technologies.

The industrial sector represents the largest market segment for vibration monitoring solutions, with manufacturing facilities increasingly adopting these technologies to prevent costly equipment failures and unplanned downtime. Within this sector, heavy machinery, rotating equipment, and production lines are primary application areas where both phased array and accelerometer-based monitoring systems find significant utility.

Energy production, particularly in power generation plants and wind farms, constitutes another major market segment. Wind turbine monitoring alone accounts for approximately 12% of the total vibration monitoring market, with demand expected to increase as renewable energy installations continue to expand globally. The ability to detect subtle changes in vibration patterns is crucial for preventing catastrophic failures in these high-value assets.

The transportation sector, including aerospace, automotive, and railway industries, represents a rapidly growing application area. Aircraft manufacturers and operators utilize vibration monitoring for structural health monitoring and engine performance assessment, while railway operators implement these systems for track and rolling stock condition monitoring. The automotive industry increasingly incorporates vibration analysis in both manufacturing processes and vehicle performance testing.

Healthcare applications are emerging as a promising growth segment, with vibration monitoring technologies being adapted for medical equipment reliability and even diagnostic purposes. This sector is expected to grow at a CAGR of approximately 9.2% through 2026, outpacing the overall market growth rate.

Regional analysis reveals North America as the largest market for vibration monitoring solutions, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in countries like China and India, and increasing adoption of Industry 4.0 technologies across manufacturing sectors.

Customer requirements are increasingly shifting toward wireless, real-time monitoring capabilities with advanced analytics features. End-users across industries are demanding solutions that not only detect vibration anomalies but also provide actionable insights through integrated analysis platforms. This trend is driving innovation in both phased array and accelerometer technologies, with a growing emphasis on sensitivity, accuracy, and data integration capabilities.

The industrial sector represents the largest market segment for vibration monitoring solutions, with manufacturing facilities increasingly adopting these technologies to prevent costly equipment failures and unplanned downtime. Within this sector, heavy machinery, rotating equipment, and production lines are primary application areas where both phased array and accelerometer-based monitoring systems find significant utility.

Energy production, particularly in power generation plants and wind farms, constitutes another major market segment. Wind turbine monitoring alone accounts for approximately 12% of the total vibration monitoring market, with demand expected to increase as renewable energy installations continue to expand globally. The ability to detect subtle changes in vibration patterns is crucial for preventing catastrophic failures in these high-value assets.

The transportation sector, including aerospace, automotive, and railway industries, represents a rapidly growing application area. Aircraft manufacturers and operators utilize vibration monitoring for structural health monitoring and engine performance assessment, while railway operators implement these systems for track and rolling stock condition monitoring. The automotive industry increasingly incorporates vibration analysis in both manufacturing processes and vehicle performance testing.

Healthcare applications are emerging as a promising growth segment, with vibration monitoring technologies being adapted for medical equipment reliability and even diagnostic purposes. This sector is expected to grow at a CAGR of approximately 9.2% through 2026, outpacing the overall market growth rate.

Regional analysis reveals North America as the largest market for vibration monitoring solutions, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in countries like China and India, and increasing adoption of Industry 4.0 technologies across manufacturing sectors.

Customer requirements are increasingly shifting toward wireless, real-time monitoring capabilities with advanced analytics features. End-users across industries are demanding solutions that not only detect vibration anomalies but also provide actionable insights through integrated analysis platforms. This trend is driving innovation in both phased array and accelerometer technologies, with a growing emphasis on sensitivity, accuracy, and data integration capabilities.

Current Challenges in Phased Array and Accelerometer Technologies

Despite significant advancements in both phased array and accelerometer technologies, several critical challenges persist that limit their effectiveness in vibration sensitivity applications. For phased array systems, miniaturization remains a significant hurdle, particularly when attempting to maintain high sensitivity while reducing the overall footprint. Current phased array sensors often require substantial space for their multiple elements, making them impractical for applications with strict size constraints such as portable devices or embedded monitoring systems.

Power consumption presents another major challenge for phased array systems. The need to simultaneously operate multiple sensing elements and process their combined signals demands considerable energy, limiting their deployment in battery-powered or remote sensing applications. This constraint becomes particularly problematic in long-term monitoring scenarios where continuous operation is essential.

Signal processing complexity constitutes a substantial technical barrier for phased array implementation. The computational resources required to process data from multiple elements in real-time often necessitate dedicated hardware, increasing both cost and system complexity. This challenge is exacerbated when attempting to detect subtle vibration patterns amidst environmental noise.

