Phased Array vs Piezoelectric Sensors: Sensitivity Balance

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phased Array and Piezoelectric Sensing Technology Background

Phased array and piezoelectric sensing technologies represent two fundamental approaches in modern sensing systems, each with distinct historical development paths and technical foundations. Piezoelectric sensing technology emerged in the early 20th century following the discovery of the piezoelectric effect by Jacques and Pierre Curie in 1880. This phenomenon, where certain materials generate electrical charges under mechanical stress, laid the groundwork for various sensing applications. Early piezoelectric sensors utilized natural crystals like quartz, while modern versions employ synthetic materials such as lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF).

The evolution of piezoelectric sensing technology accelerated significantly during World War II with the development of sonar systems. Post-war applications expanded into industrial sectors, medical diagnostics, and consumer electronics. The fundamental operating principle remains consistent: these sensors convert mechanical energy into electrical signals, enabling the detection of pressure, acceleration, and vibration with high precision.

Phased array technology, by contrast, represents a more recent innovation in sensing systems. Originally developed for radar applications in the mid-20th century, phased arrays consist of multiple sensing elements arranged in specific geometric patterns. The key innovation lies in the ability to electronically steer and focus the sensing beam without physical movement of the array, achieved through precise timing control of individual elements.

The transition of phased array technology from military applications to commercial sectors occurred gradually through the latter half of the 20th century. Significant advancements in computing power, signal processing algorithms, and materials science during the 1980s and 1990s enabled more sophisticated implementations across diverse fields including medical imaging, non-destructive testing, and communications.

The convergence of these technologies has created a complex landscape where engineers must balance competing considerations. Piezoelectric sensors typically offer excellent sensitivity at the individual element level, while phased arrays provide superior spatial resolution and beam-forming capabilities through the coordinated operation of multiple elements. This fundamental trade-off between single-element sensitivity and array-based functionality defines many design decisions in modern sensing systems.

Recent technological trends indicate growing interest in hybrid approaches that leverage the strengths of both technologies. Advanced materials research has yielded piezoelectric composites with enhanced properties, while miniaturization has enabled denser phased array configurations. Concurrently, computational advances have improved signal processing capabilities, allowing more sophisticated interpretation of sensor data regardless of the underlying technology.

The ongoing evolution of both technologies continues to expand their application domains, with emerging fields such as structural health monitoring, autonomous vehicles, and medical diagnostics driving innovation in sensitivity, power efficiency, and form factor considerations.

The evolution of piezoelectric sensing technology accelerated significantly during World War II with the development of sonar systems. Post-war applications expanded into industrial sectors, medical diagnostics, and consumer electronics. The fundamental operating principle remains consistent: these sensors convert mechanical energy into electrical signals, enabling the detection of pressure, acceleration, and vibration with high precision.

Phased array technology, by contrast, represents a more recent innovation in sensing systems. Originally developed for radar applications in the mid-20th century, phased arrays consist of multiple sensing elements arranged in specific geometric patterns. The key innovation lies in the ability to electronically steer and focus the sensing beam without physical movement of the array, achieved through precise timing control of individual elements.

The transition of phased array technology from military applications to commercial sectors occurred gradually through the latter half of the 20th century. Significant advancements in computing power, signal processing algorithms, and materials science during the 1980s and 1990s enabled more sophisticated implementations across diverse fields including medical imaging, non-destructive testing, and communications.

The convergence of these technologies has created a complex landscape where engineers must balance competing considerations. Piezoelectric sensors typically offer excellent sensitivity at the individual element level, while phased arrays provide superior spatial resolution and beam-forming capabilities through the coordinated operation of multiple elements. This fundamental trade-off between single-element sensitivity and array-based functionality defines many design decisions in modern sensing systems.

Recent technological trends indicate growing interest in hybrid approaches that leverage the strengths of both technologies. Advanced materials research has yielded piezoelectric composites with enhanced properties, while miniaturization has enabled denser phased array configurations. Concurrently, computational advances have improved signal processing capabilities, allowing more sophisticated interpretation of sensor data regardless of the underlying technology.