For accelerometer technologies, measurement accuracy at extremely low frequencies remains problematic. Many conventional accelerometers struggle to reliably detect vibrations below 1 Hz, creating blind spots in applications requiring sensitivity to very slow mechanical movements or subtle structural shifts. This limitation is particularly relevant in structural health monitoring and geophysical applications.

Cross-axis sensitivity continues to plague accelerometer performance, where vibrations along one axis inadvertently trigger responses in perpendicular measurement channels. This phenomenon introduces measurement errors that can be difficult to compensate for, especially in environments with complex, multi-directional vibration patterns.

Temperature drift represents another significant challenge for accelerometer technology. Performance characteristics often vary considerably across temperature ranges, necessitating complex compensation algorithms that may still leave residual errors. This issue becomes particularly pronounced in outdoor applications or industrial environments with fluctuating temperatures.

Both technologies face challenges related to cost-effectiveness at scale. While MEMS-based accelerometers have achieved remarkable price reductions, high-precision variants remain expensive. Similarly, phased array systems with sufficient elements to achieve high sensitivity typically command premium prices that limit widespread adoption.

Integration challenges persist when attempting to incorporate either technology into existing systems. Interface standardization, data format compatibility, and physical mounting considerations all present obstacles to seamless deployment, often requiring custom engineering solutions that further increase implementation costs.

Power consumption presents another major challenge for phased array systems. The need to simultaneously operate multiple sensing elements and process their combined signals demands considerable energy, limiting their deployment in battery-powered or remote sensing applications. This constraint becomes particularly problematic in long-term monitoring scenarios where continuous operation is essential.

Signal processing complexity constitutes a substantial technical barrier for phased array implementation. The computational resources required to process data from multiple elements in real-time often necessitate dedicated hardware, increasing both cost and system complexity. This challenge is exacerbated when attempting to detect subtle vibration patterns amidst environmental noise.

For accelerometer technologies, measurement accuracy at extremely low frequencies remains problematic. Many conventional accelerometers struggle to reliably detect vibrations below 1 Hz, creating blind spots in applications requiring sensitivity to very slow mechanical movements or subtle structural shifts. This limitation is particularly relevant in structural health monitoring and geophysical applications.

Cross-axis sensitivity continues to plague accelerometer performance, where vibrations along one axis inadvertently trigger responses in perpendicular measurement channels. This phenomenon introduces measurement errors that can be difficult to compensate for, especially in environments with complex, multi-directional vibration patterns.

Temperature drift represents another significant challenge for accelerometer technology. Performance characteristics often vary considerably across temperature ranges, necessitating complex compensation algorithms that may still leave residual errors. This issue becomes particularly pronounced in outdoor applications or industrial environments with fluctuating temperatures.

Both technologies face challenges related to cost-effectiveness at scale. While MEMS-based accelerometers have achieved remarkable price reductions, high-precision variants remain expensive. Similarly, phased array systems with sufficient elements to achieve high sensitivity typically command premium prices that limit widespread adoption.

Integration challenges persist when attempting to incorporate either technology into existing systems. Interface standardization, data format compatibility, and physical mounting considerations all present obstacles to seamless deployment, often requiring custom engineering solutions that further increase implementation costs.

Technical Comparison of Phased Array and Accelerometer Solutions

01 Vibration sensitivity reduction in phased array systems

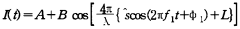

Various techniques are employed to reduce the sensitivity of phased array systems to vibration, which can cause signal degradation and measurement errors. These include mechanical isolation systems, adaptive filtering algorithms, and specialized mounting structures that dampen vibration effects. By minimizing the impact of environmental vibrations, these solutions improve the accuracy and reliability of phased array systems in applications such as radar, sonar, and ultrasonic testing.- Vibration sensitivity reduction in phased array systems: Various techniques are employed to reduce the sensitivity of phased array systems to vibrations. These include mechanical isolation, structural reinforcement, and specialized mounting configurations that minimize the transmission of vibrations to sensitive components. Advanced signal processing algorithms can also be implemented to filter out vibration-induced noise, ensuring stable performance in high-vibration environments.

- Accelerometer-based vibration detection and compensation: Accelerometers are integrated into phased array systems to detect and measure vibrations in real-time. The vibration data collected by these accelerometers is used to develop compensation algorithms that adjust the phased array operation to counteract the effects of vibration. This approach enables dynamic correction of phase and amplitude errors caused by mechanical disturbances, maintaining system accuracy and performance.