The ongoing evolution of both technologies continues to expand their application domains, with emerging fields such as structural health monitoring, autonomous vehicles, and medical diagnostics driving innovation in sensitivity, power efficiency, and form factor considerations.

Market Applications and Demand Analysis

The market for ultrasonic sensing technologies has experienced significant growth in recent years, with both phased array and traditional piezoelectric sensors playing crucial roles across multiple industries. The global ultrasonic sensor market was valued at approximately $4.9 billion in 2021 and is projected to reach $9.0 billion by 2026, growing at a CAGR of 12.8%. This growth is primarily driven by increasing demand for non-destructive testing (NDT) solutions in manufacturing, healthcare diagnostics, and autonomous vehicle development.

In the industrial sector, phased array technology has gained substantial traction due to its superior imaging capabilities and flexibility in beam steering. Manufacturing companies are increasingly adopting phased array systems for quality control processes, particularly in aerospace and automotive industries where detection of microscopic defects in critical components is essential. The ability to electronically focus and steer ultrasonic beams without mechanical movement gives phased arrays a distinct advantage in automated inspection systems.

Healthcare represents another significant market segment, with ultrasound imaging devices accounting for approximately 22% of the global medical imaging market. While traditional piezoelectric sensors still dominate portable and low-cost medical devices due to their simplicity and cost-effectiveness, phased array technology has become the standard for advanced diagnostic imaging. The superior resolution and depth penetration of phased arrays have made them indispensable for cardiac imaging, obstetrics, and interventional procedures.

The automotive industry presents a rapidly expanding application area, particularly with the rise of advanced driver assistance systems (ADAS) and autonomous vehicles. Here, the sensitivity balance between phased arrays and piezoelectric sensors becomes particularly relevant. While single-element piezoelectric sensors offer cost advantages for basic parking sensors, the industry is increasingly demanding the enhanced detection capabilities of phased array systems for more sophisticated obstacle detection and environmental mapping.

Defense and security applications represent another growing market segment, with demand for underwater sonar systems, structural health monitoring of critical infrastructure, and non-destructive testing of military equipment. In these applications, the sensitivity balance often tilts toward phased arrays despite their higher cost, as the enhanced detection capabilities and reduced false alarm rates justify the investment.

Market analysis indicates a clear trend toward miniaturization and cost reduction in phased array technology, which is gradually eroding the traditional cost advantage of simple piezoelectric sensors. This trend is expected to accelerate as manufacturing techniques improve and economies of scale take effect, potentially reshaping the competitive landscape between these technologies in price-sensitive market segments.

In the industrial sector, phased array technology has gained substantial traction due to its superior imaging capabilities and flexibility in beam steering. Manufacturing companies are increasingly adopting phased array systems for quality control processes, particularly in aerospace and automotive industries where detection of microscopic defects in critical components is essential. The ability to electronically focus and steer ultrasonic beams without mechanical movement gives phased arrays a distinct advantage in automated inspection systems.

Healthcare represents another significant market segment, with ultrasound imaging devices accounting for approximately 22% of the global medical imaging market. While traditional piezoelectric sensors still dominate portable and low-cost medical devices due to their simplicity and cost-effectiveness, phased array technology has become the standard for advanced diagnostic imaging. The superior resolution and depth penetration of phased arrays have made them indispensable for cardiac imaging, obstetrics, and interventional procedures.

The automotive industry presents a rapidly expanding application area, particularly with the rise of advanced driver assistance systems (ADAS) and autonomous vehicles. Here, the sensitivity balance between phased arrays and piezoelectric sensors becomes particularly relevant. While single-element piezoelectric sensors offer cost advantages for basic parking sensors, the industry is increasingly demanding the enhanced detection capabilities of phased array systems for more sophisticated obstacle detection and environmental mapping.

Defense and security applications represent another growing market segment, with demand for underwater sonar systems, structural health monitoring of critical infrastructure, and non-destructive testing of military equipment. In these applications, the sensitivity balance often tilts toward phased arrays despite their higher cost, as the enhanced detection capabilities and reduced false alarm rates justify the investment.

Market analysis indicates a clear trend toward miniaturization and cost reduction in phased array technology, which is gradually eroding the traditional cost advantage of simple piezoelectric sensors. This trend is expected to accelerate as manufacturing techniques improve and economies of scale take effect, potentially reshaping the competitive landscape between these technologies in price-sensitive market segments.

Current Sensitivity Challenges and Limitations

Despite significant advancements in both phased array and piezoelectric sensor technologies, several critical sensitivity challenges persist that limit their optimal performance in various applications. Phased array systems, while offering superior beam steering capabilities, struggle with sensitivity degradation at extreme steering angles, often experiencing up to 3-6 dB loss when operating beyond 45 degrees from normal incidence. This limitation becomes particularly problematic in wide-area scanning applications where consistent sensitivity across the entire field of view is essential.

Piezoelectric sensors face different sensitivity constraints, primarily related to their frequency-dependent response characteristics. Most conventional piezoelectric materials exhibit peak sensitivity within a narrow frequency band, typically showing a 10-15 dB drop in sensitivity when operating just one octave away from their resonant frequency. This frequency limitation restricts their versatility in multi-frequency applications and compromises performance in broadband sensing scenarios.

Temperature stability presents another significant challenge for both technologies. Piezoelectric sensors demonstrate sensitivity variations of approximately 0.05-0.1% per degree Celsius, which can result in substantial measurement errors in environments with fluctuating temperatures. Phased array systems, while less affected by temperature at the element level, experience phase synchronization issues across the array when subjected to non-uniform thermal conditions, leading to beam forming inaccuracies and reduced sensitivity.

Miniaturization efforts have introduced additional sensitivity trade-offs. As piezoelectric sensors are reduced in size to accommodate portable applications, their signal-to-noise ratio decreases proportionally, with sub-millimeter sensors often exhibiting 20-30 dB lower sensitivity than their larger counterparts. Similarly, compact phased arrays with closely spaced elements suffer from mutual coupling effects, which can degrade sensitivity by 2-4 dB and introduce spatial distortions in the sensitivity pattern.

Power consumption requirements create further limitations, particularly for battery-operated and remote sensing applications. High-sensitivity operation in phased arrays typically demands significant power for signal amplification and processing, with each doubling of sensitivity often requiring a 4x increase in power consumption. Piezoelectric sensors, while generally more power-efficient, still face challenges in maintaining sensitivity when operating with low-power excitation signals.

Material limitations also impact sensitivity performance. Current piezoelectric materials like PZT and PMN-PT, despite their excellent piezoelectric coefficients, exhibit sensitivity degradation over time due to aging effects, typically losing 1-2% of their sensitivity annually. Phased array systems face challenges with interface materials and coupling media, which can introduce signal losses of 3-8 dB if not optimally matched to the acoustic impedance of the target medium.

Piezoelectric sensors face different sensitivity constraints, primarily related to their frequency-dependent response characteristics. Most conventional piezoelectric materials exhibit peak sensitivity within a narrow frequency band, typically showing a 10-15 dB drop in sensitivity when operating just one octave away from their resonant frequency. This frequency limitation restricts their versatility in multi-frequency applications and compromises performance in broadband sensing scenarios.

Temperature stability presents another significant challenge for both technologies. Piezoelectric sensors demonstrate sensitivity variations of approximately 0.05-0.1% per degree Celsius, which can result in substantial measurement errors in environments with fluctuating temperatures. Phased array systems, while less affected by temperature at the element level, experience phase synchronization issues across the array when subjected to non-uniform thermal conditions, leading to beam forming inaccuracies and reduced sensitivity.