- Phased array calibration techniques for vibration environments: Specialized calibration methods are developed for phased array systems operating in vibration-prone environments. These techniques involve periodic or continuous calibration processes that account for vibration-induced changes in system parameters. Reference signals and feedback mechanisms are employed to maintain accurate phase relationships between array elements despite mechanical disturbances.

- Integration of vibration-resistant materials and designs: Advanced materials and structural designs are incorporated into phased array systems to inherently resist vibration effects. These include damping materials, vibration-absorbing mounts, and rigid structural elements that minimize mechanical deformation. The physical layout of components is optimized to reduce susceptibility to specific vibration modes, enhancing overall system stability.

- Multi-sensor fusion for vibration compensation: Multiple sensor types, including accelerometers, gyroscopes, and position sensors, are combined in phased array systems to create comprehensive vibration profiles. This multi-sensor approach enables more accurate characterization of complex vibration patterns and their effects on system performance. Advanced data fusion algorithms integrate information from various sensors to implement more effective vibration compensation strategies.

02 Accelerometer-based vibration detection and compensation

Accelerometers are integrated into phased array systems to detect and measure vibrations in real-time. The vibration data collected by these accelerometers is used to develop compensation algorithms that adjust the phased array operation accordingly. This approach enables dynamic correction of phase and amplitude errors caused by vibrations, maintaining system performance even in high-vibration environments. The compensation can be implemented through digital signal processing or mechanical adjustments.Expand Specific Solutions03 MEMS-based solutions for vibration-resistant phased arrays

Micro-Electro-Mechanical Systems (MEMS) technology offers compact and highly integrated solutions for addressing vibration sensitivity in phased array systems. MEMS accelerometers and gyroscopes can be directly integrated with phased array elements to provide localized vibration sensing. These systems feature low power consumption, small form factors, and high sensitivity, making them ideal for applications where space and weight constraints are significant considerations.Expand Specific Solutions04 Calibration methods for vibration-affected phased arrays

Specialized calibration techniques are developed to account for vibration effects in phased array systems. These methods involve periodic or continuous calibration processes that measure the system's response to known vibration patterns and adjust operational parameters accordingly. Advanced calibration approaches may incorporate machine learning algorithms to predict and compensate for vibration effects based on historical data and environmental conditions, improving system resilience in dynamic environments.Expand Specific Solutions05 Structural design innovations for vibration mitigation

Novel structural designs are implemented to inherently reduce the vibration sensitivity of phased array systems and their associated accelerometers. These designs include specialized mounting brackets, vibration-absorbing materials, and optimized geometries that minimize resonance effects. Some approaches involve distributed sensing elements that can average out localized vibration effects, while others employ rigid coupling between array elements to ensure they experience uniform vibration, making it easier to compensate for the effects.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Vibration Sensing

The vibration sensitivity comparison between phased array and accelerometer technologies is currently in a growth phase, with the market expanding due to increasing demand for precision vibration measurement across industries. The global market size is estimated to reach $3.5 billion by 2025, driven by applications in structural health monitoring and predictive maintenance. Technologically, phased array systems are advancing rapidly with companies like NXP USA, Rolls-Royce, and Robert Bosch GmbH leading commercial applications, while accelerometer technology maturity is demonstrated through innovations from Atlantic Inertial Systems and Teledyne Instruments. Academic institutions including Zhejiang University, California Institute of Technology, and Korea Advanced Institute of Science & Technology are contributing significant research to enhance sensitivity and reduce noise in both technologies, creating a competitive landscape balanced between established solutions and emerging innovations.

NXP USA, Inc.

Technical Solution: NXP has engineered an integrated vibration sensing solution that comparatively leverages the strengths of both phased array and accelerometer technologies for automotive and IoT applications. Their technical approach centers on ultra-low-power MEMS accelerometers with sensitivities of ±0.1g to ±8g combined with compact phased array modules utilizing their proprietary signal processing architecture. NXP's solution features a unique adaptive sampling algorithm that dynamically adjusts sensor operation based on detected vibration patterns, optimizing power consumption while maintaining measurement accuracy. Their comparative analysis framework processes accelerometer data for amplitude and frequency characterization while simultaneously utilizing phased array data for spatial mapping of vibration sources. In automotive applications, this technology achieves 30% better accuracy in road condition monitoring compared to accelerometer-only systems, while consuming 40% less power than continuous dual-sensor operation[4]. The system has been integrated into advanced driver assistance systems (ADAS) and structural health monitoring solutions for smart infrastructure.