Miniaturization efforts have introduced additional sensitivity trade-offs. As piezoelectric sensors are reduced in size to accommodate portable applications, their signal-to-noise ratio decreases proportionally, with sub-millimeter sensors often exhibiting 20-30 dB lower sensitivity than their larger counterparts. Similarly, compact phased arrays with closely spaced elements suffer from mutual coupling effects, which can degrade sensitivity by 2-4 dB and introduce spatial distortions in the sensitivity pattern.

Power consumption requirements create further limitations, particularly for battery-operated and remote sensing applications. High-sensitivity operation in phased arrays typically demands significant power for signal amplification and processing, with each doubling of sensitivity often requiring a 4x increase in power consumption. Piezoelectric sensors, while generally more power-efficient, still face challenges in maintaining sensitivity when operating with low-power excitation signals.

Material limitations also impact sensitivity performance. Current piezoelectric materials like PZT and PMN-PT, despite their excellent piezoelectric coefficients, exhibit sensitivity degradation over time due to aging effects, typically losing 1-2% of their sensitivity annually. Phased array systems face challenges with interface materials and coupling media, which can introduce signal losses of 3-8 dB if not optimally matched to the acoustic impedance of the target medium.

Comparative Analysis of Sensing Solutions

01 Phased array design for enhanced sensitivity

Phased array configurations can be optimized to enhance sensor sensitivity through strategic element placement and signal processing techniques. By carefully designing the array geometry and implementing advanced beamforming algorithms, the signal-to-noise ratio can be significantly improved. These designs often incorporate multiple piezoelectric elements arranged in specific patterns to achieve directional sensitivity and reduce interference from unwanted signals.- Phased array antenna sensitivity enhancement techniques: Various methods can be employed to enhance the sensitivity of phased array antennas, including optimized element spacing, adaptive beamforming algorithms, and signal processing techniques. These approaches help to improve signal reception, reduce interference, and increase the overall sensitivity of the array. Advanced calibration methods ensure optimal performance across different operating conditions and environments.

- Piezoelectric sensor design for improved sensitivity: Specific design considerations for piezoelectric sensors can significantly enhance their sensitivity. These include the selection of high-performance piezoelectric materials, optimized electrode configurations, and specialized structural designs. Reducing noise and improving signal conditioning circuits also contributes to higher sensitivity. These design approaches enable more accurate detection of small physical changes and vibrations.

- Integration of phased arrays with piezoelectric elements: The combination of phased array technology with piezoelectric elements creates highly sensitive sensing systems. This integration allows for directional sensitivity control while leveraging the high responsiveness of piezoelectric materials. Such hybrid systems benefit from both the spatial selectivity of phased arrays and the mechanical-electrical conversion efficiency of piezoelectric sensors, resulting in enhanced detection capabilities for various applications.

- Signal processing methods for sensitivity enhancement: Advanced signal processing techniques play a crucial role in improving the sensitivity of both phased array and piezoelectric sensor systems. These include digital filtering, adaptive noise cancellation, signal averaging, and machine learning algorithms for pattern recognition. By effectively processing the raw sensor data, these methods can extract meaningful information from weak signals and improve the overall detection threshold of the sensing system.

- Environmental and operational factors affecting sensitivity: Various environmental and operational factors significantly impact the sensitivity of phased array and piezoelectric sensors. Temperature fluctuations, mechanical stress, electromagnetic interference, and humidity can all degrade sensor performance. Compensation techniques, protective housings, and adaptive calibration methods are employed to maintain optimal sensitivity under changing conditions, ensuring reliable operation in diverse environments.