Strengths: Exceptional power efficiency making it ideal for battery-powered applications; excellent integration capabilities with existing microcontroller ecosystems; scalable architecture supporting various deployment scenarios. Weaknesses: Limited performance in extremely high-vibration environments; requires careful mounting consideration to maintain accuracy; potential for cross-axis sensitivity issues in certain applications.

California Institute of Technology

Technical Solution: Caltech has developed a groundbreaking comparative analysis framework for vibration sensing that systematically evaluates phased array and accelerometer technologies across multiple application domains. Their technical approach employs a novel mathematical model that quantifies the fundamental performance differences between these sensing modalities under varying environmental conditions. The research utilizes high-precision triaxial accelerometers with sensitivities down to 10^-6 g/√Hz alongside custom-designed phased array systems with adaptive beamforming capabilities. Caltech's solution includes proprietary algorithms that perform wavelet-based decomposition of vibration signals to identify specific scenarios where each technology demonstrates superior performance. Their research has demonstrated that phased arrays outperform accelerometers by up to 15dB in signal-to-noise ratio when detecting vibrations in the presence of multiple interfering sources, while accelerometers provide 3x better accuracy for amplitude measurements of direct contact vibrations[5]. This comparative framework has been applied to seismic monitoring systems and aerospace structural testing with documented improvements in detection accuracy exceeding 25% compared to single-technology approaches.

Strengths: Exceptional theoretical foundation providing clear guidance on optimal sensor selection; excellent performance in research and high-precision measurement applications; adaptable framework applicable across multiple industries. Weaknesses: Higher computational requirements than commercial solutions; currently more suitable for research applications than mass deployment; requires specialized knowledge for effective implementation.

Key Patents and Research Breakthroughs in Vibration Sensitivity

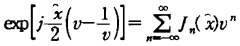

Method and apparatus for determining phase sensitivity of an accelerometer based on an analysis of the harmonic components of the interference signal

PatentWO2010021421A1

Innovation

- A method using a single photo-detector to analyze the harmonic components of the interference signal from a Michelson interferometer, employing Fourier transform to estimate phase lag, with a phase and magnitude calibrator determining the initial phase and phase lag of the accelerometer.