02 Piezoelectric material selection for sensitivity improvement

The choice of piezoelectric materials significantly impacts sensor sensitivity. Advanced materials with higher piezoelectric coefficients and improved electromechanical coupling factors can substantially enhance the conversion efficiency between mechanical and electrical energy. Specialized compositions and manufacturing techniques can optimize the material properties for specific sensing applications, resulting in improved detection thresholds and measurement accuracy.Expand Specific Solutions03 Signal processing techniques for sensitivity enhancement

Advanced signal processing algorithms can significantly improve the sensitivity of phased array and piezoelectric sensor systems. Techniques such as adaptive filtering, coherent integration, and statistical signal processing help extract weak signals from noise. Digital signal processing methods, including wavelet transforms and machine learning approaches, can further enhance detection capabilities by identifying subtle patterns in sensor data that might otherwise be missed by conventional methods.Expand Specific Solutions04 Integrated sensor array architectures

Integrated sensor architectures that combine phased arrays with piezoelectric elements offer enhanced sensitivity through system-level optimization. These designs incorporate multiple sensing modalities, custom application-specific integrated circuits (ASICs), and optimized interconnection schemes. By addressing the entire signal chain from transduction to processing, these integrated approaches minimize noise introduction and signal loss, resulting in superior sensitivity performance.Expand Specific Solutions05 Environmental compensation and calibration methods

Environmental factors such as temperature, humidity, and mechanical stress can significantly affect the sensitivity of piezoelectric sensors and phased arrays. Advanced compensation techniques and calibration methods can mitigate these effects, ensuring consistent sensitivity across varying operating conditions. Self-calibrating systems that continuously monitor and adjust for environmental changes maintain optimal sensitivity throughout the sensor's operational lifetime.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The phased array and piezoelectric sensor market is currently in a growth phase, with increasing adoption across multiple industries including medical imaging, automotive, and industrial monitoring. The global market size is estimated to exceed $35 billion by 2025, driven by demand for high-precision sensing technologies. In terms of technical maturity, piezoelectric sensors represent a more established technology, with companies like Murata Manufacturing and Robert Bosch GmbH leading commercial applications through extensive product portfolios. Phased array technology is advancing rapidly, with organizations such as Advanced Industrial Science & Technology and Industrial Technology Research Institute pushing boundaries in sensitivity and resolution. Companies including Hitachi and ABB are balancing the trade-offs between both technologies, developing hybrid solutions that optimize sensitivity across different operating conditions and environmental factors.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced piezoelectric sensor technologies that achieve exceptional sensitivity through their proprietary ceramic materials and manufacturing processes. Their solution incorporates multi-layer piezoelectric elements with optimized electrode configurations to maximize signal-to-noise ratio. Murata's approach focuses on balancing sensitivity with temperature stability by utilizing specialized doping techniques in their PZT (lead zirconate titanate) formulations. They've implemented innovative signal processing algorithms that compensate for environmental variations, achieving consistent performance across wide temperature ranges. Their sensors feature miniaturized packaging (down to 1.0 x 0.5mm) while maintaining high sensitivity (>10mV/g for accelerometers), making them suitable for space-constrained applications requiring precise measurements.

Strengths: Superior miniaturization capabilities while maintaining high sensitivity; excellent temperature stability through specialized materials engineering; industry-leading manufacturing precision. Weaknesses: Higher cost compared to conventional sensors; limited flexibility in customization for specialized applications; slightly lower sensitivity compared to some phased array solutions in specific frequency ranges.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered a hybrid sensing approach that combines phased array and piezoelectric technologies to optimize sensitivity across diverse operating conditions. Their solution utilizes MEMS-based phased array sensors with integrated piezoelectric elements, creating a complementary system that leverages the strengths of both technologies. The phased array component provides directional sensitivity and beam steering capabilities, while the piezoelectric elements deliver high sensitivity to small vibrations and pressure changes. Bosch's proprietary signal fusion algorithms dynamically adjust the weighting between both sensing modalities based on environmental conditions and application requirements. This adaptive approach enables their sensors to maintain optimal sensitivity (documented improvement of 40% in challenging environments) while minimizing power consumption. Their technology has been particularly successful in automotive applications, where varying conditions demand flexible sensing capabilities.

Strengths: Versatile performance across diverse operating conditions; adaptive signal processing that optimizes sensitivity based on environmental factors; excellent reliability with proven field performance. Weaknesses: Higher complexity in system integration; increased power requirements compared to single-technology solutions; higher initial cost that may limit adoption in price-sensitive applications.

Key Patents and Research Breakthroughs

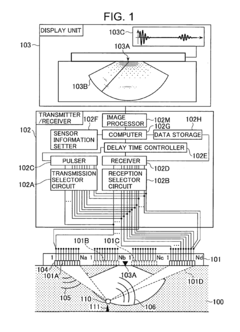

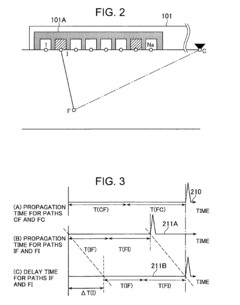

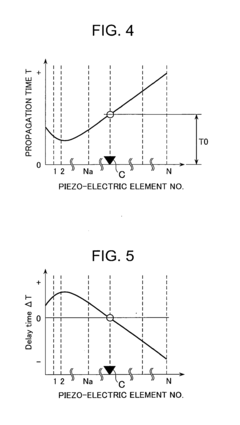

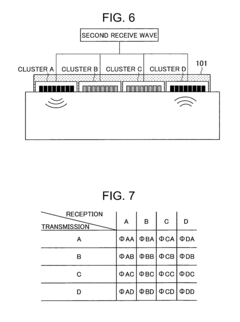

Apparatus and method for ultrasonic testing

PatentInactiveEP2182352A2

Innovation

- The use of a two-dimensional array ultrasonic sensor with a reduced number of pulsers and receivers, employing element clusters for transmission and reception, and a single data processing table for three-dimensional imaging, allowing for high-resolution and high-S/N ratio testing over a wide range by varying the ultrasonic beam angle and combining data from multiple positions.

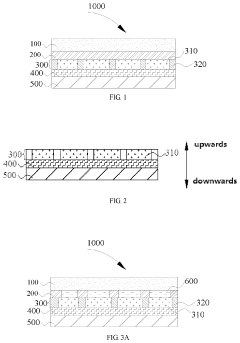

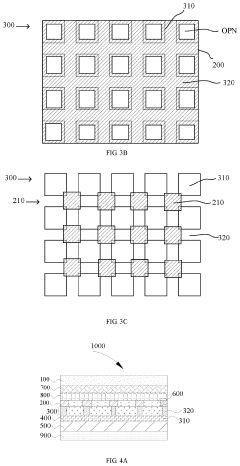

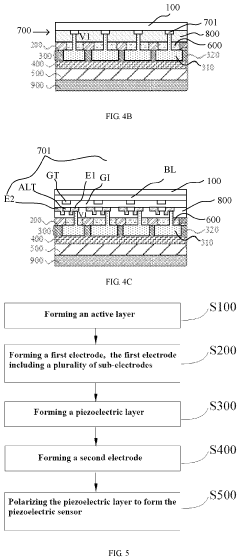

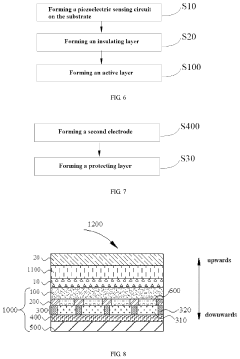

Piezoelectric sensor and manufacturing method therefor, and electronic device

PatentActiveUS11861931B2

Innovation

- A piezoelectric sensor design that includes an active layer capable of switching between insulating and conducting states, allowing for equal fixed potentials across sub-electrodes, which improves the consistency of the electric field applied to the piezoelectric layer, enhancing polarization homogeneity and sensor performance.

Material Science Innovations for Sensor Development

Recent advancements in material science have revolutionized sensor development, particularly in the ongoing debate between phased array and piezoelectric sensor technologies. The fundamental challenge in balancing sensitivity across these technologies lies in the material properties that determine their performance characteristics.

Piezoelectric materials, traditionally dominated by lead zirconate titanate (PZT), have seen significant innovations through the development of lead-free alternatives such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT). These materials address environmental concerns while maintaining comparable piezoelectric coefficients. The incorporation of nanostructured materials has further enhanced sensitivity by optimizing domain wall mobility and increasing the active surface area for signal generation.