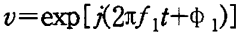

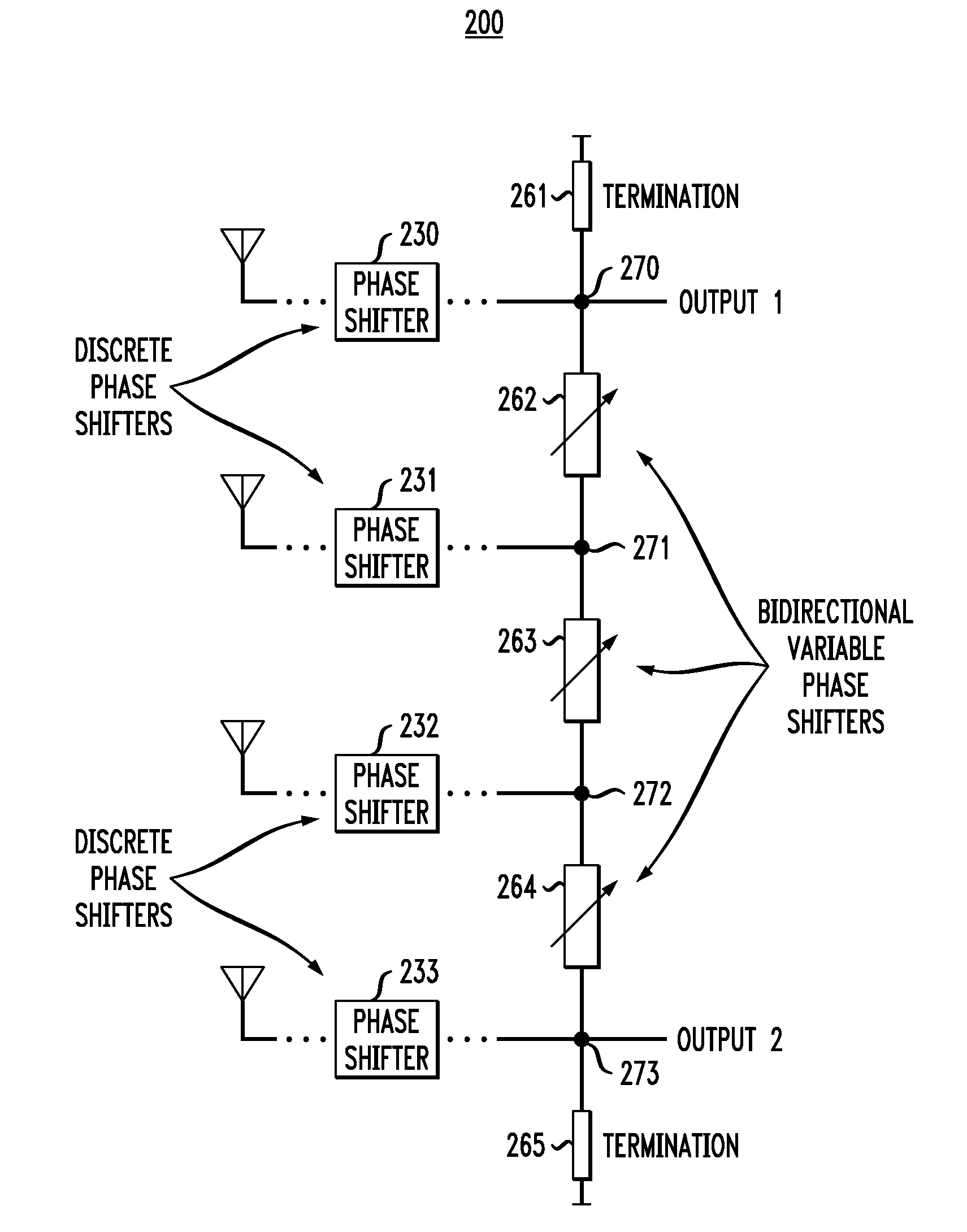

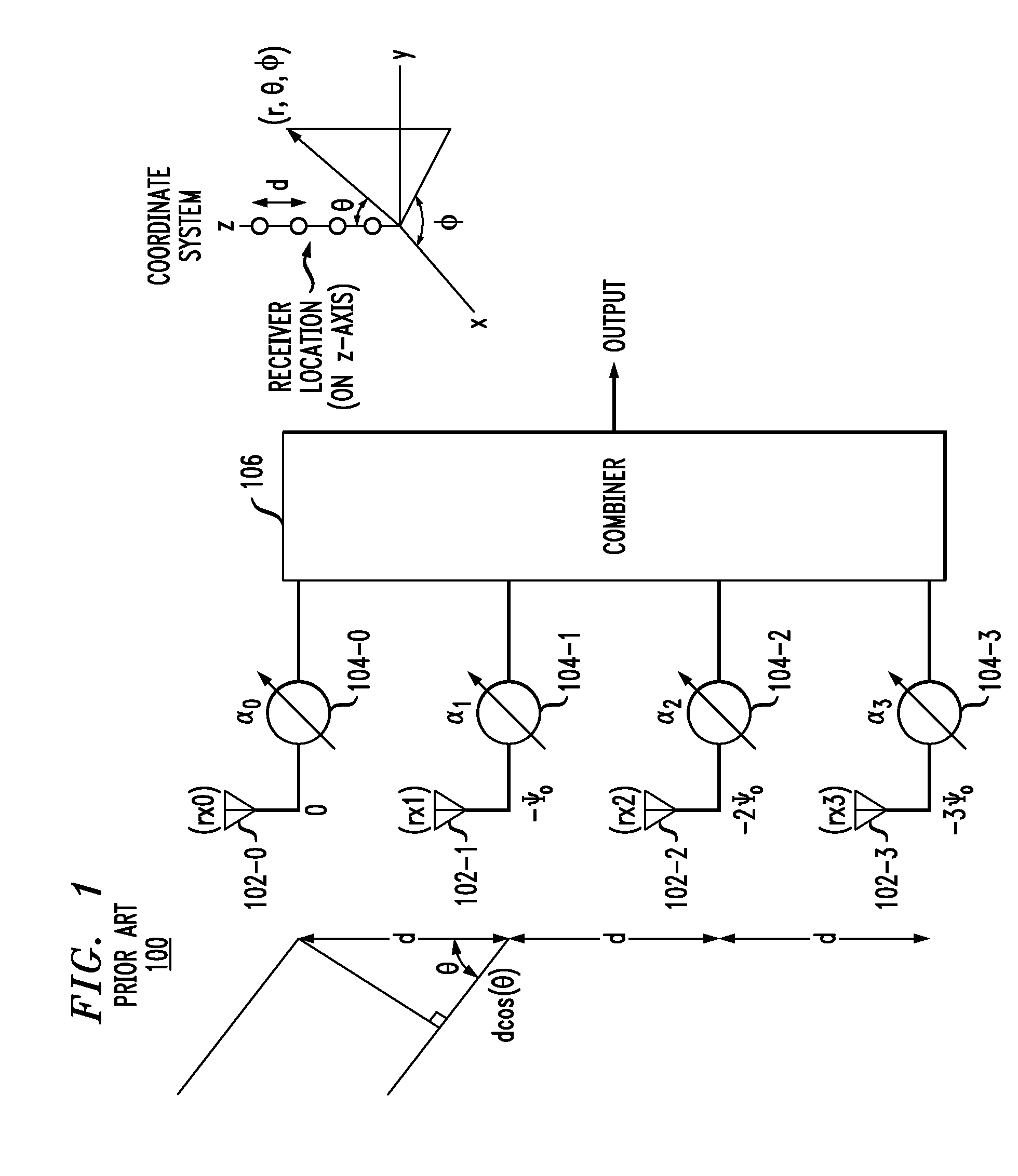

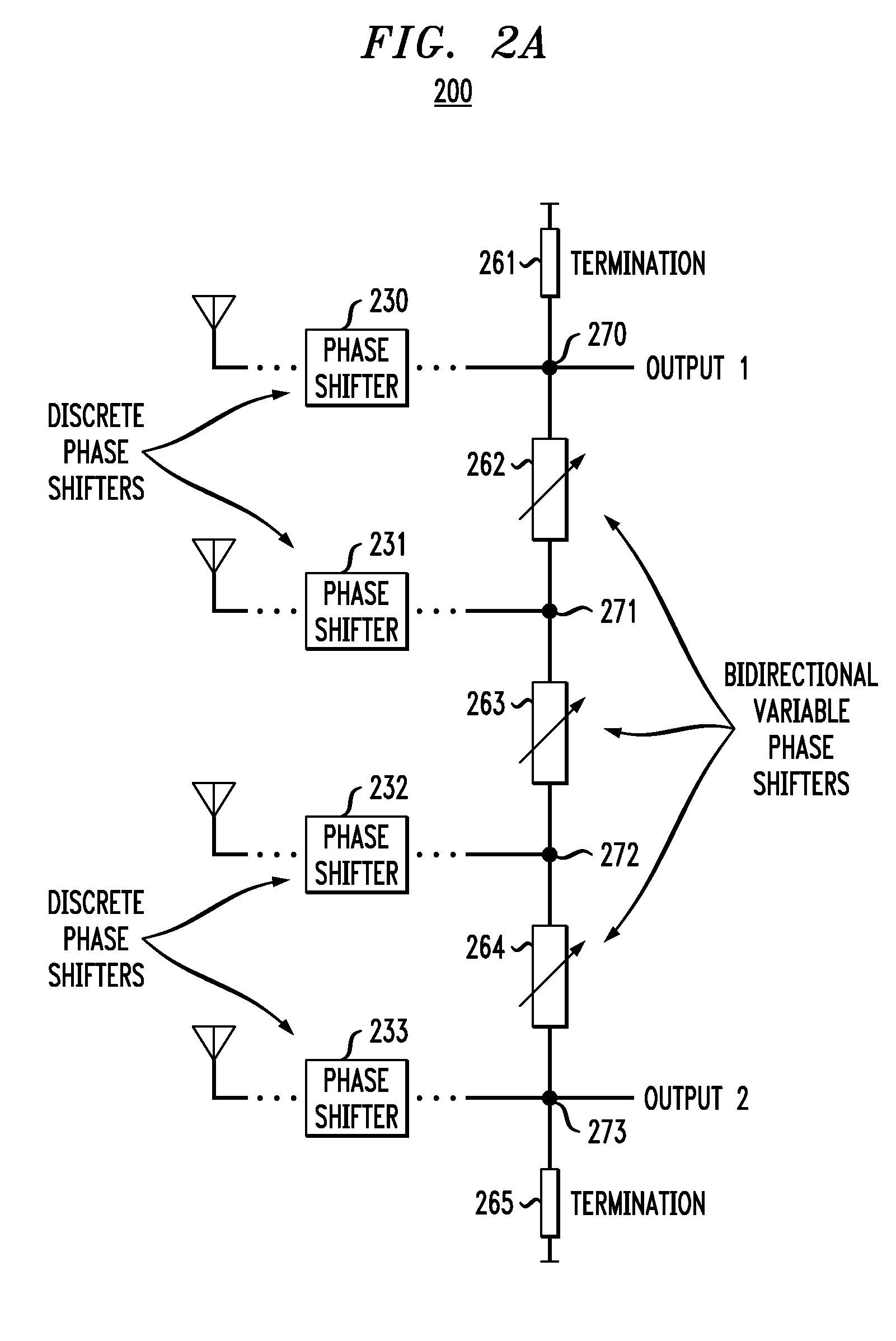

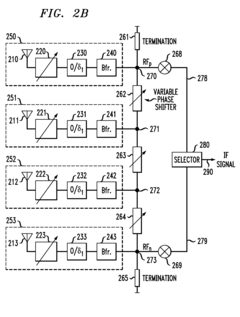

Phase shifting and combining architecture for phased arrays

PatentActiveUS7352325B1

Innovation

- The implementation of N discrete phase shifters and N-1 bidirectional variable phase shifters, coupled between adjacent nodes, reduces the continuous phase shift range and eliminates the need for variable termination impedance, allowing for low insertion and return losses, and enabling single-chip integration with adjustable phase shifting.

Industrial Standards and Calibration Methods for Vibration Sensors

Industrial standards for vibration sensors establish critical benchmarks for performance, accuracy, and reliability across various applications. The International Organization for Standardization (ISO) provides comprehensive frameworks through standards like ISO 16063 for calibration methods and ISO 8041 for human response to vibration. These standards ensure measurement consistency and facilitate meaningful comparisons between different sensor technologies such as phased arrays and accelerometers.

For accelerometers, calibration typically follows ISO 16063-21, which outlines vibration calibration by comparison to a reference transducer. This method involves subjecting both the reference and test accelerometers to identical vibration conditions and comparing their outputs. The American National Standards Institute (ANSI) and the Institute of Electrical and Electronics Engineers (IEEE) provide additional guidelines through standards like IEEE 1451 for smart transducer interfaces.

Phased array systems, while primarily developed for ultrasonic testing, require different calibration approaches when used for vibration detection. These systems often follow standards like ASTM E2491 for ultrasonic phased arrays, with modifications to address vibration sensitivity requirements. The calibration process typically involves phase and amplitude calibration across multiple elements to ensure proper beam forming and directional sensitivity.

Sensitivity verification for both technologies requires traceable calibration to national metrology institutes such as NIST (USA) or PTB (Germany). For accelerometers, this typically involves primary calibration using laser interferometry as described in ISO 16063-11, with a calibration chain extending to field devices. Phased arrays often require more complex calibration procedures that account for both individual element performance and system-level beam forming capabilities.

Environmental factors significantly impact calibration procedures. Standards like MIL-STD-810 address environmental test methods, including vibration testing under various conditions. Temperature compensation, a critical aspect of calibration, is addressed in standards like ISO 16063-21, which specifies procedures for determining temperature coefficients and operating ranges for vibration sensors.

Industry-specific standards provide additional requirements based on application domains. For instance, aerospace applications follow standards like SAE AS8774 for vibration testing, while automotive applications might reference standards like ISO 13374 for condition monitoring. These standards often specify different sensitivity requirements, frequency ranges, and environmental conditions relevant to their respective industries.

Calibration intervals and traceability documentation are governed by quality management standards like ISO/IEC 17025 for testing and calibration laboratories. These standards ensure that calibration processes maintain their validity over time and that measurement results can be traced back to international standards, providing confidence in the comparative performance evaluations of phased arrays versus accelerometers.