Phased array sensor technology has benefited from novel composite materials that combine the advantages of multiple material classes. Polymer-ceramic composites offer improved acoustic impedance matching and mechanical flexibility while maintaining high sensitivity. These composites typically utilize a 1-3 connectivity pattern, where ceramic pillars are embedded in a polymer matrix, allowing for enhanced electromechanical coupling and reduced cross-talk between elements.

Metamaterials represent another frontier in sensor material development, enabling unprecedented control over acoustic and electromagnetic wave propagation. These engineered materials with properties not found in nature can manipulate wave fronts with exceptional precision, potentially resolving the traditional sensitivity-versus-array-size trade-off in phased array systems.

Two-dimensional materials such as graphene and MXenes have emerged as promising candidates for next-generation sensors due to their exceptional electrical properties and mechanical flexibility. When incorporated into piezoelectric structures, these materials can significantly enhance charge transfer efficiency and improve signal-to-noise ratios, addressing a key limitation in conventional piezoelectric sensors.

Additive manufacturing techniques have transformed the fabrication landscape for both sensor types. 3D printing of piezoelectric materials with precise control over microstructure allows for customized sensitivity profiles, while advanced deposition methods enable the creation of complex phased array geometries with optimized element spacing and orientation.

The integration of smart materials with self-healing capabilities and stimuli-responsive properties represents the cutting edge of sensor material science. These materials can adapt to environmental changes and potentially self-calibrate, maintaining sensitivity balance over extended operational lifetimes and varying conditions, which is particularly valuable for applications requiring long-term stability.

Piezoelectric materials, traditionally dominated by lead zirconate titanate (PZT), have seen significant innovations through the development of lead-free alternatives such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT). These materials address environmental concerns while maintaining comparable piezoelectric coefficients. The incorporation of nanostructured materials has further enhanced sensitivity by optimizing domain wall mobility and increasing the active surface area for signal generation.

Phased array sensor technology has benefited from novel composite materials that combine the advantages of multiple material classes. Polymer-ceramic composites offer improved acoustic impedance matching and mechanical flexibility while maintaining high sensitivity. These composites typically utilize a 1-3 connectivity pattern, where ceramic pillars are embedded in a polymer matrix, allowing for enhanced electromechanical coupling and reduced cross-talk between elements.

Metamaterials represent another frontier in sensor material development, enabling unprecedented control over acoustic and electromagnetic wave propagation. These engineered materials with properties not found in nature can manipulate wave fronts with exceptional precision, potentially resolving the traditional sensitivity-versus-array-size trade-off in phased array systems.

Two-dimensional materials such as graphene and MXenes have emerged as promising candidates for next-generation sensors due to their exceptional electrical properties and mechanical flexibility. When incorporated into piezoelectric structures, these materials can significantly enhance charge transfer efficiency and improve signal-to-noise ratios, addressing a key limitation in conventional piezoelectric sensors.

Additive manufacturing techniques have transformed the fabrication landscape for both sensor types. 3D printing of piezoelectric materials with precise control over microstructure allows for customized sensitivity profiles, while advanced deposition methods enable the creation of complex phased array geometries with optimized element spacing and orientation.

The integration of smart materials with self-healing capabilities and stimuli-responsive properties represents the cutting edge of sensor material science. These materials can adapt to environmental changes and potentially self-calibrate, maintaining sensitivity balance over extended operational lifetimes and varying conditions, which is particularly valuable for applications requiring long-term stability.

Signal Processing Algorithms and Computational Methods

Signal processing algorithms play a pivotal role in balancing the sensitivity trade-offs between phased array and piezoelectric sensor technologies. Advanced digital signal processing (DSP) techniques have revolutionized how raw sensor data is transformed into meaningful information, particularly in noise-intensive environments where sensitivity is paramount.