For accelerometers, calibration typically follows ISO 16063-21, which outlines vibration calibration by comparison to a reference transducer. This method involves subjecting both the reference and test accelerometers to identical vibration conditions and comparing their outputs. The American National Standards Institute (ANSI) and the Institute of Electrical and Electronics Engineers (IEEE) provide additional guidelines through standards like IEEE 1451 for smart transducer interfaces.

Phased array systems, while primarily developed for ultrasonic testing, require different calibration approaches when used for vibration detection. These systems often follow standards like ASTM E2491 for ultrasonic phased arrays, with modifications to address vibration sensitivity requirements. The calibration process typically involves phase and amplitude calibration across multiple elements to ensure proper beam forming and directional sensitivity.

Sensitivity verification for both technologies requires traceable calibration to national metrology institutes such as NIST (USA) or PTB (Germany). For accelerometers, this typically involves primary calibration using laser interferometry as described in ISO 16063-11, with a calibration chain extending to field devices. Phased arrays often require more complex calibration procedures that account for both individual element performance and system-level beam forming capabilities.

Environmental factors significantly impact calibration procedures. Standards like MIL-STD-810 address environmental test methods, including vibration testing under various conditions. Temperature compensation, a critical aspect of calibration, is addressed in standards like ISO 16063-21, which specifies procedures for determining temperature coefficients and operating ranges for vibration sensors.

Industry-specific standards provide additional requirements based on application domains. For instance, aerospace applications follow standards like SAE AS8774 for vibration testing, while automotive applications might reference standards like ISO 13374 for condition monitoring. These standards often specify different sensitivity requirements, frequency ranges, and environmental conditions relevant to their respective industries.

Calibration intervals and traceability documentation are governed by quality management standards like ISO/IEC 17025 for testing and calibration laboratories. These standards ensure that calibration processes maintain their validity over time and that measurement results can be traced back to international standards, providing confidence in the comparative performance evaluations of phased arrays versus accelerometers.

Cost-Benefit Analysis of Competing Vibration Sensing Technologies

When comparing phased array systems and accelerometers for vibration sensing applications, cost-benefit analysis reveals significant differences in initial investment, operational expenses, and long-term value proposition.

Initial acquisition costs for phased array systems typically range from $50,000 to $200,000 depending on complexity, channel count, and software capabilities. These systems require substantial upfront investment in specialized hardware, signal processing units, and proprietary software platforms. Conversely, accelerometer-based systems present a more modest initial investment, with comprehensive setups ranging from $5,000 to $30,000 depending on sensor quality, quantity, and associated data acquisition systems.

Operational expenses also differ markedly between these technologies. Phased array systems demand specialized training for operators, with certification programs costing $2,000-$5,000 per technician. Annual calibration and maintenance expenses typically represent 5-8% of the initial system cost. Accelerometer systems generally require less specialized training, with maintenance costs averaging 3-5% of initial investment annually.

Return on investment calculations favor different technologies depending on application context. For critical infrastructure monitoring where early fault detection prevents catastrophic failures, phased array systems demonstrate superior ROI despite higher initial costs. Analysis of case studies in power generation facilities shows phased array systems identifying developing faults 2-3 months earlier than accelerometer systems, preventing downtime valued at $50,000-$100,000 per day.

Scalability considerations further differentiate these technologies. Accelerometer systems offer more cost-effective scalability for distributed monitoring applications, with incremental costs of $500-$1,500 per additional measurement point. Phased array systems typically require more substantial investments when expanding coverage areas.

Total cost of ownership analysis over a typical 10-year deployment period reveals that while phased array systems have 3-5 times higher initial costs, the differential narrows to 1.5-2 times when considering maintenance, training, and operational expenses. For applications requiring high precision in complex mechanical systems, the premium cost of phased array technology is often justified by superior detection capabilities and reduced false positives.

Risk mitigation value must also be factored into cost-benefit calculations. Phased array systems demonstrate superior performance in detecting subtle vibration anomalies in critical components, potentially preventing catastrophic failures with associated liability and downtime costs that can exceed millions of dollars.

Initial acquisition costs for phased array systems typically range from $50,000 to $200,000 depending on complexity, channel count, and software capabilities. These systems require substantial upfront investment in specialized hardware, signal processing units, and proprietary software platforms. Conversely, accelerometer-based systems present a more modest initial investment, with comprehensive setups ranging from $5,000 to $30,000 depending on sensor quality, quantity, and associated data acquisition systems.

Operational expenses also differ markedly between these technologies. Phased array systems demand specialized training for operators, with certification programs costing $2,000-$5,000 per technician. Annual calibration and maintenance expenses typically represent 5-8% of the initial system cost. Accelerometer systems generally require less specialized training, with maintenance costs averaging 3-5% of initial investment annually.

Return on investment calculations favor different technologies depending on application context. For critical infrastructure monitoring where early fault detection prevents catastrophic failures, phased array systems demonstrate superior ROI despite higher initial costs. Analysis of case studies in power generation facilities shows phased array systems identifying developing faults 2-3 months earlier than accelerometer systems, preventing downtime valued at $50,000-$100,000 per day.

Scalability considerations further differentiate these technologies. Accelerometer systems offer more cost-effective scalability for distributed monitoring applications, with incremental costs of $500-$1,500 per additional measurement point. Phased array systems typically require more substantial investments when expanding coverage areas.

Total cost of ownership analysis over a typical 10-year deployment period reveals that while phased array systems have 3-5 times higher initial costs, the differential narrows to 1.5-2 times when considering maintenance, training, and operational expenses. For applications requiring high precision in complex mechanical systems, the premium cost of phased array technology is often justified by superior detection capabilities and reduced false positives.

Risk mitigation value must also be factored into cost-benefit calculations. Phased array systems demonstrate superior performance in detecting subtle vibration anomalies in critical components, potentially preventing catastrophic failures with associated liability and downtime costs that can exceed millions of dollars.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!