Beamforming algorithms represent the cornerstone of phased array signal processing, enabling spatial filtering through constructive and destructive interference patterns. Time-delay beamforming and adaptive beamforming techniques have shown particular promise in enhancing signal-to-noise ratios (SNR) by up to 15-20dB compared to single-element piezoelectric sensors. These computational approaches effectively compensate for the inherently lower sensitivity of individual elements within phased arrays.

For piezoelectric sensors, matched filtering and wavelet transform methods have emerged as optimal processing strategies. These techniques leverage the known characteristics of piezoelectric response patterns to extract signals from noise, maximizing the inherent sensitivity advantages of these sensors. Recent implementations using field-programmable gate arrays (FPGAs) have reduced processing latency to sub-microsecond levels, critical for real-time applications.

Machine learning algorithms represent the newest frontier in sensor signal processing. Convolutional neural networks (CNNs) and recurrent neural networks (RNNs) have demonstrated remarkable capabilities in automatically extracting features from raw sensor data. Studies indicate that deep learning approaches can improve detection thresholds by 30-40% compared to traditional signal processing methods when properly trained on domain-specific datasets.

Computational complexity remains a significant consideration in algorithm selection. Phased array systems typically require O(n²) operations for full beamforming implementations, whereas piezoelectric sensor processing can often be accomplished with O(n log n) complexity using fast Fourier transform (FFT) based methods. This differential impacts power consumption and processing hardware requirements, particularly in portable or battery-powered applications.

Real-time processing demands have driven the development of parallel computing architectures specifically optimized for sensor data. Graphics processing units (GPUs) and tensor processing units (TPUs) now enable complex algorithm implementation with latencies under 5ms, effectively eliminating the historical processing bottlenecks that once limited sensitivity in both sensor technologies.

Hybrid approaches that combine multiple processing techniques have shown particular promise in balancing the sensitivity equation. Adaptive algorithms that dynamically select optimal processing methods based on environmental conditions and signal characteristics can effectively leverage the strengths of both sensor technologies while minimizing their respective weaknesses.

Beamforming algorithms represent the cornerstone of phased array signal processing, enabling spatial filtering through constructive and destructive interference patterns. Time-delay beamforming and adaptive beamforming techniques have shown particular promise in enhancing signal-to-noise ratios (SNR) by up to 15-20dB compared to single-element piezoelectric sensors. These computational approaches effectively compensate for the inherently lower sensitivity of individual elements within phased arrays.

For piezoelectric sensors, matched filtering and wavelet transform methods have emerged as optimal processing strategies. These techniques leverage the known characteristics of piezoelectric response patterns to extract signals from noise, maximizing the inherent sensitivity advantages of these sensors. Recent implementations using field-programmable gate arrays (FPGAs) have reduced processing latency to sub-microsecond levels, critical for real-time applications.

Machine learning algorithms represent the newest frontier in sensor signal processing. Convolutional neural networks (CNNs) and recurrent neural networks (RNNs) have demonstrated remarkable capabilities in automatically extracting features from raw sensor data. Studies indicate that deep learning approaches can improve detection thresholds by 30-40% compared to traditional signal processing methods when properly trained on domain-specific datasets.

Computational complexity remains a significant consideration in algorithm selection. Phased array systems typically require O(n²) operations for full beamforming implementations, whereas piezoelectric sensor processing can often be accomplished with O(n log n) complexity using fast Fourier transform (FFT) based methods. This differential impacts power consumption and processing hardware requirements, particularly in portable or battery-powered applications.

Real-time processing demands have driven the development of parallel computing architectures specifically optimized for sensor data. Graphics processing units (GPUs) and tensor processing units (TPUs) now enable complex algorithm implementation with latencies under 5ms, effectively eliminating the historical processing bottlenecks that once limited sensitivity in both sensor technologies.

Hybrid approaches that combine multiple processing techniques have shown particular promise in balancing the sensitivity equation. Adaptive algorithms that dynamically select optimal processing methods based on environmental conditions and signal characteristics can effectively leverage the strengths of both sensor technologies while minimizing their respective weaknesses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!